Builders and designers often face heavy walls that slow work and eat budgets. They need lighter mass timber or engineered wood products that cut weight and save time.

Steel, cement and glass cause 10 percent of energy-related CO2 emissions, says the United Nations. This post shows 11 Timbercrete tips that mix portland cement, wood fibers and ash in mass timber.

You will boost energy efficiency in buildings and lower carbon footprint. Read on.

Key Takeaways

- It blends Portland cement, wood fibers, fly ash, and slag to cut wall weight by 40% (90 vs. 150 lb/ft³) and lower embodied carbon by 30%.

- Precast panels lock into cross-laminated timber frames like Lego, speed builds, shrink foundations, and shine in the seven-story T3 Minneapolis project (2016).

- Thick Timbercrete blocks trap air to cut heat loss by 20% and use fly ash plus foam beads to reduce urban noise by 16 dB.

- A self-healing mix with recycled sawdust, polystyrene foam, and biopolymers blocks moisture, resists cracks, and can last for decades.

- Oak Ridge Lab found the mix cuts global warming potential by 25%, while the UN notes cement, steel, and glass cause 10% of energy-related CO₂ emissions.

Timbercrete and Lightweight Construction

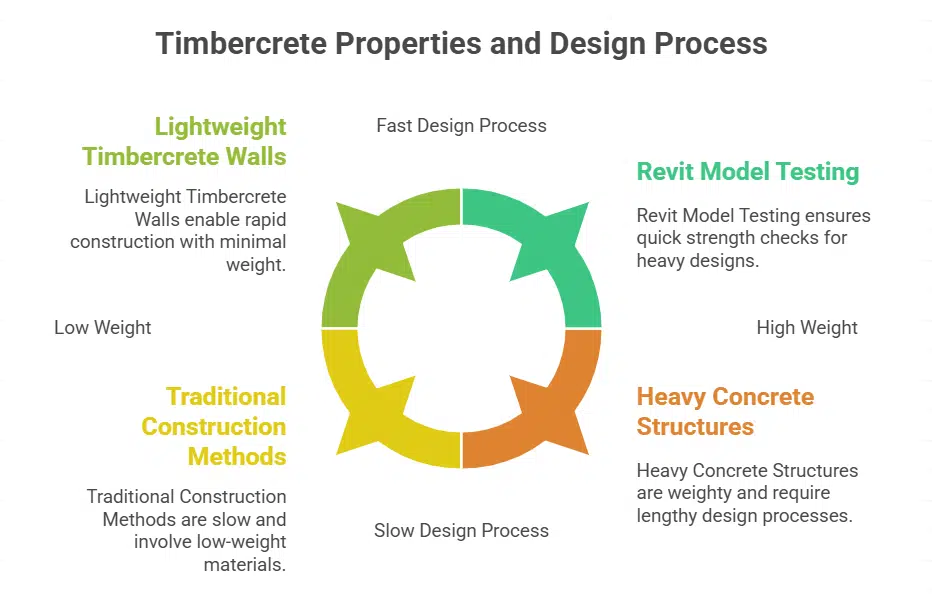

Timbercrete cuts building weight like a hot knife through butter. It mixes wood layers, fly ash, and slag for stiff, lean walls, then designers test models in Revit for fast strength checks.

Enhancing structural efficiency with Timbercrete

Engineers use Timbercrete as a sustainable building material to shrink foundation needs. It cuts its weight by half, so it eases stress on joists and beams. The concrete blocks resist fire far better than normal concrete.

Mix fly ash, iron slag, or ground-granulated blast-furnace slag into the mix to improve fire proofing, curb greenhouse-gas emissions, and aid carbon sequestration. This blend maintains strength under stress and fights cracks like self-healing concrete admixtures.

Builders stack the lightweight concrete blocks to speed up mass timber construction. They haul lighter mixes for less cost, trim fuel bills on long transports, and reduce carbon in construction materials.

Projects register low embodied carbon, earn top marks on environmental product declarations, and demonstrate lower environmental impact. Teams pair panels with cross-laminated timber (CLT) beams to gain strength and acoustic insulation.

Clients appreciate lean budgets and brisk schedules—Timbercrete performs like a feather in those plans.

Reducing overall building weight

Timbercrete reduces mass by up to 40 percent compared to normal concrete. It weighs about 90 pounds per cubic foot. Concrete sits near 150. Builders cut foundation size and cost while using sustainable building materials.

They fit glulam beam frames with cross-laminated timber panels to shed more pounds. This mix uses fly ash and ground granulated blast furnace slag. It taps recycled filler for extra lightness.

