Procurement used to be a back-office function where “success” meant negotiating the lowest unit price. That mindset doesn’t work anymore. Global disruptions, inflation swings, compliance pressure, and stakeholder expectations have changed the game, and procurement is now expected to drive measurable business value.

Strategic sourcing methods help teams move from transactional buying to a repeatable, data-backed process that aligns spending with business goals. In practice, that means making better decisions across cost, risk, quality, innovation, and sustainability—without slowing the business down.

This guide explains the 10 best strategic sourcing methods shaping modern procurement and adds practical implementation guidance as checklists, scorecards, KPIs, and a 30-60-90 day roadmap. But first, let’s take a look at:

Common Mistakes That Weaken Strategic Sourcing Programs

These issues show up in companies of all sizes. Fixing them can deliver quick wins.

- Treating procurement as an “approval gate” instead of a business partner

- Starting supplier discussions before the requirements and evaluation criteria are clear

- Measuring savings without tracking adoption and compliance

- Over-optimizing for unit price while ignoring TCO and service risk

- Relying on a single supplier without a tested contingency plan

- Running RFx events without market intelligence or a negotiation strategy

If you see two or three of these, your team doesn’t need more tools first. It needs a clearer process, better data, and stronger stakeholder alignment.

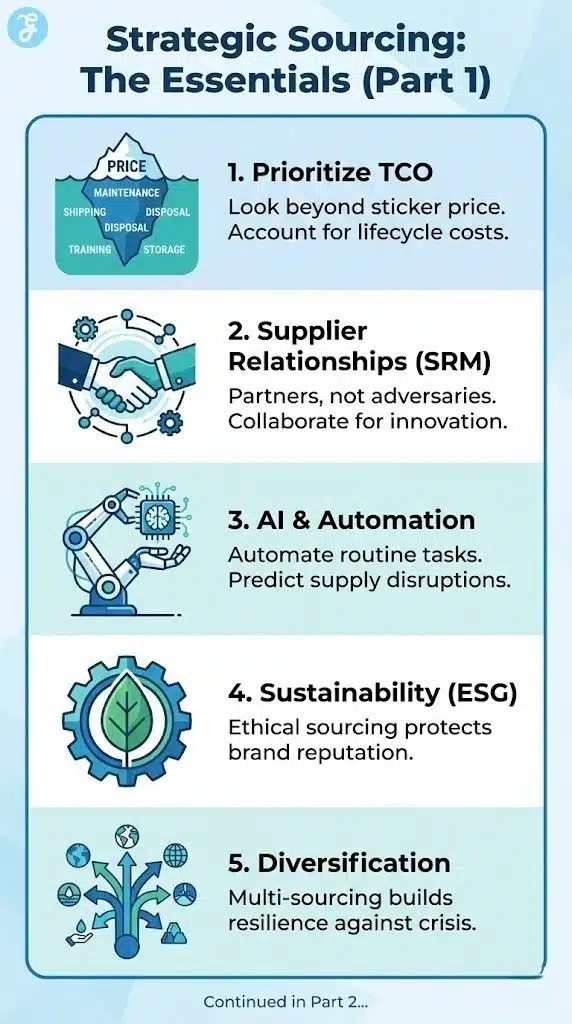

The Top 10 Most Effective Sourcing Methods For Modern Procurement

Here are the 10 proven sourcing methods for modern procurements:

1. Prioritize Total Cost Of Ownership, Not Lowest Price

The invoice price is only one piece of the cost story. A strong sourcing strategy compares options based on the full lifecycle impact, including operating costs and risk.

Common TCO elements to include:

- Purchase price and contract fees

- Freight, duties, and logistics variability

- Installation, onboarding, and training

- Maintenance, consumables, and downtime

- Quality issues, returns, and warranty claims

- End-of-life disposal, recycling, or buyback

Here’s a simple way to explain TCO to non-procurement stakeholders:

| Cost Component | Examples | Why It Matters |

| Acquisition | unit price, setup fees | often optimized, rarely complete |

| Operations | energy use, labor time | can dwarf the purchase price |

| Reliability | breakdowns, delays | creates hidden costs and missed revenue |

| Compliance | audits, certifications | reduces legal and reputational exposure |

| End-Of-Life | disposal, data destruction | prevents unexpected “cleanup” spend |

When you consistently apply TCO, negotiations shift from “who is cheapest today?” to “who is best for our business outcomes over time?”

2. Build Deep Supplier Relationship Management

Strategic sourcing methods treat key suppliers as value partners, not interchangeable vendors. With the right governance, suppliers can improve service levels, co-innovate, and help you respond faster during shortages.

