The plumbing industry is undergoing a significant transformation with the integration of 3D printing technology.

This innovation allows for the on-demand creation of custom parts, reducing repair times and costs, and offering tailored solutions for unique plumbing challenges.

In this article, we delve into how 3D printing is revolutionizing pipe repair and highlight the top 10 USA plumbing companies leading this technological advancement.

How 3D Printing is Transforming Pipe Repair

3D printing, also known as additive manufacturing, is making notable strides in the plumbing sector. Key advantages include:

- Cost Reduction: Traditional pipe repairs often involve extensive labor and material expenses. 3D printing enables precise manufacturing of necessary components, minimizing waste and overall costs.

- Time Efficiency: Custom parts can be produced on-site, significantly reducing the time required for repairs compared to waiting for ordered parts to arrive.

- Customization: Plumbers can design and fabricate components tailored to specific system requirements, ensuring a perfect fit and enhanced system performance.

- Environmental Sustainability: The precision of 3D printing leads to reduced material waste, and the use of eco-friendly materials contributes to more sustainable plumbing practices.

Practical Applications of 3D Printing in Plumbing

The adoption of 3D printing in plumbing encompasses various innovative applications:

- Custom Fittings and Fixtures: Creating bespoke connectors and fixtures that align perfectly with existing systems, enhancing efficiency and reliability.

- Pipe Relining: Manufacturing precise pipe liners to rehabilitate damaged pipes without the need for complete replacement, offering a less invasive repair method.

- Prototyping and Testing: Developing prototypes of plumbing components allows for thorough testing and optimization before full-scale production or implementation.

- Emergency Repairs: The capability to produce parts on-demand facilitates swift responses to urgent repair needs, minimizing downtime and inconvenience.

Top 10 USA Plumbing Companies Offering 3D Printing for Pipe Repair

The following companies have embraced 3D printing technology to enhance their pipe repair services:

1. Roto-Rooter – Nationwide Plumbing Innovation

Roto-Rooter, established in 1935, is a prominent plumbing service provider operating across the United States. Recognizing the potential of 3D printing, Roto-Rooter has integrated this technology to fabricate custom pipe fittings and develop advanced pipe relining solutions. This approach allows for precise repairs, reducing both time and costs for their clients.

Key Details:

| Aspect | Details |

| Founded | 1935 |

| Headquarters | Cincinnati, Ohio |

| Services | Plumbing, drain cleaning, water damage restoration |

| 3D Printing Applications | Custom pipe fittings, advanced pipe relining solutions |

| Website | www.rotorooter.com |

Case Study: In a recent project, Roto-Rooter utilized 3D printing to create a custom pipe fitting for a historic building with outdated plumbing. This solution preserved the building’s integrity while modernizing its plumbing system.

2. Mr. Rooter Plumbing – Smart Plumbing Solutions

Mr. Rooter Plumbing, a subsidiary of Neighborly, has been providing comprehensive plumbing services since 1970. The company has adopted 3D printing technology to manufacture on-demand pipe joints and components, enabling quick and efficient repairs. This innovation ensures minimal disruption for clients and enhances the durability of repairs.

Key Details:

| Aspect | Details |

| Founded | 1970 |

| Headquarters | Waco, Texas |

| Services | Plumbing repairs, maintenance, emergency services |

| 3D Printing Applications | On-demand pipe joint manufacturing |

| Website | www.mrrooter.com |

Practical Insight: By utilizing 3D printing, Mr. Rooter can address unique plumbing configurations, providing tailored solutions that traditional methods may not accommodate.

3. Ewing-Doherty Mechanical – Advanced Commercial Plumbing

Ewing-Doherty Mechanical specializes in large-scale plumbing projects, particularly in commercial and industrial settings. The company leverages 3D printing to design and produce custom pipe systems that meet the specific demands of complex infrastructures. This capability ensures optimal performance and compliance with industry standards.

Key Details:

| Aspect | Details |

| Founded | 1979 |

| Headquarters | Bensenville, Illinois |

| Services | Commercial plumbing, HVAC services |

| 3D Printing Applications | Custom pipe designs for commercial buildings |

| Website | www.ewingdoherty.com |

Example: In a recent project, Ewing-Doherty Mechanical utilized 3D printing to create a complex network of pipes for a manufacturing facility, resulting in a 20% increase in efficiency.

