Do you feel stuck with slow deliveries and missed deadlines? Many future supply chain managers face broken workflows in logistics management. They might lack clear project management steps or strong communication skills.

They end up chasing lost packages instead of planning ahead.

Logistics managers play a vital role in supply chain management. They need a mix of precision and agility in each move. They lean on data analysis, predictive analytics, ERP software, and WMS tools.

We will cover ten skills to sharpen your analytics, leadership, and communication. Keep reading.

Key Takeaways

- Plan ahead: tie forecasts to goals, use 2024 market trends, and adopt eco-friendly packaging to cut carbon output.

- Use AI and machine learning to forecast demand and track shipments. A 2023 survey shows 78% of teams call advanced analytics a must-have skill.

- Communicate clearly by sharing simple status updates, using cross-cultural cues, and negotiating with empathy to resolve conflicts early.

- Lead teams by setting clear goals, delegating tasks, mentoring staff, and earning PMP or Six Sigma belts to boost performance.

- Harness ERP, WMS, TMS, AI, IoT sensors, blockchain, and robotics tools, and follow international trade laws plus environmental rules to avoid fines.

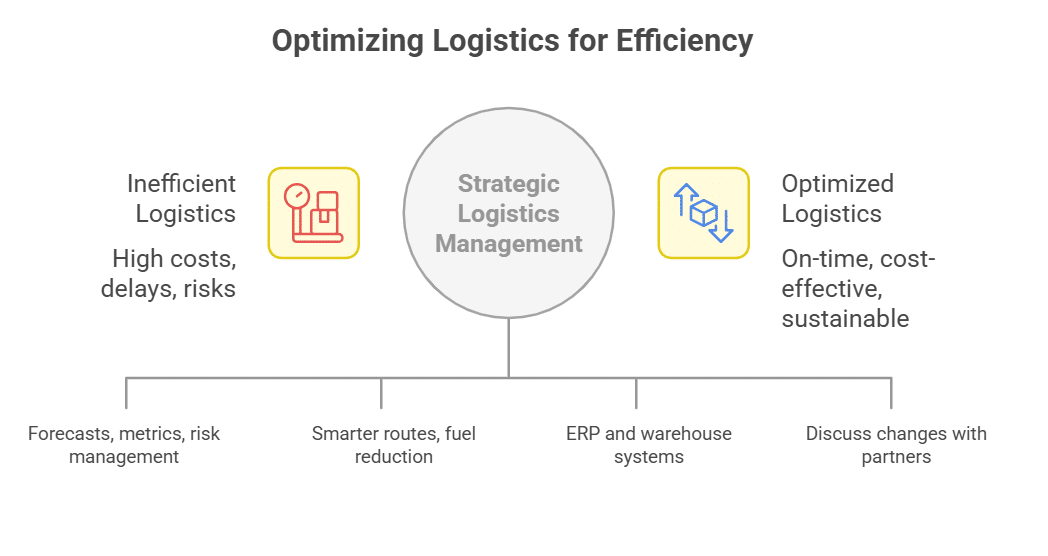

Strategic Thinking and Planning

Logistics managers draft roadmaps that tie forecasts to key goals, and they run risk management drills to spot supply chain risks. They use metrics from business intelligence tools to set targets for on-time delivery and cost-benefit analysis.

Managers map routes, tweak layouts, and refine contingency plans to cut fuel burn and dodge delays.

Teams tap enterprise resource planning and warehouse management systems to boost supply chain efficiency. Leaders eye 2024 market trends and mix in green logistics with sustainable packaging choices.

They test smarter route optimization to trim carbon output. Senior managers discuss changes with partners in other regions to keep goods rolling. This mix of data analysis and stakeholder talk keeps projects on track.

Data Analysis and Interpretation

A good report acts like a compass for logistic pros. Data literacy drives smarter logistic plans. Managers use data analytics and reporting to boost supply chain visibility and coordination.

They apply demand forecasting and trend analysis to cut costs and curb delays. A 2023 survey shows 78 percent of logistics teams rate advanced analytics as a must have skill. Firms use warehouse platforms and shipping management software to track shipments in real time.

Managers must learn new analytics tools to stay sharp or they fall behind. A skilled pro taps AI models and machine learning to forecast demand swings. They link inventory, transit, and cost data in enterprise planning solutions for a full view.

Crisp graphs and clean reports spark fast decisions, cut spoilage, and boost on time levels. This active use of data drives supply chain management success.

Communication and Negotiation Skills

Logistics managers shape deals in logistics and supply chain management with clear communication, active listening, and strong written communication skills. They blend non-verbal cues with friendly tone to coordinate with suppliers, customers, and internal teams.

