Many sellers see tiny shifts in consumer demand turn into big stock swings up the supply chain. Recent feedback from StockIQ clients shows a shift from product shortages and long lead times to excess inventory.

This guide shows seven tactics to tame the bullwhip effect, with better demand forecasting, real time EDI, IoT devices, predictive analytics, and vendor managed inventory. Read on.

Key Takeaways

- Use real-time EDI, IoT sensors, and predictive analytics to improve demand forecasts. StockIQ clients saw a shift from product shortages to excess stock.

- Share data instantly via EDI links and RFID tags so teams adapt in minutes. Faster insights cut lead times and tame order swings.

- Adopt vendor-managed inventory with automated replenishment. Machine learning tools sync stock to real demand and cut manual errors.

- Standardize pricing and place small, frequent JIT or kanban orders. This approach smooths demand, lowers storage costs, and eases inventory swings.

- Monitor with dashboards and S&OP reviews. Early alerts help teams cut missed orders by 15–35% and reduce inventory by 10–30%.

How can demand forecasting be improved to reduce the bullwhip effect?

Salespeople mine past sales data and forecasting tools to spot seasonal swings and demand spikes. That tactic cuts overproduction and stockouts and tames the bullwhip effect by matching production with real consumer needs.

Data exchange via EDI modules lets suppliers and retailers share order changes in real time. Smart forecasts help supply chain teams spot shifts fast, so planners tweak schedules without delay.

Algorithms in warehouse systems blend past sales patterns with fresh sensor data, so managers see market swings. S&OP meetings adjust safety stock and min-max order levels across every node in the network.

Early warning alerts ping planners when buffers dip below thresholds, preventing empty shelves or inventory piles. These moves drive lean manufacturing and boost inventory optimization across links.

Why is real-time data sharing important in the supply chain?

National supply chain databases or shared portals give staff up-to-date views of stock and orders. This cuts errors in demand forecasting and tames order swings that fuel the bullwhip effect.

Connected devices, part of the Internet of Things (IoT), track pallets on warehouse floors and report inventory levels in real time. Dashboards using machine learning algorithms and predictive analytics offer instant replenishment recommendations.

Electronic data interchange links vendors and buyers so they see the same figures at the same moment.

Fast data exchange stops teams from overreacting to tiny shifts in consumer demand. Suppliers tweak purchase orders based on real-time sales data in a vendor-managed inventory (VMI) system.

That slashes lead times and eases seasonal demand fluctuations for perishable goods. Teams adapt to supply chain disruptions within minutes, cutting fulfillment delays sharply. Ongoing analysis of incoming feeds fuels agile tweaks in strategy and boosts supply chain visibility across every warehouse.

How can lead times be reduced effectively?

Long lead times slow real-time reactions and boost excess inventory. Cutting those days lets teams react quick and cut costs.

- Implement EDI to automate order steps and slash lead times in order processing. It reduces manual work so teams act quick.

- Reserve slots with trusted carriers to cut lead times on shipping and meet target dates. That step boosts performance metrics and lifts profits.

- Release monthly production plans to key suppliers so they can prep ahead of time and account for lead times. Early sharing streamlines material flow and trims slack.

- Apply JIT and demand forecasting to match stock levels to actual sales and shorten lead times across the supply chain. This approach shrinks cycle times and eases inventory fluctuations.

- Buy direct from makers to remove middle stops and trim transit days. Fewer steps cut supply chain delays and tame the bullwhip effect.

- Track goods in real time with radio tags and a smart sensors network in warehouses. Teams gain clear visibility into inventory and movements.

- Hold weekly S&OP meetings to align teams and tweak orders on the fly. Quick syncs help adjust schedules to avoid shortages.

