Your supply chain feels slow. You stack paper, you chase orders. You want to speed up your delivery network. You hear workflow automation can cut errors, save time. But myths on automation slow your move to digital transformation.

Key Takeaways

- Automation won’t replace workers, it shifts tasks to higher-value roles. Postal services lost jobs but email tech created new posts. Dock workers now run robotic arms, and data analysts guide AI. Labor shortages rose as older staff retired and young people chose tech roles.

- Small firms can afford automation with no-code tools and free 30-day trials from providers like Nintex. They link to Microsoft or Salesforce, cut setup costs in half, ramp up in days, and use AI alerts to trim stockouts and boost visibility.

- Automation handles complex workflows. In 2022, a mid-size freight firm automated 40% of paperwork and cut errors by 50%. AI bots tie transport management systems and cloud databases to sort reverse logistics and customs forms.

- Modular rollouts cut costs and show ROI in weeks. Companies buy small parts first, then scale. One FMCG firm cut freight costs by over 10% and slashed manual work by 80%. Perishables moved from farm to shelf in 24 hours using predictive analytics with robotics.

- You must update automated systems and track KPIs. RPA bots still need rule tweaks. Teams that use continuous testing and data governance saw a 30% jump in productivity. Best-of-breed stacks with UiPath, Zapier, and machine learning avoid vendor lock-in.

Myth 1: Automation Will Completely Replace Human Jobs

Many firms link automation with job cuts. They fear AI and robots will eliminate roles. History shows tech shifts jobs, not ends careers. Postal services lost spots, but email tech spawned new posts.

Storage hubs hire machine operators and data analysts. Big data analytics needs human insight. Cloud tools demand constant review. IoT devices need monitoring and tuning. Workers keep goods moving.

Reports show labor shortages rose as older staff retired and young people chose tech roles in logistics.

Logistics teams use workflow automation to cut repetitive tasks. Staff shift to complex problem solving. A dock worker might run a robotic arm, not heavy lifting. A scheduler builds demand forecasts with predictive analytics.

A manager sets key performance indicators then tracks results. AI suggests moves but humans define goals. Teams gain cost savings and boost employee productivity. Firms win competitive advantage in the cloud and global supply chains.

Automation strategy still needs human oversight and data governance.

Myth 2: Only Large Enterprises Can Afford Automation

Small firms often think automation demands huge budgets. Advances in digital transformation have cut costs and raised access. Modular, scalable workflow automation tools now lower entry barriers.

Providers such as Nintex offer free 30-day trials and tiered pricing. Integration with Microsoft or Salesforce also halves setup costs.

Tools require no code or deep IT skills. Several startups and warehouses ramp optimisation in days. Workflow automation cuts repetitive tasks and drives cost savings. A small supplier trimmed stockouts and improved supply chain visibility with AI alerts.

Your team may find employee productivity climbs as supply chain disruptions fade. Predictive analytics dashboards forecast buffer stock needs before disruptions strike. Your CFO will send a thank you note.

Myth 3: Automation Only Applies to Simple Workflows

Many people assume workflow automation works only on simple tasks. It can handle invoice approvals and data entry in an inventory system. Automation software now tackles complex steps that need judgment.

AI bots link to transport management systems and cloud databases to follow data governance rules. They sort, flag, and route tasks in reverse logistics and customs paperwork. The change lifts employee productivity.

This boosts logistics efficiency and cuts data leaks.

Companies find big gains when they digitize paper forms in supply chain operations. A mid-size freight firm automated 40 percent of paperwork in 2022 and cut errors by half. Tools like data models drive predictive analytics on order patterns.

Software bots tie systems together, from warehouse controls to tracking platforms. High variability operations, including third-party logistics, still see fast wins from targeted workflow automation.

Myth 4: Automated Systems Are Too Expensive to Implement

Modular automation cuts upfront costs fast. It uses standard modules that fit into existing racks. Companies can buy small parts first, then scale. Phased rollouts spread expenses over months.