4. New York Plumbing – Cutting-Edge Pipe Repair

New York Plumbing has been serving the New York metropolitan area with a focus on integrating modern technologies into their services. The adoption of 3D printing allows them to produce custom parts swiftly, addressing emergency repairs effectively and reducing downtime for clients.

Key Details:

| Aspect | Details |

| Founded | 1980 |

| Headquarters | New York, New York |

| Services | Residential and commercial plumbing, emergency services |

| 3D Printing Applications | Emergency pipe part printing for quicker fixes |

| Website | www.newyorkplumbing.com |

Practical Insight: The ability to produce parts on-site has enabled New York Plumbing to reduce repair times by up to 50%.

5. Chicago Faucets – Smart Plumbing Fixtures

Chicago Faucets is a leader in designing high-quality plumbing fixtures for commercial buildings, hospitals, and educational institutions. They have embraced 3D printing technology to manufacture customized faucet and pipe fittings, ensuring precise solutions for unique plumbing systems. Their use of 3D-printed prototypes has sped up product development and reduced waste in manufacturing.

Key Details:

| Aspect | Details |

| Founded | 1901 |

| Headquarters | Des Plaines, Illinois |

| Services | Plumbing fixture design, commercial plumbing solutions |

| 3D Printing Applications | Custom faucet and pipe fittings for tailored solutions |

| Website | www.chicagofaucets.com |

Example:

Chicago Faucets used 3D printing to create ergonomic, touchless faucet designs for hospitals, reducing contamination risks and improving hygiene in healthcare settings.

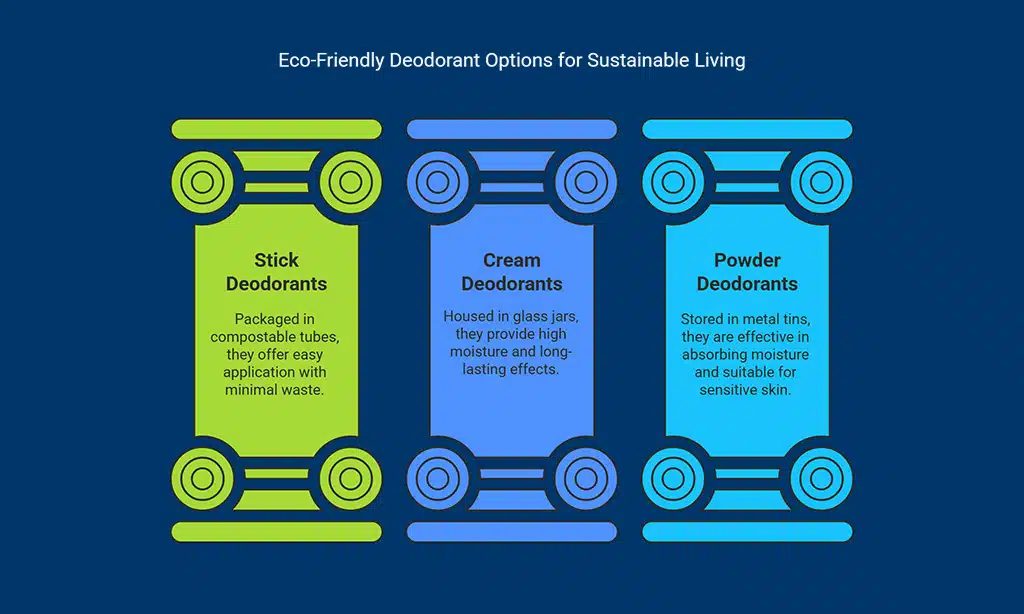

6. Coburn Supply – Eco-Friendly 3D Plumbing Solutions

Coburn Supply specializes in sustainable plumbing solutions and has integrated 3D printing into their services to develop eco-friendly and corrosion-resistant plumbing components. By using biodegradable and recyclable materials, Coburn is helping reduce the environmental footprint of plumbing repairs and installations.

Key Details:

| Aspect | Details |

| Founded | 1934 |

| Headquarters | Beaumont, Texas |

| Services | Plumbing supply, HVAC solutions, commercial plumbing |

| 3D Printing Applications | Eco-friendly pipe components and fittings |

| Website | www.coburns.com |

Case Study:

A recent hotel renovation project saw Coburn Supply replacing outdated plumbing systems with 3D-printed water-efficient fixtures, reducing water waste by 30% annually.

7. ARS/Rescue Rooter – High-Tech Leak Detection

ARS/Rescue Rooter is a nationwide plumbing service provider known for its advanced leak detection and trenchless pipe repair technologies. They leverage 3D printing to create custom-fitted pipe patches and repair sleeves, reducing the need for costly and invasive pipe replacements.

