Many logistics teams fret over high energy bills and carbon emissions that hit their bottom line. Solar energy is the most abundant resource, and logistics ops now use solar panels, wind turbines, and biomass to power their fleets.

This guide shows ten clean energy options, from hydropower plants to hydrogen fuel cells, and how battery storage and AI can cut costs and carbon footprints. Read on to power up your supply chain.

Key Takeaways

- Solar panels cut emissions and fuel bills. Panel prices fell steeply in the last decade and modules last about 30 years. Earth delivers 10,000× our energy needs in sunlight.

- Wind turbines onshore and offshore can meet global electricity demand. Smart grids link them to EV chargers and warehouse power to tame fuel-price swings.

- Bioenergy made up 32% of U.S. renewable use in 2023. Biodiesel and renewable diesel trim CO₂ by up to 80%, while biomass boilers and biogas generators heat storage and run cold chains.

- Green hydrogen from water electrolysis emits only water vapor. AI-driven route tools guide fleets to on-site electrolyzer hubs for fast refueling and lower carbon footprints.

- Hydropower ranks as the largest renewable source, and storage lakes back up supply. Geothermal has run turbines for over 100 years and warms warehouses. CSP mirrors heat fluid above 1,000 °F. Wave, tidal and OTEC pilots aim to power ports by 2028.

How does solar energy benefit logistics operations?

Solar panels power warehouses and last-mile delivery vehicles with minimal emissions, cutting carbon footprints while trimming grid consumption. This abundant energy source works even under cloudy skies, helping logistics services stay on schedule.

Earth intercepts solar light at a rate ten thousand times higher than humanity’s energy consumption, so firms tap nearly endless solar power. Panel costs sank steeply in the past decade, and modules last about thirty years, yielding decades of budget relief.

Rooftop solar installations link power converters and storage units to save surplus juice for night shifts. Logistics teams sync charging stops with peak sun hours using route optimization tools, boosting energy efficiency and cutting fuel bills.

Solar farms power forklifts and cranes at distribution centers, curbing grid demand and supporting renewable electricity. This shift shrinks carbon footprints and drives down operational costs across supply chains.

What are the advantages of wind energy in logistics?

Wind turbines power large logistics hubs around the world with renewable energy. They capture kinetic energy from passing air and turn it into power. Onshore farms and offshore sites use taller towers and larger rotor blades to boost output.

This renewable energy source cuts fuel costs and shrinks carbon footprints in supply chains. Operators link turbines to energy systems that feed warehouses, ports, and transport depots.

Experts say wind power’s technical potential could exceed all global electricity needs.

Companies cut bills when they tap wind power for truck charging stations. Stable wind flows help planners avoid price swings in fuel. Smart grids match output to demand and run systems that plan air freight routes.

Net zero emissions targets get extra help from constant breeze at coastal hubs. Logistics managers use advanced turbine designs to smooth power dips and peaks. Offshore wind farms, in particular, bring steady breeze to charge electric vehicles.

What role does hydropower play in logistics?

Flowing water drives turbines in power stations built along rivers. This method catches energy as water drops from high to low elevations. It ranks as the largest renewable energy source in the electricity sector.

Logistics hubs plug into this clean power, a cornerstone of renewable energy logistics, for warehouse lights and to charge electric vehicles (evs).

Storage lakes also feed irrigation and act as backup supply at distribution sites. Teams hook these dams to AI tools and blockchain technology in the energy infrastructure. This green grid slashes reliance on fossil fuels, cutting co2 emissions and boosting a circular economy.

Rainfall shifts from climate change may lower output, yet firms adapt with route optimization and battery storage to keep trucks on time.

How is geothermal energy used in logistics?

Teams tap geothermal energy through wells deep underground. They reach hot water and steam in hydrothermal reservoirs. Operators have tapped hydrothermal reservoirs for electricity generation for over 100 years.

They send that steam into a turbine that spins a generator. Logistics hubs draw electricity from these generators to power forklifts and conveyors. That clean energy source cuts greenhouse gas emissions and shrinks carbon footprints for warehousing and transport.

