ABS plastic is a versatile and resilient material that has been used in various industrial applications for many years. Its strength, durability, and flexibility make it ideal for a wide range of purposes. It is also affordable which makes it an attractive option for businesses seeking to keep costs down while still producing high-quality products. In this article, we will explore why ABS material is so popular in different industrial applications and how it can benefit your business.

Industries Making Use of ABS Plastic

ABS plastic is a lightweight thermoplastic that has a wide range of uses in many industries. It is one of the most popular plastics used in 3D printing and injection molding, due to its good balance between strength and flexibility. ABS plastic is also frequently used in the automotive, aerospace, and medical industries.

Automotive parts such as bumpers, grilles, interior trim pieces, wheel covers, and more are often made using ABS plastic because they can easily be formed into complex shapes.

In aerospace applications, ABS plastic may be used for structural components or cabin interiors.

Food handling and equipment industries make use of ABS plastic for its durability, heat resistance, and cost-efficiency. ABS material is lightweight yet strong enough to withstand impact and any other outdoor conditions. It’s also resistant to high temperatures allowing it to be used in food handling equipment like trays or hot/cold containers. ABS plastic is easy to work with as it can be molded into different shapes which makes it an ideal choice for creating custom food handling equipment with intricate designs.

Additionally, the medical industry makes use of ABS plastic for durable items like hearing aids or prosthetic devices. Thanks to its versatile properties and easy formability, ABS plastic is highly valued in many industries.

Why ABS Plastic is used in Various Industrial Applications?

ABS plastic is a thermoplastic polymer widely used in industrial applications due to its excellent properties. It has good strength and toughness, high resistance to chemicals and heat, excellent dimensional stability, low moisture absorption, surface hardness, and easy processability.

