Imagine running a store where shelves empty out just when customers rush in, leaving you scrambling and sales slipping away. It’s like playing catch-up in a game you can’t win, right? Stockouts hit hard, frustrating shoppers and hurting your bottom line in the supply chain.

We’ve all been there, watching profits vanish because inventory levels drop too low without warning.

Did you know artificial intelligence transforms inventory management with demand forecasting and real-time inventory tracking? This tech spots patterns in consumer behavior, using machine learning to predict needs before they spike.

In this post, we’ll explore nine ways AI stops stockouts cold, from predictive analytics to automated reordering in your warehouses. You’ll gain tips to boost operational efficiency and keep customer satisfaction high.

Ready to outsmart shortages?

Key Takeaways

- AI uses machine learning to predict demand patterns from historical sales data, as seen in tools like Linnworks software.

- Real-time inventory tracking with RFID tags spots low stock levels instantly, preventing stockouts in supply chains.

- Automated reordering sets points based on demand, reducing manual errors and overstock with predictive analytics.

- AI syncs inventory across locations using cloud-based systems, avoiding duplicates and boosting efficiency.

- Trend analysis recognizes seasonal shifts, adjusting stock levels to cut waste and improve customer satisfaction.

Effortless Demand Forecasting

Imagine AI as your crystal ball, spotting demand spikes before they hit, thanks to machine learning algorithms that crunch real-time data from sales patterns and customer habits. This tech cuts down on guesswork, slashing overstock risks and keeping shelves stocked just right, so you never miss a sale.

Predicting customer demand with accuracy

AI spots customer demand patterns like a hawk eyes its prey. It uses machine learning algorithms to analyze data from historical sales data and seasonal demand. This cuts guesswork in inventory forecasting.

Retailers love how artificial intelligence predicts shifts in customer behavior. Picture a busy store manager, no longer sweating over empty shelves. AI inventory management software, such as Linnworks, optimizes stock levels with ease.

It transforms inventory management through demand forecasting and real-time tracking.

Generative AI boosts product visibility in transportation, dodging stockouts and overstock piles. Automated systems send restocking alerts to keep things smooth. They provide actual real-time inventory levels in the supply chain.

This ensures the right amount of stock stays ready. AI brings automatic reordering, which improves inventory efficiency. Think of it as a smart sidekick, always one step ahead in supply chain management.

Predictive analytics helps avoid those pesky empty aisles, keeping customer satisfaction high.

Reducing dependency on historical data

AI cuts back on old sales records for predictions. It pulls in fresh info like current trends and market shifts. Suppose your store faces a sudden craze for a new gadget. Machine learning spots it fast, without digging through dusty historical data.

Tools like Linnworks step in here. They optimize stock levels with predictive analytics. This keeps shelves full, no guesswork needed.

Businesses love this shift. It dodges errors from outdated patterns. Think of it as a smart friend whispering tips on demand patterns. AI mixes real-time data with clever algorithms.

That way, inventory forecasting feels spot on. Supply chain efficiency jumps up. You avoid those empty racks that frustrate customers. Plus, it ties into systems for seamless inventory management.

Real-Time Inventory Tracking

AI spots low stock levels in a flash, using RFID tags to keep tabs on every item without a single delay. It pinpoints those sluggish products gathering dust, helping you shuffle them out before they tie up your cash, and who wouldn’t want that kind of sharp-eyed assistant.

Monitoring stock levels instantly

AI watches stock levels like a hawk, spotting changes in the blink of an eye. This real-time inventory tracking means you always know what’s on hand, no more guessing games. Picture a busy warehouse where shelves empty fast; AI jumps in with instant alerts.

It uses machine learning to track every item, cutting down on surprises. In the supply chain, this tech provides actual real-time inventory levels, keeping the right amount of stock ready.

Tools like Linnworks optimize these levels, making sure nothing runs dry.

Generative AI boosts product visibility in transportation, dodging stockouts and overstock piles. Automated systems fire off restocking alerts, like a trusty sidekick warning you before trouble hits.

