The logistics and supply chain industry has undergone unprecedented transformations in 2025. From disruptive technologies to geopolitical tensions, several events have shaped the way goods move globally.

Companies worldwide have adapted to automation, AI, sustainability initiatives, and new trade policies, influencing supply chain efficiency and resilience.

In this article, we explore the Top 10 Logistics and Supply Chain Stories that significantly impacted the industry, offering a glimpse into the future of global trade.

The Top 10 Logistics and Supply Chain Stories of 2025

The logistics and supply chain industry in 2025 has been defined by groundbreaking advancements and critical challenges. From AI-driven automation to sustainability efforts, each development has left a lasting impact on global trade. Here’s a detailed look at the key events that shaped the industry this year.

1. The Rise of AI and Automation in Supply Chains

Artificial Intelligence (AI) and automation have revolutionized logistics, improving speed, accuracy, and efficiency across global supply chains. These technologies are not only enhancing operational efficiency but also reducing costs and streamlining complex logistics networks. AI-powered analytics are enabling companies to predict demand fluctuations, optimize route planning, and automate routine tasks, leading to more agile and resilient supply chains.

Key Developments:

- AI-powered demand forecasting to reduce inventory shortages.

- Autonomous warehouses leveraging robotics for streamlined operations.

- AI chatbots optimizing customer service and real-time tracking.

Case Study: Amazon’s Fully Automated Warehouses

Amazon led the shift by integrating AI robots that handle packaging and fulfillment, reducing dependency on human labor while improving efficiency by 35%.

2. Major Disruptions in Global Shipping and Trade

2025 saw significant supply chain disruptions due to port congestion, labor strikes, and changing trade policies. These disruptions have challenged companies to rethink their logistics strategies, emphasizing resilience, agility, and digital transformation. Logistics and supply chain stories this year have highlighted the importance of real-time tracking, diversified supplier networks, and improved inventory management to mitigate risks and maintain supply chain efficiency.

Impact:

- Increased shipping costs due to container shortages.

- Delays in global trade due to labor unrest at major ports.

- Shift towards nearshoring as companies seek regional alternatives.

Solutions Adopted:

- Companies investing in diversified supplier networks.

- Digital twin technology to simulate and mitigate disruptions.

3. Sustainable Logistics: The Push for Greener Supply Chains

Sustainability remains a top priority in logistics and supply chain stories, with companies adopting eco-friendly practices to minimize their environmental footprint. Businesses are investing in renewable energy sources, optimizing transportation routes to reduce emissions, and implementing circular economy principles to extend the lifecycle of materials.

Additionally, stricter government regulations and growing consumer demand for sustainability have further pushed organizations to integrate green logistics strategies into their operations.

Sustainability Initiatives in 2025:

- Electric and hydrogen-powered delivery fleets.

- Carbon offset programs for logistics companies.

- Increased use of biodegradable and reusable packaging.

Table: Green Initiatives in Logistics

| Initiative | Impact |

| Electric Vehicles | Reduced carbon footprint |

| Smart Route Optimization | Lower fuel consumption |

| Sustainable Packaging | Less plastic waste |

4. The Expansion of E-commerce and Last-Mile Delivery

The rise of online shopping has increased the demand for fast, efficient last-mile delivery solutions. Consumers expect faster delivery times, real-time tracking, and flexible delivery options, pushing companies to innovate in logistics.

The growth of e-commerce has also led to increased urban congestion and sustainability concerns, prompting companies to explore electric vehicles, alternative delivery methods, and AI-driven logistics planning.

Advancements:

- Drone deliveries: Companies like UPS and FedEx piloting drone technology.

- Autonomous delivery robots: Amazon Scout and Starship robots gaining traction.

- Micro-fulfillment centers: Closer distribution hubs reducing delivery times.

5. The Evolution of Smart Warehousing and Robotics

Warehouses in 2025 have embraced robotics, AI, and IoT to enhance productivity, streamline operations, and reduce human dependency. Smart warehouses leverage interconnected systems that communicate in real-time, enabling automated inventory management and predictive maintenance.

AI-driven analytics optimize storage space, while robotics handle picking, packing, and sorting tasks with higher accuracy and efficiency. The integration of these technologies has significantly lowered operational costs and improved turnaround times, making supply chains more agile and resilient to disruptions.

Technological Advancements:

- IoT-enabled real-time tracking of goods.

- AI-driven warehouse management systems.

- Robots handling repetitive tasks to increase efficiency.

Example: Tesla’s AI-Driven Inventory Management

Tesla’s AI-powered warehousing system reduced supply shortages by 30%, optimizing stock management with predictive analytics.

6. Cybersecurity Threats and Digital Resilience in Logistics

As logistics increasingly depend on digital platforms, cybersecurity threats have surged, affecting supply chain security. Companies have faced rising instances of ransomware attacks, data breaches, and hacking attempts, causing significant disruptions in global trade.

The reliance on cloud-based logistics management systems and IoT-enabled tracking has further exposed vulnerabilities, making cybersecurity a top priority for industry leaders. In response, firms are investing heavily in AI-driven threat detection, blockchain-based security protocols, and robust encryption techniques to fortify their digital infrastructure against potential threats.

Major Cybersecurity Risks in 2025:

- Ransomware attacks disrupting global logistics operations.

- Data breaches exposing sensitive customer information.

- Hacking attempts targeting supply chain software.

Countermeasures Implemented:

- Advanced encryption for logistics data protection.

- AI-driven threat detection systems.

- Blockchain technology for secure transactions.

