Are you tired of running out of stock at the worst possible time? Smart inventory management is the key to boosting profits and keeping customers happy. This blog will show you 10 easy ways to improve your inventory replenishment and avoid those costly stockouts.

Stick around, and let’s fix this together!

Key Takeaways

- Use data-driven tools like Warehouse Management Systems to track inventory and cut stockouts by 20%.

- Set Min/Max stock levels to avoid overstocking and keep operations smooth.

- Monitor inventory turnover rates to manage fast-moving items and reduce holding costs by 15%.

- Automate replenishment with software to save time and boost efficiency.

- Use predictive planning to forecast demand and prevent empty shelves.

Leverage Data-Driven Replenishment

Hey there, readers, let’s talk about making inventory replenishment smarter with data. Think of data as your reliable partner, always ready to help you avoid costly errors. Technology, like Warehouse Management Systems (WMS), provides real-time inventory tracking.

It monitors stock levels and sends reorder notifications before you’re out of stock. This reduces mistakes and keeps your supply chain running seamlessly. No more guesswork, just clear insights to steer you.

Now, imagine having a clear view into your warehouse operations. Using data-driven tools, you can adopt strategies like Just-in-Time (JIT) inventory. This smart approach cuts holding costs by ordering only what you need, exactly when you need it.

Vendor-Managed Inventory (VMI) is another great option, allowing suppliers to take care of restocking for you. Both improve operational efficiency, saving you money and hassle. Rely on data, and see your inventory management thrive!

Set Minimum and Maximum Stock Levels

Setting minimum and maximum stock levels is a smart way to keep your inventory in check. Think of it as finding the sweet spot, like Goldilocks with her porridge, not too much, not too little.

With a Min/Max policy, you set a bottom limit to avoid stockouts and a top limit to prevent overstocking. This helps maintain smooth operations and keeps customer satisfaction high.

Plus, inventory management software can step in to automate ordering when levels hit that minimum mark.

Got a busy warehouse? Using this method stops dead stock from piling up and frees up space on those pallet racks. The software handles the heavy lifting by tracking stock levels for you.

So, no more guesswork in inventory control. It’s like having a trusty sidekick making sure your supply chain management stays on point. Stick with this approach, and watch bottlenecks at checkouts disappear.

Monitor Inventory Turnover Rates

Hey there, let’s chat about keeping tabs on your inventory turnover rates. This is all about how fast your stuff sells and gets replaced. If you’ve got fast-moving items, like trendy gadgets, they’re often on-demand and fly off the shelves.

Slow-moving items, think seasonal decor, might sit around longer and need a periodic check. Watching these rates helps you avoid piling up dead stock or running out of hot sellers.

Dig into this a bit more, okay? Fast-moving goods need quick restocks to match customer behavior, while slow-moving items can tie up cash if ignored. By tracking inventory turnover, you spot these patterns and tweak your stock levels.

Tie this to real-time inventory tracking, and you could cut stockouts by 20% and slash holding costs by 15%. So, grab that inventory management software, maybe even warehouse management tools with barcode systems, and keep your supply chains humming smoothly.

Automate Replenishment Processes

Let’s talk about simplifying life with automation in inventory management. Envision reducing errors and saving a ton of time. Replenishment software handles this effortlessly; it streamlines calculations and manages purchase orders smoothly.

This allows you to focus less on tedious math and more on expanding your business. Plus, it provides up-to-the-minute inventory tracking, ensuring you’re always aware of stock levels.

Now, consider this a reliable partner for your warehouse. Such tools suggest optimal reorder points and quantities while adapting to your growth. They integrate seamlessly with your current systems, enhancing operational efficiency.

With inventory management solutions like these, you’re equipped to maintain high customer satisfaction and prevent frustrating backorders. Isn’t that impressive?

Optimize Reorder Points

Hey there, Readers, let’s chat about getting those reorder points just right for your inventory replenishment. Think of reorder points, or ROP, as your safety net, telling you exactly when to restock before running dry.

Use the simple formula, ROP equals Lead Time Demand plus Safety Stock, to nail this down. It’s like knowing when to refill your coffee mug before the last sip.

Now, imagine tweaking these points with smart tools like inventory management software. These systems tap into predictive models to forecast demand and set reorder points with precision.

Pair this with seasonal demand adjustments from historical data, and you’re not just guessing, you’re planning. Stick with this approach, and watch stockouts shrink while operational efficiency soars.

Incorporate Safety Stock Strategies

Safety stock strategies are your safety net, folks. Think of them as an extra stash of inventory, just in case life throws a curveball. They act as a buffer against sudden spikes in demand or supply chain hiccups.

