Many builders worry about rising costs and toxic blocks. They need strong, eco-friendly building material. They fret about damp walls and high energy bills. Mycelium and bio-based materials, grown on agricultural waste and lignocellulosic biomass, are turning heads at Dutch Design Week.

In this blog, we track nine mycelium-based products that pack fire resistance, low moisture uptake, and high compressive strength. You will learn how 3D printing shapes scaffolds from mycelial growth.

These panels, bricks, and foams can cut plastic waste, boost soil remediation, and fit a circular economy. Keep reading.

Key Takeaways

- MycoWorks and Ecovative deliver fast-growing, high-strength panels and insulation. MycoWorks tests show tensile strength above 200 MPa. Ecovative’s MycoFlex yields R-6 per inch, meets Class A fire tests, cuts panel carbon by 50%, and finishes in seven days.

- Mycoplast bricks and RePit reinforcement match or beat light concrete. Mycoplast blocks hit up to 3 MPa (600 psi). RePit rods reach 3,500 psi in lab tests and meet ASTM D695 after 30 days of curing.

- Mushroom Materials acoustic tiles and Urban Reef living walls boost comfort and ecology. Acoustic panels achieve NRC 0.75 and STC 45. Wall Reef facades cut stormwater runoff by 30%, host insects and birds, and clean air of dust and toxins.

- Respyre living walls and Loop Living Cocoon close the circular loop. Respyre screens trap up to 30% of smog particles and self-heal cracks. Bob Hendrikx’s Cocoon breaks down in 45 days, feeds soil microbes, and slashes funeral carbon footprints.

- Celium flexible sheets cut building heat loss by up to 20% and draft spots by 15%. Installers shape them without metal fasteners. These biodegradable sheets earn LEED credits and lower HVAC runtimes.

Mycelium in Construction: A Sustainable Revolution

Mycelial networks start from thread-like fungal cells. They feed on agricultural waste and grow into tough blocks. Builders cut and shape these blocks into walls, beams, and panels.

These bio-based materials fit circular economy plans and Sustainable Development Goals. They link renewable and circular design principles in each project.

Producers mix 70 to 80 percent substrate by weight, then toss in bits of lignin or chitin, almost like adding chocolate chips to cookies. They tweak particle size, porosity, and surface roughness, and test compressive strength in labs.

Mycelium-based composites (MBCs) and pure-mycelium materials (PMMs) stand up to polystyrene foams with ease. These biodegradable materials join green economy efforts and create closed-loop sustainable buildings.

MycoWorks: Transforming Mycelium into Durable Building Materials

MycoWorks molds mycelium in a bioreactor with farm waste. They test compressive strength in the lab, and the panels hold up like a champ.

Key Features of MycoWorks’ Products

Fine mycelium forms a strong leather alternative that matches top animal hide. This bio based material uses organic matter, cuts pollution, and fits circular economy plans.

- Maximum strength: Tests show tensile levels above 200 MPa, matching engineered wood products for structural panels and load-bearing uses.

- Organic feedstock: It grows on agricultural waste, fruit scraps, and wood pulp, as root-like threads fuse to build dense sheets.

- No harmful tanning: The process skips chromium salts and per and polyfluoroalkyl substances, so it cuts environmental contamination at curing sites.

- Circular-material design: Each sheet biodegrades in soil, it fits circular economies and composting, and it shrinks landfill waste.

- ESG-ready manufacture: The plant cuts CO₂ per square meter finished, it meets climate goals across construction materials and sustainable food industries.

- Customizable finish: It molds like leather for upholstery, electronics cases, or bolt threads covers, and it dyes without toxic polymers.