Providers offer free trials and flexible pricing plans to smooth digital transformation. Some see ROI in weeks.

Gantry designs let staff store pallets on floors. That setup slashes new construction costs. Automation teams link predictive analytics with robotics. That combo boosts logistics efficiency and sparks business innovation.

Perishables can move from farm to shelf in 24 hours. Logistics managers gain better cost savings and control.

Myth 5: Once Automated, Processes No Longer Require Updates

Some believe that once teams launch workflow automation they never need to tweak processes. That view cracks when systems miss a rule change. RPA bots still need maintenance. A small change in demand forecasting can throw off robotized orders.

Leaning on predictive maintenance or generative AI does not free you from checking data governance and performance metrics. You must map processes and set up a central dashboard for ongoing KPI tracking.

Cross-functional teams, plus a governance board, test workflows and refine rules. Solutions like Nintex send alerts for outdated rules and compliance gaps.

Logistics efficiency in a digital economy faces updates when tech advances and market demands shift. Supply chain optimization demands tweaks after new security patches or vendor changes.

In-house tools or third-party logistics providers both face evolving system requirements. Teams adopt an automation maturity model to shift from ad hoc fixes to strategic oversight.

Continuous testing boosts service quality and customer satisfaction. That approach cuts cost savings and limits non-compliance risk. Growth teams report a 30 percent jump in employee productivity when automation adapts to fresh demands.

Iterative improvement sustains your business innovation engine.

Myth 6: Automation Is Incompatible With Complex Logistics Networks

Modern AI drives digital transformation in sprawling supply chain networks. Transport management systems and warehouse management tools link via APIs to AI engines. These tools cut freight costs by more than 10 percent and slashed manual work by 80 percent at a leading FMCG company.

One logistics provider logged a 712 percent drop in freight expenses with AI in procurement.

Autonomous vehicles link to online databases to speed loading at distribution centers. Smart sensors feed clean data into digital systems with strict data governance and full data security.

Firms ship perishable goods from farm to store in 24 hours using just in time planning. Predictive analytics and machine learning drive clear choices in carrier selection and supplier collaboration.

Myth 7: Relying on a Single Automation Vendor Is the Only Option

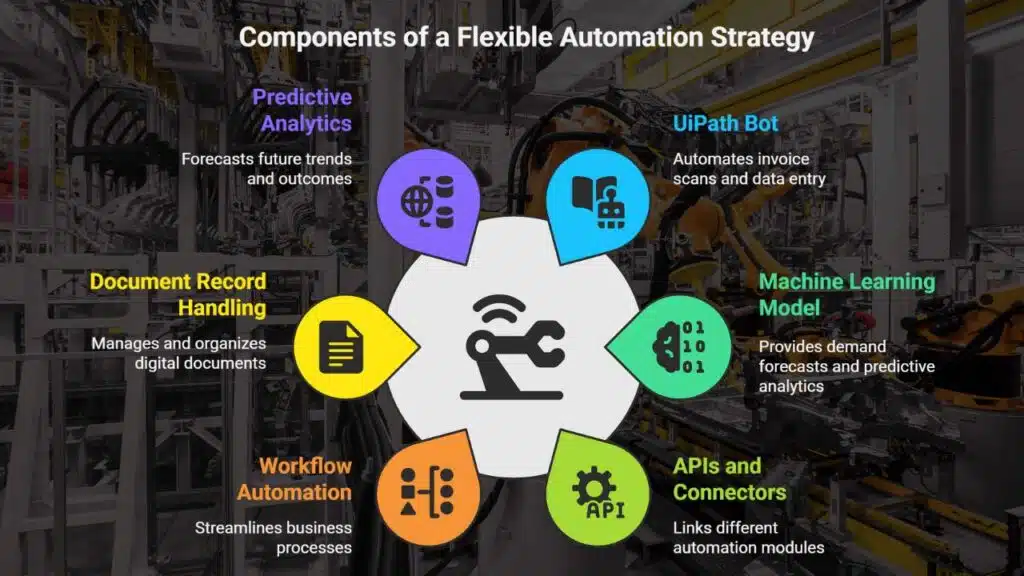

Mature organizations tap multiple automation tools. You stack pieces like a sandwich, mixing an UiPath bot for invoice scans with a machine learning model for demand forecasts. APIs and Zapier connectors link these modules.