By using this approach, you keep customer satisfaction high and avoid the dreaded stockouts. Plus, repeat business becomes a breeze with this backup plan.

Now, let’s break it down with a simple formula: ROP equals Lead Time Demand plus Safety Stock. This means you calculate how much you need during supplier wait times, then add a little extra for peace of mind.

It’s like packing a spare tire on a road trip, always ready for the unexpected. With safety stock in your inventory management system, you’re set to handle market dynamics without breaking a sweat.

Address Dead Stock Proactively

Hey there, let’s tackle a pesky problem: dead stock. You know, those items just sitting in your warehouse, gathering dust, tying up cash you could use elsewhere. It’s like having a guest who overstays their welcome.

Frees up cash tied in excess inventory for other business needs, right? So, take action now. Spot slow-moving items early with inventory tracking tools, and don’t let them linger.

Dig into your data to see what’s not selling. Maybe run a quick sale or bundle dead stock with hot products to move it out. Use inventory management software for real-time insights, and keep tabs with regular audits or cycle counting.

Trust me, staying on top of this saves headaches and boosts operational efficiency. Keep that stock moving, and watch your warehouse breathe easier!

Align Replenishment with Product Life Cycles

Let’s chat about matching your inventory replenishment to product life cycles. Think of your products like a garden, okay? Some bloom fast, like fast-fashion tees, while others stick around longer, like sturdy tools.

You gotta know where each item stands, whether it’s just sprouting or nearing its end. This keeps you from overstocking stuff that’s fading out or missing out on hot new trends. AI and machine learning can help here, analyzing market behavior to guide your moves.

Pay attention to seasonal demand too. Say you’ve got holiday decor; don’t order a mountain of it in January. Instead, plan with tools like inventory management software to time your purchase orders right.

This way, you dodge dead stock eating up space and cash. Even better, syncing with life cycles boosts customer satisfaction by having the right goods at the right moment. So, use these insights to stay sharp and keep your stock levels spot on.

Factor in Supplier Lead Times

Hey there, readers, let’s chat about supplier lead times and why they matter for inventory replenishment. Ever order something and wait forever for it to arrive? That’s lead time, the gap between placing a purchase order and getting the goods.

If it’s short, you can go for on-demand replenishment, restocking right when you need to. But, with long lead times, plan ahead with periodic replenishment to avoid empty shelves.

Ignoring this can mess up your stock levels and hurt customer satisfaction big time.

Now, think of lead times as a game of guess and catch. You’ve got to sync your reorder points with how fast suppliers deliver. Use the Reorder Point formula, which is Lead Time Demand plus Safety Stock, to stay ahead.

Also, team up with your supply chain partners. Strong supplier relationships can cut delays and boost operational efficiency. So, keep tabs on those timelines with real-time inventory tracking, and watch your inventory management shine!

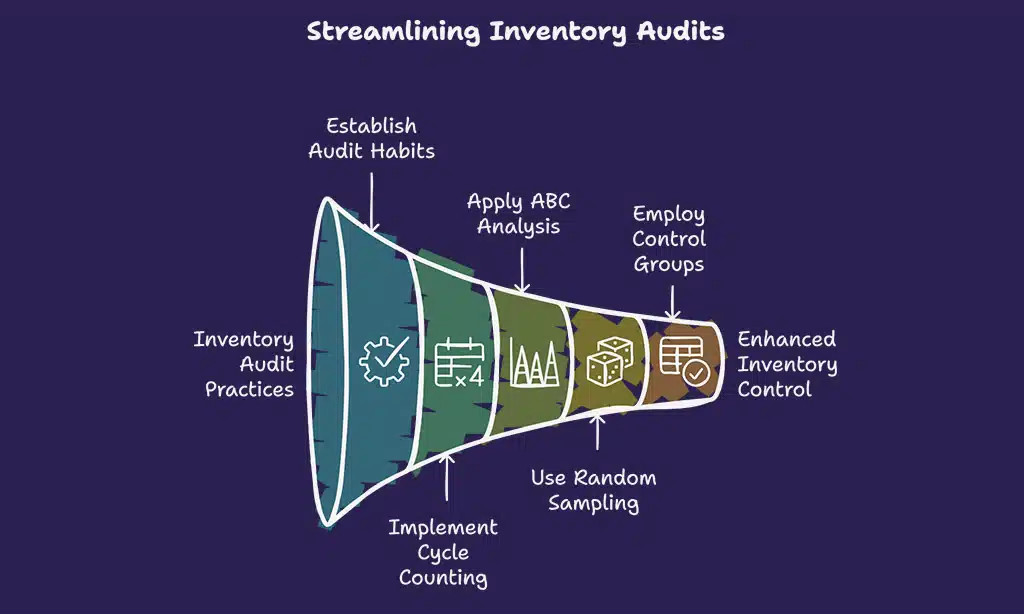

Use ABC Analysis to Prioritize Inventory

Got a pile of inventory to sort through? Let’s talk about ABC Analysis, a handy trick to prioritize your stock based on value and inventory turnover rates. It splits your items into three groups: A for high-value stuff with fast sales, B for medium movers, and C for slow-moving items.