Managers also use heat exchangers to extract thermal energy for facility heating. This process uses Earth’s core heat to warm warehouses and docks. Hot water flows through pipes under floors and radiators in loading bays.

It warms each room like a giant blanket. Smart control panels, IoT sensors, and SCADA systems monitor flow and temperature. This setup boosts operational efficiency and trims fuel costs.

What is biomass energy and how does it support logistics?

Biomass energy uses organic materials to make heat and power. Wood, charcoal, farm residues and waste feed a biorefinery or a gasifier. Anaerobic digestion can turn manure or food scraps into biogas for ovens or generators.

This type of renewable source cuts greenhouse gas emissions more than coal or oil. The energy sector taps biomass to drive renewable energy generation. Logistics planners see carbon footprint reduction and lower carbon levels in transit hubs.

Trucks can run on biofuel from plant residues or field waste to save diesel use. Warehouses heat storage areas with biomass boilers instead of natural gas. A small scale biofuel plant on site cuts fuel bills and lowers shipping costs.

Generators powered by biogas keep cold chains alive at remote docks. This cut in fuel economy demand helps fleet operators reach sustainability targets. Many carriers pair biomass energy with solar panels or wind turbines for backup power.

Readers get fuel for thought in how renewables boost logistics efficiency.

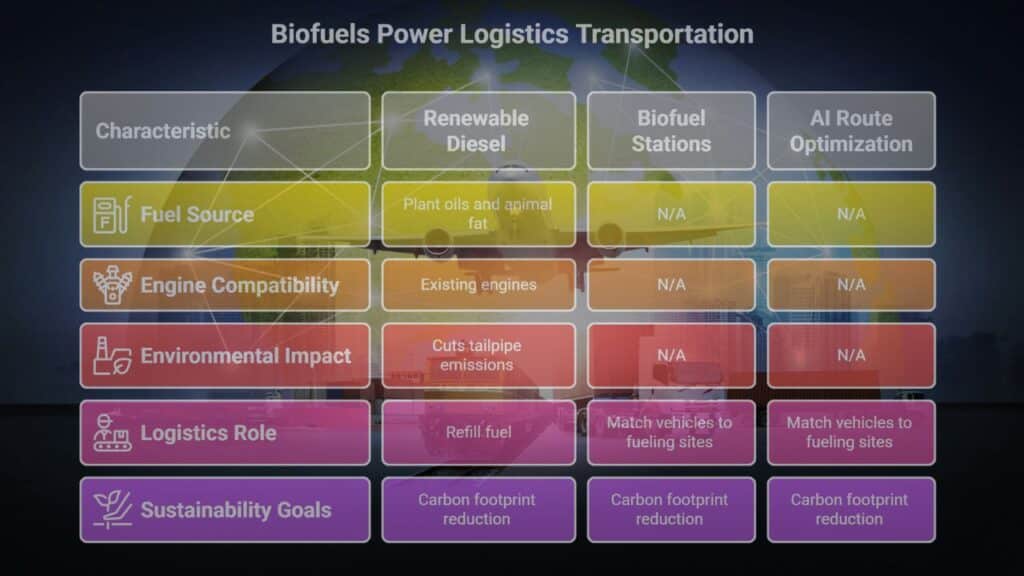

How can biofuels power logistics transportation?

Trucks swap fossil diesel for renewable diesel in existing engines. This blend burns cleaner and cuts tailpipe emissions. Drivers refill at biofuel stations along major routes. Some carriers use AI and route optimization to match vehicles to fueling sites.

Biofuels made up 32 percent of U.S. renewable energy consumption in 2023. Biorefineries turn plant oils and animal fat into biodiesel and renewable diesel. Fleets that mix trucks with EVs and biofuel trucks drive carbon footprint reduction.

Logistics teams add sustainable energy tools to meet energy transition goals.

What is renewable hydrogen and its impact on logistics?

Renewable hydrogen comes from water using solar panels and wind turbines. Electrolysis breaks water into hydrogen and oxygen. Big rigs and vans use this fuel in fuel cell engines. Those engines only emit water vapor.