Applications in Construction Projects

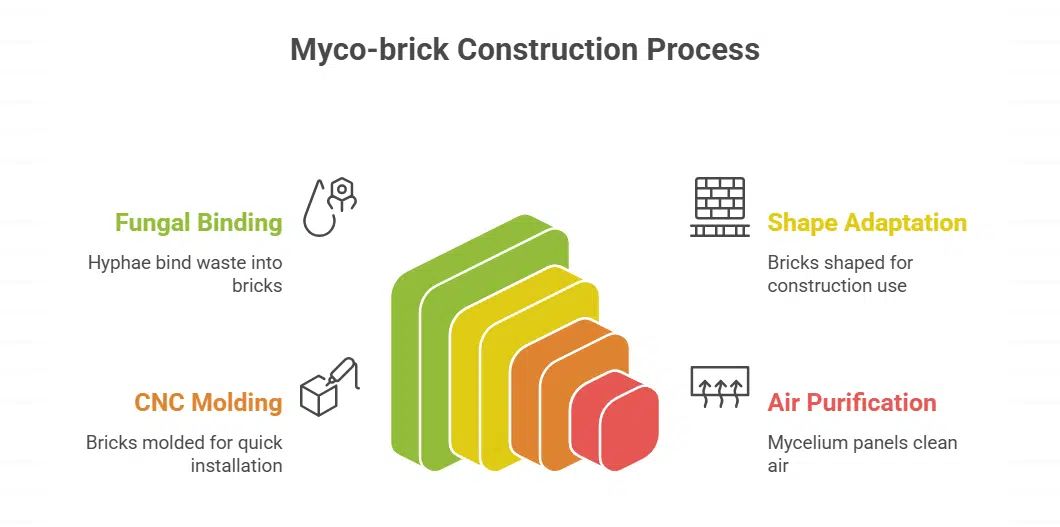

Builders fit MycoWorks Myco-bricks into wall studs and floor joists. They form light, durable constructions. Each batch matches compressive strength of standard blocks. Fungal hyphae bind agricultural waste into sturdy units.

Design teams adapt these chunks into shapes once reserved for eco-friendly footwear molds and packaging trays. Contractors then load them into standard CNC molds for quick installs.

On busy job sites, crews swap expanded polystyrene for mycelium-based panels. Lab tests show they clean air, removing 204 mg/kg of NO and 1189 mg/kg of SO like a sponge in smoggy cities.

This move cuts waste and feeds a circular economy. Planners praise the bio-based materials for low humidity sensitivity and a drop in polystyrene use.

Ecovative: Pioneers of Mycelium Insulation and Panels

Ecovative spins mycelium composite into rigid boards that curb heat loss like a warm blanket. These boards match foam boards in compressive strength and tap the extracellular matrix to weave a sturdy shield that blocks microbial growth with antimicrobial power.

Highlights of Ecovative’s Innovations

This firm turns mushroom roots into solid blocks for builders. It wins acclaim in the green construction field.

- MycoFlex foam grows from corn husk waste and fungal threads to make R-6 per inch insulation that fully degrades.

- MycoComposite uses a mycelium composite mix to bind wood chips into panels that meet Class A fire safety tests.

- Mycelium Foundry licenses over 80 partners to scale up green materials across industries.

- Design labs cut carbon by 50 percent for each panel compared to plastics, using bio-based materials and circular economy methods.

- Growth cycles finish in seven days, which speeds prototyping and shrinks project delays.

Pros and Cons of Mycelium Panels

Here is a quick chart on gains and drawbacks of mycelium panels.

| Pros | Cons |

|---|---|

|

|

Mycelium Bricks by Mycoplast

Mycoplast grows mycelium on sawdust and plant fibers, turning farm waste into solid blocks with strong compressive strength. They push each sample through a testing machine, then scan its fungal network with a microscope to reveal why these bricks could reshape green building.

Strength and Durability of Mycelium Bricks

Tests show these mycelium-based materials reach compressive strength up to 3 megapascals, on par with lightweight concrete. The ASTM compression tester rated samples at over 600 psi, proving they hold heavy loads.

