Are your stock levels off in your supply chain? Do you see stockouts and upset customers? You might chase demand forecasting that fails before you know it.

Supply chain disruptions cost firms an average of 184 million dollars per year. This post shows seven forecasting errors that wreck your plan. You will learn to fix each one with real-time tracking, predictive analytics, and machine learning algorithms.

Read on.

Key Takeaways

- Skip real-time data, and you fly blind. 84% of B2B customers expect live tracking. Firms using sensors, predictive analytics, and machine learning see 198% more success.

- Lean only on old sales records, and you miss shifts fast. Market swings can slice off 6–10% of revenue and dent customer satisfaction.

- Ignore outside shocks like Category 4 hurricanes or port strikes, and you face empty shelves and rising costs. Supply chain disruptions cost firms an average of $184 million per year.

- Underestimate lead times, and your freight rates can climb 25–30%. Track forecast accuracy weekly to keep it above 99% and nip delays in the bud.

- Lock data in silos and skip backup plans, and risks mount. In 2024, 57% of firms saw vendor failures. Cross-team planning and shadow suppliers guard your logistics plan.

Ignoring Real-Time Data Insights

Teams that skip real-time tracking fly blind, like a ship without a compass. They miss shifts in demand patterns and stock swings. 84% of B2B customers expect real-time tracking to guard inventory management and boost customer satisfaction.

Gaps in data analysis force firms to load high safety stock and erode profit margins.

Early adapters use sensor networks, simulation models, and advanced analytics to spot supply chain disruptions. They tap machine learning and predictive analytics to tweak demand forecasting on the fly.

Companies that shift plans fast see 198% more success in seizing new chances. This tactic wards off last-minute labor shortages and keeps operations humming.

Relying Solely on Historical Data

Relying on long past sales data can blind teams to sudden market shifts. Market volatility squashes old projections like a deflated beach ball, so past records lose their punch fast.

This hurts demand forecasting and dents profit margins, dropping customer satisfaction.

Short product lifecycles cut data points, leaving inventory forecasting blind and eroding operational efficiency. Supply chain management teams tap SAP ERP or Amazon Forecast and deploy machine learning algorithms to sense demand shifts.

These tools use predictive analytics and advanced analytics to spot new demand patterns in real-time data.

Failing to Account for Market Variability

Logistics teams ignore wild swings in customer behavior, at their own risk. 73% of managers report a sharp hit to operational efficiency over two years due to economic shifts. Shortages in labor and supply chain disruptions can throw off demand forecasting.

Rigid plans soak up cash in excess inventory or leave critical SKUs empty.

Trend analysis and demand sensing can spot those shifts fast. AI programs and sensor networks feed planners fresh, real-time data. Virtual model software builds what-if scenarios for market research.

Teams tweak orders with real-time tracking, tightening inventory management and lifting customer satisfaction.

Overlooking External Factors Affecting Demand

Seasonal weather shifts or sudden labor shortages can blindside your demand forecasting. A Category 4 hurricane may clip delivery lanes, while a long port strike can stall stock. Many teams ignore these outside snags, then face empty shelves, rising holding costs, bruised profit margins, and angry customers.

That slump hits customer satisfaction in minutes. Supply chain disruptions cost firms about $184 million each year, and they can slice off 6 to 10 percent of revenue. Planners who link real-time data feeds from IoT sensors with neural networks boost inventory management and spot demand shifts faster.

A toy maker once stockpiled new Coke after a pop trend, then watched it fizz out. Scenario planning can fix that. Use a Delphi technique to call in a panel of experts and vet market research.

You can tie in predictive analytics or deploy a virtual equipment model to test seasonal swings. This workflow lifts inventory forecasting accuracy, cuts waste, and fuels operational efficiency.

Misaligning Inventory Levels with Forecasted Demand

Warehouses choke on excess inventory, and bills pile up every day. Holding costs spike, profit margins shrink. Shops face stockouts when demand jumps, and leave customers staring at empty shelves.

Accurate demand forecasting needs real-time data, connected sensors, predictive analytics, and simulation models.

Operations falter when teams ignore low inventory turnover and sudden shifts in demand patterns. Supply chain management tools must tap advanced analytics, wireless tags, and machine learning algorithms to tune reorder points.

Smart demand planning cuts storage fees and stops gaps before they hit sales.