Logistic fleets cut carbon footprint when they use green hydrogen. Drivers refuel fast at new charging infrastructure hubs. AI aids route optimization to link fleets with refuel spots.

Warehouses add onsite electrolyzers to store clean fuel. This switch boosts renewable energy logistics and cuts costs.

How does concentrated solar power (CSP) work for logistics?

Mirror arrays aim sunlight at a central receiver unit. That unit heats a special fluid above 1,000°F. Steam then spins a turbine, a core power generation step. Logistics hubs tap that clean heat for warehouse lighting.

They power conveyor belts, charging docks and forklifts. CSP teams with solar arrays and wind turbines in hybrid setups. Those renewable energy sources support renewable energy logistics.

Planners link them to battery banks and smart grids.

Storage tanks hold high temperature fluid until circuits need it. A plant in the Mojave Desert proved its worth in 2015. Government incentives cut upfront costs. Control systems use artificial intelligence (ai) to adjust output.

The tech drives carbon footprint reduction in rail yards and ports. Managers charge electric vehicles (evs) at off peak hours. They pair CSP with route optimization tools. The system eases spikes in electricity consumption at night.

What types of ocean energy are used in logistics?

Wave energy converters ride swells like surfers to tap ocean energy. WaveRoller devices off harbors move with each crest and trough. Ports link them to onshore grids to generate electricity for cranes and yard lights.

This switch cuts diesel and fuels carbon footprint reduction at cargo hubs.

OTEC plants use warm surface water and cold depths to spin turbines. A 10-megawatt system can power container lifts and EV charging in port microgrids. These sustainable technologies add renewable sources to logistical centers.

Many ports eye OTEC pilots by 2028 to push toward carbon neutrality.

How does tidal energy contribute to logistics energy needs?

Tidal energy uses ocean currents and tides to power coastal operations. Sea turbines spin as tides flow, feeding port grids. They run cranes and charge electric vehicles (EVs). This clean power cuts dock costs.

Ports cut their carbon footprint, adding sea turbines to solar panels and wind turbines. This blend boosts renewable energy logistics, and fits many renewable energy projects. It powers IoT sensors that track routes and helps route optimization.

Renewable Energy Applications in Warehousing

Warehouses can soak up sun with solar cells on rooftops, then stash power in storage modules to keep lights and conveyors humming. Smart chargers and energy sensors team with wind farm inputs to cut costs and shrink carbon footprints.

How can renewable energy improve warehouse efficiency?

Solar panels slash energy expenses, reduce carbon dioxide emissions.

Wind turbines boost energy security, cutting reliance on fossil fuels.

- Install solar panels on warehouse roofs, cut grid bills, feed power into conveyors and lighting.

- Set up wind turbines near loading bays, harness consistent airflow, back up main power.

- Use geothermal power or heat pumps, keep indoor climate steady, slash HVAC energy.

- Add battery storage systems, save extra renewable energy, cover peak usage without spikes.

- Integrate energy management systems and smart sensors, track consumption for renewable energy logistics and combat climate change.

- Charge electric vehicles and forklifts on-site with green power, aid EVs and route optimization.

- Deploy LED lighting tied to microgrids, slash lighting costs, boost carbon footprint reduction.

What renewable technologies are best for warehousing?

Warehouses slash carbon footprints with clean energy. They tap solar panels and wind turbines too.

- Rooftop solar arrays generate warehouse electricity with minimal emissions, they drive major carbon footprint reduction.

- Ground-mount wind turbines feed large logistics hubs, they spin steadily to cut grid power needs, they boost renewable energy logistics.

- Geothermal plants tap stable ground warmth, they heat and cool storage bays, they slash HVAC power use.

- Renewable hydrogen fuel cells back up critical systems, they emit zero emissions, they power lights and forklifts after dusk.

- Electric vehicles (EVs) use on-site chargers, they link to solar panels or wind turbines, they drive renewable energy projects in warehouses.

