You see piles of trash right outside your door. It hurts to think of all the plastic and gadgets we toss. Some old toys or cans could last longer. Yet most end up as waste.

McKinsey says we throw away 80 percent of material value in consumer goods. This post will show you five ways circular logistics can slash waste in supply chains and boost a circular economy.

You will learn how reverse logistics, eco-design, and digital IDs boost reuse. You will see how they cut CO2 emissions. Keep reading.

Key Takeaways

- We throw away 80% of the material value in consumer goods (McKinsey).

- Brands use reverse logistics. They track returns with digital passports, RFID tags, robotics, and a distributed ledger. They cut waste by 20% and errors by 30% in pilot runs (SEKO).

- Renault, Patagonia, Mara Seaweed, and Signify design items for repair and reuse. Patagonia turned 520 tons of ocean plastic into new gear in 2020. Minor Figures runs 150 refill spots in the UK.

- H&M, Vodafone, and Ethique reward users with points, discounts, and tree plantings. One in three shoppers say they will pay more for strong recycling programs.

- LiquiDonate and Wiliot share goods and data to repurpose items. On-site digesters and new recycling plants turn kitchen scraps and scrap metal into biogas and new materials.

Reverse Logistics: Extending Product Lifecycles

Brands reroute used devices to repair hubs, they swap landfill runs for fresh revenue streams. The Ellen MacArthur Foundation shows how product passports, closed-loop chains and after-market loops stretch gadget life and slash carbon loads.

How does reverse logistics facilitate product returns for reuse or recycling?

Reverse logistics lets firms bring back used items. It uses returns management technology, digital product passports, RFID tags to track each part. Workers sort items for reuse, repair, or recycling.

This step cuts landfill waste. SEKO Logistics uses consolidated returns to save fuel and drop carbon emissions.

Ellen MacArthur Foundation calls reverse logistics vital in a circular economy model. Smart sorting helps post consumer goods flow back into a circular supply chain. Recycled materials return to new products.

Refurbished products extend life cycles. Companies see lower supply chain costs and bigger ROI. This model links to climate action and waste reduction.

How can reverse supply chains minimize waste efficiently?

Smart robotics run reverse logistics lines. They process 10,000 post-consumer returns per day with 30% fewer errors. Predictive analytics spot return trends fast. Pilot tests cut waste by 20% in trial runs.

A supply chain visibility platform tracks goods end to end in the circular supply chain. It gives a 360 degree view on each item. That view boosts circular economy goals.

A distributed ledger logs each returned part. It halts greenwashing block by block. SEKO Logistics global network ties local hubs across the value chain around the world. Partners share transport, sorting, disposal plans to boost waste reduction.

Advanced recycling machines shred and purify plastics and metals. This mix of tech and teamwork turns trash into sustainable products.

Eco-Design: Building Sustainable Products

Eco-design cuts waste at the start by using life cycle assessments. Digital product passports help companies track parts, so they build items that last and cycle back.

How can products be designed for durability and recyclability?

Renault has cut prices on used parts since 1949 and offers warranties like a safety net under a tightrope walker. Its components snap apart in a few clicks to ease repair or remanufacture.

Patagonia fixed over 100,000 shirts in 2020 and turned 520 tons of ocean plastic into gear. That shows how sturdy threads and clear life cycle labels keep waste management simple. Mara Seaweed swaps plastic wraps for seaweed polymer pouches, and Ethique ships bars in paper wraps, planting a tree per order.

These brands earn B Corp or ISCC Plus stamps to prove green standards in circular supply chain designs.

Signify loans lights under a Product as a Service model, then takes back bulbs to sort and reclaim materials. Southern Glazers puts reduction before reuse in every bottle design. Minor Figures runs 150 refill spots in the UK and turns old cartons into green energy.

Digital product passports record each item’s journey. That info tool helps firms spot parts that last and those that head back to the loop.

What material choices reduce waste in product design?

Mara Seaweed invests in energy efficient drying and greener processes to cut waste. Fast fashion retailer H&M plans to use all recycled materials by 2030, trimming landfill loads. Consultancy Pyxera Global directs teams to durable plastics, adding digital product passports to speed recovery in a circular supply chain.

Coffee roaster Kua Coffee wraps beans in recyclable film and turns grounds into compost.

Algae film and paper slices packaging waste and cuts the 30% of eCommerce emissions that packing causes. Furniture label Room & Board sends old fixtures to nonprofits, giving them new life instead of trash.

