Many supply chain teams face delays, lost packages, and high costs. They still use manual steps and old software in warehouse operations. This slows down order fulfillment and hurts customer trust.

Fast, clear data flows can fix this.

98% of logistics managers say artificial intelligence makes their work easier. We show seven labs that use AI, robotics, blockchain, and big data analytics. You will see how they cut costs, speed up deliveries, and boost sustainability.

Read on.

Key Takeaways

- 98% of logistics managers say AI makes work easier. Labs use machine learning, predictive analytics, and digital twins to forecast demand, cut waste, lower storage costs by 30%, and speed up warehouse turnaround by 20%.

- Robotics labs run autonomous mobile robots, automated guided vehicles, and robotic arms with computer vision. These bots pick up to 2,000 units per hour, drive self-driving forklifts in –20 °C cold rooms, and sync in real time with ERP systems.

- Blockchain labs log every shipment in tamper-proof ledgers and use smart contracts to trigger payments and checks. This approach cuts fraud, speeds approvals, boosts visibility, and gives regulators live data for compliance.

- Sustainable hubs run on solar and wind power. They use IoT sensors and robotic process automation to track freight, charge electric vehicles, cut carbon footprints, and help SAP and Oracle clients trim energy bills.

- Labs boost last-mile delivery with GPS- and LiDAR-guided drones and autonomous rovers. They raise first-attempt success by 30%, cut wrong drop-offs by 20%, and give customers live tracking updates.

AI-Powered Supply Chain Optimization

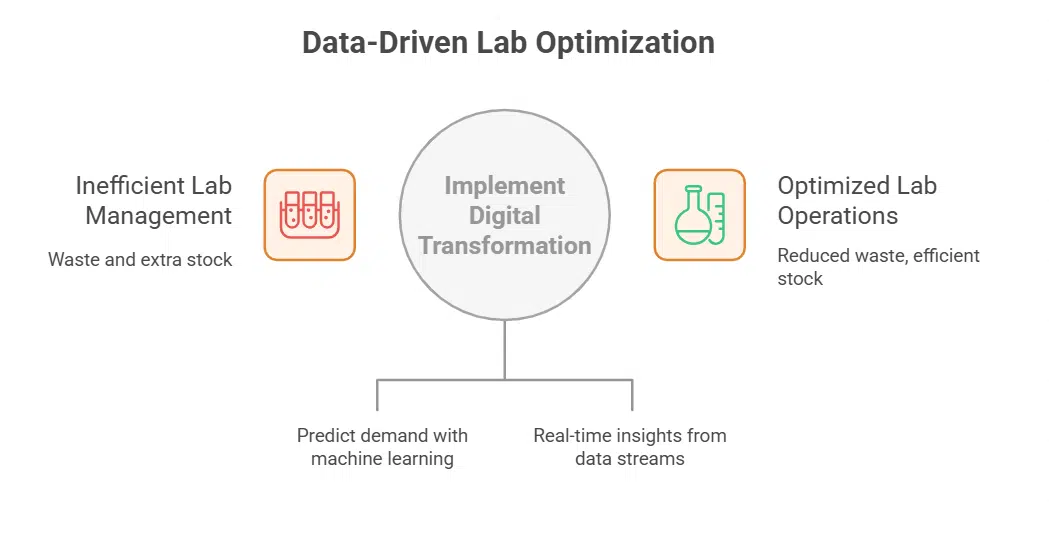

Labs use machine learning and predictive analytics to forecast demand, cutting waste and extra stock. Next, see how digital twins and a cloud platform turn data streams into real time insights.

How does machine learning improve predictive analytics in logistics?

Machine learning scans shipping data from IoT devices, a cloud platform, and ERP systems. It automates routine scheduling tasks and boosts shipping efficiency. Teams free up time for urgent issues.

Algorithms forecast delays in global supply chains. The system picks the best provider for each delivery by weighing time sensitivity, compliance rules, and price changes. Planners cut storage costs by up to 30 percent and balance stock levels in real time.

Big data analytics, driven by neural nets, builds a virtual model, a digital twin, for logistics managers. It tests route changes and demand shifts at low risk. Predictive intelligence slashes turnaround times by 20 percent in warehouse operations and distribution centers.

Firms in the shipping industry, third party logistics providers, and ecommerce teams launch faster with this smart platform.

Robotics and Warehouse Automation

Self-driving forklifts and metal-claw handlers buzz like a hive, guided by camera view and tied to your enterprise resource planning to pick, pack, and ship in record time—read on to learn more.

What advanced robotics technologies streamline warehouse operations?

Warehouse bots like autonomous mobile robots roam aisles with sensors from the internet of things, scanning barcodes, lifting pallets, and moving boxes without breaks. Automated guided vehicles and conveyors team up, following painted lines or QR codes on floors, syncing with a warehouse management system and an ERP platform in real time.

Robotic arms with computer vision pick items at rates of up to 2,000 units per hour. These machines cut errors and speed up order fulfillment for any logistics service provider.

A new breed of energy-smart storage robots thrives in cold chain warehouses. They haul crates in minus 20 degree rooms and track temperature for compliance. Robotic picking arms handle fragile goods and heavy inventory alike.

This shift to automation drives down labor costs, slashes waste, and boosts supply chain management performance.

Blockchain for Transparent Logistics

A distributed ledger on a chain platform logs every shipment move in real time. Automated contracts cut fraud, boost visibility, and speed up approvals.

How does blockchain secure and optimize supply chain transactions?

Blockchain ranks high among emerging technologies that shake up supply chain management. Enterprise ledger platforms write each transfer to a tamper-proof record, guarded by public key cryptography and a consensus algorithm.

