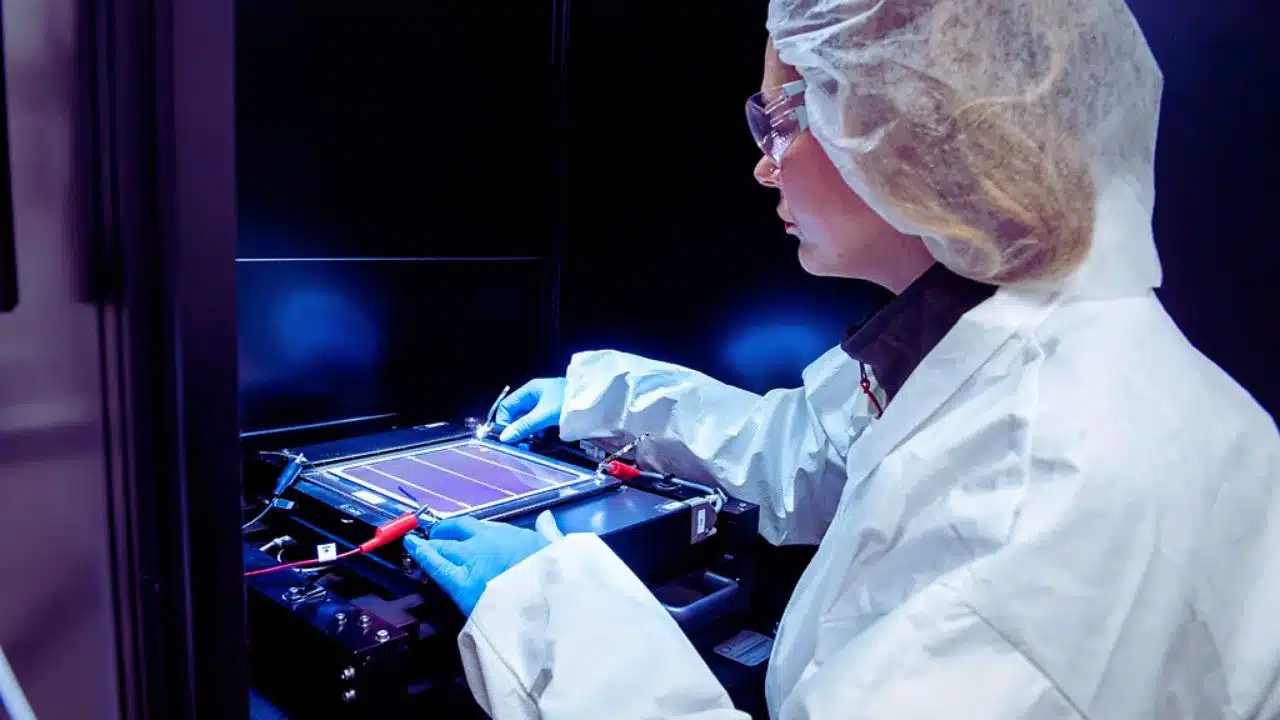

Scientists in the US and South Korea report major gains in perovskite solar cell durability, showing devices that keep about 90% output after 1,500 hours at 90°C and others that hold over 85% after 1,000 hours at 85°C/85% humidity—two stress tests that mirror the harsh heat and moisture that often ruin perovskites.

Perovskite photovoltaics have surged in efficiency in recent years, but heat-driven chemical reactions, ion movement inside the device, and fragile interfaces have repeatedly shortened lifetimes. The latest results attack those weak points from two directions: one study redesigns the perovskite “additives” to reduce defects and stabilize hidden interfaces, while the other replaces a common but stability-harming component inside the hole-transport layer to keep devices robust during damp heat and even during encapsulation.

What happened (two studies)

1) US team: Ionic liquid additive survives 90°C stress

A Nature Energy study led by researchers associated with Purdue University and Emory University reports an engineered ionic liquid additive—methoxyethoxymethyl-1-methylimidazole chloride (MEM-MIM-Cl)—designed to improve how the perovskite crystal forms and to stabilize buried interfaces, including interactions with NiOx (nickel oxide) layers.