Relocating its plant near seaweed beds shrinks transport miles and lowers greenhouse gas output.

Incentivizing Recycling and Reuse

Apps scan digital product passports and dish out eco-credits when users drop old phones at certified e-recycling hubs. The Ellen MacArthur Foundation backs deposit-return systems as a smart way to spark reuse and shrink landfill loads.

How can consumers be encouraged to participate in recycling programs?

H&M offers in-store drop boxes and reward points to drive recycling. Vodafone sets up drop boxes for used phones and tablets in its retail outlets. Signify uses a Product as a Service model to collect spent lamps and recycle them at end of life.

Ethique plants a tree for each online order, blending cause marketing with circular supply chain tactics. These moves trim waste, lower greenhouse gas emissions and spur more reused content.

Minor Figures installs refill stations in shops across the UK to cut packaging waste. Mara Seaweed trials compostable pouches and shifts some production closer to consumers to ease recycling loops.

Brands earn B Corp marks to prove their sustainability bona fides. Digital product passports boost consumer trust in returned goods. About one third of shoppers will pay higher prices for products backed by strong recycling programs.

What incentives motivate the return of used products?

Companies set up trade-in deals, letting you swap old gadgets for discounts or store credit. They tie loyalty rewards or special offers to each return. Retailers like H&M and Vodafone reward customers in stores when they drop off used items.

Deposit schemes nudge people to give back reusable containers or electronics. Circular supply chain players even pay bonuses when they boost material yields.

Automated systems route each return to the right recycler or charity, cutting out hassle. Some brands post their circular economy wins online, sparking pride and peer praise when fans send items back.

Digital product passports track every part, unlocking repair or reuse under a net zero push. Supplier deals hinge on a brand’s knack for driving returns, so partners add perks to get customers on board.

Collaboration Across Value Chains

Teams share digital product passports, just like a pit crew, to spot leak points in the circular supply chain. IoT sensors track each part, slashing carbon footprint and sparking fresh reuse ideas.

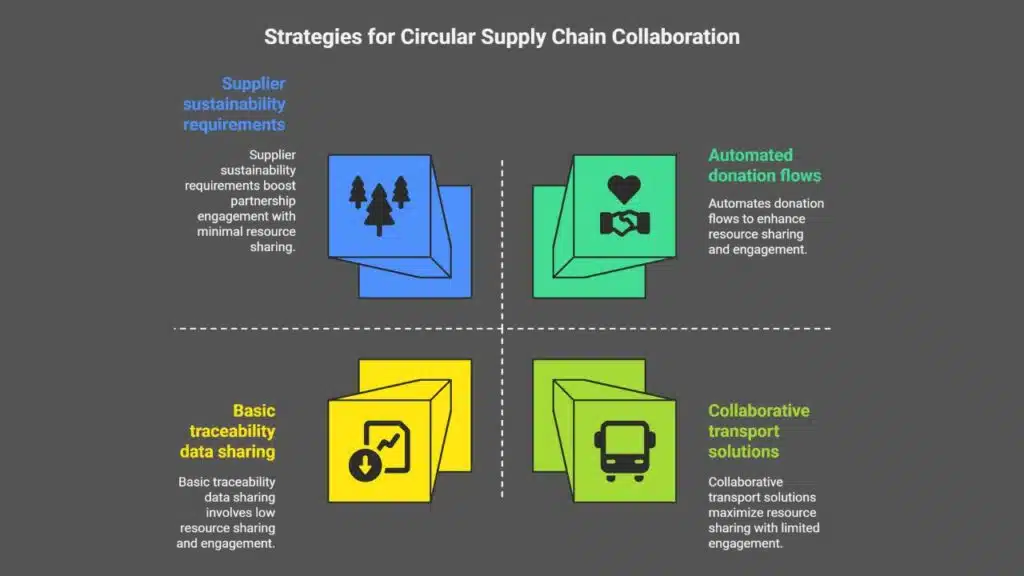

How do partnerships with suppliers and stakeholders promote circular practices?

Smart partnerships slash waste and cut costs. The LiquiDonate platform automates donation flows, sending unsellable items to nonprofits and strengthening vendor bonds. Wiliot sensor tags offer real time stock insights that uncover waste loss.

Room & Board repurposes old furniture by routing fixtures to local charities, locking suppliers into reuse loops. Pyxera Global trains teams to map recovery steps and improve circular supply chain models.