This prevents overstocking too, saving cash on holding costs. Think of it as your inventory’s guardian angel, using predictive analytics for smooth operations. With real-time data flowing, supply chain efficiency soars, and customer satisfaction stays high.

AI transforms inventory management this way, blending in cloud-based systems for quick wins.

Identifying slow-moving products

AI spots slow-moving products fast, like a hawk eyeing its prey. It uses real-time inventory tracking to check stock levels every second. This helps businesses see which items sit on shelves too long.

Think of it as your inventory whispering secrets about what’s not selling. With machine learning techniques, AI analyzes historical sales data and demand patterns. That way, you avoid waste and tie up less cash in dead stock.

Generative AI steps in here, boosting product visibility across supply chains. It prevents overstock surpluses that eat into profits. Tools like Linnworks optimize inventory levels, sending restocking alerts to keep things balanced.

In manufacturing, AI aids predictive maintenance and supply chain optimization too. You get better inventory control, minimizing risks from slow movers. It’s like giving your warehouse a smart sidekick that never sleeps.

Automated Reordering

AI sets reorder points on its own, using machine learning to spot when stock dips low, like a watchful guard dog that never sleeps. This cuts out those pesky manual slip-ups in restocking, keeping shelves full and customers grinning, all while you sip your coffee without a worry.

Setting reorder points automatically

AI brings automatic reordering to boost inventory efficiency, like a smart assistant that never sleeps. This setup uses real-time data to set reorder points, preventing stockouts and overstock messes.

- AI spots low stock levels fast, using machine learning to calculate reorder points based on demand patterns and historical sales data, much like a weather forecaster predicting rain before you get soaked.

- Tools like Linnworks software optimize these points, tying into predictive analytics for safety stock adjustments, and they generate restocking alerts to dodge overstock surpluses, keeping your shelves just right.

- In supply chain management, this automating prevents manual slip-ups, with generative AI improving product visibility in transportation, similar to having eyes everywhere on your inventory trail.

- Real-time inventory tracking pairs with this to provide actual stock levels, helping in warehouse management by minimizing waste and ensuring operational efficiency, think of it as your inventory’s personal bodyguard against surprises.

- For retail spaces, AI sets these points to handle seasonal demand shifts, integrating with cloud-based inventory management systems to avoid supply chain disruptions and boost customer satisfaction.

- Predictive maintenance in manufacturing benefits too, as AI links reorder points to supplier collaboration, cutting procurement delays and building resilient supply chains, like a well-oiled machine that runs without hitches.

- Inventory optimization shines here, with features like electronic data interchange automating orders, reducing risks from stock control issues and enhancing logistics management across sales channels.

- Generative AI in this area combats cargo theft by tracking shipments, setting points that account for alternative suppliers and inventory turnover rates, ensuring you stay ahead of the game.

- Efficiency jumps, as AI in inventory management software handles trend analysis, adjusting points for market changes and preventing those dreaded stockouts, almost like magic but backed by solid data.

Preventing manual errors in replenishment

AI automates reordering in inventory management, cutting out those pesky manual slip-ups that lead to stockouts. When juggling orders, one wrong calculation can empty your shelves.

Automated systems generate restocking alerts based on real-time inventory tracking, keeping levels just right. This stops overstocking too, saving you from wasted space and cash. Generative AI boosts product visibility in the supply chain, much like a watchful eye that never blinks.

Linnworks, an AI inventory management software, optimizes stock levels with predictive analytics. It transforms how you handle replenishment, improving efficiency without the human errors that sneak in.

It acts as your reliable sidekick, providing actual real-time inventory levels to match demand patterns. Such tools prevent manual mistakes, letting you focus on growth instead of guesswork.

Syncing Inventory Across Multiple Locations

Imagine juggling balls in a circus, where each ball is a warehouse full of goods, and AI acts as your trusty spotter, keeping everything from crashing. It links stock data through cloud-based systems, spotting duplicates like a hawk, so you avoid those costly mix-ups and keep customers grinning ear to ear.

