You feel stuck when your goods stall at seaports. You worry about stockouts and lost sales. You need Risk Mitigation Strategies In Multinational Supply Chains.

The coronavirus outbreak showed how one glitch can stop a worldwide supply chain. This post uses predictive analytics, blockchain, and risk assessment tips to sharpen your risk management and aid business continuity.

Keep reading.

Key Takeaways

- Use the GONE model and ISO 31000 to rate risks by chance and cost. Feed scores into ERP tools and dashboards for real-time tracking of parts and weak spots.

- Spread orders with an 80/20 or 50/50 split and add suppliers in Asia, Europe, and Latin America. This multi-sourcing cuts single-region risk and shortens lead times.

- Track shipments with IoT sensors and record every move on blockchain like Hyperledger Fabric. Early adopters saw COVID-19 delays fall by 20%.

- Build buffer stock in cold storage before hurricane season and plan air or rail backup routes. Write clear contracts with NIST standards and FMEA-backed risk-sharing clauses.

- Run drills and scenario tests for floods, cyberattacks, or strikes. Monitor events like the Russian-Ukrainian war and rate hikes, as The New York Times notes, to adapt fast and keep goods moving.

Identify and Assess Risks

External supply chain risks can shut down a factory, delay shipments, or spike costs. They cover demand swings, environmental risks, trade restrictions, and economic shifts. Internal supply chain risks strike from manufacturing disruptions, staff turnover, flawed schedules, and weak backup plans.

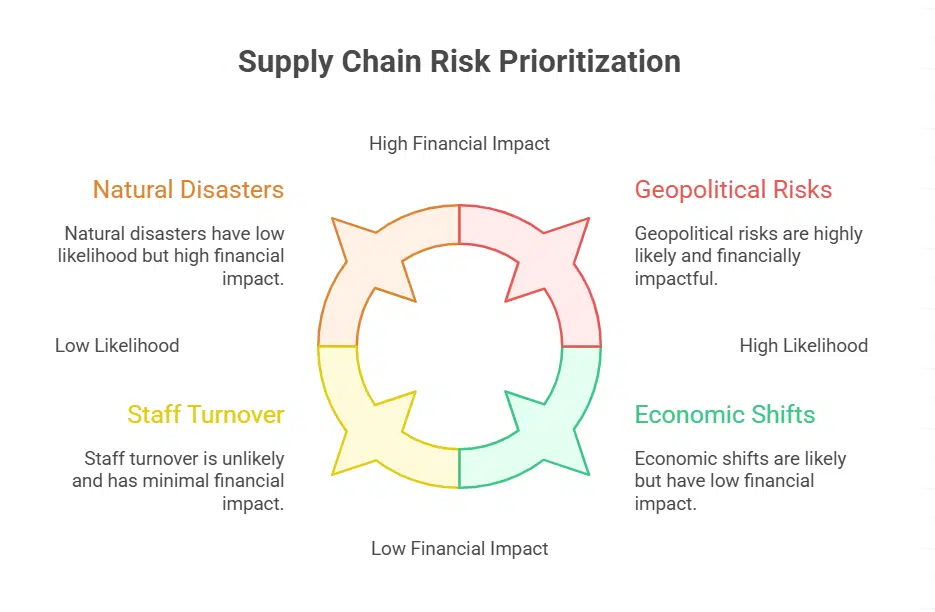

Analysts sort hazards into Global, Operational, Natural, and Economic groups under the GONE model. Teams rank each risk by likelihood and financial impact, then feed scores into risk mitigation strategies.

Supply chain risk management teams use software, like risk assessment modules in ERP systems, plus supply chain mapping tools to track parts, and spot bottlenecks. They run scenario planning sessions and use predictive analytics to forecast disruptions.

They lean on ISO 31000 standards, big data models, and dashboards for real-time supply chain visibility. This blend of strategy and tech helps leaders act fast when geopolitical risks or natural disasters hit.

Diversify the Supplier Base

Retailers shifted from single-sourcing to multi-sourcing after the COVID-19 pandemic to keep goods flowing. They use the 80/20 rule or a 50/50 split to spread orders. Many nearshore parts to the US, while others friend-shore to allied nations.

They cut single-region risks. They plan across a global supply chain. They track vendors with predictive analytics and smart sensors in risk assessment dashboards.

Companies add backup suppliers in Asia, Europe, and Latin America. They pay higher fees to local vendors, but they slash lead times. They run failure mode and effects analysis and SWOT analysis to test financial stability.

They boost supply chain resilience with risk mitigation strategies. They update business continuity plans with real-time data.

