Running out stock? Or stuck with piles unsold items? Poor forecasts hurt profits every day—but better tools fix these headaches fast!

The right demand-planning tools slash guesswork by 30%, says recent retail studies—no magic needed! This list reveals ten smart solutions, like AI-powered forecasts & cloud-based trackers—all built specifically to boost your numbers.

Keep reading if you want shelves stocked just right!

Artificial Intelligence [AI] and Machine Learning [ML] in Demand Planning

AI and ML spot hidden patterns in sales data, making forecasts sharper than ever. These tools learn from past mistakes, so they get better with every prediction.

Enhancing demand accuracy through predictive analytics

Predictive analytics helps businesses guess future needs better by studying past patterns like seasonal trends or customer behavior—no crystal ball needed! It crunches historical sales data using machine learning algorithms so you know exactly what’s coming next—whether hot products will fly off shelves or collect dust—before orders pile up unexpectedly at your warehouse doorsteps

“Good predictions beat good luck every time.”

Logility’s AI-powered tools show how smart tech spots hidden clues buried deep inside big datasets—like sudden spikes linked back-to-school shopping sprees lurking beneath normal-looking spreadsheets—so retailers stay ahead without drowning under surplus stock shortages anymore either way around here folks

Big Data Analytics for Better Forecasting

Big data tools crunch past sales numbers like a calculator on steroids—spotting patterns you’d miss with just gut feelings—so your shelves stay stocked without guesswork; keep reading if you hate running outta hot sellers!

Leveraging historical and real-time data

Demand planners rely on both past sales records and live updates like IoT sensors or CRM inputs—this combo sharpens forecasts dramatically! Historical patterns reveal seasonal spikes or slow months while current signals track sudden shifts—like Walmart adjusting orders during holiday rushes based on hourly POS feeds.

Modern tools like Logility blend big-data crunching power + predictive models so businesses spot hidden links between economic swings & buying habits faster than old-school Excel sheets could manage It’s why top-performing retail teams now prioritize multi-channel integration—linking Google Analytics clicks directly back-end ERP stock alerts cuts guesswork down hard.

Cloud-Based Demand Planning Software

Cloud-based demand planning tools let teams access data from anywhere, making updates fast and easy. These platforms cut costs by ditching bulky hardware while boosting real-time collaboration across departments.

Improving agility and accessibility

Cloud platforms revolutionize demand planning by making data available anytime, anywhere. Real-time monitoring systems let teams track inventory levels across warehouses instantly, cutting delays and boosting decision speed.

Modern software like Logility uses AI to automate restocking, so businesses stay agile without manual guesswork.

Accessible dashboards show key metrics like forecast accuracy and inventory turnover ratios in simple visuals. Teams spot trends faster, adjust orders quickly, and avoid overstocking or stockouts.

With cloud-based tools, even suppliers collaborate seamlessly—no more outdated spreadsheets or messy email chains slowing things down. The result? Smoother operations and happier customers.

Internet of Things [IoT] for Real-Time Demand Sensing

Smart shelves and connected sensors track stock levels in real time, cutting guesswork. IoT devices feed live data into demand planning tools, helping businesses stay ahead of sudden shifts.

Monitoring inventory needs with connected devices

Connected devices powered by IoT are changing how businesses track stock levels—think smart shelves or RFID tags sending live updates straight into your inventory system. These gadgets catch every movement, helping spot shortages before they hurt customer satisfaction.

“Real-time tracking cuts guesswork out—your warehouse knows what’s needed before you do.”

With IoT sensors feeding real-time data into cloud-based tools like Logility, companies slash errors caused by outdated spreadsheets. Pair them with predictive analytics, suddenly you’re dodging both empty shelves AND piles excess stock gathering dust.

Advanced Analytics Dashboards

Advanced analytics dashboards turn complex inventory data into clear visuals, helping you spot trends and act fast—keep reading to see how these tools can sharpen your demand planning.

Providing visibility into inventory trends

Advanced analytics dashboards put inventory trends in plain sight. They track key metrics like Forecast Accuracy and Inventory Turnover Ratio, so businesses spot problems fast. These tools compare forecasted vs.

actual sales, helping teams adjust before stock runs out or piles up too high.

Real-time dashboards highlight early warning signs for demand spikes or drops. Logility’s AI-powered software, for example, automates tracking and flags issues with inventory planning.

With clear visuals on seasonal trends and customer behavior, companies cut waste and keep shelves stocked right.

Simulation and Scenario Planning Tools

These tools test different outcomes before making decisions—like playing chess with your inventory numbers.They help you spot risks early so surprises don’t derail your plans later on.

Preparing for various demand scenarios

Demand shifts fast, like weather in spring. Tools for scenario planning help businesses dodge surprises. Simulation software lets you test different market trends without real risk.

Think of it as a practice game before the big match.

Look at Logility’s AI-powered options or Integrated Business Planning [IBP] software. They predict changes before they hit inventory levels hard. The Delphi Method and statistical forecasting add backup plans when demand spikes or dips suddenly—no need to cross fingers and hope anymore! Keep an eye on early warning indicators too—they scream trouble early so fixes happen quick.

Collaborative Planning, Forecasting, and Replenishment [CPFR]

CPFR brings teams together to share data and refine forecasts. It bridges gaps between sales, supply chain, and suppliers for sharper inventory decisions.

