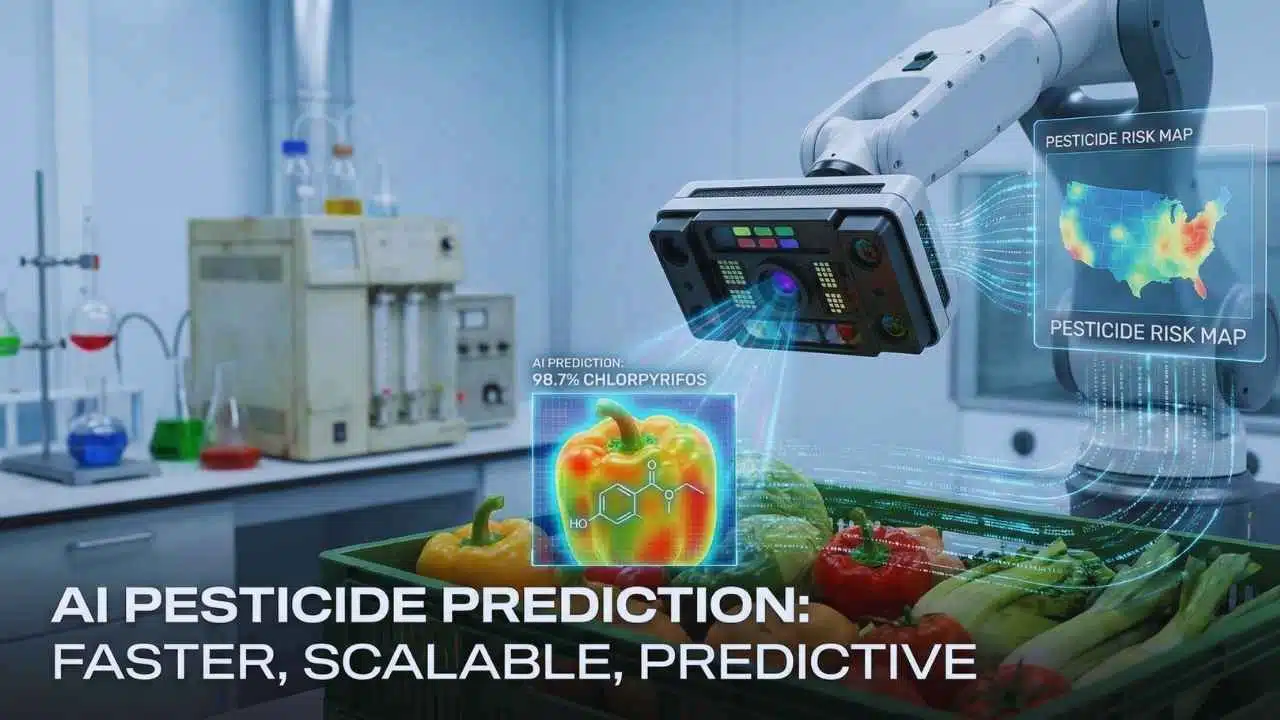

AI pesticide residue prediction is gaining attention as researchers and food-safety teams explore how models can estimate residue risk before harvest—helping prevent violations while lab testing remains the final proof for compliance.

What AI pesticide residue prediction is and why it matters now?

AI pesticide residue prediction refers to using machine-learning models to estimate how much pesticide residue may remain on a crop at harvest or at a later time point. Instead of only measuring residues after food is already in the supply chain, prediction aims to flag risk earlier—when growers, suppliers, or inspectors can still adjust decisions.

Pesticide residues are small traces that can remain after pesticides are applied to protect crops from insects, weeds, and plant diseases. Regulators manage potential health risk by setting legal limits for specific pesticide–food combinations. These limits are commonly called maximum residue limits (MRLs) or “tolerances,” depending on the jurisdiction. They are not “zero residue” rules. They are thresholds designed from toxicology and dietary exposure assessments, plus safety margins.

In most countries, the system works through two connected parts:

- Rules and limits: what is allowed, and how much is allowed on each food.

- Monitoring and enforcement: sampling food, testing it in labs, and acting when results exceed legal limits or violate approval rules.

The challenge is that monitoring is largely reactive. Testing tells you what happened after application and after harvest. AI pesticide residue prediction is being proposed as a prevention layer: estimating what is likely to happen, so problems can be avoided before food enters markets.

This shift matters because food supply chains are getting faster and more complex. A crop can be harvested, packed, exported, and sold across borders quickly. When a residue issue shows up late, costs rise: rejected shipments, product recalls, supplier disputes, and damaged trust with consumers.

How residue limits and monitoring work in real life?

Residue rules are often misunderstood. They do not mean “pesticides are safe in any amount.” They also do not automatically mean “any detection is dangerous.” Risk depends on dose: how much is present, how much a person consumes, and how toxic the compound is at specific exposure levels.