Learning cross-cultural cues, they adapt to time zones and respect local norms. This practice boosts supply chain efficiency, improves teamwork, and resolves conflicts early.

Teams share status updates, contract terms, and risk reports in simple language to avoid confusion. They negotiate with empathy, juggle pricing points, and reach agreements that cut supply chain risks.

Inventory planning system data and stock tracking solution dashboards feed into talks. Solid conflict resolution also helps them lock in on-time shipments.

Leadership and Team Management

Leaders light a fire under their staff with clear goals and smart task delegation, they coach crew in project management or use ERP systems to track progress. They nurture talent, and they drive time critical moves with WMS support, to shape high performing, adaptable teams that can dodge supply chain risks.

This approach boosts operational success, and it sparks a collaborative workplace culture.

Senior managers step in as mentors, they host change management and risk management workshops, and they chase PMP or Six Sigma belts to stay sharp. Team projects and leadership roles help crew hone communication skills, active listening, and negotiation skills.

These soft skills fuel employee engagement, and they prep squads for freight on board deadlines or sudden market trends.

Adaptability and Problem-Solving Abilities

Adaptability and flexibility help managers handle sudden port closures or rush orders. They use ERP dashboards and WMS data to spot supply chain risks early. AI tools scan market trends and feed real-time alerts.

Teams update contingency plans to curb disruptions.

Problem-solving and critical thinking drive smart moves in a breakdown. Project management steps map tasks and assign clear roles. Change management and innovation keep teams agile amid regulatory updates.

Resilience grows with continuous learning, self-awareness and hands-on drills.

Proficiency in Supply Chain Technology and Tools

Logistics managers harness enterprise resource planning (ERP), warehouse management systems (WMS) and transport management systems (TMS) to boost operations. They track inventory in real time, cut errors and speed up delivery.

AI and IoT sensors send live data to dashboards. Robotics handle sorting and packing with tight accuracy. Blockchain links each scan, so teams see every move.

New managers start with basic stock-control software and simple analytics tools. Mid-level pros build custom dashboards and use AI to forecast demand. Senior teams install robotic arms in warehouses and test driverless vehicles on docks.

They upskill with online courses to master automation, IoT and blockchain tools.

Knowledge of Regulatory and Compliance Requirements

A clear grasp of international trade laws and transport regulations helps you avoid costly fines. You apply safety standards and customs compliance for daily operations, from shipping classification codes to export declarations.

Managers use risk management tools, conduct risk assessments and build contingency plans that protect supply chain systems from natural disasters or geopolitical events, so you never drop the ball.

They mix data analysis, project management and active listening during team sessions to boost supply chain efficiency.

Logisticians run training on environmental compliance checklist and reverse logistics to match carbon rules. They pair warehouse management systems, AI tools and strong communication skills to track goods and keep service quality high, like a seasoned juggler balancing orders.

Studying global trade agreements and green regulations sharpens financial acumen and digital literacy. It also hones negotiation skills.

Takeaways

Future logistics managers need a wide skillset, from data analysis to team leadership. Active listening and negotiation skills calm heated talks. They work faster than a decongestant clears a runny nose.

Leveraging artificial intelligence and warehouse software spots bottlenecks early. Smart planning, risk management, and digital transformation keep supply chains nimble and efficient.

With these talents, you can steer operations through storms and land on time.

FAQs on Essential Skills for Future Logistics Managers

1. What data analysis skills do future logistics managers need?

They must analyze data and read statistics without fuss. They spot market trends early. They find supply chain risks before they bite. This work boosts operational efficiency.

2. What communication skills matter most in logistics?

Managers need clear written communication for reports, and active listening in meetings. They read body language to catch hidden cues. They handle negotiations with suppliers and carriers. Strong skills build lasting partner relations.

3. How do managers use risk management to protect the supply chain?

They build contingency plans for storms, cyber security threats, or staff vacancy. They guard brand loyalty and reputation. This work fuels organizational resilience when trouble strikes.

4. Why master warehouse management systems, digital transformation, and artificial intelligence?

They use computer programs and robots to track inventory and speed orders. They juggle dimensional weight rules, first-in, first-out rotation, and just-in-time flow. This trio drives supply chain efficiency every step of the way.

5. What leadership style suits future logistics managers?

An empathetic style lifts employee engagement, like a captain who hears every sailor. It guides smooth change management. It also sparks creativity and stronger team bonds, boosting operational efficiency.

6. Why are financial acumen and strategic planning vital for logistics?

Managers track costs, plan budgets, and forecast expenses. They build a solid strategy for supply chain management and market trends. This skillset steers the ship toward profit and smooth operations.