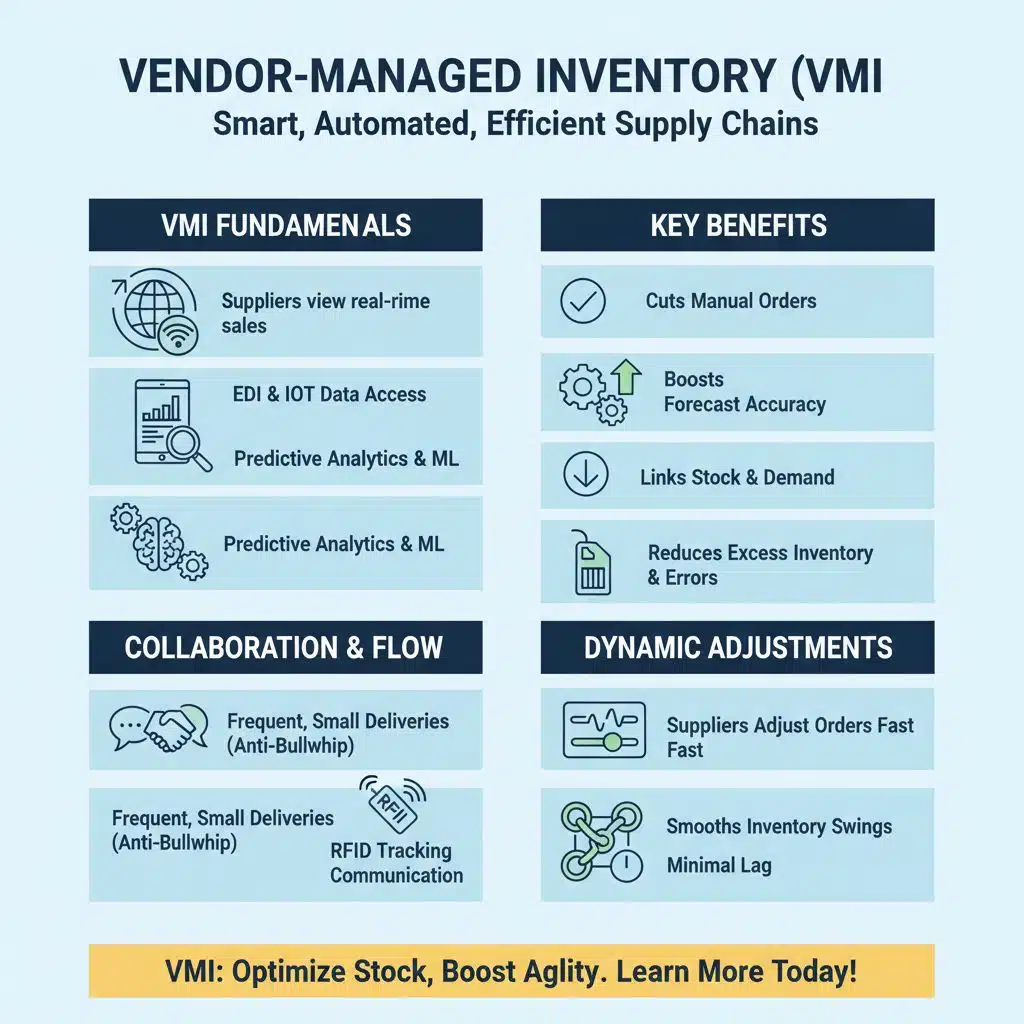

What are Vendor-Managed Inventory (VMI) systems and how do they help?

Vendor-managed inventory (VMI) systems let suppliers view real-time sales via EDI and IoT sensors. Suppliers access updated forecasts in dashboards. Automated VMI taps predictive analytics and machine learning for replenishment suggestions.

This setup cuts manual order work. It boosts forecast accuracy and links stock levels with actual demand. Partners see data instantly, so they spot gaps fast. It shrinks excess inventory and trims delays and errors.

Teams hold joint problem-solving sessions and set common KPIs. They plan small, frequent deliveries to curb the bullwhip effect. RFID tags track goods on store shelves. Real-time communication ties data flows across the supply chain.

Suppliers adjust order quantities with minimal lag. This smooths out wild inventory swings.

How does standardizing pricing and promotions minimize supply chain variability?

Standardizing pricing means setting steady rates all year round. Shoppers see no flash sales. They buy in small, even batches. That avoids demand spikes that feed the bullwhip effect in supply chains.

It helps demand forecasting in ERP tools and predictive analytics. Teams can tune safety stock and inventory optimization with real time data via electronic data interchange (EDI) and IoT sensors.

Companies often order big batches to fight inflation. That skews order patterns and fuels excess inventory or shortages. Consistent prices reduce that urge. Firms can pair stable pricing with optimized minimum order quantities to smooth orders.

That cuts inventory fluctuations and eases warehouse stress. Supply chain managers get clear demand signals. Sales and operations planning, mixed with steady pricing, keeps supply chains calm.

How can order quantities and inventory levels be optimized?

Smaller orders trim excess inventory while cutting the bullwhip effect. Safety stock for key items can fend off shortages but stay cost-effective.

- Place smaller, more frequent orders to align your stock with consumer demand and fight supply chain disruptions.

- Keep a safety stock of essential goods at lean levels, so you prevent inventory shortages without tying up cash.

- Streamline your order process with a kanban system and Just-In-Time methods to smooth out inventory fluctuations.

- Shorten cycle times in order placement and fulfillment so your team adjusts stock to seasonal demand faster.

- Limit your component vendors for similar parts to boost supply chain visibility and minimize process gaps.

- Connect parts planning directly to your production schedules to match inventory levels to actual output.