- Energy management systems monitor real-time power flows, they shift loads to low-cost hours, they steer renewable sources to peak demand.

How do warehouses integrate solar and wind energy?

Solar panels sit on broad roofs to catch sun rays. Wind turbines stand nearby to feed power into the system.

- A sensor system reads sun levels and wind speed and tweaks output in real time.

- An Energy Management System balances loads and cuts waste across lighting and machinery.

- A microgrid links solar panels, wind turbines and battery storage to feed renewable energy to lights and equipment.

- Net metering sends extra power back to the grid, and credits drive down bills.

- EV charging bays draw on on-site power to fuel electric vehicles (EVs) for dock shifts.

- Durable panels last about 30 years, and they slash carbon footprint with steady output.

- Logistics teams track renewable energy projects to log carbon footprint reduction and report savings.

Renewable Energy in Transportation within Logistics

E-trucks, H₂-powered trucks, SAF-fueled planes, and smart route apps slash emissions and speed up shipping, so keep reading to see renewables power transport.

What renewable fuels power logistics transportation?

Electric vehicles help cut carbon footprints in fleets. Fleets rely on biofuels, renewable diesel and green hydrogen to power trucks and jets, driving renewable energy logistics.

- Biodiesel ramps fleet engines with fatty acid methyl ester from plants, and it trims carbon footprint by up to 80 percent compared to fossil diesel.

- Renewable diesel uses hydrogen-treated oils, it swaps one-to-one with diesel in existing engines and shrinks carbon emissions by nearly 60 percent.

- Bioethanol powers light trucks with fermented sugars, it blends into gasoline and offers around 20 percent carbon footprint reduction per mile.

- Renewable natural gas, aka biomethane, fuels heavy transports, it captures methane from landfills and cuts greenhouse gases by over 50 percent.

- Green hydrogen runs fuel cell trucks, it comes from water electrolysis via electrolyzers powered by wind turbines and solar panels, and emits only water vapor.

- Sustainable aviation fuel (SAF) drops into jet tanks, it blends with conventional fuel, cuts air cargo carbon footprint by roughly 70 percent, and meets ASTM standards since 2020.

- Electricity charges electric vehicles (EVs) at solar-backed stations, it drives silent city hauls and enables zero tailpipe emissions.

How is electric vehicle technology revolutionizing logistics?

Logistics fleets are going electric. They cut fuel cost fast.

- Operators adopt battery powered tractors with smart battery management. They boost uptime and shrink servicing fees.

- Route optimization tools sync with telematics. They guide electric vehicles (evs) on the fastest green path and lower idle time.

- Charging station grids at depots charge evs off-peak. They tap solar panels and wind turbines, boosting renewable energy logistics.

- Regenerative braking systems recover wasted motion energy. They refill the battery pack and stretch driving range.

- Onboard IoT sensors send live battery health alerts. Managers spot faults early and plan maintenance smooth.

- Shared renewable hydrogen hubs supply fuel cell trucks alongside evs. They add flexibility for heavy haul runs.

- Fleet management software balances load and charge schedules. It shifts recharge times to trim demand fees.

What infrastructure supports renewable transportation energy?

A grid link shapes how big rigs charge via solar panels. Pumping green hydrogen powers trucks with only water vapor as exhaust.

- Smart grid networks route power to EV chargers in real time, cutting outages and boosting uptime.

- Battery energy storage systems trap excess power from wind turbines or solar panels, and feed it back during peak hours for carbon footprint reduction.

- Fast charging stations dot highways and city hubs, letting electric vehicles (EVs) juice up in minutes, not hours.

- Onsite electrolyzers split water into green hydrogen, fueling trucks that emit only water vapor, slashing carbon footprint.

- Hydrogen pipeline grids link production sites to depots, making renewable hydrogen available in remote logistics yards.

- Microgrids cluster wind farms, solar arrays and batteries to power ports when main lines fail.

- Energy management tools monitor loads on trucks and warehouses, trimming waste and driving renewable energy logistics gains.

- Rooftop solar arrays link to warehouse meters, cutting grid draw and powering conveyors, lights and EV docks.