The researchers report solar cells reaching 25.9% power conversion efficiency and retaining 90% of initial performance after 1,500 hours of continuous 1-sun illumination at 90°C, a notably harsh combined light-and-heat condition.

They also report strong “fatigue resistance” under diurnal cyclic ageing, positioning the additive as a potential route to operational resilience rather than short-lived lab performance.

2) South Korea team: Damp-heat stable cells at 85°C/85% RH

A separate peer-reviewed study published by the Royal Society of Chemistry (Energy & Environmental Science) from UNIST and collaborators targets a different stability bottleneck: the hole-transport layer (HTL) recipe often used with spiro-OMeTAD.

The team replaces the commonly used additive 4-tert-butylpyridine (tBP)—described in the paper as causing “substantial detrimental effects” and hindering thermal stability—with ethylene carbonate (EC), which forms a solvation complex with Li+ ions and enables effective p-doping without tBP.

The authors report 25.56% efficiency (certified 25.51%) and show encapsulated devices maintaining over 85% of initial efficiency after 1,000 hours under damp-heat conditions of 85°C/85% relative humidity.

Why heat kills perovskites (and how these fixes work)

Perovskite cells are typically built as thin-film “stacks,” and their failures often start at interfaces: ions migrate, defects multiply, and layers chemically react when stressed by heat, light, or moisture.

In the MEM-MIM-Cl approach, the ionic liquid is engineered to regulate crystal growth and suppress defect-driven degradation by forming a novel intermediate phase through chelation with undercoordinated Pb(II), while also stabilizing buried interfaces through synergistic interactions (including with NiOx).

In the EC approach, stability improves partly because removing tBP preserves a higher glass transition temperature and the Li+:EC coordination helps suppress ion migration, which the study links to better retention under thermal and damp-heat stress.

Key results at a glance

| Research approach | What was changed | Reported efficiency | Harsh-condition test | Reported retention | Scale notes |

| Ionic-liquid additive (MEM-MIM-Cl) | Engineered ionic liquid to regulate growth + stabilize buried interfaces (incl. NiOx) | 25.9% | Continuous 1-sun + 90°C for 1,500 h | 90% after 1,500 h | Diurnal cyclic ageing showed “fatigue resistance” |

| tBP-free spiro-OMeTAD HTL (EC) | Replaced tBP with ethylene carbonate to enable LiTFSI solvation + stable doping | 25.56% (cert. 25.51%) | Damp heat 85°C/85% RH for 1,000 h (encapsulated) | >85% after 1,000 h | Mini-modules: 23.22% (25 cm²) and 22.14% (100 cm²) |

What it means for commercialization

The new 90°C, 1,500-hour result matters because it directly targets one of the toughest real-world killers—combined heat and illumination—while keeping efficiency near the top tier of today’s perovskite research.

The 85°C/85% RH, 1,000-hour result matters because it hits a widely used damp-heat stress condition and pairs it with practical device steps like EVA-based encapsulation processing, which the paper frames as important for maintaining integrity during prolonged exposure.

Both studies also emphasize manufacturability in different ways: the ionic liquid work highlights design principles for functional additives, while the EC-based HTL work explicitly reports performance in larger-area mini-modules (25 cm² and 100 cm²).

Final Thoughts

These two results point to a clearer roadmap for perovskite solar cell durability: reduce defects and stabilize buried interfaces so heat and light do less damage, and redesign charge-transport layers so additives no longer undermine the device under damp heat.

The next technical checkpoints are expected to focus on longer operational testing, broader temperature cycling, and scaling from mini-modules to larger panels while maintaining both efficiency and stability.

If these durability gains translate reliably to mass production, perovskites (including perovskite-on-silicon tandems) could become more viable for hot-climate deployment where rooftop temperatures frequently soar.