This best of breed approach cuts costs, it boosts supply chain management and it tightens data governance.

Teams dodge vendor lock-in, they shape a flexible automation strategy that grows with them. Workflow automation blends with document record handling and predictive analytics. Compatibility across platforms comes standard these days.

This mix and match strategy drives logistics efficiency and fuels digital transformation.

The Importance of Addressing Automation Misconceptions

Myths about automation in logistics stall digital transformation and hurt logistics efficiency. A report from Transporeon TMS shows many firms delay automating just-in-time orders due to fears of security breaches, job cuts, and data privacy risks.

Nintex RPA platform and Cimcorp North America turnkey team hold workshops to debunk myths and lift employee productivity. Clear automation strategy guides teams to cut repetitive tasks, speed up processes, and hit key performance indicators for cost savings.

Addressing false beliefs sparks business innovation and builds resilience against supply chain disruptions. Process automation maturity models map steps, point out barriers, and light a path toward operational excellence.

Data governance software and forecasting modules protect sensitive information, improve data quality, and fend off cyber threats. Smart outsourcing and older platform patches can boost retention, customer engagement, and reputation.

Practical Steps to Embrace Automation in Logistics

Logistics teams need clear steps to start automation. These actions boost workflow automation, cost savings, and logistics efficiency.

- Pinpoint major bottlenecks in paper-heavy workflows, like manual invoice entry or order logging, to guide digital transformation.

- Sketch a process map from supplier order through delivery, highlight delays and redundant business processes.

- Pick simple, repeatable tasks, such as barcode scans and data entry, to cut repetitive tasks and raise employee productivity.

- Set key performance indicators and data governance policies. Form a cross-functional oversight board to track results and guide continuous improvement.

- Link systems with application programming interfaces, streamline data management, and enable data-driven decision-making.

- Use predictive analytics tools to forecast demand, fuel quicker response, and strengthen negotiations with retailers and suppliers.

- Arrange demos and partner with a consultant for robust training, test AR glasses for real-time troubleshooting, and secure long-term support.

- Review your current automation maturity against a model, plan next investments, and accelerate your automation strategy and business innovation.

Takeaways

Myth-busting clears the path for new ideas. Teams can test new tools like workflow automation and predictive analytics. Nintex links with Microsoft, Salesforce, and SAP platforms for easy fits.

Good data governance and checks keep things on track. Fresh plans beat old doubts and spark bold action. You hold the key to lasting change.

FAQs

1. What is a common automation myth that slows business innovation in logistics?

Many folks think automation in logistics means a sky high budget. They fear the promised cost savings will not arrive. That myth stalls digital transformation, logistics efficiency and business innovation.

2. How can workflow automation free staff from repetitive tasks and boost employee productivity?

Simple. Bring in workflow automation to handle the jobs. It is like having a robot do the heavy lifting. The team gains time, spots issues faster. This lifts employee productivity, shrinks repetitive tasks and sparks logistics innovation.

3. Can digital transformation in the supply chain really cut costs?

Yes, with a smart automation strategy. It ties predictive analytics to real time data. You track key performance indicators (kpis) as you go. That drives cost savings and better logistics management.

4. Does artificial intelligence make logistics vulnerable to cyberattacks and data breaches?

AI can help, but hackers may sniff data gaps like dogs on a trail. This can lead to cyberattacks. You need tight data governance and strong data protection. Use user friendly tools to raise your guard.

5. How do leaders fix automation challenges when a legacy system slows the logistics chain?

They merge old tools with new methodologies. They show strong leadership. They add workflow automation, predictive analytics and creativity. That shakes free the chain and sparks business innovation.