A magnetic drill press is a piece of portable drilling equipment that uses an electromagnet or permanent magnet base to drill holes in metal.

A magnetic drill press is a machine tool that drills holes in metals using a cutting tool attachment and an electromagnet. A core drill is a cutting tool that is attached to a magnetic drill press. The core drill is hollow on the inside but has cutting edges on the surface and the teeth.

A magnetic drill press is also known as a magnetic core drilling machine, a magnetic drilling machine, a magnetic drill machine, a magnetic drill machine, a mag base drill, or a magnetic drill.

Thread cutting (tapping), Twist drilling, Reaming, and Countersinking can all be done using a magnetic drill press. To drill holes in metal, a portable magnetic drill press employs a cutting tool known as a core drill, annular cutter, or annular core cutter.

Part of magnetic drill press:

A magnetic drill press is made up of only four parts: a magnetic base, a drill stand, a motor, and an arbour.

Magnetic Base

To swiftly clamp (adhere) the machine to the workpiece to be drilled, a powerful electromagnet is incorporated into the base of a magnetic drill press. When charged, this magnet bonds to the workpiece, securing the machine base to the metal workpiece and allowing the operator to feed the workpiece steadily. The electromagnet is crucial in a portable magnetic drill press because it keeps the machine steady, prevents it from dismounting during drilling, and allows it to work overhead, horizontally, or vertically. A magnetic drill press is normally used on ferrous materials, although it can also be used on non-ferrous materials like stainless steel with the application of clamping devices.

Drill Stand

The drill stand, which houses the electric switches for the motor and magnet, as well as the magnet indicator and PCBs, is the primary body of the magnetic drill press. The motor and magnetic base are held together by the body of the magnetic drill press. The feed handle is affixed to the body as well. The motor’s upward and downward feed is aided by the magnetic drill press’s body, which allows it to travel on it. The body of the magnetic drill press also doubles as a handle for lifting and transporting the equipment. The majority of the time, cast iron is used for the body.

Motor

The motor is the most important part of a magnetic drill press. It’s a motor that runs on a direct current (DC). The motor’s output power ranges from 800 to 2300 watts, depending on the amount of power required for drilling. A larger diameter hole necessitates a more powerful motor. The motor used in drilling and tapping equipment will have a clockwise and anti-clockwise rotation option. The electronics that control the motor’s speed and torque are normally housed on the motor.

Arbour

On a magnetic drill press, the motor is connected to an arbour, also known as a tool holder or chuck. It’s a type of clamp used to hold core drills in place. For the magnetic drill press, there are two types of chucks: industrial arbour (manual tightening) and quick change drill chucks. Attaching core drills is straightforward and quick with quick-change drill chucks. They don’t have to manually tighten the screws or jaws. Different forms of spindle holders, such as Morse taper, can be found on arbours and chucks. A variety of core drill shafts can be accommodated by the chuck (shanks).

A magnetic core drilling machine differs from a typical drilling machine in the following ways:

The main difference between a conventional drilling machine and a magnetic core drilling machine is that a magnetic core drilling machine, unlike a conventional drilling machine, is portable and flexible, meaning it can be moved from one location to another and fixed horizontally, vertically, sideways, and so on. Any other drilling equipment can’t match this level of versatility.

Another distinction is that a core drilling machine just cuts on the periphery of the hole rather than the entire surface, requiring it to cut very little material and so being faster and more cost-effective. As a result, a magnetic drill press is three to four times faster than typical drilling machines under normal conditions.

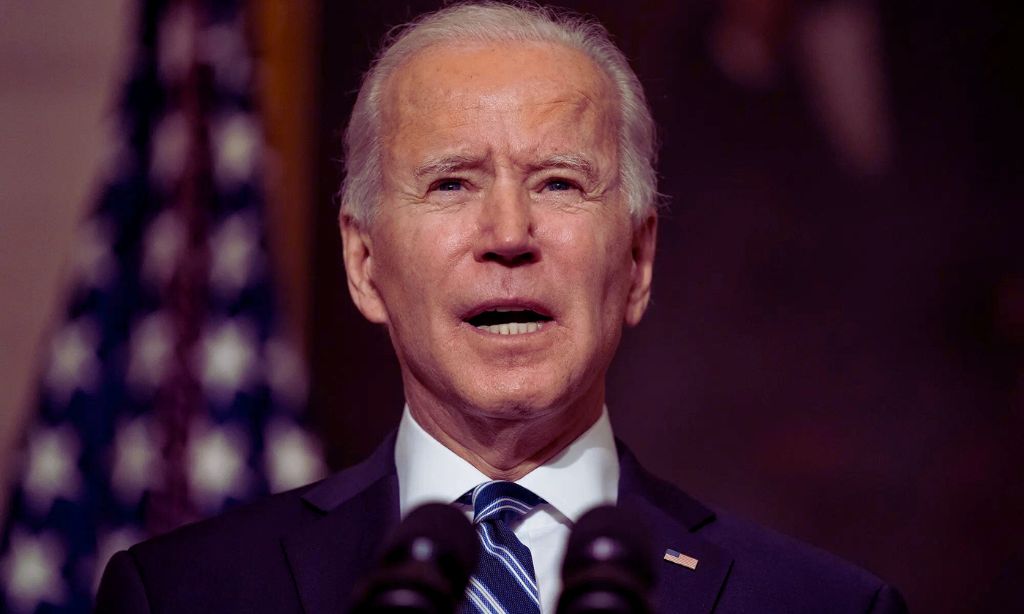

Apart from this, you can also read Entertainment, Tech, and Health-related articles here: Squid Game Season 2, Joe Biden net worth, Crackstream, The Matrix 4, Goku, Kung Fu Panda 4, Leonardo DiCaprio net worth, Diabolik Lovers Season 3, Twitch Error 2000, Alyson Hannigan, Brent Rivera net worth, Emma Watson net worth, 444 angel number, 666 angel number, 1616 angel number, 777 angel number, 333 angel number, Dave Portnoy net worth, Messi net worth, Keanu Reeves net worth, The Equalizer 3, The 100 Season 8, Gina Carano net worth, Bruno Mars net worth, KissAnime, Jim Carrey net worth, PDF Drive, Youtbe, Bailey Sarian Net Worth, Bollyshare, Afdah, Moviezwap, Y8, Jalshamoviez, Project Free TV, Kissasian, Mangago, Jio Rockers, M4uHD, Hip dips, M4ufree, NBAstreams XYZ, CCleaner Browser review, Avocado Calories, Bear Grylls net worth, Highest Paid CEO, The 100 season 8, Sundar Pichai net worth, Grimes net worth, and, F95Zone.