- Wind energy farms near ports feed cleaner power to cranes and rail yards via dedicated lines.

- Repair shops house specialized tool kits for EVs and hydrogen vehicles, keeping each rig in top form for green transport.

Challenges in Adopting Renewable Energy in Logistics

Fleet managers hit a wall with the steep cost of solar panels and battery storage that promise a smaller carbon footprint. They wrestle over microgrid setups and energy management systems as permitting hurdles drag on.

What are the main barriers to renewable energy adoption?

Logistics firms face steep price tags. They lack stable, clean power to meet carbon footprint goals.

- High capital expense hits budgets. PV arrays, aero generators and other gear require millions upfront. Many renewable energy projects stall like trucks in gridlock, driving up costs in logistics.

- Lack of stable resource flow frustrates planners. Wind and sun fade at odd hours, and altered rainfall strains hydropower units. Spotty power undermines carbon footprint reduction goals.

- Grid ties pose tech puzzles. Many hubs lack smart grid links or battery banks, so trucks sit idle at night. This gap slows renewable energy logistics growth.

- Complex codes slow rollout. Permits, zoning laws and safety checks drag renewable projects. Teams lose weeks in red tape.

- Skilled crews remain scarce. Few techs master PV arrays or aero generator repairs. Faulty upkeep can stall a whole route.

- Market risk spooks investors. Price swings on carbon credits and fuel rates scare off backers, chilling renewable energy deals. Firms cling to diesel as a safe bet.

How do costs impact renewable energy use in logistics?

You face rising bills that can stall the shift to green power.

| Cost Category | Impact on Operations | Tools & Concepts |

|---|---|---|

| Capital Outlay | Creates high entrance barrier | Photovoltaic module prices plunged over past decade, RETScreen |

| Service Fees | Adds to daily budgets | Lithium ion battery bank checks, demand response |

| Levelized Cost of Energy | Guides fuel investment | HOMER Pro, LCOE |

| Financing Charges | Extends payback horizon | Green bonds, OpenModelica |

| Grid Access Fees | Inflates site expenses | PVsyst grid module, tariff forecasting |

What solutions exist to overcome renewable energy challenges?

Switching to green power needs smart fixes. Logistics teams fight high costs and tech gaps.

- Get grants and tax credits from U.S. Department of Energy programs and state funds, using government support to reduce solar panel outlays.

- Team up with national labs and research organizations, testing new battery storage in renewable energy setups.

- Build local energy grids, linking solar panels, wind turbines and storage units, to smooth out power gaps and drive carbon footprint reduction.

- Sign long-term clean power contracts, locking in rates and avoiding price spikes.

- Fit IoT sensors and energy management software in storage hubs and trucks, spotting issues and boosting uptime.

- Use AI and digital twin models to match power use to output, cutting waste and lowering costs.

- Hold skill workshops with technical schools, giving staff fuel for new tech.

- Tap biofuel blends and renewable hydrogen in fleets, cutting diesel use and carbon footprint.

Takeaways

Logistics firms can cut costs and emissions with renewable energy from solar panels, wind turbines, and water power. Heating and cooling run on geothermal heat, while trucks drink renewable diesel and green hydrogen.

Chargers in yards feed electric trucks with green current. Pipes in the ground keep warehouse floors warm or cool. This mix slashes the carbon footprint, while saving big on utility bills.

Green power moves goods, and gives you peace of mind about the planet.

FAQs

1. What role do wind turbines play in logistics centers?

They spin tall, they feed clean power to vehicles and sorting gear, they cut fuel bills, they shrink carbon clouds.

2. Can solar panels power my fleet depot?

Yes, they sit on roofs, soak up sun, they can juice lights, computers, even charging bays for electric vehicles.

3. What is the first step to add renewable power?

I once asked a buddy who runs a depot. He said, talk to a local installer. They run tests, map roof space, point out ideal spots. Then pick wind turbines or solar panels.

4. Will these sources really save money?

They slash bills over time, they need an upfront cost, then they run for years, they pay back like a steady friend.