Enhancing accuracy through team collaboration

Team collaboration boosts demand planning accuracy. Tools like Collaborative Planning, Forecasting, and Replenishment [CPFR] help teams share data in real time. This reduces errors and aligns inventory with actual customer demand.

Sales, marketing, and supply chain teams work together using shared dashboards. They track forecasted vs. actual sales, spot trends early, and adjust orders faster. Better teamwork means fewer stockouts or overstocking—saving money while keeping customers happy.

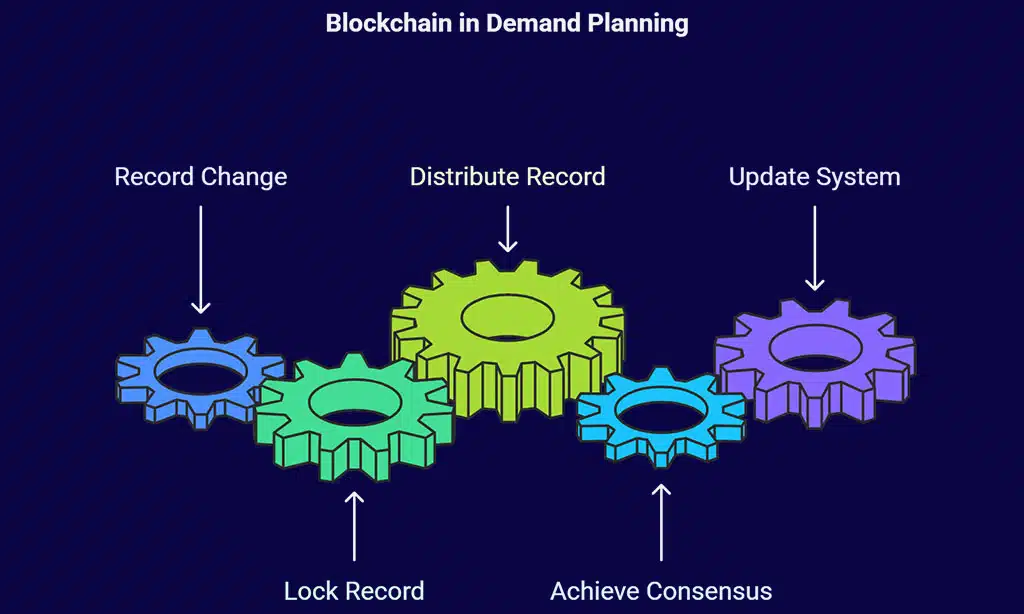

Blockchain Technology for Secure Demand Planning

IBP software ties together sales forecasts, inventory levels, and production schedules in one place—no more juggling spreadsheets or guessing games. Want to see how smooth this makes things? Dive deeper!

Integrated Business Planning [IBP] Software

IBP software ties demand planning and supply chain management into one smooth system. It helps businesses stay ahead by syncing sales forecasts with inventory needs in real time.

Unifying demand and supply chain management

Integrated Business Planning [IBP] software unifies demand forecasts and supply processes, eliminating guesswork and mismatched plans between teams like purchasing or production scheduling departments, who previously worked without shared goals.

With tools such as Logility’s AI-powered platform, which enhances speed-to-market decisions by analyzing extensive historical sales data alongside current market trends, operations become smoother from start to finish, replacing the inefficiencies of siloed systems.

This ensures efficiency in meeting targets without wasting resources on preventable mistakes, and promotes a seamless workflow that supports effective decision-making across departments.

Benefits of Using Demand Planning Tools

Demand planning tools cut down on wasted stock and missed sales. They help businesses stay ready for what customers want, without the guesswork.

Reducing stockouts and overstocking

The right demand planning tools cut stockouts and stop overstocking. AI-driven software like Logility uses machine learning to predict customer demand accurately, so you order just enough.

Real-time data from IoT devices helps track inventory needs before shelves go empty or overflow.

Cloud-based systems boost forecast accuracy by analyzing historical sales trends and seasonal demand patterns. Tools with advanced dashboards show key metrics like fill rate and inventory turnover ratio at a glance.

This prevents financial losses from guesswork and keeps customers happy with reliable stock levels.

Takeaways

Demand planning tools like AI, cloud software, and IoT help businesses predict needs and cut waste. These solutions boost forecast accuracy, lower costs, and keep shelves stocked without excess.

From real-time dashboards to blockchain tracking, smart tech makes inventory management easier. Try Logility or CPFR tools for sharper data-driven decisions. Better planning means happier customers—start optimizing today!

FAQs on Demand Planning Tools That Improve Inventory Accuracy

1. What are demand planning tools?

Demand planning tools help businesses predict customer demand, optimize inventory, and reduce financial losses. They use machine learning and historical sales data to improve forecast accuracy.

2. How do these tools improve inventory management?

They analyze market trends, seasonal demand, and customer behavior. This helps businesses adjust stock levels, cut waste, and boost customer satisfaction.

3. Can small businesses use demand planning software?

Yes. Some tools work with Google Sheets or Microsoft Excel. They automate data analysis, making inventory forecasting easier without needing complex ERP systems.

4. Do these tools only work for retail businesses?

No. They help ecommerce platforms, manufacturers, and supply chain managers. They track lead times, product launches, and economic trends for better decision-making.

5. Why is forecasting accuracy important?

Bad predictions lead to overstocking or stockouts. Demand planning tools use predictive analytics to minimize inaccuracy, keeping operations smooth and costs low.