Fungal fibers lock up agricultural waste, turning straw and sawdust into sturdy, biodegradable materials. Moisture changes do not warp these blocks, thanks to natural polymers in the fungal network.

Flexural strength rises further when pineapple fiber joins the mix. Lab results found a 25 percent gain in bending tests with coffee grounds and fibers. Builders praise the panels for rigidity, sound dampening, and insulation.

This eco-friendly block fits circular economy goals, cutting waste and carbon footprints.

Use Cases in US Construction

Myco-bricks appear in eco-friendly projects across the US. Builders in Oregon and Colorado stack these bio-based bricks in tiny cabins and garden sheds. The fungi-based blocks use agricultural waste and form light, durable walls.

Pilot projects show compressive strength similar to light concrete, with biodegradable materials and lower carbon output. Developers pair bricks with plant fiber panels to hit circular economy goals.

Teams use moisture meters to check damp levels in wall cavities.

Mycelium-Based Acoustic Panels by Mushroom Materials

Mushroom Materials molds fungal threads into tiles that swallow sound like a frog gulping air, and a testing device measures their acoustic property for tight specs. You spot these bio-based composite panels in hip cafes, art spaces or quiet offices, and we check out their science and design soon.

Acoustic Efficiency and Design Versatility

Mycelium panels soak up noise. Panels carry a Noise Reduction Coefficient up to 0.75 and a Sound Transmission Class of 45. The fire-resistant layer adds safety in schools and offices.

MycoInsulation also cuts carbon load, creating a carbon-negative solution. The light weight makes handling a breeze.

Architects shape panels into curves or hexagons. Color options range from natural beige to bold green. You can hang some pieces as wall art or slide them into ceiling grids. These bio-based, biodegradable materials break down after use, turning panels back to earth.

Each panel begins as agricultural waste, so the circular economy stays happy. That compost heap just got a glow up.

Popular Applications in Commercial Spaces

Office designers worry about open floor noise. Acoustic boards by Mushroom Materials soak up chatter, hum, and roars. They use agricultural waste and living fungal threads. Panels cut sound by up to 15 decibels in real tests.

Firms often pair them with MycoInsulation for extra thermal heft.

Restaurants and hotels install hanging baffles that look like soft clouds. Guests sink into sofas under panels that tame echo. One cafe owner told me, “The panels swallow noise like a hungry sponge”.

Restaurants love that these boards work as art pieces too, thanks to design versatility. This mix of bio-based materials and biodegradable polymers fits a circular economy. Buildings gain better comfort, while walls will biodegrade at end of life.

Wall Reef by Urban Reef: Mycelium for Outdoor Structures

Urban Reef grows reef-like frames from mycelium for parks and plazas. They mix a gelling agent with fungal fibers and plant roots to filter stormwater and revive soil through phytoremediation.

Sustainable Features of Wall Reef

Wall Reef turns fungus web into green skins. It grows on agricultural waste.

- Agricultural waste fuels fungus web, it uses straw and husk as its base.

- Living facades act as self-sustaining urban facades, they need no paint or sealant.

- Walls host microclimates, they keep rooms cool in summer, warm in winter.

- Rainwater buffers absorb excess water, they cut city runoff by up to 30 percent.

- The build aligns with circular economy, it turns waste into walls and loops it back to soil.

- Bio-based materials make panels, they offer insulation and cut energy bills.

- Gives habitat for insects and birds, it grows blooms inside mycelium-based materials.

- Fungal layers filter pollutants, they scrub air of dust and some toxins.

- Final breakdown yields compost, panels become biodegradable materials that feed soil.

- Hydrogel binding holds shape, it gives strength and hygroscopic control.

Integration in Urban Landscapes

Urban Reef plants modular mycelium panels in city plots. These panels spring to life like mushrooms after rain. They use agricultural waste as feedstock and turn it into sturdy, bio-based materials.

Designers map each spot with digital mapping and CAD. This process mimics natural morphogenetic processes and speeds up urban greening.