A practical SRM cadence often includes:

- Monthly operational reviews for delivery, quality, and issues

- Quarterly business reviews (QBRs) for performance trends and roadmaps

- Quarterly innovation sessions focused on new ideas, not pricing

- Annual risk reviews for financial health, capacity, and compliance

If SRM feels “soft,” anchor it in measurable commitments such as cycle times, defect rates, and continuous improvement targets. Relationships matter, but outcomes matter more.

3. Integrate AI And Automation Into Sourcing Workflows

Digital sourcing is no longer optional. Automation reduces admin work, and AI improves decision quality by finding patterns humans miss.

High-value use cases include:

- Spend classification and anomaly detection

- Supplier discovery and shortlisting

- Contract analytics (obligation tracking, clause flags)

- Risk monitoring (news signals, location risk, financial alerts)

- Predictive forecasting for lead times and price volatility

A good rule is to automate anything repeatable, then reserve human time for negotiation, stakeholder alignment, and supplier development. Technology should raise the team’s leverage, not add more tools to manage.

4. Source For Sustainability And ESG Without Sacrificing Performance

Sustainability is now tied to brand trust, investor expectations, and regulatory requirements. Modern sourcing evaluates suppliers on environmental and social practices alongside cost and quality.

ESG sourcing actions that create real impact:

- Require evidence of labor standards and supplier codes of conduct

- Track emissions and packaging reduction opportunities

- Prioritize suppliers with renewable energy plans and transparent reporting

- Add right-to-audit clauses and clear remediation steps

Sustainable sourcing can also reduce costs. Lower packaging weight cuts freight, and energy-efficient products often lower operating expense. The goal is not “greenwashing,” but verifiable improvements.

5. Diversify Supply With Multi-Sourcing And Resilient Designs

Consolidation can deliver volume discounts, but it increases single-point-of-failure risk. Multi-sourcing improves resilience when geopolitical events, weather, labor disruptions, or capacity limits appear.

A resilient multi-sourcing model usually:

- Keeps a qualified “backup” supplier warm with 10 to 15 percent of volume

- Defines clear triggers for shifting allocation (service failures, risk ratings)

- Standardizes specs so alternate suppliers can ramp faster

- Builds dual qualification into the product lifecycle and engineering change control

The biggest mistake is waiting until a disruption happens to qualify backups. Resilience is built before you need it.

6. Use Nearshoring And Friend-Shoring To Reduce Hidden Supply Chain Costs

Long supply chains create long lead times, freight volatility, and weaker visibility. Nearshoring brings supply closer to demand, and friend-shoring reduces exposure by sourcing from politically aligned regions.

What to include in the nearshoring business case:

- Reduced inventory carrying costs from shorter lead times

- Faster responsiveness to demand shifts

- Improved quality oversight and site access

- Lower disruption risk and potentially better IP protection

Even when labor costs rise, the total value can improve once you account for speed, risk, and working capital.

7. Implement Category Management As A “Mini-Business” Model

Category management organizes spending into defined groups and assigns ownership to category experts who understand markets, cost drivers, and supplier landscapes.

A strong category strategy includes:

- A clear category definition and scope boundaries

- A supply market analysis (trends, constraints, pricing drivers)

- Stakeholder requirements and demand management levers

- A supplier segmentation model (strategic, preferred, transactional)

- A 12- to 24-month roadmap with savings and risk targets

Categories like microchips, logistics, and marketing services behave differently. Treating them as the same “procurement process” leaves value on the table.

8. Make Data-Driven Decisions With Spend Visibility And Market Intelligence

Spend visibility turns procurement from reactive to proactive. Once data is clean and categorized, the team can identify consolidation opportunities, policy violations, and demand reduction levers.

Useful analytics for day-to-day sourcing:

- Top suppliers by spend, growth, and business criticality

- Price variance across business units for identical items

- Maverick spend (off-contract buying) by department

- Contract coverage and renewal timelines

- External indices linked to key commodities or labor rates

Negotiations improve when you can show facts, not opinions. Data turns conversations into shared problem-solving instead of positional bargaining.

9. Adopt Agile Procurement For Fast-Moving Categories

Traditional RFx cycles can be too slow for software, digital services, and emerging tech. Agile procurement focuses on speed and learning without losing control.

Agile sourcing patterns that work:

- Short discovery sprints to clarify requirements and success metrics

- Pilot engagements with measurable outcomes and exit clauses

- MVP contracts (for example, 90 days) that expand only when value is proven

- Modular statements of work that adapt as needs evolve

This approach reduces the risk of committing to a multi-year deal before you truly understand the solution.