Unifying stock visibility across stores and warehouses

AI syncs stock views across all your spots, like stores and big storage spots. Imagine this mess, you got items scattered everywhere, and nobody knows the real count. Tools like Linnworks step in, they pull everything together with cloud-based systems.

This setup gives you real-time inventory tracking, so you spot what’s low right away. Generative AI boosts product visibility in transportation, it cuts down on those sneaky stockouts and extra piles of goods.

Think of it as a watchful eye that combats cargo theft, keeping tabs on every box.

Supply chain pros love how AI dishes out actual real-time inventory levels. It makes sure the right stock sits ready, no more guessing games. Automated systems fire off restocking alerts, they dodge overstocking pitfalls too.

In manufacturing, AI handles predictive maintenance and supply chain tweaks, unifying views to avoid duplicate entries or missing bits. Healthcare folks focus on patients, not logistics chaos, thanks to this smooth flow.

Truck driver recruiting gets a lift too, as efficient chains run without hitches. Vendor-managed inventory fits right in, optimizing those levels across spots.

Avoiding duplicate or missing stock entries

AI keeps inventory in sync across stores and warehouses. Like a well-oiled machine, it unifies stock views in real time. No more headaches from duplicate entries that mess up counts.

Tools like Linnworks step in, using machine learning to spot and fix missing stock data fast. This boosts inventory management and cuts errors in supply chain management.

Generative AI sharpens product visibility, much like a hawk eyeing its prey. It delivers actual real-time inventory levels, so you always have the right stock on hand. Automated systems fire off restocking alerts, dodging stockouts and overstock piles.

Think of it as your trusty sidekick in inventory optimization, preventing those costly surprises. AI even transforms demand forecasting and real-time tracking, making sure nothing slips through the cracks.

Trend Analysis for Better Insights

AI spots seasonal demand shifts, like holiday spikes in toy sales, and tweaks your stock plans on the fly. Picture machine learning crunching predictive analytics from past patterns, it keeps your shelves stocked without the guesswork, saving you from those empty-aisle headaches.

Recognizing seasonal and market trends

AI spots seasonal demand shifts like a hawk eyeing its prey, using machine learning to crunch historical sales data and spot patterns. For example, your business sells more coats in winter, and AI flags that trend early, so you adjust stock levels before the chill hits.

Tools like Linnworks optimize inventory with predictive analytics, keeping you ahead of market twists. Generative AI boosts product visibility in transportation, slashing overstock surpluses while dodging stockouts.

This tech transforms inventory management through demand forecasting, providing real-time data to match supply with actual needs. Automated systems send restocking alerts, preventing empty shelves or waste.

In manufacturing, AI drives supply chain optimization and predictive maintenance, building resilient supply chains. You gain better insights into demand patterns, improving customer satisfaction and operational efficiency.

Adjusting inventory strategies accordingly

AI spots trends in seasonal demand, like holiday spikes or summer slumps. It uses machine learning to tweak inventory levels fast. Picture a store owner dodging empty shelves during peak times; that’s the magic here.

Companies apply predictive analytics to match stock with market shifts. They cut waste and boost customer satisfaction this way.

Firms integrate AI with cloud-based inventory management systems for smarter moves. Take Linnworks software; it optimizes stock levels through real-time data. This prevents overstocking or stockouts in supply chains.

AI even handles predictive maintenance in manufacturing, keeping operations smooth. It builds resilient supply chains by spotting risks early. Suppliers collaborate better, minimizing delays.

Inventory turnover improves as strategies adapt to demand patterns. Generative AI enhances visibility, just like in transportation where it combats cargo theft. Healthcare pros focus on patients, not logistics, thanks to these tweaks.

Truck driver recruiting gets a lift too, aiding overall efficiency.