Leverage Technology for Supply Chain Visibility

Hidden data can cost millions. AI systems track containers with IoT sensors. Blockchain records every transfer on a shared ledger. Supply chain mapping finds weak spots and critical nodes.

Cloud platforms share updates across all distribution centers. Automated inventory reports cut guesswork at the last mile. Predictive analytics spot demand shifts before disruptions hit.

Centralized dashboards give managers unified views. Real-time data drives quick risk mitigation strategies. Credit rating services feed predictive financial reports. Teams link trends to supply chain resilience goals.

IoT devices monitor cold storage and last mile shipments. Cloud software boosts operational efficiency in global supply chains. Early adopters saw covid-19 pandemic delays drop by twenty percent.

Establish Robust Contracts and Compliance Standards

Contracts set clear goals for suppliers. They include performance metrics and risk-sharing clauses in every supply chain risk management plan. You run vendor risk assessments before signing to flag weak links.

Predictive analytics and FMEA scan data to catch issues early. They boost your risk mitigation strategies.

Define user roles and network access control to guard sensitive data. Set data stewardship standards that name owners and limit usage. Require disaster recovery and business continuity plans in each deal.

Tie performance monitoring systems to real-time dashboards. Select regulatory compliance rules for all third-party vendors. Add insurance clauses to cover natural disasters and supply chain disruptions.

Build Supply Chain Resilience

Firms add redundancies to build supply chain resilience, such as more factory capacity and closer suppliers near key markets. Teams keep buffer inventory ahead of hurricane season to guard against shortages.

Companies deploy flexible transport options like air freight and rail shifts, so goods keep moving. Leaders set up strategic stockpiles for critical items; no one likes empty shelves.

Industry peers form alliances to share tips and best gear. Plants run the same software and systems, matching product lines across sites. Managers tap predictive analytics, scenario planning, and digital twin tools to spot weak spots early.

Nearshoring and multi-sourcing boost supply chain agility and cut lead times.

Conduct Regular Risk Assessments

Teams schedule risk reviews on a set cadence. They boost supply chain resilience with each check.

- Map supply chain network and spot key nodes with digital mapping tools.

- Run scenario tests to model natural disasters, trade war impacts, and power outages.

- Assess suppliers for political, geographic, and economic risks.

- Audit logistics partners for disaster readiness, including cold transport checks.

- Apply data science, predictive analytics, and FMEA to forecast risk scenarios.

- Build contingency plans with advanced data models for worst-case events.

- Review performance data, follow National Institute of Standards and Technology audit steps, and train staff via American Military University.

- Check business continuity plans, test backup sites, and adjust buffer stock levels.

Implement Contingency Plans for Disruptions

Contingency plans halt supply chain disruptions fast. They fit solid risk mitigation strategies.

- Map suppliers across your global supply chain to spot weak spots that fuel supply chain disruptions.

- Apply the Prevention Preparedness Response Recovery model to cover every phase of supply chain risk management.

- Form an incident response crew in each region to make swift, firm decisions during emergencies.

- Craft multiple backup plans like Plan B, Plan C, and Plan D for natural disasters, cyberattacks, or port strikes.

- Set clear communication channels so every employee knows their duties the moment a crisis hits.

- Record every contingency process in one master document to create a single source of truth for business continuity.

- Audit freight carriers for disaster readiness to boost supply chain resilience and meet compliance standards.

- Use predictive analytics to refresh plans after economic shifts, geopolitical risks, or a covid-19 pandemic wave.

Foster Strong Relationships with Suppliers

Managers host weekly video chats with key partners, they share data from IoT sensors. This open communication builds trust; it fuels coordinated responses during crises. They use FMEA and predictive analytics in joint scenario planning.

Performance monitoring systems track quality, delivery, compliance and risk analysis across a global supply chain when disruptions hit. Companies add backup suppliers and set performance metrics in their sourcing plans.

Industry alliances share best practices, resources, and risk reduction tips. Strong ties boost supply chain resilience and business continuity during natural disasters or supply chain disruption during the covid-19 pandemic.

Maintain Buffer Inventory Levels

Companies add safety stock to buffer inventory during supply chain disruptions. This step guards global supply chain resilience during natural disasters or the covid-19 pandemic. They store critical items in cold storage units ahead of hurricane season.

They use cloud-based ERP and the internet of things for supply chain mapping and real-time visibility. They run failure effect analysis on key parts to spot hidden vulnerabilities.

Teams adjust buffer levels during new product launches or market expansions to boost business continuity. They use predictive analytics and scenario planning as key risk mitigation strategies to balance safety stock with cost efficiency.