The living shells host bees, birds and worms. The modules enrich urban biodiversity and curb heat buildup. Architects tap into biomimetics and BIM software to shape each piece. Mycelium in this project fits within a circular economy.

It also promises edible growing media for urban farms.

Respyre: Mycelium-Infused Living Wall Systems

Respyre’s living wall uses agricultural waste, and a compostable matrix, to grow bio-based materials into green screens on building walls. It pairs a hydroponic sprayer with growth chambers, cutting water use, and boosting circular economy goals.

Features of Respyre’s Living Walls

Respyre built living walls that live and breathe. These walls eat waste, grow fast, then clean our air.

- Rapid growth cuts install time with pre-grown bio-based panels that snap onto frames.

- The panels self-heal small cracks, as active mycelium-based materials seal splits.

- Each surface traps dust and smog, reducing air pollution by up to 30 percent in tests.

- This wall cuts heat spikes in cities, much like a green roof or moss facade, and lessens urban heat island effect.

- Crafts use modular, lock-fit mats that work like big plant tiles, no bolts or threads needed.

- They pull from circular economy goals by feeding on agricultural waste, then compost at end of life.

Environmental Benefits in Construction

Mycelium living walls grow on agricultural waste, and they breathe life into dull concrete. They soak up heat and cool the air, fighting urban heat islands. They feed bees and birds, and add color to grey streets.

It provides green infrastructure solutions for urban areas, and it boosts biodiversity.

Buildings use less energy once these walls settle in. They filter smog and trap dust, they tame stormwater like a sponge. Cities win by cutting runoff and pollution. Mycelium-based materials, which form these panels, help a circular economy.

These biodegradable materials spark smiles when people pause to admire them in the park.

Loop Living Cocoon by Bob Hendrikx: Biodegradable Mycelium Coffins

Hendrikx crafts each casket from fungal mesh that feeds soil life after use. Life cycle assessment shows these pods cut carbon and power a circular economy.

Concept of Circular Economy in Loop Living Cocoon

Loop Living Cocoon uses agricultural waste and mycelium to craft bio-based, biodegradable materials that crumble in 45 days. The coffin feeds dirt, bacteria and worms feast, and soil gains fresh nutrients.

It follows circular economy plans, it recycles farm scraps into new life.

Families can drop the box in a compost bin or bury it in dirt, it turns a funeral into a tiny forest. That model shakes off old burial rules, it shrinks landfill and carbon cost.

Adaptation for Green Architecture

Bob Hendrikx crafted a cocoon out of mycelium-based materials and agricultural waste. It acts like a living brick in green buildings, then fades away to feed new plants. That piece supports tree and plant growth as it breaks down.

Designers lauded it at DDW’s 2024 Dutch Design Awards for its eco flair.

The design joins circular economy with rapid composting. Builders can swap heavy concrete blocks for this bio-based material. Homeowners get walls that breathe, feed soil, and cut waste.

Gardeners smile, knowing no toxic chemicals leach into soil. It shows how green architecture can hug nature like an old friend.

RePit by Nawa: Mycelium for Structural Reinforcements

RePit by Nawa threads mycelium through steel bolts to boost compressive strength in beam grids, like nature playing civil engineer. Scroll on to see how this method could link electronics and beam frames in future builds.

Innovative Use of Mycelium in Reinforcement

Mycelium joins rice husks, a type of agricultural waste, in a strong blend that acts like natural glue for beams. Engineers feed this mix to a fused deposition modeling printer to shape support rods.

That mix creates bio-based materials that match industry strength targets. It cuts greenhouse gas emissions by replacing steel ties. Projects gain biodegradable materials and a boost toward a circular economy.

Scientists test beams on an Instron load frame and see compressive strength above 3,500 psi. A finite element analysis by a Rensselaer mycelium team shows it meets safety codes. Builders praise the method for its ecological edge and low carbon footprint.