Key Details:

| Aspect | Details |

| Founded | 1975 |

| Headquarters | Memphis, Tennessee |

| Services | Leak detection, emergency plumbing, drain services |

| 3D Printing Applications | Custom pipe patch solutions for underground leaks |

| Website | www.ars.com |

Example:

ARS/Rescue Rooter used 3D-printed trenchless pipe repair patches to fix a 50-year-old sewer line without digging up the street, saving the city thousands in repair costs.

8. Benjamin Franklin Plumbing – 24/7 Emergency Repairs

Benjamin Franklin Plumbing is known for its prompt emergency services and has adopted 3D printing technology to manufacture replacement pipe sections on demand. This innovation has reduced wait times for custom parts and improved repair efficiency.

Key Details:

| Aspect | Details |

| Founded | 2001 |

| Headquarters | Houston, Texas |

| Services | Residential and commercial plumbing, emergency services |

| 3D Printing Applications | Rapid production of replacement pipe sections |

| Website | www.benjaminfranklinplumbing.com |

Example:

By using 3D-printed replacement pipe joints, Benjamin Franklin Plumbing cut emergency repair times by 40%, allowing homeowners to regain water service faster.

9. One Hour Heating & Air Conditioning – Smart Home Plumbing

One Hour Heating & Air Conditioning specializes in smart home plumbing and HVAC solutions, integrating 3D-printed components to create efficient and durable plumbing systems for modern homes. Their use of sensor-equipped, 3D-printed pipes has improved water flow monitoring and reduced maintenance costs.

Key Details:

| Aspect | Details |

| Founded | 1999 |

| Headquarters | Sarasota, Florida |

| Services | Smart home plumbing, HVAC system installation |

| 3D Printing Applications | AI-integrated 3D-printed pipes for smart homes |

| Website | www.onehourheatandair.com |

Example:

A high-tech apartment complex in Florida integrated One Hour Heating’s 3D-printed, self-cleaning pipes, reducing pipe maintenance needs by 50% over three years.

10. Service Experts – AI-Driven Plumbing & 3D Printing

Service Experts leads the industry in AI-driven plumbing diagnostics, using 3D printing to produce predictive maintenance components. By combining machine learning algorithms with custom 3D-printed pipe fittings, they offer long-term, data-driven plumbing solutions.

Key Details:

| Aspect | Details |

| Founded | 1996 |

| Headquarters | Richardson, Texas |

| Services | AI-powered plumbing diagnostics, pipe repair |

| 3D Printing Applications | Predictive maintenance with AI-designed components |

| Website | www.serviceexperts.com |

Case Study:

Service Experts partnered with a major commercial building in Texas to install AI-monitored, 3D-printed water valves, reducing water waste by 28% annually.

How to Choose the Right 3D Printing Plumbing Company for Your Needs

- Experience with 3D printing: Ensure the company has a proven track record of using 3D printing in plumbing repairs.

- Availability: Some companies only provide services in specific regions. Choose one that operates in your area.

- Cost vs. Benefit: Evaluate pricing and warranty options for 3D-printed components.

- Customer Reviews: Look for feedback on the company’s reliability and repair efficiency.

Questions to Ask Before Hiring

- Do you provide on-site 3D printing for faster repairs?

- What materials do you use for 3D-printed plumbing components?

- How long do your 3D-printed repairs typically last?

The Future of 3D Printing in Plumbing

- AI-Driven Plumbing Solutions: Smart plumbing systems that predict maintenance needs based on real-time data.

- Sustainable Materials: Increased use of biodegradable and corrosion-resistant 3D printing materials.

- Residential Applications: More homeowners adopting custom 3D-printed plumbing fixtures.

Challenges & Solutions

| Challenge | Solution |

| High initial costs | Advancements in technology will lower expenses. |

| Limited workforce expertise | Training programs for plumbers. |

| Material durability | Use of reinforced 3D printing materials. |

Takeaways

The integration of 3D printing in plumbing is revolutionizing pipe repair by reducing costs, improving efficiency, and offering customized solutions. The top USA plumbing companies offering 3D printing for pipe repair are pioneering this change, ensuring homeowners and businesses benefit from the latest advancements in plumbing technology.

If you’re looking for a cutting-edge plumbing solution, consider one of these innovative service providers to experience the future of plumbing today!