They track financial impact and regulatory compliance with warehouse management software. They foster supplier relationships to reduce internal supply chain risks. It helps maintain customer trust during unpredictable market swings.

This practice supports supply chain agility and protects profitability.

Monitor Geopolitical and Economic Changes

Geopolitical risks like political unrest and shifting trade policies can stall goods at ports or spike tariffs. The Russian-Ukrainian war cut off titanium oxide, and paint makers chased scarce pigment.

Managers tap market intelligence, real-time data, and scenario planning to flag brewing disruptions. Global supply chain managers use visibility tools and predictive analytics to spot export bans in Eastern Europe.

Currency swings can double raw material costs overnight, and inflation can erode margins on essential parts. The New York Times notes market demand swings, downturns, and rate hikes shape warehousing costs.

Assessing suppliers with failure mode and effects analysis (FMEA) reveals weak links in payment terms and cash flow. Adaptive sourcing, buffer inventory, and risk mitigation strategies build supply chain resilience, though paying steep prices may strain budgets.

Use Real-Time Data for Decision-Making

Risk software from a supply chain risk management platform offers real-time visibility into a global supply chain and ranks high among risk mitigation strategies. Connected sensors track shipments across oceans.

Automated inventory reports show buffer levels for each warehouse. Trend analysis, a branch of predictive analytics, forecasts demand surges and shortages. Consolidated dashboards unify shipping logs, factory outputs, and quality metrics.

You spot odd spikes or sudden downtime, so you cut supply chain disruptions.

Fresh data powers scenario planning with real examples. Transport provider scores and route maps adjust on the fly. Live credit feeds from lending bureaus flag a shaky supplier. You pivot away before delays hit inventory buffers.

Real-time numbers also feed stress tests on manufacturing risks, environmental risks, and costs. This approach boosts supply chain resilience and business continuity, with clear regulatory compliance in view.

Invest in Cybersecurity Measures

Industrial sensors and cloud hubs spice up supply lines. They also attract cybersecurity threats such as malware, ransomware, and phishing scams. We set vendor rules for strong security standards and test cyber risks before we sign deals; these checks also ensure regulatory compliance and form core risk mitigation strategies.

User roles and access controls lock down systems. We roll out weekly updates to antivirus, antispyware, and packet filters. We track regulatory changes to keep those tools up to date.

Software platforms pull real-time data. Supply chain visibility, powered by predictive analytics, spots weak links in global supply chain management to head off disruptions.

Staff join risk awareness training each quarter. We run hack drills and fire drills to sharpen crisis response. We deploy backup controls and design disaster recovery plans that mirror our business continuity goals.

This planning shrinks system downtime by days. It steers us clear of financial losses and supports supply chain resilience.

Train Teams on Risk Awareness and Management

All staff join internal risk awareness training on supply chain threats. Leaders share best practices and real data to drive learning.

- Host workshops that cover common supply chain risks and explain their impact on manufacturing, pricing, and ESG objectives.

- Offer classes on risk management best practices drawn from scenario planning and predictive analytics case studies.

- Provide sessions on safe computer and internet practices to guard against cybersecurity threats and data breaches.

- Train teams on risk assessment tools to boost adoption of supply chain mapping and vulnerability scoring systems.

- Run scenario-based drills that mimic natural disasters and political shifts to sharpen response and business continuity.

- Schedule regular refreshers to reinforce knowledge on external and internal supply chain risks and new regulatory changes.

Adopt Sustainable and Ethical Practices

Local sourcing cuts transport emissions and lowers environmental risks. Teams track supplier relationships with vendor grade sheets that score labor, waste, and emissions. They form partnerships with suppliers that share green values and run product life review to spot hidden impacts.

Eco-management software tracks energy use and water waste across sites.

Compliance with green laws tightens supply chain risk management. Such actions support risk mitigation strategies and boost supply chain resilience. They protect businesses from reputational damage and supply chain disruptions.

Distributed ledger platforms record each step, boosting transparency in ethical sourcing.

Integrate Risk Mitigation into Overall Strategy

Companies merge risk mitigation strategies with their core business goals. They embed supply chain risk management across finance, operations, and logistics. Strategic plans set targets for supply chain resilience and business continuity.

They link contingency rehearsals to budget reviews. Top executives sponsor technology investments like demand forecasting and route visualization platforms, and they fund backup sites and inventory buffer levels.

Leaders champion regular risk assessments and security audits to spot financial, environmental, and cybersecurity threats. Teams run policy tracking software to track regulatory changes.

They align contingency plans with corporate responsibility and health and safety standards. They hold quarterly reviews to keep tactics fresh. This approach yields long-term resilience and sustained competitive advantage.