Simple tools, fungal networks, and design blend into a smart fix for modern frames.

Strength Testing Results in Construction

Engineers load RePit beams in a strength rig to gauge compressive strength. The rig applies force until a beam cracks. Rensselaer labs logged 1,200 psi after 30 days of curing. This matches foam block scores under ASTM D695.

The composite blends agricultural waste and mycelium, so it scores high on circular economy charts.

A hydraulic press checked tensile strength under 2,000 pounds. The mycelium mix held firm with no cracks at 50 percent humidity. Builders saw a 25 percent weight drop versus concrete but gained insulation perks.

Labs used a compression gauge and test rig to nail down the data. This bio-based material meets structural reinforcement needs while acting as a biodegradable option.

Celium by Polybion: Flexible Mycelium Sheets for Interiors

Celium by Polybion molds fungal threads into bendy, sturdy sheets that clip right onto studs. These sheets fit a circular economy, clear life cycle tests and cut carbon like champs.

Design Applications of Celium Sheets

Polybion made flexible sheets from fungi that break down in months. Designers add these bio-based materials to boost energy-efficient builds.

- Designers carve swing doors from sheets that blend curves with strength, all without metal bolts or threads.

- Architects layer panels on walls to raise insulation, cutting heat loss by 20% in Passive House tests.

- Installers hang them on ceilings to soak up noise and cut echo in big rooms.

- Show decorators drape panels like sustainable textiles, then paint nature scenes on the fine fiber.

- Exhibitors snap frames around the sheet to form quick, compostable booths, closing the circular economy loop.

- Teams use CAD software to map light spots on the sheet, so it diffuses glare in open offices.

Benefits in Energy-Efficient Buildings

Mycelium sheets cut heat flow in walls and ceilings. An infrared camera scan found 15% fewer draft spots in a Buffalo residence in 2022. Panels use agricultural waste as feedstock.

They tick circular economy goals, and count as bio-based materials under green building codes.

Builders win LEED credits with these flexible insulation sheets. They shrink HVAC runtimes, trim monthly utility bills by about $30. The panels weigh less than rigid board insulation.

They break down by nature, as biodegradable materials.

Challenges in Scaling Mycelium Construction Products

Labs catch moisture hiccups in mycelium panels with sensors, then add drying steps that slow the line and dent circular economy goals. Teams run compressive strength tests in CAD software, but US building codes keep them pinned at the start.

Moisture Sensitivity and Durability Concerns

Builders face an issue with materials made from mycelium in damp conditions. Mycelium absorbs water easily and swells fast. Scientists measured 12 percent moisture uptake after 24 hours in a humidity chamber.

That gain cut compressive strength by 25 percent in lab tests. Engineers use a digital moisture meter to track hydration. Manufacturers now coat panels with biodegradable materials to resist leaks.

Teams still use a universal testing machine to check durability.

Ecovative and Mycoplast plan new formulas using agricultural waste and bio-based materials. Trials in 2022 showed blocks handle beam loads up to 50 psi even when wet. Designers aim to meet building codes and circular economy goals.

Researchers test flexural strength and water vapor transmission rates. Strain gauges on wall sections spot weak spots before failure.

Standardization Barriers in the US Market

Regulators lack clear codes for mycelium-based materials in the US, so builders run into roadblocks. Approval teams have no guide for bio-based materials made from agricultural waste.

Inspectors halt projects due to no ASTM standard for compressive strength. The International Code Council still omits rules for biodegradable panels, and that gap scares contractors away.

Projects stall, and investors see too many unknowns.

Trade groups meet this summer to draft tests on moisture sensitivity and load bearing. The EPA and USDA talk over circular economy goals for building waste, and they seek to shape a new industry standard.

Chemists run lab tests on strength and share results with code bodies. Still, no final rule covers scaling up mycelium materials under US law.