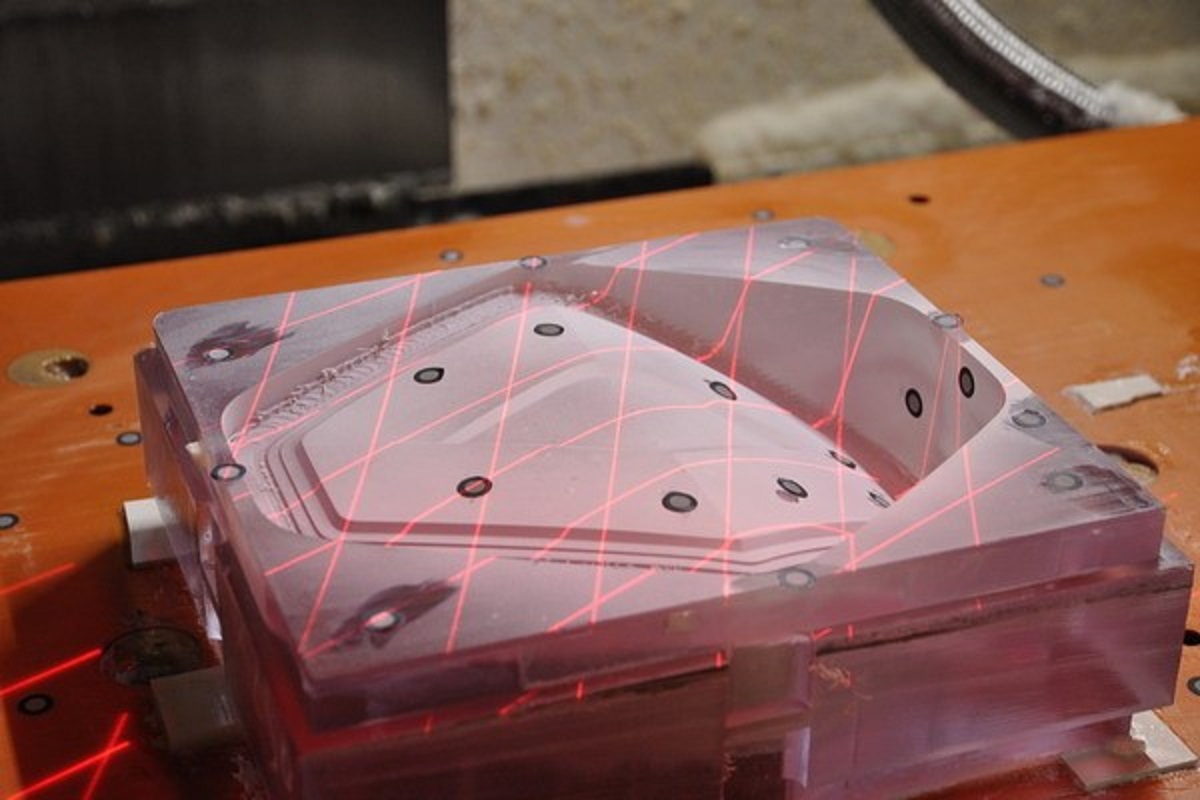

The most important use of ABS plastic is in injection molding, Its strength and heat resistance are especially beneficial in injection molding processes as it enables the creation of complex shapes quickly and efficiently while retaining their quality throughout various treatments.

Additionally, its light weight makes it suitable for automotive parts such as dashboards and fuel tanks while its surface hardness allows for a strong finish that can withstand wear and tear over time.

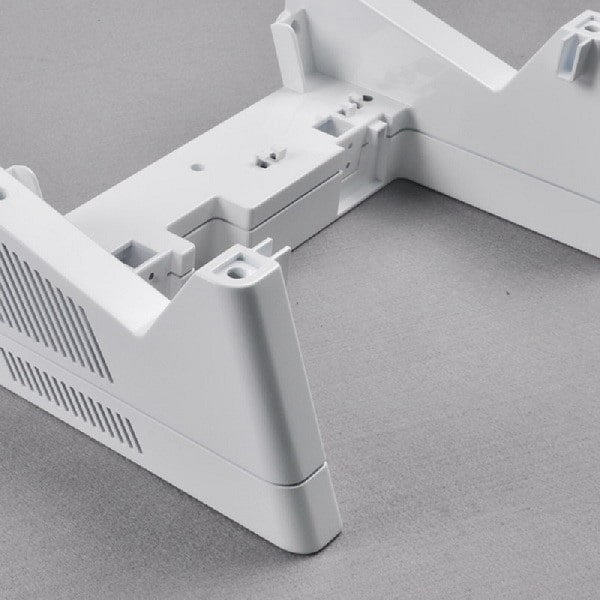

In addition to these uses, ABS plastic is also used in the electrical and electronics industry for making high-grade enclosures, connectors, circuit boards, etc.

Furthermore, it can be molded into various shapes and sizes without sacrificing any of its properties. From medical equipment to automotive components, ABS plastic is easy to process and provides excellent performance over traditional materials such as metals and other plastics.

Therefore, it is an ideal solution for businesses looking for a durable product that can withstand wear and tear while providing superior performance over time.

Tips to Consider When Machining ABS Plastic

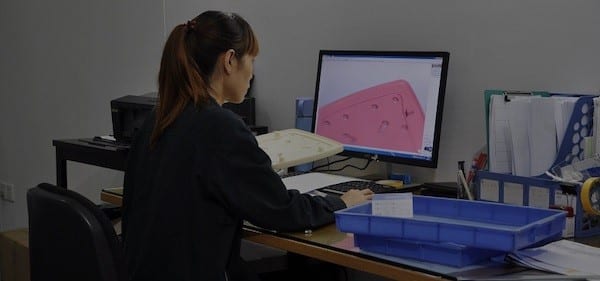

When machining ABS plastic, there are several factors that need to be taken into account.

First, it is important to understand the type of material being worked with and its properties. ABS plastic is a thermoplastic commonly used in consumer products due to its strength and durability, but can also be difficult to machine. The heat generated during machining can cause warping or even melt the plastic if proper precautions are not taken. It is therefore important to use sharp cutting tools for best results, and lower speeds when cutting thicker parts.

Tool selection must also consider the size and shape of the part as well as its desired finish. Additionally, it is important to monitor temperature levels while machining ABS plastic so that they do not exceed recommended limits.

Finally, the machinist must take into account any dust or other debris generated during machining and take steps to protect themselves from any potential hazards. With proper care and attention taken throughout the process, ABS plastic can be machined with excellent results.

By taking these considerations into account when machining ABS plastic, the best possible outcome can be achieved while avoiding potential problems along the way.

Conclusion

In conclusion, ABS plastic is popularly used in various industrial applications because of its excellent properties such as good thermal stability, superior strength, and lightweight. It is also easy to process, cost-effective, and provides superior performance when compared with other materials. Therefore, it is an ideal choice for industries across the world.