Conduct Scenario Planning for Worst-Case Events

Scenario planning tests a supply line for its breaking point. Teams use stress testing and predictive analytics to catch blind spots.

- Model floods, quakes, or pandemics in a simulation model to mimic real shocks and test your chain.

- Feed your risk scenario with real-time data and predictive analytics to spot weak spots.

- Draft plan B, plan C, and plan D for delivery breakdowns, supplier insolvency, or port closures.

- Call in your crisis response unit for a timed drill, then score their moves to trim decision lag.

- Map every link across borders, flag gaps in supply chain mapping, and seal each one fast.

- Run regular fire drill sessions and stress tests, then refine each step for better supply chain resilience.

- Compare your findings against natural disasters archives, Covid-19 pandemic data, and insolvency rates from 2022.

- Debrief after each exercise in a learning jam session so teams lock down quick fixes and boost agility.

Monitor and Evaluate Supplier Performance

Smart teams watch supplier metrics every week. This cuts risk and boosts supply chain resilience.

- Track on-time rates with an app, logging if suppliers hit 95% or more. High delivery reliability cuts supply chain disruptions fast.

- Audit disaster response plans, checking fire drills, backup power, and buffer stocks. A drill or two can save weeks of downtime.

- Review defect rates each week, flagging any rise above 2%. Lean quality control fights manufacturing risks.

- Scan supplier credit scores monthly, spotting cash traps before they wreck orders. A shaky balance sheet can halt your line.

- Deploy a live dashboard to watch batch temps and lead times. This tool boosts supply chain visibility and lets teams act in real time.

- Verify permits and safety docs in each report, tracking regulatory compliance. Missing certificates can cost big fines.

- Test supplier drills and buffer inventories in surprise checks to prove business continuity plans. Such checks build trust in your supplier relationships.

- Leverage predictive analytics models to forecast weather or port closures, and run scenario planning for delays. Firms tweak shipping routes to dodge storms.

- Hold risk review calls after each glitch, share frank feedback, plan next moves. This open talk cements strong partnerships.

Collaborate Internally Across Departments

Staff in procurement, logistics, IT, and finance share data to drive risk mitigation strategies. Teams link operations, management, and HR for quick updates. Crisis response teams tap a predictive analytics tool and a central system for supply chain visibility.

They spot threats in the global supply chain fast.

Shared plans with input from HR and ops cut response time. They run scenario planning with strategic and front-line groups. A single view of risk boosts supply chain resilience and aligns budgets with business goals.

Takeaways

Teams boost safety by mixing suppliers across regions. They watch goods on the move with GPS sensors and blockchains like Hyperledger Fabric. Leaders write clear contracts to nail down delivery terms.

Firms hold extra stock in buffer warehouses and run Monte Carlo simulation to test weak links. These steps make the global network bend, not break, when chaos strikes. Managers set backup routes and train crews to roll with punches.

FAQs on Risk Mitigation Strategies In Multinational Supply Chains

1. What are top risk mitigation strategies in a global supply chain?

Start with risk identification, map your supply chain end to end, then run scenario planning. Add supplier diversification and an inventory buffer. Use predictive analytics to spot problems early. These steps boost supply chain resilience and agility.

2. How does predictive analytics cut supply chain risks?

Predictive analytics draws on past data, it spots trends in manufacturing risks, environmental risks, even natural disasters. It gives you clear supply chain visibility. Think of it as a data-driven crystal ball for planning and control risks.

3. Why is supplier diversification vital in managing supply chain disruptions?

Relying on one source is like walking on a tightrope without a net. Spread orders across regions, it reduces external supply chain risks, geopolitical risks, even financial impact from a single supplier’s hiccup. Healthy supplier relationships smooth the path.

4. How can companies keep business continuity during a global health crisis?

Build extra stock in a cooled goods buffer, and drill your team with risk awareness training. Have backup routes, backup suppliers, backup plans. This adaptation keeps goods flowing when pandemics or natural disasters strike.

5. What role does regulatory compliance play in supply chain risk management?

Rules shift fast, a bit like traffic lights in rush hour. Non-compliance can cost fines, slow customs, or even halt shipments. Stay on top of regulatory changes, train staff, guard against security breaches and cybersecurity threats. That keeps your supply chain legal and moving.

6. How do firms assess and control the financial impact of supply chain risks?

Begin with risk assessment, score each risk by likelihood and cost. Tie that into your business strategy and financial stability plans. Track supplier health, monitor internal supply chain risks, then adjust budgets or buffers to contain losses.