Smaller footings speed up site work and trim soil removal. Teams save days and dollars on excavators and concrete trucks. Mass timber construction meets passive cooling goals with ease.

Owners enjoy a clear roof line and simple floor plan. They cut embodied carbon and leave a lighter mark on the land.

Thermal and Acoustic Insulation Properties

Timbercrete locks in warmth like a wool sweater, it handles thermal conductivity with ease, and it lets your window unit rest more. It tames noise like a friendly librarian and hits top sound transmission class scores, so you can ditch the traffic roar.

Improved energy efficiency

Thick Timbercrete blocks trap air, and they cut heat loss by up to twenty percent. This blend uses fly ash from coal power plants and reclaimed wood fiber to boost insulation. Architects use energy modeling to map heat transfer and show big cuts in cooling bills.

You slash energy consumption, and you shrink embodied carbon at the same time.

Homeowners brag about lower winter bills, no kidding. A flow analysis tool checks gaps around the frame, revealing near perfect seals. The mix also boosts carbon sequestration, as it locks in CO2.

This approach ranks high among sustainable building materials in the US.

Noise reduction for urban environments

Timbercrete walls trap city sounds. The blocks mix fly ash and foam beads for low density and high acoustic insulation. A trial near a busy road cut noise by 16 decibels. Builders pair these panels with clt beams for a strong, light shell.

This setup forms a buffer zone outside busy streets.

Sustainable building materials shine in this approach. A mix of mass timber and Timbercrete reduces internal stress and vibration. Neighbors near highways report calmer nights. The system uses recycled fibers and paints that cut greenhouse gas emissions.

It halves embodied carbon compared to standard concrete walls.

Sustainable Innovations in Timbercrete

Concrete experts fuse agri-waste and industrial by-products, like coal residue, into Timbercrete. They add a self-healing mix and renewable polymers, so walls heal like skin after a scrape.

Incorporation of recycled materials

Mixers blend wood scraps and fly ash into cement. They use sawdust from lumber mills to fill molds. The mix adds polystyrene foam from old air conditioner cases. It cuts material costs and shrinks waste mountains.

The process makes strong, lightweight wall panels.

Life Cycle Assessment finds this mix cuts embodied carbon by up to thirty percent. Contractors hail it as a circular economy hero. Project teams cite its use of sustainable building materials.

Each panel locks in carbon as trees grow on managed sites. Builders add steel reinforcement rods for extra strength. Crews attach panels with wood screws and lag screws.

Lower carbon footprint production

Timbercrete cuts embodied carbon by up to 30 percent versus traditional reinforced concrete. It blends recycled wood chips with fly ash, slashing cement production needs. Materials scientists at Oak Ridge Lab measured a 25 percent drop in global warming potential.

This mix locks in carbon through its wood content.

Builders pick this sustainable building material to meet green codes. Mass timber construction joins forces with Timbercrete panels in urban infrastructure. It reduces emissions tied to cement production and curbs embodied carbon.

This approach supports sustainable construction practices from foundations to flooring.

Advanced Timbercrete Design Solutions

Engineers blend CAD software and finite element analysis to cut weight and boost strength. They merge laminated wood frames with high-strength concrete mixes, and watch bold shapes rise in record time.

Pre-cast modular panels

Workers cast panels in a factory rather than on site. Crews stack components like playing cards. Connectors lock panels in place, using cross-laminated timber and high-strength concrete.

Clever use of fly ash cuts embodied carbon by 30 percent. This method sequesters carbon inside the panels. A concrete mixer and automated formwork speed the process. Prefab panels cut delays at limberlost place where crews once wrestled with wet pours.

Prefab panels join like Lego bricks. Crews fix them in days instead of weeks. They handle fewer trucks downtown, so noise and dust drop fast. A hydraulic press shapes each piece to strict tolerances.

Factories mix self-healing concrete with agricultural waste and bioplastics to mitigate cracks. This step extends ultimate strength and cuts carbon reductions in half. Owners see lower stresses on walls and less fatigue failure near corners.

Developers praise these panels as sustainable building materials that cut environmental impact.

Customizable shapes for unique architecture

Architects shape Timbercrete like modeling clay, forming sweeping curves and bold angles with custom molds. Designers add fly ash and pigments to meet sustainable building materials goals.

Builders cut weight and embodied carbon, using mass timber construction or cross-laminated timber for frames. The material locks carbon, turning each block into a small sequestration site.

Craft crews pour Timbercrete into 3D printed forms or carved molds like a sculptor at work. Some teams compare curves to rammed earth walls, but they install Timbercrete way faster.

Panels can fold, bend, and arch, without extra steel or mortars. Projects boost environmental impact scores and feed sustainable construction practices with artful facades.

