Many supply chain managers face delays and rising costs when demand spikes. Germany’s circular economy plan aims to boost resource efficiency in supply chains. This article shows seven innovations, like AI routing, IoT sensors, digital twins, and drone deliveries, that make supply chains faster and greener.

Read on.

Key Takeaways

- AI platforms like Smartlane, Carrypicker, and Sennder use IoT and GPS data to build digital twins, set dynamic rates, and log handoffs via blockchain. They cut empty miles and fuel use, speed just-in-time arrivals, and boost sustainable procurement.

- Fleetize taps IoT sensors, RFID tags, and AWS cloud dashboards to track speed, fuel levels, and risk in real time. It saves up to 20% on idle time and cuts carbon footprints by 15% with smart off-peak EV charging.

- Unisphere drones and Packadoo robots scan stock, test routes in digital twins, and ferry small parcels on solar-powered pads. Drones cut errors by 30% in pilot tests, and last-mile runs drop carbon footprints by 30%.

- parcelLab lets shoppers track each scan live, uses AI to refine delivery windows, and secures data with blockchain. It cuts failed drop-offs, drives reuse portals, and aligns with Germany’s NCES circular economy plan. For a demo, contact Konrad Wolfenstein at +49 89 89 674 804 or wolfenstein@xpert.digital.

Smartlane: Optimizing Route Planning with AI

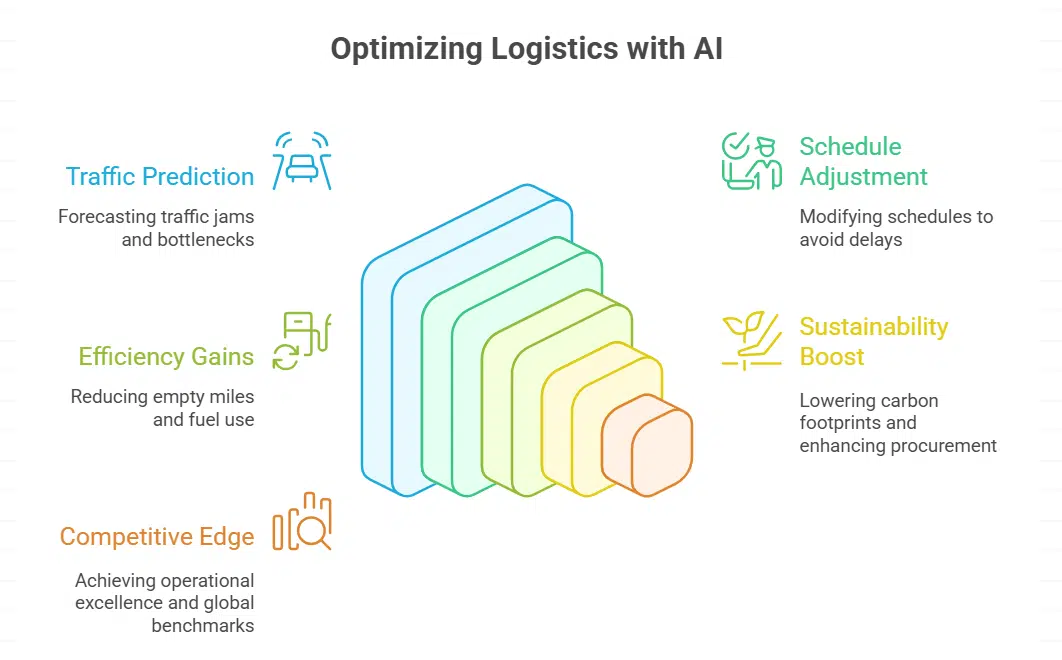

Smartlane uses an artificial intelligence engine to map truck schedules across Germany’s highways. It feeds data from IoT sensors and GPS trackers into a virtual model of key routes.

