Many supply chains stall when parts arrive late or stock runs out, and teams feel stuck. A digital twin is a virtual model of your network that uses real-time data and artificial intelligence to mirror every move, spot trouble, and help plan fixes.

In this post, we look at five big names that use digital twins for predictive analytics, scenario planning, and better inventory management. You will learn how Mars cuts shipment delays, how Rolls-Royce boosts engine uptime, and how smart devices and learning models power real-time visibility.

Read on.

Key Takeaways

- Mars links IoT sensors onforklifts and trucks to digital twins. They run predictive maintenance and machine-learning route tests to cut fuel use, trim transit time, and forecast demand from past sales so they avoid stockouts.

- Rolls-Royce runs engine digital twins with real-time data and AI. Teams spot wear, schedule predictive maintenance, and boost engine uptime across their fleets.

- Bayer Crop Science builds virtual factories with macro-level models and live sensor feeds. They simulate workflows like a flight simulator to cut waste, find bottlenecks, and guide R&D before full production.

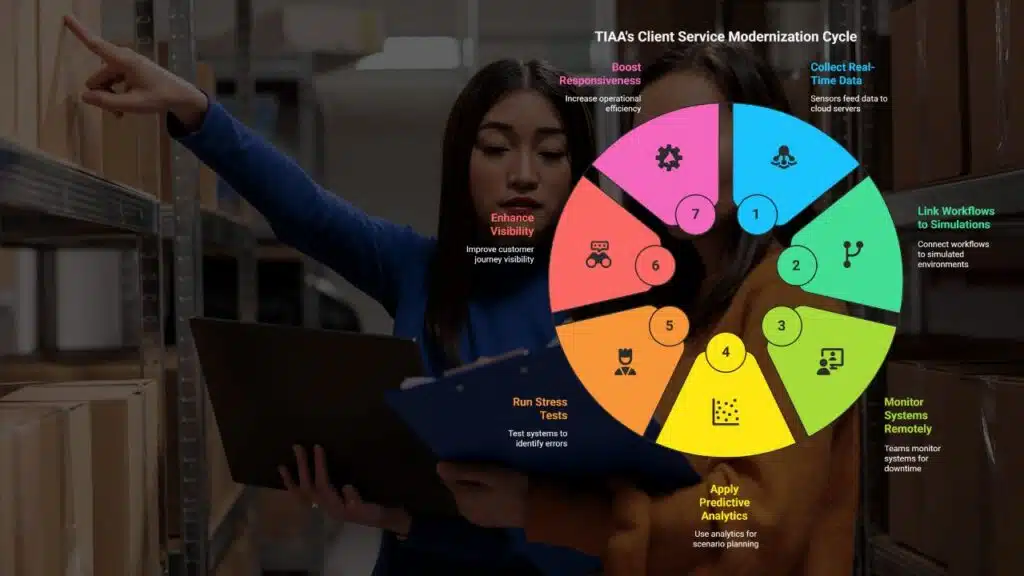

- TIAA merges IoT devices, AI, and machine learning in one digital twin of its support systems. It runs stress tests, drives automated decisions, and aims for zero defects in client service operations.

- NTT IndyCar fits 25 race cars and key gear with IoT-linked twins via AWS IoT TwinMaker. Teams track each brake pad and tire, run predictive maintenance, and optimize logistics for all 17 races.

Mars: Optimizing Supply Chain Efficiency

Mars uses digital twins to track assets in real time. The digital models link IoT devices on forklifts and trucks to cloud computing. They run predictive maintenance routines to stop breakdowns before they happen.

Analysts test delivery routes with machine learning, cutting fuel use and transit time. This setup gives teams clear supply chain visibility and boosts operational efficiency.

Teams tap digital twins for demand forecasting. Models pull past sales and trend data to predict needs. Simulations of warehouse inventory help avoid stockouts and improve inventory management.

Mars uses scenario planning to speed up production and cut waste. Remote monitoring cuts the need for onsite checks in risky sites. Mars checks cost and complexity so leaders invest only in viable digital twins.