Durability and Weather Resistance

Timbercrete stands firm against driving rain and cold snaps, shrugging off moisture like a duck’s feathers.

This blend, similar to self-healing concrete with reduced embodied carbon, locks water out while it sequesters carbon deep inside its core.

Enhanced resistance to moisture and weather conditions

Builders face leaks and rot when water seeps into walls. Timbercrete links wood fiber and cement to block moisture. It fights corrosion and stops cracks like self-healing concrete.

This mix uses fly ash, and meets standards for sustainable building materials.

Structures must stand up to rain, snow, wind and sun. Timbercrete shrugs off freeze and thaw cycles, and it beats rammed earth construction in damp climates. It rivals ultra-high-performance concrete, trimming environmental impact.

Contractors pair it with mass-timber frames for durable homes.

Longevity in diverse climates

Timbercrete fights heat, frost, wind and heavy rain with ease. Wood fiber and fly ash cut embodied carbon, and the porous mix sequesters carbon deep inside. It stands up like a champ against bending moments, and fights mold and cracking.

Coatings block UV rays and salt spray near coastlines. Mixing waste wood and recycled aggregates follows sustainable construction practices. Long-term tests show panels can last decades in cold plains or humid tropics.

Applications of Timbercrete in the US

Builders clip Timbercrete panels onto mass timber frames for single-family dwellings, they count on carbon capture and low weight. Contractors slot pre-cast modules into office pods, they run BIM scans and yield tests, and call it a breeze for shaping new skylines.

Residential lightweight structures

Timbercrete blends sawdust, fly ash from asphalt plants, and cement into panels that weigh nearly half of standard concretes. This product fits sustainable building materials lists and cuts embodied carbon in half during production, lowering total environmental impact.

It slashes waste in disposal sites by tapping recycled inputs. Its low mass helps mass timber construction crews lift pieces without cranes or heavy gear.

Cross-laminated timber (CLT) joins Timbercrete to craft home walls that sequester carbon and resist rupture under linear-elastic loads. Its achromatic finish matches nature or bold interior lighting themes.

Homeowners praise the quiet rooms, thanks to thermal and acoustic insulation in self-healing concrete cores.

Commercial lightweight projects

Commercial teams adopt mass timber assemblies to cut load, boost strength. Factories offload light Timbercrete blocks that slice embodied carbon by up to 30 percent. These sustainable building materials help lock in carbon sequestration in walls.

The 2016 T3 Minneapolis project stood at seven stories, it became North America’s largest mass timber building at the time. It showed cross-laminated timber (clt) cores withstand wind and hail, while reducing weight on soft soils.

Developers tap modeling apps for design, they use robotic arms for precise cuts. Panels arrive pre-cast, they contain fly ash and recycled fibers, they lock in strength. Construction crews praise the self-healing concrete blend in cores, it stands up to moisture, wind, hail.

Workers smile, they see how sustainable construction practices, environmental impact goals, and openai tools converge on site, to build a lighter, greener skyline.

Takeaway

Timbercrete proves a game-changer for US builders, cutting weight and cutting carbon, with residual ash and layered wood panels boosting strength. This mix taps carbon sequestration, it slashes energy use, it tames noise.

You get weather tough walls, you get fast-build charms. Contractors snap up precast modular panels, racing the clock, stacking walls like giant blocks. Light floors mean lean foundations, glue-lam beam framing rides to the rescue, cutting emissions.

Your next project can wear a green crown thanks to these sustainable building materials.

FAQs on Timbercrete Innovations for Lightweight US Structures

1. What is Timbercrete in lightweight US structures?

Timbercrete mixes wood fiber, repairing cement, and coal residue. It makes a strong block that still feels light. This blend uses sustainable building materials, it cuts embodied carbon. I saw one under the blue sky, it felt like a pillow. Builders love this for lightweight jobs.

2. How do these materials help protect the environment?

They trap carbon in wood and cement. This aids carbon sequestration, it slows climate change. Builders use mass timber construction and layered wood boards, they rely on sustainable sourcing for wood. These steps cut the environmental impact. It is a big win for the environment.

3. Are these materials strong enough for big buildings?

Yes. mass timber construction, layered wood boards, and repairing cement can hold a lot. These sustainable building materials act like a body builder that lifts heavy beams. Coal residue blocks stay solid, they cut embodied carbon. They need less repair and last a long time.

4. Can these innovations fit local building rules?

Yes. Many US states update codes to allow Timbercrete. Teams add these new takes into blueprints fast. They follow safe, proven steps in sustainable construction practices. This approach lowers environmental impact, it trims embodied carbon. It works with modern building laws.