Do you feel buried by missing pallets and late orders? Many teams still track inventory by hand or with old software. They waste hours hunting for boxes. This mess slows the supply chain and raises costs.

Here is a neat fact. Internet of things sensors and machine learning can spot low stock in real time. They also flag worn out robots for predictive maintenance. This post will show 10 future-ready warehouses that use artificial intelligence and digital twins.

It will also cover automated guided vehicles and cloud-based warehouse management systems. You will find tips to cut maintenance costs, shrink your carbon footprint, and speed up order fulfillment.

Keep reading.

Key Takeaways

- IoT sensors on shelves and pallets send data to a cloud WMS. They raise pick accuracy from one error in 300 picks to one in 1,000,000 picks and hit 99.9 percent order accuracy.

- AI-powered gauges scan heat and vibration to flag repairs early. Amazon cut downtime by 30 percent on Black Friday while Siemens cut maintenance costs by 25 percent and Walmart cut refrigeration spoilage by 20 percent.

- Robots and AGVs like Exotec Skypod move goods fast. They handle 50 percent more peak loads and boost pick rates by up to 200 percent while keeping workers safe.

- ML forecasts blend past sales, weather data, and social media buzz to cut stockouts and excess inventory in real time.

- Cloud WMS on AWS or Azure links AI, IoT, and robotics for live control. Solar power and right-size packing trim waste, costs, and emissions.

Real-Time Inventory Tracking with IoT Sensors

IoT sensors attach to shelves, pallets, and boxes. They stream data to a cloud platform via gateways like LoRaWAN and BLE beacons using the MQTT protocol. This feed updates warehouse management systems with counts, locations, and status in real time.

Data analytics fuse inputs into one smart ecosystem. Automation lifts pick accuracy from one error in 300 picks to one in 1,000,000 picks.

Technicians use mobile dashboards to spot low stock and set safety stock levels. Teams slash stockouts and speed last-mile delivery. Smart warehousing hits 99.9 percent order accuracy, and AI driven predictive analytics fine-tune demand forecasting.

Annual maintenance costs remain around 3 to 5 percent of initial investment. This system boosts supply chain reliability and customer satisfaction.

Predictive Maintenance Powered by AI

Smart gauges sit on conveyor belts, forklifts, and motors, measuring heat, vibration, and power use. A neural network scans those data streams, spotting odd patterns before a part fails.

The system might flash a warning, “Belt needs service,” then push the task into a maintenance queue. Amazon trimmed downtime by thirty percent during Black Friday, using that mix of IoT devices and deep learning.

This blend of sensors and predictive analytics cuts repair bills, boosts uptime, and keeps warehouse operations humming.

Siemens slashed maintenance costs by twenty five percent after it tapped real time analytics and machine learning pipelines to flag worn bearings. Walmart’s refrigeration units now send temperature alerts, cutting spoilage by twenty percent in cold supply chains.

Assets range from power panels to fire alarms, all tied to cloud platforms and big data analysis tools. This proactive view on equipment health lets teams swap parts on a schedule, not in a crisis.

Warehouse Robotics for Streamlined Operations

Mobile robots roam warehouse floors with precise routes. Warehouses use automated storage and retrieval systems to stash and fetch goods. Robotic manipulators pick, move, and place items with fine control.

Lighter, modular parts join PC-based programming for fast software updates. IoT sensors feed data to AI modules and cloud-based warehouse management systems (WMS).

Robotic handling cuts mis-picks and trims returns in inventory management. AMRs dance like ants as they shift goods to picking stations. Exotec Skypod tackled a 50 percent holiday spike with ease.

Pick rates jump 50 to 200 percent, and teams see up to 200 percent more output. Robotic automation steers smarter resource allocation and lifts worker safety.

Advanced Demand Forecasting with Machine Learning

Machine learning algorithms use time series analysis and neural networks to sift past sales, seasonal trends, and events like storms. They pull in social media buzz and price shifts, then output simple demand forecasts.

A cloud machine learning service links to warehouse management systems (WMS) to feed real-time sales and weather data into predictive analytics. This mix helps supply chain managers cut stockouts and reduce extra stock, boosting inventory optimization.

Data teams watch each SKU live, noting when a slow mover can become a bestseller after a viral post. An open source ML library flags sudden demand and suggests space moves or new promos, so shelves match customer needs.

Retailers can switch from B2C to B2B in weeks, thanks to flexible forecasts that adapt fast. Manual methods crack under sudden shifts, while smart AI rigs adapt without missing a beat.

Smart Order Fulfillment Systems

A stock picker pod links picking, packing, buffering, sorting, and sequencing in one rack system. This automated system hits 99.9% order accuracy and speeds up processing. Artificial intelligence shifts picker paths on the fly for urgent orders, cutting steps and time.

The warehouse management system taps data from IoT sensors and real-time analytics on the cloud.