Authorities set limits by combining toxicology with expected consumption patterns. That includes assessing long-term exposure and, for some chemicals, potential short-term exposure. Limits also reflect how pesticides are supposed to be used, including required waiting periods between application and harvest (often called pre-harvest intervals). If a farmer follows the label instructions, residues are expected to remain within the legal limit.

Monitoring programs then test foods to verify compliance. Many programs publish annual summaries showing broad trends: how often residues are detected, how often limits are exceeded, and what commodities or countries show higher risk patterns.

Below is a simplified view of how monitoring typically operates across large programs:

| Step | What happens | Why it matters |

| Sampling | Agencies or partners collect food samples from farms, markets, processing sites, or ports | Sampling design affects what problems are detected |

| Lab testing | Samples are prepared and tested with validated analytical methods | Legal enforcement usually requires lab-grade confirmation |

| Compliance check | Results are compared against limits for each pesticide–food pair | Exceedances can trigger actions, alerts, or import controls |

| Follow-up | Investigations, supplier actions, targeted re-testing, or enforcement | Prevents repeat issues and protects consumers |

A key point: even strong monitoring systems cannot test every lot of food. Agencies and companies must prioritize. This is one reason prediction tools are gaining interest. If a model can highlight “higher probability” scenarios, inspection and quality-control resources can be used more efficiently.

What AI models are trying to predict and the data they need?

Residue levels depend on many interacting factors. Two farms can apply the same pesticide, yet end up with different residues because conditions differ.

AI pesticide residue prediction models typically aim to estimate:

- Whether residues are likely to be detectable

- Whether residues are likely to exceed a legal limit

- The likely concentration range (for example, mg/kg)

To do that, models need structured inputs. Common predictors include:

- Crop factors: crop species, variety, surface characteristics (waxy skin vs leafy surfaces), growth stage

- Pesticide factors: active ingredient, formulation type, application rate, number of sprays, interval between sprays

- Timing factors: days between last application and harvest

- Weather factors: rainfall after application, temperature, sunlight intensity (which can drive degradation), humidity, wind (which can affect drift and deposition)

- Field and soil factors: soil type, irrigation practices, canopy density

- Historical residue data: previous lab results for similar conditions

In recent research, a major hurdle keeps showing up: small datasets. Residue trials are expensive. They require controlled applications, repeated sampling, lab analysis, and careful documentation. That means many residue datasets are limited in size, scattered, or inconsistent in format. Researchers are therefore experimenting with techniques that handle small data better and reduce prediction error.

In practical terms, prediction accuracy matters most near thresholds. If residues are far below limits, decisions are easy. If residues are near limits, small errors can flip decisions. A model that reduces error—even modestly—could help growers and supply chains adjust before harvest.

Where prediction can fit in the farm-to-market timeline?

Prediction tools are most useful when they create decision points early enough to act. Here is a simple timeline that shows where AI pesticide residue prediction could sit:

| Timeline stage | Typical decisions today | What prediction could add |

| Before spraying | Which pesticide to use; how often to spray | “Lower-risk” options based on past residue patterns |

| During the season | Whether to repeat applications | Early warning if multiple sprays raise likely residues |

| Pre-harvest window | Harvest timing; compliance checks | Risk estimate: “safe,” “borderline,” or “needs action” |

| Post-harvest | Testing and shipping | Smarter testing priority for higher-risk lots |

| Import/export | Border checks and documentation | Risk scoring to focus limited inspections |

Even if prediction becomes strong, it does not replace lab testing. It changes how testing is prioritized and how problems are prevented.

What public data suggests about overall residue risk and compliance?

While prediction tools are emerging, existing monitoring programs still form the backbone of food-safety verification. Across major jurisdictions, annual summaries frequently show high overall compliance levels, even when residues are detected.

This is an important nuance for consumers: detection is common because modern labs can measure very low levels. But detection does not automatically mean unsafe exposure. Monitoring reports often distinguish between:

- No residues detected

- Residues detected but below legal limits

- Residues exceeding legal limits or violating rules

However, compliance patterns vary by commodity, pesticide type, and supply chain. Certain crops tend to show more frequent detections because they receive more treatments or have surfaces that hold residues differently. Imports can also show different patterns due to differences in approved pesticides, usage practices, or enforcement capacity across countries.

Comparison: how food safety teams interpret results?

| Result category | What it means | Typical action |

| No residues detected | Nothing measurable above the method’s detection limit | No action needed |

| Residues detected, within limit | Legal and expected under proper use | Generally acceptable; may inform trends |

| Exceedance (above limit) | Potential violation; may imply misuse or timing issues | Investigation, enforcement, increased targeting |

| Not authorized pesticide | Substance not approved for that crop/jurisdiction | Often treated seriously; may trigger alerts |

This is where AI pesticide residue prediction could have its biggest impact: helping keep “borderline” situations from crossing into exceedance territory. If a model suggests risk is rising, a producer could extend the interval before harvest, reduce later sprays, or switch to alternative methods. A buyer could request pre-shipment testing or hold high-risk lots until confirmation is available.