Partners view the same record, boosting transparency and trust. This method cuts reliance on legacy systems and manual record-keeping in warehousing, maritime transport, and enterprise resource planning (ERP).

Automated digital agreements, known as smart contracts, trigger payments and checks on chain. Companies drop paper logs and outdated databases. Regulators tap real-time data for strict rules, meeting compliance in a single view.

This shift makes last mile delivery and operations more agile, data-driven, and clear.

Sustainable Logistics Innovation Labs

Some start-ups power pilot hubs with solar power and wind energy, and they even charge electric vehicles using that clean energy. They deploy Internet of Things sensors and robotic process automation to track freight and cut carbon in real time.

What eco-friendly solutions are being developed for logistics?

Start-ups deploy energy-efficient cold storage pods powered by solar cells and Internet of Things (IoT) sensors. They cut carbon footprints in warehousing. Automated forklifts with computer vision and robotic process automation stack pallets higher in slim aisles.

These tools push supply chain management forward. That move spares space and shrinks energy demand. SAP and Oracle clients see leaner warehouse operations and lower bills. APICS certified supply chain professionals praise the shift.

Emerging technologies like electric trucks and last-mile drones grab headlines in sustainable delivery. Autonomous vehicles use AI and machine learning for precise route planning, cutting greenhouse gas.

A venture capital fund backs Ramco systems in tying Oracle tracking to vehicle telemetry. Clean energy engines power cargo vans on urban streets. Consumers enjoy quieter, cleaner home delivery.

Last-Mile Delivery Enhancements

Delivery drones and autonomous rovers use GPS, LiDAR, and geolocation to dodge roadblocks, hop fences, and land your parcel on your porch—read on.

How are drones and autonomous vehicles transforming last-mile delivery?

Drones now carry packages like clockwork. They run on energy-saving batteries that curb pollution. They use GPS and computer vision to plan routes, and they send live updates for real-time tracking.

This setup gives customers more flexible drop-offs and boosts supply chain management teams’ speed.

Self-driving vans roam neighborhoods with sensors like LiDAR. Robots adapt vehicle routing on the fly. They can raise first-attempt delivery success by up to 30 percent and cut wrong drop-offs by 20 percent.

Start-up companies use artificial intelligence (ai) and autonomous navigation. More brands report higher customer retention while trimming carbon footprints.

Big Data Analytics and Digital Twins

Teams use predictive analytics with a digital twin platform and Apache Spark to model shipping routes in near real time. It shines a light on blind spots so they jump on weak links before they break.

How do real-time insights improve logistics planning?

Real-time analytics feed a central dashboard with live data. It shows pickup times, third-party carrier status, and hub flows. Operations staff spot delays fast, so they prevent larger hold ups.

Live tracking boosts service reliability and speeds up decision-making. Many firms add artificial intelligence (AI) tools and computer vision to flag slowdowns in warehouse operations.

A digital twin model simulates routes and hub movements under stress. Planners view scenarios for storms, port strikes, or roadblocks in maritime transportation and trucking. They tweak plans on the spot to curb waste and cut fuel use.

Centralized data platforms deliver end-to-end visibility and boost interoperability across carriers. Emerging technologies speed up logistics and supply chain management and drive supply chain innovation.

Geolocation and Crowd Shipping Technology

Geolocation tools pinpoint each drop site, and mapping services tag them like pins on an old map. One driver jokes, “I’m racing the clock!” as a crowd shipping app, fueled by a location sensor on a mobile device, zips orders along the fastest lanes.

How do geolocation and crowd shipping enhance delivery accuracy?

Platforms powered by geolocation match packages to available shippers in real time, acting as digital matchmakers for parcels and drivers. They tap into crowd shipping networks and emerging technologies to cut wrong stops.

A GIS system within each IoT device sends live coordinates, guiding delivery drivers to the exact drop spot. This feeds data into supply chain management dashboards for quick reroutes.

IoT devices on parcels share precise positions every minute, boosting transparency and customer trust. Mobile applications push live shipment updates, so recipients know exactly when a drop lands on their porch.

That lively feedback loop amps up delivery satisfaction and cuts confusion.

Takeaways

These seven labs drive change with artificial intelligence, machine learning, and blockchain. They streamline chain flows, cut waste, and boost speed. Smart machines and unmanned aircraft slash manual tasks in large hubs.

Virtual models give teams live views and clear paths. Geolocation tools track goods in real time and cut delivery errors. Global carriers and shippers can tap this momentum and raise their game.

FAQs on Logistics Innovation Labs Making Waves Globally

1. What are logistics innovation labs?

They are hubs for testing emerging technologies in real work. They use computer vision to guide robots and speed up warehouse operations. They spark digital transformations in supply chain management. Staff learn new skills and solve real problems.

2. How do labs use artificial intelligence?

They run artificial intelligence (AI) models to spot patterns and track every move of a package. They deploy artificially intelligent tools to read labels, sort boxes, and cut mistakes. It is like giving each box a brain. Staff get data, they act fast, and errors drop.

3. Who funds these labs?

Often private equity steps in with cash, and it bets on new tech. The consulting firm PricewaterhouseCoopers backs some labs, it brings data power. The Confederation of Indian Industry funds labs in Asia, it drives talent development. Many labs also team up with technology startups to spark fresh ideas.

4. How do labs change the maritime industry?

They bring digital transformations to ports and docks. They test systems that log ships, track cargo, and swap paper files for screens. They speed up loading, cut wait times, and help ships sail on time. It is like turning a slow tanker into a fast jet.

5. Do labs work on sustainable development goal 7?

Yes, they focus on green power and clean energy. They test solar panels on rooftops, they plug in electric trucks, and they trim carbon use. All this ties into sustainable development goal 7, the call for affordable clean energy. They save money, and they help the planet.