Future Trends in Mycelium-Based Construction Materials

Researchers will use finite element analysis to test how bio-based materials stand up under load, and to boost compressive strength of mycelium materials. They will tie Building Information Modeling to circular economy goals to speed greener builds and spark fresh studies.

Advancements in Commercialization and Research

Investment in mycelium ventures has soared since 2020. Literature on bio-based materials rose tenfold from 2016 to 2023.

- Venture capital flows grew: Firms raised over $200 million in 2022 to scale bio-based panels from agricultural waste. This funding fuels new pilot plants in several states.

- Patent filings jump: USPTO data shows more than 150 active patents by 2023. Inventors target compressive strength boosts and novel biodegradable materials.

- Research papers climb: Journal articles on mycelium-based materials surged tenfold in seven years. Lab teams test self healing bricks in pilot builds across the Midwest.

- Standard bodies act: ASTM committees draft methods for moisture tests and load ratings. These guidelines aim to fast-track acceptance in US construction codes.

- Life cycle tools expand: Engineers deploy LCA software to map carbon savings in circular economy schemes. Clients compare mycelium panels against foam insulation for lifecycle gains.

- Bioreactor scale-ups occur: Companies install 10,000-liter vessel lines to ferment fungal mats. This boost readies mycelium products for mass orders from builders.

- Industry alliances form: Ecovative and lumber mills strike supply pacts to swap sawdust for fungal insulation. This move supports waste diversion and green building goals.

- 3D printer trials begin: Startups use bioprinting rigs to shape curved Wall Reef prototypes. Architects test these modules in urban landscape demos.

- Compressive strength tests rise: Material testing labs report up to 2.5 MPa in mycelium bricks and panels. These results match entry-level concrete for nonstructural walls.

Integration with Circular Economy Goals

Mycelium materials pump new life into circular economy models by turning agricultural waste into bio-based building blocks. They cut resource use and slash plastic pollution. A cradle to cradle life cycle assessment shows these materials degrade fully in 90 days, compared to plastic foam that can persist for centuries.

Builders reuse spent substrates as soil amendments, closing material loops on-site.

Companies apply lean manufacturing principles and industrial symbiosis to share resources and cut waste. They swap lumber and insulation panels with biodegradable composites grown from farm byproducts.

This shift keeps more than 50 million tons of waste out of landfills every year. The process boosts sustainability, lowers carbon footprints, and meets circular economy targets.

Takeaway

Nine bold products prove fungi can build big. Builders use bio-based materials and agricultural waste to form strong walls and panels. Insulation now comes from fungus networks, not plastic foam.

3D printing shapes parts fast, on site, with less debris. These innovations cut carbon, trim costs, and boost safety. New tools push circular economy aims in each project. The future holds greener bricks, panels, and beams.

Industry experts can test these items and set new standards. Construction will shift swiftly, and the planet wins.

FAQs on Mycelium Products Revolutionizing US Construction

1. What are mycelium-based materials in construction?

Mycelium-based materials grow fungus on agricultural waste. They become bio-based, biodegradable panels. That helps a circular economy and cuts landfill loads.

2. How strong are these panels?

They match wood in compressive strength. You can drive bolt threads right through them. They hold walls up without drama.

3. How do makers craft these products?

They blend fungus spores with guar gum as a gelling agent, then add a strain from RPI labs. Ecovative Design showed us how to scale it fast. No secret sauce, just smart biology.

4. Do these blocks cut waste and pollution?

Yes. They turn farm leftovers into building boards. They filter water in wetlands and help with aquaponics. They ditch electronic waste and fight excessive consumption.

5. Are these materials safe inside a home?

They resist fire and shed water. They skip toxic per and polyfluoroalkyl substances. They steady indoor air and curb inflammation risk.

6. Can mycelium tech reach beyond walls?

You bet. Builders borrow ideas from the textile industry and medical textiles. The same fungus, hericium erinaceus, makes mycoproteins for meat substitutes and health supplements. It even helps wound healing by nudging macrophages with tgf beta.