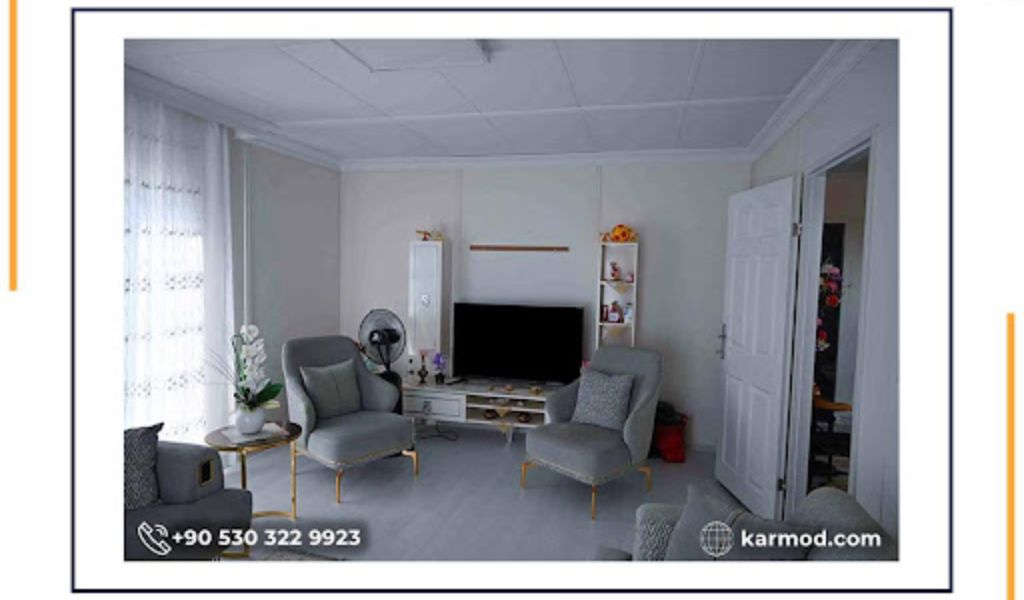

The newly popularized modular homes are being wondered about by many people who dream of their own houses. It has been developed in the prefabricated building sector, which has many advantages with an innovative style and is produced with the use of full technology. Modular houses are a housing model that is completely pre-production in modern facilities and is ready for use after shipment with installation at the place of use.

Innovative modern design, safe modeling, fast production with the use of technology, easy transportation, and fast installation for professionals are the main advantages of modular homes.

What are Prefabricated Buildings?

It is useful to briefly mention the prefabricated buildings where modular houses are developed and produced. Prefabricated is the abbreviation of the word prefabricated. Basically, prefabricated structures are the name given to the structures that are built by expert teams by being transported to the field by post-production transport vehicles, the pre-production of which is carried out in factory facilities.

The pre-production of the building model provides important advantages such as the use of full material without wastage, eliminating the negativities of field production, and fast installation. This advantage is reflected in the final cost of building prices as its cost.

Modular Homes as an Innovative Housing Model

Since the pre-production of modular houses is carried out entirely in modern factory facilities, it saves both time and budget. The use of technology in design and production provides great convenience for the safe and fast production of modular houses. Alluring models designed by experts in special software programs are produced by passing through technological machine lines that work integrated into the same program.

It needs the least manpower in the machine line and the building safety error risks are completely eliminated in modular homes. The structural safety of these innovative houses is ensured by the use of special steel metals. All of the steel metals are shaped in the machine line from the carriers to the wall and roof trusses. Since the details in the design are produced in exact measurements on the technological machine line, possible errors are completely eliminated.

End of Field Productions With Modular Homes

All of the materials used in modular houses are prepared by pre-production in modern factory facilities. Field production in classical reinforced concrete style buildings is completely eliminated in modular homes. All details such as steel carrier metals, insulated wall blocks, doors and windows, electrical and plumbing materials and accessories, roof trusses, and covering materials are pre-manufactured. Pre-production is completed very quickly as it is carried out in factory facilities. The production of the modular house can be completed within hours and ready for shipment. The modular houses, which are prepared by packing the materials, are loaded on the vehicles on the planned day and transported to the place where the installation will be made. All of the maritime, land, and air logistics facilities can be used as a means of transportation. For example, air cargo transportation facilities can be used to transport the houses needed after the disaster.

Fastest Installation in Modular Homes

The pre-engineered building model and ease of shipment make modular homes extremely attractive. Installation can be done by moving to any part of the world. The most important detail that gives the advantage of fast installation to modular houses is the partial pre-production model. When the vehicle carrying all the components of the house from the factory reaches the place where the house will be used, the installation begins immediately. First, the professional team downloads the materials from the vehicle and starts the installation of the modular house. These houses, which do not need field production, can be built within days and made ready for use.

First, guides called “floor U” are placed on the concrete floor, which was prepared according to the house plan. On top of that, H-shaped carrier H metals and wall blocks are started to be placed. At the same stage, doors and windows are placed according to the plan. After the installation of load-bearing systems and walls, omega steels are placed on the upper parts of the wall. Steel roof trusses are stacked on these in the project range. Metal purlins are placed on the trusses. On top of that, wood OSB (Oriented Strand Board) is applied. A special barrier is laid on the OSB and then the roof cover is covered.

Here is an example of the installation speed. The installation time of a 100 m2 modular house in 3+1 plan can be completed in 4 days on average. After the assembly, the modular house, where interior and exterior paintwork is applied in 3 to 4 days, is made ready for the session.

Why are Modular Homes so Affordable?

The fact that the prices of modular houses are economical can be easily explained by the advantages we have explained above. First of all, modular houses are prepared by experts in the prefabricated building sector without any additional project costs. Since the production is carried out in factory facilities equipped with modern technology without wastage, significant savings are achieved in materials. Likewise, the labor costs in the production phase are almost non-existent. Ease of shipment and fast installation by the professional team of the manufacturer make modular house prices very attractive.