Bayer Crop Science: Virtual Factories for Strategic Planning

Virtual factories use macro-level models to test network setups and spot weakness. They run simulations like a flight simulator, showing how a plant, its equipment, and workflows interact.

These tests drive scenario planning, cut waste, and boost operational efficiency. Sensors feed real-time data into digital twins, letting supply chain managers catch disruptions early.

They tweak distribution layouts and suppliers to slash bottlenecks.

System twins map unit functions to fix leaks in performance. The company uses those twins to track materials for recycling at end of life. Teams tap predictive analytics and real-time visibility to forecast downtime and guide R&D to refine processes before full production.

IBM and Siemens built a Service Lifecycle Management solution that links design, production, and maintenance in one platform. This platform aids dynamic planning, optimizes resources, cuts risk, and trims carbon footprint.

TIAA: Simplifying Client Service Operations

TIAA deploys digital twins to modernize client service operations. The tool merges IoT devices, AI, and machine learning algorithms to deliver advanced cognitive tasks in a single interface.

Connected sensors feed real-time data to cloud servers. Model links tie service workflows to simulated environments for continuous improvement.

Teams cut downtime and aim for zero defects across internal support systems with remote monitoring and automated decision making. Predictive analytics and prescriptive analytics guide scenario planning before new support policies live.

Simulation runs stress tests on internal systems to spot errors and reduce defects. Real-time visibility gives support reps a clear view of each customer journey. Data science supports these changes and boosts responsiveness, operational efficiency, and reliability.

NTT Indycar: Improving Real-Time Monitoring and Maintenance

NTT IndyCar runs digital twins on cars and gear. Engineers link IoT devices on 25 race vehicles with cloud infrastructure servers. Component twins track each brake pad and tire in real time.

Data science and AI spot wear and trigger predictive maintenance hours before a breakdown. A virtual simulation of parts stock cuts safety stock and speeds repairs. Remote diagnostics boost supply chain visibility for fast fixes.

Teams call it the digital pit crew.

Race support teams use real-time analytics to plan transport routes. Modeling and simulation drives optimized logistics for event gear and spares. Supply chain resilience drops downtime risk at each 17-race schedule stop.

Automated decision making balances warehouse management systems with inventory management. Predictive analytics help forecast demand for tires, engines, and fuel. AWS IoT TwinMaker spots anomalies on track, cutting team costs and waste.

Takeaways

Every firm can spot risks with a digital twin. It links real-time data from IoT sensors and machine learning. This setup makes scenario simulation simple. Teams cut waste fast and plan orders with AI.

ERP software and WMS work with cloud platforms. The path shows better supply chain outcomes.

FAQs

1. What is a digital twin in supply chain management?

A digital twin is a digital mirror of real assets, like trucks or shelves. It ties into iot devices, erp systems, and WMS, so you get real-time data on stock levels and flows. This view boosts supply chain visibility and helps teams steer operations.

2. How do digital twins use predictive analytics and demand forecasting?

Digital twins feed big data analytics with sales and machine data. Data science models then run predictive analytics to spot trends. You get early alerts on what to buy and when, which fuels accurate demand forecasting and dynamic planning.

3. Can digital twins cut risk and waste in the supply chain?

Yes, they catch supply chain disruptions before they bite. Scenario simulation and scenario planning help you test “what if” fixes, like rerouting trucks. This approach drives waste reduction, risk mitigation, and stronger supply chain resilience.

4. How do digital twins boost operational efficiency in warehousing and at distribution centers?

They tie into WMS, fleet management, and erp systems, so every shelf and truck is tracked in real time. You see inventory management gaps, optimize resources, and speed up reverse logistics. The result: better labor productivity and smoother flows.

5. What role do AI and the cloud play in digital twin tech?

Artificial intelligence powers predictive maintenance, so machines get fixed before they break. The cloud stores all real-time visibility data, and it scales with your needs. This mix fits right into industry 4.0 and drives digital transformation.

6. Are there data security or policy issues with digital twins in a global supply chain?

Absolutely. You must guard data security and follow policy rules on who sees what. Good data management and secure connections keep customer experience safe and strengthen supply chain transparency.