10. Practice Collaborative Sourcing Across Departments And Ecosystems

Procurement outcomes improve when the right stakeholders are involved early. Collaboration reduces rework, aligns requirements, and accelerates adoption.

Internal collaboration typically means:

- Procurement involvement during design and planning, not after decisions

- Joint requirement definition with engineering, finance, and end users

- Clear approval workflows and role clarity to avoid delays

External collaboration can include group purchasing organizations or peer benchmarking networks. Used carefully, these models can increase leverage while maintaining governance.

Strategic Sourcing Best Practices Checklist For Every Sourcing Event

Use this checklist to ensure each project follows a consistent standard, even when timelines are tight. It also helps you spot gaps before they become rework.

Before You Go To Market

- Define the business outcome (cost, speed, quality, innovation, risk reduction)

- Confirm scope, constraints, and must-have requirements

- Identify internal stakeholders and decision owners

- Validate baseline spend and current supplier performance

- Build a TCO model (even a lightweight one) for comparison

- Decide the sourcing method (RFx, auction, negotiation, direct award with justification)

During Supplier Evaluation

- Use a weighted scorecard and document scoring logic

- Verify capacity, lead time, and service model

- Confirm compliance requirements (data security, labor, certifications)

- Review contract terms early, not at the end

- Ask for improvement ideas, not just pricing

Before Award And After Onboarding

- Run reference checks and validate critical claims

- Agree on KPIs, reporting cadence, and escalation paths

- Finalize implementation milestones and responsibilities

- Capture lessons learned for the category playbook

A checklist should not slow you down. It should keep you from missing the few things that cause the biggest downstream pain.

KPI Dashboard: The Metrics That Prove Procurement Value

Savings alone is not enough to show value. A balanced dashboard ties procurement work to performance, risk, and stakeholder outcomes.

| KPI | What It Measures | Common Formula Or Signal | When To Use It |

| Cost savings | negotiated value | baseline vs contracted | reporting to finance |

| Cost avoidance | prevented increases | forecast vs actual | inflationary markets |

| TCO improvement | lifecycle savings | TCO baseline vs new TCO | capex/opex decisions |

| On-time delivery | supplier reliability | OTIF / OTD rate | operational categories |

| Quality | defect impact | PPM, returns, warranty | manufacturing/ops |

| Contract compliance | adoption | % spend on contract | “maverick spend” reduction |

| Supplier risk rating | exposure | composite risk score | critical categories |

| Cycle time | speed | days from intake to award | agile sourcing |

To make the dashboard actionable, set thresholds and define escalation steps. A KPI with no owner or response plan becomes a vanity metric.

Supplier Due Diligence And Risk Management In Modern Sourcing

Risk management is no longer a yearly audit task. It should be embedded into the sourcing process and updated as conditions change.

Key Risk Categories To Evaluate

- Financial: liquidity, debt load, customer concentration

- Operational: capacity constraints, sole-site manufacturing, quality history

- Geographic: weather exposure, geopolitical instability, port dependency

- Compliance: labor practices, sanctions screening, certifications

- Cyber and data: security controls, incident history, access boundaries

A quick way to standardize decisions is to use a simple risk matrix:

| Risk Level | Typical Signals | Recommended Action |

| Low | multiple sites, stable finances | standard monitoring |

| Medium | capacity tight, limited redundancy | contingency plan + quarterly checks |

| High | sole source, weak financials, high disruption exposure | dual-source plan + executive review |

Risk management should be visible to stakeholders. When the business chooses higher risk for speed or cost, document the rationale and the mitigation plan.

Negotiation Playbook For Strategic Sourcing Outcomes

Negotiation is not just about price. Strategic sourcing creates leverage by aligning stakeholders, defining options, and using data to shape the discussion.

A practical negotiation plan often includes:

- BATNA clarity: what you will do if you cannot agree

- Cost driver analysis: what actually impacts supplier margin

- Concession strategy: what you can trade without losing value

- Non-price levers: payment terms, warranties, service levels, flexibility

- Governance: who can approve what, and when

When suppliers push back, focus on shared goals. If lead time is the biggest pain, a slightly higher price might be worth it if it reduces inventory and stockouts. Negotiation should optimize the full value equation.

Stakeholder Intake And Alignment: The Hidden Lever Behind Strategic Sourcing Methods

Even the strongest sourcing strategy fails if stakeholders don’t adopt the contract. One of the most overlooked strategic sourcing methods is building a clean intake and alignment process that makes procurement easier to work with, not harder.

A good intake process answers three questions early: what are we buying, why now, and what “good” looks like. That clarity prevents late-stage scope changes that derail timelines and weaken negotiation leverage.