Three Spirit makes sustainability a must for vendor approval, shaping greener product design and material use. SEKO Logistics links global sites, so partners share transport and curb emissions.

Southern Glazers Wine and Spirits earns nods as a green leader by aligning supplier goals in closed loop programs. Automated nonprofit matching and donor incentives drive more partners into circular economy plans, fueling resource recovery and driving waste reduction.

How does sharing resources and knowledge help minimize waste?

Traceability data sharing slashes waste in a circular supply chain. Data analytics spot inventory gaps and shape repair plans. Teams upload SKU-level reports to a distributed ledger for full life cycle views.

Industry certifications like ASCM and ISCC Plus demand clear reporting and audit-ready archives. Cross-functional squads from ops, legal, finance, brand, and ESG swap insights in regular meetings.

Green HR drives ongoing learning about zero waste and sustainable sourcing. Carbon workshops guide staff to trim greenhouse gas emissions in food systems and EV recycling. Digital product passports connect parts info to real stores, cutting packaging waste.

Partners share resource-efficient operations data, passing the baton with real metrics. Teams spot surplus materials and launch circular business models.

Treating Waste as a Resource

An on-site digester eats kitchen peelings, then powers a small farm with clean biogas. RFID chips track old power cells, so labs can pull out metals, cut landfill piles, and feed a circular supply chain.

How can waste be repurposed into valuable materials?

Patagonia turned 520 tons of ocean plastic into new garments in 2020. Kua Coffee grinds used grounds into compost, cutting food loss. Room & Board sends unwanted fixtures to nonprofits, fueling local builds.

Minor Figures transforms cartons into green energy, powering machines. Renault’s design for disassembly lets parts slip into fresh assemblies. Mara Seaweed tests low-heat dryers for leftover shoots, shaping animal feed chips.

LiquiDonate links unsellable goods with shelters, securing more value before landfill. Some plants ferment organic scraps to spark biogas production, fueling electric trucks. Teams track items through digital product passports, boosting transparency.

These tactics fit circular economy plans, driving waste reduction and renewable energy in sustainable practices.

What are the latest innovations in waste-to-resource technologies?

Smart sensors from Wiliot tag pallets and packages. They give real-time data for reuse and recycling. Automation cuts manual labor and speeds repurposing. Data analytics map break-even points and ROI for new projects.

Public ledgers record every repurposed batch, giving audit-ready logs for ESG and tax perks. Serial tracking helps firms hit zero waste goals.

ISCC Plus checks every step and drives fresh tech in 2023. LiquiDonate software reroutes surplus to hunger relief in hours. New pilot plants use advanced recycling to shred mixed metals and textiles.

Some zones still lack these tools. Circular economy models push for wider spread. Firms test digital product passports for reusing parts in EVs and batteries.

Takeaways

Five circular moves cut waste fast and spark big gains. Reverse logistics helps brands reuse goods and slash landfill piles. Digital product passports boost trace and speed returns.

Battery recycling and eco design extend product life. Teams share data, use certifications, and apply automation tools. New paths steer us from throwaway ways to circular supply chains.

FAQs

1. What is circular logistics and how does it slash waste?

Circular logistics loops goods back like a boomerang for reuse. It uses reverse logistics and a circular supply chain instead of a linear supply chain. It cuts waste and drives cost reduction.

2. How does the circular economy boost textile recycling and biodegradable waste reduction?

It treats old clothes like gold it can spin into new fabric. It tackles food losses and biodegradable waste. It keeps materials moving, shrinking waste and cost.

3. What are digital product passports and how do they aid waste-management?

Think of a digital product passport like a hotline for a phone, a shirt or a toy. It shows where items come from and what they are made of. You can repair, reuse or recycle. It stops solid waste from piling up.

4. Can circular strategies fight climate change in food security and farming?

Yes, circular strategies like regenerative farming return nutrients to soil, cut food losses, and boost food security. They act as nature-based solutions that tackle water usage and climate change head on.

5. How do electric cars and cell recycling fit into this model?

It treats used batteries like treasure, drives electric cars, then cells go back through cell recycling. It ties into renewable sources and clean energy. That cuts greenhouse gas emissions and lowers energy consumption.

6. Why do the Paris Agreement and national determined contributions matter?

They set clear targets under the Paris Agreement for climate action. Nations must lower emissions, share sustainable practices, and embrace circular strategies. That spells hope in the fight against climate change.