Intelligent pallet sequencing stacks pallets in the exact drop order, so drivers slide them off the trailer with ease. An automated order consolidation tool fills trucks to the brim, slashes empty miles, and trims trips.

Floor staff juggle many orders at once, while AI ranks tasks in real time. Omnichannel retailers plug into this smart ecosystem, linking web, store, and mobile channels in a single view.

High accuracy and full transparency give supply chain teams a real edge in logistics optimization.

IoT-Driven Temperature and Environment Monitoring

Internet of things (IoT) sensors keep watch over temperature, pressure, and humidity in coolers. They send real-time status updates on sensitive goods. Automated environmental monitoring cuts spoilage of vaccines, fresh produce, or chemicals.

Walmart used this setup in refrigeration to cut spoilage by 20 percent. Environmental sensors spot fire or gas leaks before they flare up, boosting safety.

Energy management systems (EMS) link to IoT networks and adjust HVAC and lighting for peak efficiency. The system sends instant alerts when heat dips or spikes, so staff act fast to stay compliant.

Data analytics feed warehouse management systems with insights on energy use and inventory status. This smart solution guards perishable and hazardous items, and trims bills, like a watchdog that never sleeps.

Automated Guided Vehicles (AGVs) for Material Handling

Automated guided vehicles (AGVs) replace manual carts and move goods. Vision sensors and proximity sensors let AGVs map floors. Manual labor drops as the vehicles work round the clock.

Handling mistakes shrink, and inventory accuracy jumps thanks to warehouse automation.

Control software links AGVs to cloud gateways for dynamic route planning. It also feeds data into inventory management platforms. Conveyors and robotic arms merge with vehicles to smooth material flow.

This setup cuts the number of required trucks and speeds deliveries, driving logistics optimization. Warehouses adapt fast when orders surge or business needs change.

AI-Enhanced Workforce Management and Scheduling

AI spots order surges, lulls, and worker output to set the right head count. This dashboard taps predictive analytics in a warehouse management system to cut costs and boost operational efficiency.

AI-integrated WMS shifts staff to busy aisles in real time. Robotics take on routine tasks, ease labor shortages, and free employees for strategy and training. Data analytics and ML models refine schedules, guard smooth running across all zones.

Team leads offer each worker upskilling and oversight to refine skills. Cobot arms lift boxes, while humans control quality and complex work. Adjustable workstations reduce strain, lower injury risk, and ease fatigue.

This blend of technology builds a safe, agile floor.

Cloud-Based Warehouse Management Systems (WMS)

Cloud-based warehouse management systems link AI and IoT for real-time data. Amazon Web Services or Microsoft Azure host many platforms. These systems run machine learning models alongside RFID tags and sensors.

Managers update workflows via PC-based programming in minutes. Teams see live inventory at each distribution center. This design scales with demand, so firms add storage space on the fly.

APIs power data exchange with automated systems and collaborative robots. Oracle Cloud WMS and SAP Logistics offer open APIs for integration. The digital ecosystem handles order fulfillment, last-mile delivery, and vendor managed inventory.

Cloud WMS supports omnichannel sales with flexible picking methods. Businesses budget for software licensing, monthly updates, and security audits. This setup cuts stock errors, boosts customer satisfaction, and refines supply chain management.

IoT for Enhanced Supply Chain Visibility

IoT integration creates a unified digital ecosystem in warehouses. It shares live data across connected devices and distribution centers. IoT sensors deliver precise status updates and location tracking of goods.

The network yields operational intelligence that links storage racks to freight vehicles.

Enhanced visibility speeds shipment consolidation and smart route planning in supply chain management. Teams use real-time analytics for last-mile delivery estimates. They spot wear early and trigger predictive maintenance for material handling equipment and vehicles.

That transparency lets workers fix disruptions before delays grow. Integration with transportation systems cuts emissions and boosts road efficiency.