This way, you focus your energy on what matters most to your business.

Dig into this method, and you’ll see why it boosts inventory control. Use it with tools like inventory management software to track data. Mix in practices such as random sample counting or control group counting to keep things accurate.

With ABC Analysis, you’re not just managing stock; you’re sharpening operational efficiency, one item at a time.

Collaborate with Suppliers for Better Efficiency

Hey there, let’s chat about working hand in hand with your suppliers to boost efficiency. Think of it like a dance, where both partners need to know the steps to avoid tripping. By teaming up closely, you can share vital info using tools like the CPFR framework.

That stands for Collaborative Planning, Forecasting, and Replenishment, and it helps everyone stay on the same page with data sharing. This way, your inventory management gets a real lift, cutting down on guesswork.

Now, imagine having supply chain partners who feel like part of your crew. Collaboration among these folks can sharpen your replenishment game big time. Toss in some cool tech, like AI-powered systems and machine learning, to study market dynamics.

These tools spot trends and help tweak your plans fast. Strong supplier relationships also mean smoother purchase orders and better logistics management. So, get cozy with your suppliers, and watch your operational efficiency soar!

Use Centralized Dashboards for Real-Time Insights

Centralized dashboards are a game-changer for keeping tabs on your inventory. Imagine having a single screen that shows you everything, right down to the last item on the shelf. With real-time inventory tracking, you get immediate visibility into stock levels, so you dodge those pesky stockouts before they even happen.

This tool pulls data from every corner of your business, blending it into clear insights. No more guessing games; you’ll know exactly what’s moving and what’s not.

Think of it like having a trusty sidekick, always ready with the latest scoop. These dashboards integrate data to suggest the best reorder points and quantities for your needs. They’re scalable too, growing with your business and fitting snugly into your existing processes.

By using inventory management software with real-time updates, you boost operational efficiency and keep customer satisfaction high. It’s like having eyes everywhere, without lifting a finger!

Conduct Regular Inventory Audits

Hey there, let’s talk about keeping your stock in check. Regular inventory audits can save you from headaches down the road.

- First off, make audits a habit to boost accuracy in inventory control. By doing them often, you catch mistakes before they mess up your stock levels. Think of it as a quick health check for your warehouse; it keeps everything running smooth.

- Try cycle counting as a key method to stay on top of things. This means checking small chunks of inventory daily instead of one giant count. It cuts errors and saves time, making it a breeze compared to full-blown counts.

- Explore ABC Analysis during audits to focus on what matters most. This trick sorts items by importance, so you spend energy on high-value stuff first. It’s like prioritizing the big fish in a small pond.

- Give Random Sample Counting a shot for a quick snapshot. Pick random items to check instead of everything at once. This way, you spot issues without turning your day into a total grind.

- Test out Control Group Counting for extra precision in your checks. Focus on a specific batch to compare against your records. It’s a neat way to double-check data and keep inventory tracking tight.

- Use replenishment software to make audits less of a chore. This tool automates counts and flags oddities in real-time inventory tracking. It’s like having a trusty sidekick who never misses a beat.

- Keep customer satisfaction in mind while auditing stock. Accurate counts mean you won’t run out of popular items or overstock dead stock. Nothing beats happy shoppers who get what they need, right when they need it.

- Schedule audits to match your operational efficiency goals. Pick times that don’t clash with busy hours, so your team isn’t stretched thin. It’s all about working smart, not just hard.

- Tackle slow-moving items during these checks to avoid clutter. Spotting dead stock early lets you clear space for hot sellers. Think of it as trimming the fat to keep your warehouse lean.

- Build standard operating procedures, or SOPs, for every audit. Clear steps mean everyone knows the drill, cutting down on slip-ups. It’s like giving your crew a roadmap to follow without guessing.

Minimize Stockouts with Predictive Planning

Dig into predictive planning, folks, and see how it can save your business from the headache of stockouts. Imagine running a store and suddenly, bam, you’re out of a hot-selling item.