At a system level, prediction can also support fairness. When monitoring relies heavily on targeted checks, producers may worry about uneven scrutiny. Transparent, evidence-based risk scoring could make targeting more consistent—if it is validated and governed well.

How prediction and rapid screening could work together in food safety?

There are two different “AI paths” in pesticide residue control:

- Prediction: forecasting residues based on conditions and application history

- AI-assisted screening: using machine learning to interpret quick tests (like spectroscopy-based approaches) that can flag likely residue issues faster than full lab methods

They serve different purposes. Prediction is about prevention and prioritization. Screening is about speed and scale when testing is needed.

A realistic quality-control system could combine both:

- Step 1: Predict risk before harvest or before shipment

- Step 2: Screen high-risk lots quickly to decide whether deeper testing is needed

- Step 3: Confirm in a lab for compliance, enforcement, or final release decisions

This layered design can reduce waste and focus expensive lab capacity on the samples that matter most.

Practical example: how a buyer might use AI pesticide residue prediction?

A food buyer sourcing strawberries from multiple farms might face tight shipping deadlines and limited testing capacity. Instead of testing every farm equally, the buyer could:

- Collect spray logs and harvest schedules

- Add basic weather and location data

- Run a residue risk model

- Assign a risk score to each lot

Lots marked “low risk” might receive routine spot checks. Lots marked “higher risk” could require pre-shipment testing or delayed harvest to allow residues to decline. Over time, the buyer could measure whether model decisions reduce exceedances and rejected shipments.

For growers, prediction could also reduce stress. If a model provides early warning, growers can change course while the crop is still in the field. That is cheaper than dealing with rejections later.

The biggest limitations and what must be proven next?

AI pesticide residue prediction is promising, but it also carries risks if used carelessly or marketed as a guarantee. The strongest concerns fall into five areas:

1) Data quality, coverage, and bias

Residue outcomes depend on precise details: exact application rates, timing, crop stage, and weather. If these inputs are missing or inaccurate, predictions can be misleading. Many datasets also represent limited regions or controlled trial conditions rather than real-world variability.

Bias can also appear if datasets overrepresent certain farms, climates, or commodities. A model trained mostly on one growing region may fail elsewhere.

2) Generalization across crops and regions

A model that works well for one crop may not work for another. Leafy greens, berries, and thick-skinned fruits behave differently. Even within one crop, cultivation practices differ. Prediction tools must prove they can generalize—or clearly state where they cannot.

3) Transparency and auditability

Food safety decisions affect livelihoods. If a shipment is rejected because an algorithm flagged risk, stakeholders will demand explanations. Models need traceable inputs, understandable outputs, and validation records. “Black box” systems may face resistance unless governance is strong.

4) Regulatory acceptance and legal standards

For enforcement, regulators typically require validated lab results. Prediction can guide actions, but it cannot replace confirmatory testing in most legal contexts. The role of prediction is therefore supportive: prevention, prioritization, and risk management.

5) Risk communication to consumers

Consumers may hear “AI predicts residues” and assume widespread danger. But public monitoring often shows that most tested foods remain within legal limits. The responsible message is balanced: prediction helps prevent the minority of cases that go wrong, while testing confirms compliance.

What “good enough” performance might look like for real-world use

| Use case | What the model must do well | What failure looks like |

| On-farm decision support | Identify high-risk scenarios early enough to act | False reassurance leads to exceedance |

| Supply-chain testing priority | Rank lots reasonably by risk | Too many false alarms waste testing capacity |

| Import screening support | Highlight patterns that warrant attention | Bias unfairly targets specific origins without evidence |

| Research and planning | Reveal drivers (timing, weather, rate) | Spurious correlations mislead decisions |

The next phase for AI pesticide residue prediction should focus on rigorous validation: multi-season testing, multiple regions, varied weather conditions, and transparent reporting of error ranges. Models should also be evaluated in operational settings—how they change decisions, how often they reduce exceedances, and whether they lower costs without increasing risk.

What this shift means for growers, buyers, and regulators?

AI pesticide residue prediction is best understood as a new “early warning” layer in food safety. It does not replace lab testing. It aims to reduce surprises by helping stakeholders act sooner: adjusting spray programs, extending pre-harvest intervals, prioritizing high-risk lots for testing, and focusing inspections where they are most needed.

If these tools are validated carefully and governed transparently, they could make residue control more efficient and less disruptive. That could mean fewer rejected shipments, fewer compliance disputes, and stronger consumer confidence—without changing the core principle that compliance decisions must still be grounded in verified measurements.