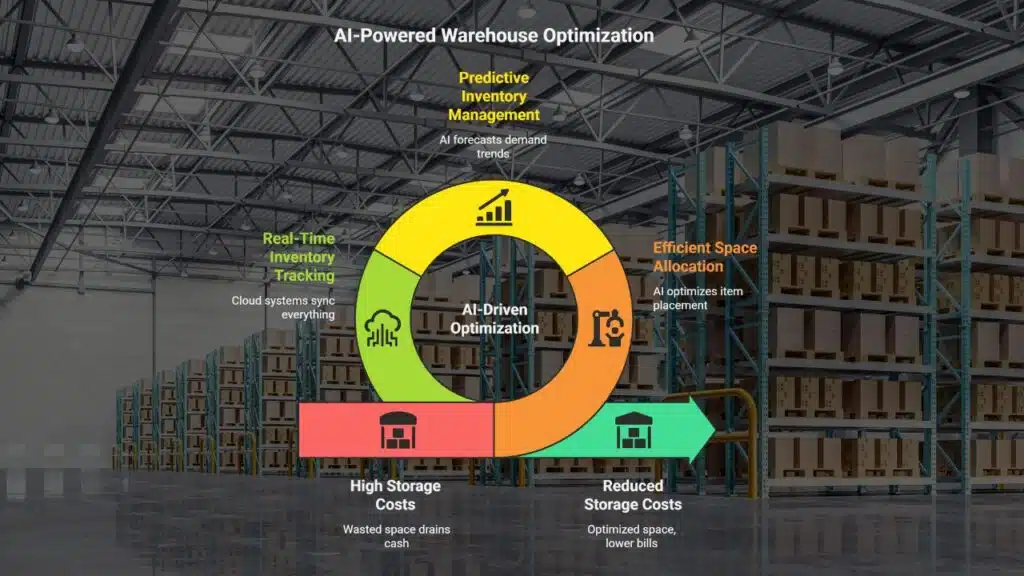

Optimized Warehouse Storage

Picture your warehouse like a packed lunchbox, where AI shuffles items to squeeze in more without waste, cutting down those hefty storage bills. You know, it’s like having a smart buddy who spots empty spots and fills them fast, boosting your inventory turnover while keeping costs low—want to see how this magic unfolds in your setup?

Allocating space efficiently

AI spots the best spots for goods in your warehouse. It uses real-time data to place items where they move fast. Think of it like packing a suitcase, you put the stuff you need most right on top.

This cuts down on wasted space and lowers storage costs. Tools like Linnworks help with this inventory optimization. They keep stock levels just right, no more, no less.

Generative AI steps in for warehouse management too. It predicts needs based on trends, much like a smart friend who knows what you’ll want next. In manufacturing, AI handles predictive maintenance to avoid breakdowns.

This boosts supply chain efficiency and minimizes waste. Real-time inventory tracking ensures everything flows smooth, preventing those empty shelves.

Reducing storage costs

AI cuts storage costs in warehouses by smart space use. Your shelves sit half empty while cash drains away on unused room. Machines learn from real-time data to spot what sells fast.

They shuffle items like a game of musical chairs, packing hot sellers close and slow ones farther back. Linnworks software steps in here, optimizing stock levels to dodge overstock piles.

That means less waste and lower bills.

Generative AI boosts this by predicting trends, much like a weather forecast for your inventory. It flags seasonal demand shifts early, so you adjust without hoarding extras. Think of it as trimming the fat from your supply chain.

Predictive analytics teams up with machine learning to fine-tune warehouse management. Cloud-based systems sync everything, slashing costs through better inventory turnover. Automated alerts keep things tight, preventing those costly surpluses that eat up space.

Enhancing Supply Chain Efficiency

AI boosts supplier teamwork, like a well-oiled machine that spots issues before they jam the works. It cuts procurement holdups with predictive analytics, keeping your goods flowing smooth as silk, and hey, who.