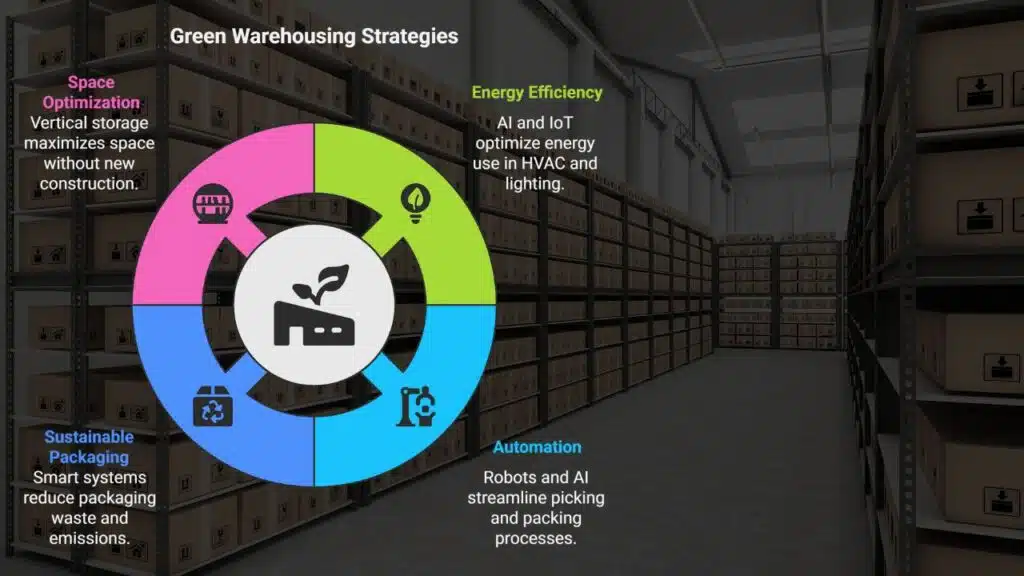

Green Warehousing with AI and IoT Integration

Solar panels and windmills drive smart hubs with artificial intelligence and IoT sensors. Energy Management Systems steer HVAC, lights, and conveyors in real time. Robots pick and pack with energy-efficient motors.

Machine learning alerts staff to spikes in energy use. Automation replaces bulky, power-hungry machines. Such shifts make operations lean and green.

Right-sized packaging systems shape each box to fit items. Cloud-based warehouse management systems guide sustainable packaging rules at every step. Smart scales and cutters remove extra material, so waste drops.

Smaller boxes need fewer pallets and trucks, cutting transport emissions and costs. Vertical storage solutions boost cubic footage, so facilities can grow without new buildings. These eco moves lift profits while trimming waste.

Cybersecurity Solutions for Smart Warehouses

Smart warehouses attract more cyber threats than ever. Cyberattacks on supply chains rose 600% last year. IoT devices that link to open networks face easy hacks. Breaches in warehouse management systems could leak private files and stall operations.

Teams plan for 2025 with stronger shields; they add firewalls, intrusion detection systems, and data encryption to block attacks.

Managers run regular security audits and apply the latest software updates. They train staff to spot phishing and use multi-factor authentication. Network segmentation locks hackers into one zone.

Artificial intelligence watches data flows and flags odd behavior fast. Blockchain ledgers trace parts from suppliers and stop tampering. These layers guard data, protect stock, and keep orders moving.

Scalability and Modular Warehouse Designs

Teams add new modules as they need storage or automation to trim capital expenditure. Modern warehouse automation uses modular robotic arms and conveyor segments that lock into existing layouts.

A vertical racking system lets companies grow storage without new walls. Operators install units in phases, thanks to plug and play modules, and lock in future proof upgrades.

IoT sensors and API integrations connect warehouse management systems with AGVs and predictive maintenance tools. Cloud platforms let operators deploy software updates for demand forecasting and real-time analytics with no downtime.

Unified digital ecosystems share data across robotics, autonomous vehicles, and inventory management systems. This adaptive model cuts waste, reduces carbon footprint, and sharpens logistics optimization.

Takeaways

These smart hubs think with AI and sense with IoT sensors. They track stock live, cut delays, and boost order accuracy. They call on machine learning to forecast demand and guide AGVs.

They feed data into cloud WMS for real-time control and alerts. They run predictive maintenance on robots, so gear stays prime. They trim carbon footprints with green warehousing tactics and energy systems.

They drive clear views across the supply chain and speed last-mile delivery.

FAQs

1. What makes a warehouse future-ready with AI and IoT?

A future-ready warehouse uses artificial intelligence (ai) and internet of things (iot) sensors. It runs machine learning (ml) and predictive analytics. It links smart warehousing to warehouse automation and warehouse management systems (wms). It makes order fulfillment hum like a well-oiled machine.

2. How do iot sensors and data analytics help?

Sensors on shelves and forklifts feed real-time analytics into a central system. That data drives demand forecasting and inventory management. Managers spot low stock or slow movers in a flash, and fix issues fast.

3. Can AI handle predictive maintenance on equipment?

Yes, it flags wear on robot helpers and guided carts before they break down. It uses predictive maintenance and historical data analysis. It cuts downtime, saves repair costs, and keeps operations rolling.

4. How does AI boost supply chain and last-mile delivery?

AI runs supply chain optimization and automated decision-making. It taps into logistics management tools to pick the best routes. It speeds last-mile delivery, cuts fuel waste, and raises customer satisfaction.

5. What green warehousing practices can AI support?

AI tracks energy use and suggests sustainable packaging. It tunes heating, lighting, and forklift paths to lower the carbon footprint. It helps a warehouse act green, without losing speed or flexibility.

6. Are there risks with unsecured networks and blockchain technology?

Yes, iot technology can open doors to hackers if networks stay unsecured. You need strong data management rules and regular software updates. A blockchain layer can lock down records, but it adds another layer to your infrastructure.