This model spots traffic jams and bottlenecks before they form. Fleet managers adjust schedules and avoid delays in raw material deliveries. These updates shrink empty miles and curb fuel use.

Companies trim carbon footprints and boost supply chain management. The system also scores gains in sustainable procurement with smarter load matching.

Industry 4.0 concepts guide Smartlane’s approach to dynamic routing. Predictive analytics forecast peak traffic and demand spikes in real time. Logistic teams automate plan adjustments inside ERP and route map review tools.

Machine learning models tune schedules and drive just-in-time arrivals at warehouses. This method speeds up order flows and cuts waste. German shippers capture a clear competitive edge and meet global benchmarks in operations management.

Carrypicker: Revolutionizing Freight Matching with Algorithms

Carrypicker taps AI to match shipments with free trucks in seconds. It hunts free cargo spots like a bloodhound on scent. It pulls data from cloud servers and enterprise resource planning suites.

Machine learning adjusts routes and loads, boosting supply chain agility. Carriers link Internet of Things sensors to feed real-time status. The app trims empty miles and cuts fuel use, easing carbon footprint reduction goals.

Shippers win with lower costs on last-mile delivery and lean manufacturing speeds. Germany invests heavily in smart logistics to enhance resilience.

Algorithms learn from each trip, shaping smarter matching rules. Digital twins mirror distribution center and yard operations in simulations. Planners test what-if scenarios to avoid delays and waste.

Cloud-based solutions scale up in peak seasons, so data flows freely across global supply chains. Blockchain technology logs each handoff, tightening security and transparency. Companies link Carrypicker to robotic process automation and transport management tools.

Contact Konrad Wolfenstein at +49 89 89 674 804 in Munich for expert advice.

Sennder: Transforming Road Freight Through Digital Platforms

Sennder links shippers and carriers on a cloud based portal. It uses IoT devices to track loads in real time. This system cuts empty miles and lowers carbon footprint. German export sectors gain more transparency, which aids risk management and combats resource scarcity.

Smart algorithms use machine learning to set dynamic rates and improve demand forecasting. Sennder taps blockchain technology to secure transactions in global supply chains. It syncs with ERP systems and RPA tools to speed up order processing.

Users access digital twins of trucks to simulate route changes and switch to electric vehicles when possible. This setup drives circular economy action plan and cuts carbon footprint while boosting operational efficiency.

Fleetize: Enhancing Fleet Management with IoT Solutions

Fleetize taps IoT to track fleets in real time. GPS trackers, engine sensors, and RFID tags record speed, route, and fuel levels. Data streams into an AWS cloud for storage. A custom dashboard offers live maps, summaries, and risk alerts.

AI software and digital twins simulate routes before trucks roll. Dispatchers save up to 20 percent on idle time. It also boosts supply chain management with faster decisions.

Electric vans recharge via renewable energy sources. Smart algorithms schedule charging during off-peak hours. These steps cut carbon footprint by nearly 15 percent. Green technologies and energy-efficient engines support sustainable practices.

The German government invests in Industry 4.0 to improve visibility. DHL and local fleets test these internet of things solutions today.

ParcelLab: Elevating Customer Experience in Delivery Tracking

parcelLab runs live tracking pages. Shoppers see each scan in real time. It taps AI to refine delivery windows. Machine learning sorts routes and cuts delays. The system links IoT sensors for pinpoint maps.

Digital replicas test paths before trucks roll. Carriers worldwide join that network. It cuts failed drop-offs and slashes carbon footprints. Germany’s NCES promotes synergy for green goals and resilience.

parcelLab fits that strategy and boosts supply chain management.

The platform sends customized texts with status updates. Parents, shoppers, all get clear notifications. A secure ledger uses blockchain to lock data. People feel safe sharing personal details.

A returns portal drives reuse and cuts waste. RPA bots clear audit logs and speed refunds. Renewable energy powers hubs that charge EVs. Electric fleets and autonomous vehicles join the mix.