That’s a missed sale and a grumpy customer. Predictive planning uses smart tools like intelligent reordering systems to guess what you’ll need before you run dry. These systems tap into predictive models to forecast demand and nail down exact reorder points.

With this, you cut the risk of empty shelves by a solid 20%, according to real stats on real-time inventory tracking. Plus, it trims holding costs by about 15%. That’s money back in your pocket, right?

Now, let’s chat about seasonal demand, a sneaky little trickster that can mess up your stock levels. Think about holiday rushes or summer spikes in certain goods. Predictive planning looks at historical data to spot these patterns early.

It helps you stock up just enough, not too much, before the big rush hits. By using inventory management software, you get real-time insights to stay ahead of the game. This approach, paired with demand forecasting, keeps customer satisfaction high and prevents dead stock from piling up.

So, gear up with these strategies, and watch your operational efficiency soar!

Continuously Refine Replenishment Strategies

Hey there, let’s chat about keeping your inventory game sharp. Markets evolve fast, and sticking to old plans can leave you with too much stock or empty shelves. Take a close look at your inventory management systems often.

Use insights from AI and machine learning to spot trends in market dynamics. These tools help you tweak your approach before problems hit, keeping customer satisfaction high.

Now, think of your strategy as a garden that needs regular care. Pull out outdated methods like weeds, and plant fresh ideas. Check your inventory turnover rates to see what’s moving or sitting as dead stock.

Factor in the Economic Order Quantity formula, EOQ equals the square root of (2 times demand times ordering cost divided by holding cost), to balance expenses. Keep refining your reorder points, and stay ahead of the game with real-time inventory tracking.

Implement Demand Forecasting for Accuracy

Holy cow, have you ever thought about how guessing future sales can save your business from a big mess? Demand forecasting is your crystal ball for inventory management. It helps you plan stock levels just right, so you’re not stuck with too much or too little.

With accurate demand forecasting, you can nail resource allocation, cut risks, and boost inventory optimization. Plus, it keeps customer satisfaction high by making sure products are ready when needed.

Now, let’s chat about the cool tools that make this magic happen. Advanced analytics and AI are game-changers for spot-on forecasts. These tools dig into customer behaviors, weather patterns, seasonal demand, and even geopolitical conditions to predict what’s coming.

Pair them with inventory management software, and you’ve got a powerhouse for real-time inventory tracking. So, take a leap, and watch your operational efficiency soar with sharper demand forecasting!

Takeaways

Hey there, wrapping up our chat on smarter inventory replenishment feels like crossing the finish line of a big race. We’ve tackled some neat tricks, from using demand forecasting to peeking at real-time inventory tracking with slick POS systems.

Isn’t it cool how these tools can boost your stock game? Let’s keep tweaking those plans, and watch your business zoom ahead. Got any wins to share? Drop a line!

FAQs on Best Practices for Smarter Inventory Replenishment

1. What’s the big deal with inventory replenishment, and how does it boost customer satisfaction?

Hey, let’s chat about keeping those shelves stocked just right. Smart inventory replenishment means using tools like inventory management software and demand forecasting to avoid empty racks or overstocked warehouses, keeping your customers happy with what they need, when they need it.

2. How can I dodge the trap of dead stock with best practices?

Listen up, dead stock is like a bad penny, always turning up when you least want it. Use ABC analysis to spot slow-moving items early, and pair it with real-time inventory tracking to stop over-ordering junk that just sits there gathering dust.

3. Why should I care about reorder points and safety stock in inventory control?

Well, think of reorder points as your trusty alarm clock, waking you up before you’re out of goods. Safety stock is your backup plan, a little buffer stock to cover unexpected spikes in seasonal demand. Together, they keep your stock levels steady, so you’re never caught off guard.

4. Can inventory turnover rate help me with operational efficiency?

Absolutely, pal, a solid inventory turnover rate is like a scoreboard showing how fast you’re moving product. It helps you tweak purchase orders and use the EOQ formula to order just the right amount, cutting waste and boosting efficiency in warehousing.

5. How does just-in-time inventory fit into smarter stock management?

Just-in-time inventory, or JIT, is your secret weapon for lean operations. It syncs with supplier relationships to bring in goods only as needed, slashing costs on storage and reducing risks of dead stock in places like grocery stores.

6. What role do barcode systems and cycle counting play in inventory optimisation?

Hey there, let’s break this down quick. Barcode scanning and systems like RFID tags make inventory tracking a breeze, catching errors before they snowball. Cycle counts, done regularly via standard operating procedures, keep your data spot-on, so your point of sale system and warehouse management software always match market dynamics.