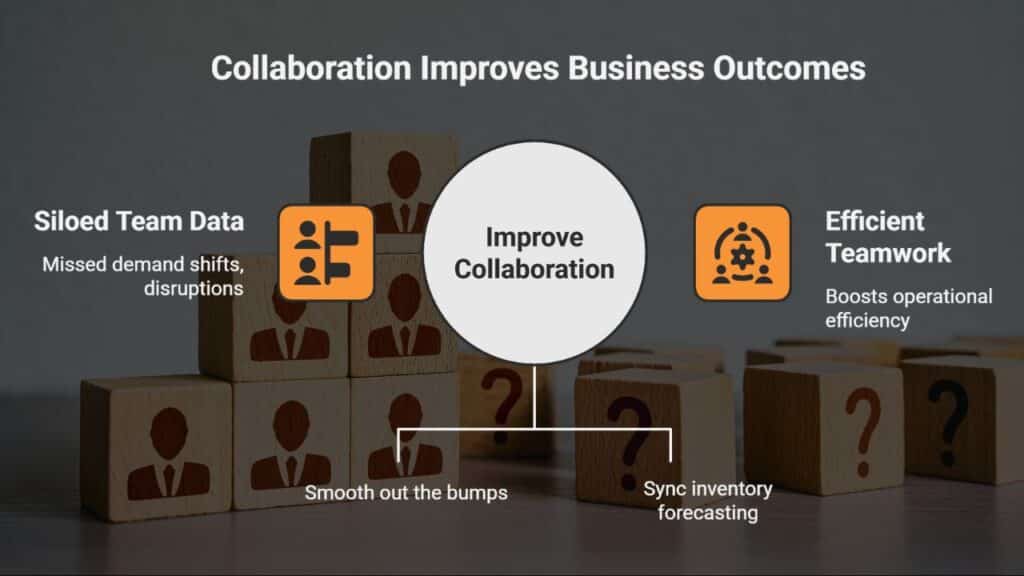

Lack of Collaboration Between Teams

Teams that lock data in silos shoot themselves in the foot, they miss demand shifts and fuel supply chain disruptions, and they act like ships passing in the night without sharing demand patterns.

This gap hurts profit margins and dents customer satisfaction.

Cross department chat and joint planning with suppliers and customers smooth out the bumps, a shared dashboard with advanced analytics and ML models helps sync inventory forecasting, and that simple step cuts excess inventory while boosting operational efficiency.

Using Outdated Forecasting Tools

Old spreadsheets and legacy ERP block your view of demand. Those tools only crunch past sales. They miss sudden market trends and ignore real-time data. Managers end up with too much stock or empty shelves.

This leads to supply chain disruptions and unhappy customers.

Switch to AI-driven platforms like ThroughPut, with machine learning and advanced analytics for demand forecasting and inventory management. This system pulls streams from IoT sensors, social feeds, even weather reports.

It senses demand patterns, flags labor shortages, tracks last-mile deliveries. You cut excess inventory, boost operational efficiency, protect profit margins, and win a competitive advantage.

Neglecting to Monitor Forecast Accuracy Regularly

Neglecting to track forecast accuracy feels like steering a truck blindfolded. You miss spikes in demand forecasting, then face empty shelves or piles of excess inventory. Skipping weekly checks on inventory accuracy, which needs to stay above 99%, risks supply chain disruptions and customer satisfaction dips.

Ignoring order fulfillment time lets delays slip by, hurting profit margins. You need sensors, digital twin models, and predictive analytics dashboards to catch drift fast.

Set alerts on cost per unit handled and scan labor turnover each month. Link demand sensing feeds into your IoT technologies so the system flags odd demand patterns right away. Machine learning algorithms can spot shifts in market trends before they blow up your plan.

Use real-time data to tweak forecasts daily and keep your logistics plan sharp. Don’t let poor monitoring leave you chasing problems after they hit.

Overcomplicating Forecasting Models

Complex models add layers of calculations and data feeds. They strain software integration, cause project delays, and hold up returns on technology investments. Teams load inventory forecasting with predictive analytics, machine learning algorithms, and big data streams.

This setup slows demand forecasting and drags supply chain management performance.

Teams can lose sight of inventory levels when they chase endless variables. Simple data analytics often boost operational efficiency and cut supply chain disruptions. Good models use key metrics like turnover rates, lead times, and demand shifts.

Staff can adapt plans fast, spot market trends, and save funds.

Underestimating the Impact of Lead Times

Incorrect lead time estimates wreck inventory forecasting. They force managers to chase slow shipments. Companies see costs rise as freight rates climb 25 to 30 percent. Supply chain disruptions now stretch recovery from two weeks to six weeks.

That eats into customer satisfaction.

Staff use neural networks for demand forecasting. Predictive analytics and real-time tracking nip delays in the bud. That action saves time, cuts waste, and boosts operational efficiency.

Better inventory management stops excess inventory and stock gaps.

Skipping Contingency Planning

Skipping backup plans feels like driving blindfolded. Chaos hits when a vendor folds. 57% of firms saw vendor failures in 2024. Leaders skip pressure-testing against what-if scenarios, then freeze when a storm hits.

No one likes a plan built on hope alone.

Use demand forecasting tools, real-time tracking, machine learning models to spot shifts ahead. Build shadow suppliers and safety stock. That step keeps inventory management strong and customer satisfaction high.

It fights supply chain disruptions and secures profit margins.

Takeaways

You have seen how small errors in demand forecasting can blow up a logistics plan. Real-time data, inventory forecasting, and predictive analytics guard you against nasty surprises.

A survey method helps you tap team wisdom fast. Stay agile, watch lead times, and tweak your strategy on the fly. Laugh at one hiccup, learn from it, then sprint ahead. Solid demand planning means happier customers, leaner inventory, and fatter profit margins.

FAQs

1. What are the top forecasting errors in my logistics plan?

Most managers skip demand sensing, ignore market trends, feed bad data into predictive analytics, and rely on guesswork.

2. How does bad demand forecasting lead to excess inventory and sink profit margins?

When you miss demand shifts, you order too much stock. You tie cash up in excess inventory, and your profit margins dive.

3. Why does poor data quality wreck my supply chain management?

Bad data is like a blindfold on a driver. It hides real needs, it trips up inventory management, and it sparks logistics challenges.

4. Can real-time tracking and predictive analytics stop supply chain disruptions?

Yes, real-time tracking spots delays fast, predictive analytics warns of looming disruptions, and you can reroute stock before trouble hits.

5. How do labor market shifts and workforce management issues affect my plan?

A tight labor market and an aging crew cause labor shortages at docks and in final delivery. You face slower service and fleet management strains.

6. What tools help improve inventory forecasting and cut waste?

Use machine learning algorithms and advanced analytics to spot demand patterns, add quantitative forecasting and digital transformation, trim waste, cut energy consumption, and boost operational efficiency.