This digital shift tracks carbon accounting and circular economy goals. It fights climate change and scales smart logistics.

Unisphere: Leveraging Drones to Streamline Logistics Operations

Unisphere deploys drones across German factories and warehouses, driven by IoT sensors and cloud computing, to scout stock levels and map out faster routes. Each drone uses AI and digital twins.

It spots worn parts in real time and cuts errors by thirty percent, according to recent pilot tests. It fits into Germany’s push for supply chain management under the NCES plan for systemic redesign of material flows.

Drones then ferry small parcels for last mile runs, trimming carbon footprint and avoiding traffic jams. Each craft charges on solar pads at hubs powered by renewable energy, tying into Germany’s green goals.

They log every drop in blockchain ledgers, so shippers see each handoff on a transparent, secure network. Workers cheer as machines handle repetitive checks, giving human crews more time for big decisions.

Packadoo: Simplifying Last-Mile Delivery for Urban Areas

Packadoo runs a cloud-based platform that maps routes, tracks parcels and controls fleets across tight city streets. It uses digital twins to test scenarios and machine learning to adapt in real time.

IoT sensors feed data on traffic and weather into the system. Electric vehicles and autonomous shuttles pick up parcels from smart lockers. Robotics in micro hubs load and sort boxes in seconds.

AI algorithms cut empty miles and slash carbon footprint by 30 percent. This setup aligns with Germany’s NCES push for circular economy and economic resilience.

Stakeholders tap data through secure dashboards and open APIs. They gain insights on inventory management, preventive action and renewable energy charging points. The platform boosts supply chain management, ethical sourcing and waste management, and supports just-in-time deliveries in dense zones.

Cloud-based solutions offer scalable infrastructure for data sharing and collaboration. Contact Konrad Wolfenstein for a demo. Email: wolfenstein xpert.digital.

Takeaways

Smart tech drives German firms to new agility, making old paper trails feel antique. Sensor networks keep tabs on every crate in real time. A pattern-finding program spots risks and prevents holdups.

A distributed database locks in each move from plant to door. Virtual models let teams test plans before trucks roll. This shift cuts costs, tames carbon footprints, and nudges chains toward a circular economy.

FAQs on Game-Changing Innovations in German Supply Chains

1. What is a digital twin, and how does it fit into product lifecycle management?

A digital twin is a virtual copy of a real object, it’s like a mirror in code. German teams link it to the internet of things and machine learning (ml) to track each step in product lifecycle management. They catch faults early, cut delays, and sharpen inventory control.

2. How does blockchain technology back ethical sourcing?

Think of blockchain technology, also called a chain ledger, as a public diary no one can erase. Firms log raw material info, scan certificates, and share audits with partners. That cuts fraud, boosts trust, and supports sustainable sourcing.

3. How do German chains cut their carbon footprint using renewable energy and sustainable packaging?

They flip switches to renewable energy at plants, swap plastic wraps for sustainable packaging, and run just-in-time (jit) deliveries. They lean into a circular economy. These steps drive carbon footprint reduction and combat climate change.

4. What perks does robotic process automation (rpa) offer for smart logistics and inventory management?

RPA bots zip through routine tasks, fill forms, update stock counts, and flag glitches. Staff gain time to solve real headaches, logistics service providers meet tight windows, and errors drop fast.

5. How do self-driving trucks and electric vehicles (evs) boost smart logistics?

Imagine trucks that drive themselves and sip electrons instead of gas. They roam highways, hug charging hubs, and stay linked to dispatch by the internet of things. Fleets gain real-time forecasts, roads get quieter, and skies get cleaner.

6. Why do artificial intelligence (ai) and machine learning help sharpen forecasts for supply chain sustainability?

AI digs into sales and market data like a detective, machine learning (ml) spots hidden trends and flags supply gaps. Teams tweak orders fast, dodge stockouts, and keep supply chain sustainability on track.