Intake Questions That Reduce Rework

- What problem are we solving, and what outcome matters most (cost, speed, quality, risk, innovation)?

- Is this a new requirement or a replacement of an existing supplier/contract?

- What are the must-haves vs. nice-to-haves?

- Who approves the decision, and who will use the product/service daily?

- What is the deadline, and what happens if we miss it?

Simple RACI To Keep Decisions Moving

Use a lightweight responsibility model so approvals don’t get stuck in email loops.

| Activity | Procurement | Business Owner | Finance | Legal/Compliance |

| Requirements definition | C | A/R | C | C |

| RFx/market engagement | A/R | C | C | C |

| Supplier evaluation | A/R | A/R | C | C |

| Commercial negotiation | A/R | C | C | C |

| Contract terms | C | C | C | A/R |

| Go-live and adoption | C | A/R | C | C |

Adoption Safeguards After Award

Once the contract is signed, value only appears if buying behavior changes. Keep post-award steps short and visible:

- Publish the “how to buy” path (catalog link, preferred SKUs, approved services)

- Set contract compliance goals by department (and report them monthly)

- Add a renewal calendar so stakeholders aren’t surprised by expirations

- Create an escalation path for service issues to prevent off-contract switching

This is where procurement earns trust. When intake is clean and adoption is managed, the rest of your strategic sourcing approaches—TCO, SRM, multi-sourcing, and ESG—translate into real savings and lower risk.

30-60-90 Day Implementation Plan For Improving Your Sourcing Program

If you’re upgrading procurement maturity, start with moves that create visibility and repeatability. Then build advanced capabilities like SRM, AI, and category playbooks.

| Timeframe | Focus | Outcomes You Should See |

| Days 1–30 | baseline + governance | clean spend view, intake process, sourcing templates |

| Days 31–60 | category priorities | top categories selected, scorecards live, first wave RFx |

| Days 61–90 | performance + resilience | KPI dashboard, SRM cadence, backup supplier qualification |

Momentum matters. Even a small number of well-executed projects can build stakeholder confidence and unlock bigger transformation work.

RFx Scorecard Template: Align Weighting To What The Business Truly Values

A scorecard prevents “loudest voice wins” decisions. It also makes supplier feedback easier because you can show where they scored well and where they didn’t. Keep the first version simple, then refine it by category over time.

| Evaluation Area | Typical Weight | Notes |

| Commercial | 20–35% | price, payment terms, indexation logic |

| Service and delivery | 20–30% | lead time, SLAs, support model, flexibility |

| Quality and technical fit | 15–30% | specs, testing results, integration effort |

| Risk and compliance | 10–20% | financial health, ESG, security, continuity |

| Innovation | 5–15% | roadmap, process improvements, value adds |

One practical tip is to set “gate criteria” alongside weighted scoring. For example, a supplier might need to meet minimum security requirements or provide proof of capacity before they can be considered, even if they offer a strong price.

Key Takeaways For Procurement Leaders

Modern procurement wins by balancing cost, resilience, compliance, and innovation. These strategic sourcing approaches—from TCO and SRM to agile procurement and ESG—give teams a practical playbook for creating measurable value.

If you want fast impact, start with spend visibility, a repeatable sourcing workflow, and a KPI dashboard. Then build deeper category strategies and supplier partnerships that make the organization more competitive over time.

Frequently Asked Questions (FAQs)

Here are answers to some of the most commonly asked questions:

What Is The Difference Between Strategic Sourcing And Traditional Procurement?

Traditional procurement is transactional and reactive, focused on completing purchases and negotiating price. Strategic sourcing is proactive and long-term, aligning purchasing decisions to business goals while optimizing cost, risk, and supplier value across the entire lifecycle.

Why Are Strategic Sourcing Methods Important for Executive Leadership?

They turn procurement into a predictable value engine. Leaders gain better budget control, fewer disruptions, stronger compliance, and clearer visibility into where money is going and what risks are attached to critical suppliers.

How Does AI Impact Strategic Sourcing?

AI improves speed and decision quality by automating routine tasks and analyzing data at scale. It can flag spend anomalies, surface supplier risk signals earlier, and support predictive planning for lead times and price volatility.

What Role Does Sustainability Play in Modern Sourcing?

Sustainability is a risk and reputation issue as much as an environmental one. By evaluating suppliers for environmental and labor practices, companies reduce the chance of scandals, meet stakeholder expectations, and often find efficiency gains like lower packaging and freight costs.

What Is Nearshoring, and When Does It Make Sense?

Nearshoring moves sourcing closer to your primary market to reduce lead times and logistics volatility. It makes sense when speed, agility, and risk reduction outweigh the labor-cost advantage of distant supply locations.