Improving supplier collaboration

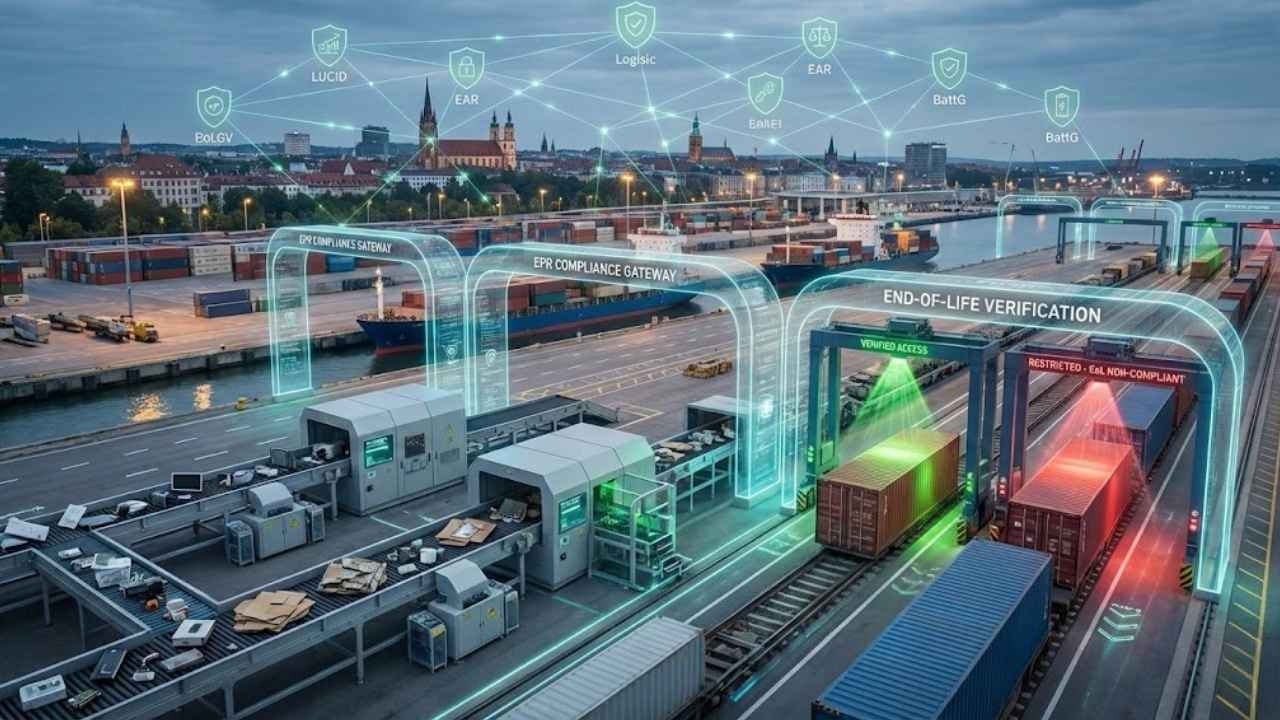

AI teams up with suppliers to spot risks early. It fights cargo theft in the supply chain, keeping goods safe and on track. It acts like a watchful guard dog, always alert. Generative AI boosts product visibility in transportation, cutting down on stockouts and extra stock piles.

This setup creates resilient supply chains that handle bumps without breaking a sweat.

Suppliers share real-time data through AI tools, like those in manufacturing for predictive maintenance. Machine learning analyzes trends, dodging supply chain disruptions before they hit.

Chatting with vendors via smart systems smooths out delays in procurement. AI inventory management software, such as Linnworks, optimizes these links, ramping up operational efficiency.

Vendor managed inventory becomes a breeze, with everyone in sync.

Minimizing delays in procurement

AI spots trouble in the supply chain before it bites. It fights cargo theft by tracking shipments in real time, like a watchful guard dog. A truck hits a snag, but machine learning jumps in, finding alternative suppliers fast.

That keeps procurement rolling without a hitch. Generative AI boosts product visibility in transportation, slashing those pesky delays. Plus, it helps recruit truck drivers quicker, easing bottlenecks in the flow.

Predictive analytics builds resilient supply chains, dodging disruptions with smart risk management. Think of AI as your crystal ball, forecasting issues in warehouse management and supply chain efficiency.