- Share your production plans early with vendors to account for long lead times and avoid unexpected shortages.

- Use S&OP meetings and real-time communication tools like EDI to spot demand changes, and tweak order sizes for smarter inventory optimization.

What predictive analytics and AI tools help manage the bullwhip effect?

IoT sensors feed real-time inventory and consumer behavior data into predictive analytics platforms, so teams catch demand spikes fast. Machine learning models refine demand forecasting, shrinking order swings that spark the bullwhip effect.

Automated replenishment tools run deep learning routines on live sales figures, then push new inventory targets to warehouse managers. Early warning systems alert supply chain teams the moment safety stock dips below a set threshold.

How can collaboration between supply chain partners be strengthened?

Supply chain teams break down walls with clear data. Partners share real-time data on orders and stock levels via enterprise software or an EDI link. Shared KPIs like fill rate and delivery speed keep goals in line.

Weekly sales and operations planning meetings help spot delays. RFID tags let vendors track stock with real-time scans. A lean supplier roster for similar materials makes planning simple.

Managers join forces at joint problem solving sessions. Buyers, producers and shippers run through targets together. Vendor-managed inventory tools let suppliers top up when stock dips.

This sync cuts stockouts and excess inventory. Partners spot supply fluctuations fast and adapt with ease.

Why should order batching be minimized in logistics?

Large batches warp supply chain math. They spike the bullwhip effect. Smaller, more frequent orders smooth inventory flow and cut demand forecasting errors. Just-in-Time (JIT) systems fit this model; they link restocking to real consumer demand.

Lower batch sizes ease communication between partners and trim buffer stocks.

Small orders drop storage costs and curb excess inventory. Smart sensors and RFID tags feed real-time data to forecasting tools, taming inventory fluctuations. Third-party logistics teams breeze through order processing when batch sizes shrink.

How can supply chain strategies be monitored and adjusted continuously?

Continuous monitoring lets teams spot changes fast. This step drives better supply chain management and cuts waste.

- Advanced analytics dashboards show key metrics, they blend real-time data sharing with market trends.

- Regular reviews of safety stock and min-max ranges match consumer demand shifts with inventory planning.

- Early warning systems alert teams about low safety inventory, they help prevent inventory shortages.

- Demand forecasting tools update models daily, they adjust for seasonal demand and demand fluctuations.

- S&OP meetings unite sales and operations, they refine plans with shared insights.

- Tracking sensors feed status on goods in motion, they boost supply chain visibility across touchpoints.

- Strategic stockpiling gets quarterly reviews, they keep excess inventory under control.

- Inventory optimization software tunes reorder levels, it uses an AI model to drive lean pull inventory.

- KPI reports track missed orders and stock-outs, they aim to cut missed orders by 15 to 35 percent.

- Continuous improvement loops measure results and tweak tactics, they drive inventory reductions of 10 to 30 percent.

- Bullwhip effect analysis informs strategy tweaks, it guides long-term planning in response to order surges.

Takeaways

StockIQ teams tested these seven moves. They spot order swings with machine learning. Connected sensors and RFID tags tie data streams. They keep inventory tight and shipment times low.

You can tame demand swings and cut waste fast.

FAQs on Ways to Handle Bullwhip Effect in Logistics

1. What is the bullwhip effect in logistics?

It is like a whip in your supply chain. Small shifts in consumer demand swing orders wildly up the chain. This causes inventory fluctuations, excess inventory, or inventory shortages. It hits retail businesses hard.

2. How can I use demand forecasting to tame the beast?

Use forecasting methods with early warning systems and advanced analytics, picture smart sensors catching signals in real time, and radio tags tracking shelves. Feed data to a machine-learning algorithm, this boosts forecast accuracy and cuts long lead times.

3. Can price promotions trigger the bullwhip effect?

Yes, price promotions can spark ration gaming, that leads to order spikes and price fluctuations. It messes up supply chain management and ruins inventory optimization.

4. How does vendor-managed inventory (VMI) help in inventory management?

A VMI, or partner stock service, sends supplies, handles distribution, invoicing for you. This lifts supply chain visibility, trims excess inventory and dodges inventory shortages.

5. Will artificial intelligence really cut bullwhip effects?

Yes, artificial intelligence uses real-time communication, advanced analytics, and predictive analytics to spot market trends like a hawk. It feeds data into sales and operations planning (S&OP), this calms demand fluctuations and eases supply chain disruptions.

6. How do I handle seasonal demand, and avoid stockouts?

Plan early for seasonal demand, use key performance indicators, track consumable goods and global supply chains for hiccups like a semiconductor shortage. Keep flexible lead times, talk often with distributors, this fends off inventory shortages.