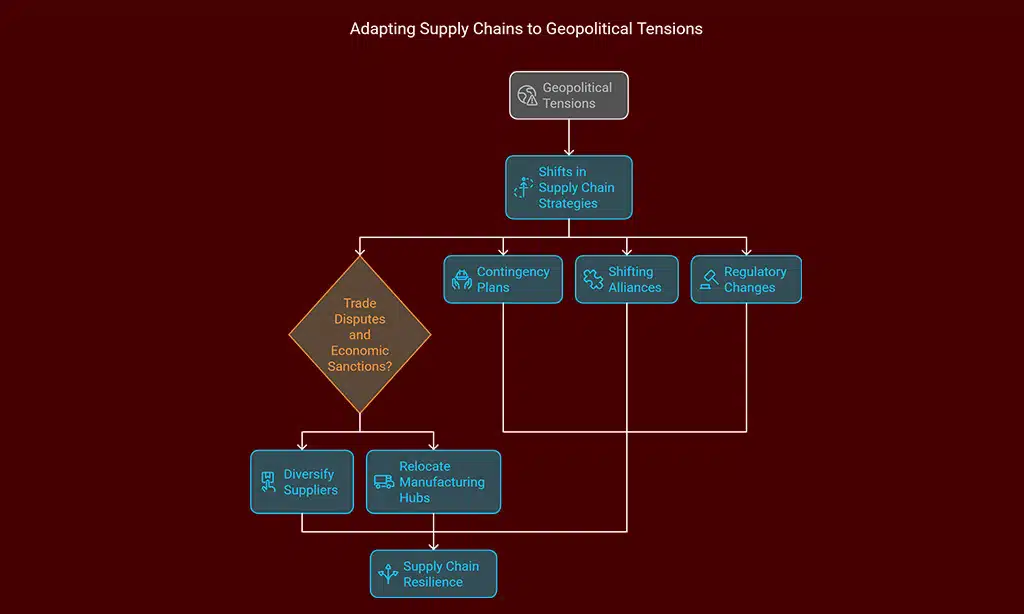

7. The Impact of Geopolitical Conflicts on Supply Chains

Geopolitical tensions have led to shifts in global supply chain strategies, prompting businesses to rethink their sourcing, production, and distribution networks. Trade disputes, economic sanctions, and regional conflicts have forced companies to diversify suppliers, relocate manufacturing hubs, and implement contingency plans to mitigate risks.

Additionally, shifting alliances and regulatory changes have added layers of complexity, requiring adaptive strategies to maintain supply chain resilience and efficiency.

Effects on Logistics:

- Trade restrictions affecting key suppliers.

- Companies relocating production to politically stable regions.

- Increased costs due to tariffs and border restrictions.

8. Blockchain Adoption for Supply Chain Transparency

Blockchain technology is transforming logistics by ensuring transparency and traceability. By providing a secure and immutable ledger, blockchain enables real-time tracking of shipments, reducing fraud and errors in the supply chain.

Companies are increasingly adopting blockchain for smart contracts, automated documentation, and authentication of goods, improving efficiency and trust among stakeholders. This technology also enhances compliance with regulatory requirements and fosters greater accountability in global trade.

Benefits of Blockchain in Supply Chains:

- Real-time tracking of shipments.

- Secure and tamper-proof documentation.

- Reduction in counterfeit products.

Example: Walmart’s Blockchain Integration

Walmart implemented blockchain for food traceability, reducing contamination risks and ensuring quality assurance.

9. The Role of 3D Printing in Logistics and Manufacturing

3D printing is disrupting traditional supply chains by enabling on-demand manufacturing, reducing lead times, and minimizing the need for large inventory storage. By allowing companies to produce parts and products closer to the end consumer, 3D printing significantly cuts transportation costs and mitigates supply chain risks.

Industries such as automotive, healthcare, and aerospace are leveraging this technology to create customized, high-quality components efficiently. The ability to rapidly prototype and manufacture goods with minimal waste also supports sustainable logistics practices, making 3D printing a key driver of future supply chain innovations.

Advantages:

- Reduced dependency on overseas suppliers.

- Customization of products with lower lead times.

- Sustainable production with minimal waste.

Industries Benefiting:

- Healthcare (prosthetics, implants).

- Automotive (spare parts manufacturing).

- Aerospace (rapid prototyping of aircraft components).

10. The Changing Workforce: Labor Shortages and Automation

With labor shortages increasing, companies are turning to automation and upskilling programs to bridge the skills gap and enhance workforce efficiency. Robotics and AI-driven solutions are being deployed to handle repetitive tasks, allowing human workers to focus on higher-value activities.

Additionally, firms are investing in training initiatives to equip employees with the necessary skills to work alongside advanced technologies, ensuring a smoother transition to an automated and digitally integrated logistics ecosystem.

Key Challenges:

- Shortage of skilled workers in logistics.

- Resistance to automation replacing human jobs.

Solutions Implemented:

- Employee retraining programs for tech-based roles.

- Increased wages and better working conditions to retain staff.

Key Takeaways from 2025’s Logistics and Supply Chain Trends

The logistics and supply chain industry has experienced remarkable transformations, driven by technological advancements, sustainability efforts, and geopolitical influences. These trends have reshaped the way companies manage operations, optimize efficiency, and ensure resilience in an increasingly complex global landscape.

- AI and automation continue to revolutionize logistics efficiency.

- Sustainability efforts are shaping eco-friendly supply chain operations.

- Cybersecurity threats necessitate stronger digital protection measures.

- Geopolitical conflicts influence global supply chain restructuring.

- Blockchain ensures transparency and trust in logistics operations.

Wrap Up

The Logistics and Supply Chain Stories of 2025 reflect an industry in rapid evolution. From AI-driven automation to blockchain-powered transparency, these innovations are reshaping global trade.

As businesses adapt to sustainability, digital transformation, and geopolitical shifts, the future of logistics remains dynamic and promising.

What do you think was the most impactful logistics story of 2025? Share your thoughts in the comments!