It uses real-time data to generate restocking alerts, just like Linnworks does for optimizing inventory levels. In manufacturing, predictive maintenance stops breakdowns that slow procurement.

Automated systems ensure the right stock arrives on time, improving supplier collaboration every step of the way.

Advanced Integration Capabilities

AI links up with ERP and CRM setups in a snap, pulling data from cloud-based inventory management systems to spot trends fast. Imagine your team making sharp calls on stock levels, thanks to machine learning that ties in real-time data from barcode systems and AWS, dodging those pesky supply chain hiccups before they bite.

Connecting seamlessly with ERP and CRM systems

AI connects smoothly with ERP and CRM systems, pulling in key data for smarter choices. For instance, your team spots low stock fast through real-time inventory tracking. They use predictive analytics to forecast demand patterns.

This setup boosts inventory management and supply chain efficiency. Take Linnworks, an AI inventory management software that optimizes stock levels. It ties into cloud-based inventory management systems for seamless flow.

Generative AI steps in here, improving product visibility to dodge stockouts. Automated systems send restocking alerts, keeping things just right. Imagine chatting with a supplier via integrated tools, minimizing delays.

Machine learning digs into historical sales data, spotting trends. This all helps with automatic reordering and better inventory control. Plus, it links with barcode systems for accurate counts across sales channels.

Enabling better decision-making with data

AI pulls data from ERP and CRM systems, giving you a clear picture of inventory levels. Managers spot trends fast with this setup. Picture a busy warehouse boss, juggling orders like a circus performer, but now AI hands him real-time insights to dodge stockouts.

Linnworks software optimizes those stock levels, using machine learning to crunch historical sales data. This prevents overstocking, just like generative AI boosts product visibility in transportation.

You make smarter calls on demand patterns and supply chain efficiency. Think of it as having a wise old friend whispering tips during tough choices. Predictive analytics flags risks early, tying into cloud-based inventory management systems for seamless flow.

In manufacturing, AI drives predictive maintenance and cuts disruptions, keeping operations smooth. Real-time data from barcode systems ensures you avoid those empty shelves that frustrate customers.

Takeaways

We’ve seen AI tackle stockouts through sharp demand forecasting, real-time tracking, and auto reordering. These methods make inventory management a breeze, cutting errors and saving time like a well-oiled machine.

Imagine your business dodging empty shelves, boosting customer satisfaction with spot-on stock levels. Explore tools like Linnworks for that edge in supply chain efficiency. I once watched a small shop turn chaos into calm with AI alerts, proving it’s no tall tale.

Jump in now, and watch your operations soar without a hitch.

FAQs

1. Hey, ever wonder how demand forecasting stops those pesky stockouts?

Well, artificial intelligence crunches historical sales data and spots seasonal demand patterns, like a weather vane pointing to rain. This way, you keep inventory levels just right, avoiding empty shelves that frustrate customers.

2. Can predictive analytics really boost inventory management?

You bet, it uses machine learning to predict supply chain disruptions before they hit, much like a crystal ball for your stockroom. Businesses see better inventory optimization and higher customer satisfaction as a result.

3. What’s the deal with real-time inventory tracking in preventing shortages?

Artificial intelligence integrates with radio frequency identification and barcode systems for instant updates on stock levels. It feels like having eyes everywhere in the warehouse, catching low inventory before it turns into a crisis.

4. How does AI handle supply chain management to avoid stockouts?

Through trend analysis and simulations, it forecasts inventory needs across sales channels. Picture it as a chess master planning moves ahead; this leads to resilient supply chains and smarter pricing strategies.

5. Tell me about inventory forecasting with AI, does it work?

Absolutely, machine learning analyzes demand patterns and suggests alternative suppliers when risks pop up. It minimizes waste and boosts operational efficiency, turning potential headaches into smooth sailing.

6. Is cloud-based inventory management systems the key to no more stockouts?

They sure are, offering integration capabilities with real-time data and predictive maintenance. Imagine your inventory data chatting with Amazon Web Services like old pals, ensuring inventory turnover stays high and shipments track without a hitch.