Many small and medium-sized manufacturing businesses struggle with improving efficiency without making costly investments in new equipment or automation. While modern machinery and advanced technology can certainly boost productivity, there are several low-cost or even cost-free strategies that can significantly enhance your manufacturing efficiency.

This article explores practical and proven ways to optimize production, improve workflow, and enhance employee productivity without spending on expensive new tools or machinery. If your company is facing bottlenecks, delays, or inefficiencies, these strategies will help you streamline operations and maximize output with existing resources. And if you’re looking for additional support, consider exploring software for production planning to complement these methods.

Common barriers to manufacturing efficiency

Before implementing changes, it’s essential to understand the most common inefficiencies in production processes. Do you recognize these issues in your own facility? Many companies struggle with poor organization, lack of real-time data, and ineffective communication, which significantly impact performance.

One of the biggest challenges is the absence of real-time control over production processes. Without access to up-to-date information, you and your managers make decisions based on outdated or incomplete data, which can lead to delays and inefficiencies. Another issue is the lack of communication between departments. When your employees don’t have clear information about priorities, it results in unnecessary downtime and duplicated work. Additionally, a disorganized workflow can cause workers to waste time switching between tasks or waiting for instructions, further reducing efficiency.

Other common obstacles include:

- Limited tracking of employee performance – Without proper monitoring, it’s difficult to identify areas for improvement or inefficiencies in work habits.

- Unstructured production schedules – Poor scheduling often leads to bottlenecks, missed deadlines, and inefficient use of resources.

- Lack of clear standard operating procedures (SOPs) – Employees work less effectively when they don’t have defined guidelines to follow.

Addressing these barriers is the first step toward increasing productivity without major capital investments.

Optimizing production without spending on equipment

Enhancing manufacturing efficiency doesn’t always require new machines – often, it’s about making better use of what you already have. Think of it as getting more mileage out of your existing resources rather than buying something new. One effective way to achieve this is by refining production schedules. By improving scheduling and work assignments, your business can minimize downtime and avoid bottlenecks.

Another crucial aspect is standardizing processes. Creating clear and well-documented workflows ensures tasks are completed consistently and efficiently. Your employees follow structured steps, reducing mistakes and improving overall output. Furthermore, streamlining communication between teams significantly reduces delays and errors. Even something as simple as using real-time dashboards or shared online schedules can ensure that all your employees have the most current information about production status.

Other practical strategies include:

- Rearranging workstations for better efficiency – Organizing the layout of machinery and tools can minimize wasted movement and time.

- Implementing lean manufacturing principles – Reducing unnecessary steps in production can help eliminate waste and boost productivity.

- Encouraging cross-training among employees – Having a more flexible workforce allows your business to reallocate labor where it’s needed most.

Simple changes such as reorganizing workstation layouts or adjusting shift structures can yield significant productivity improvements.

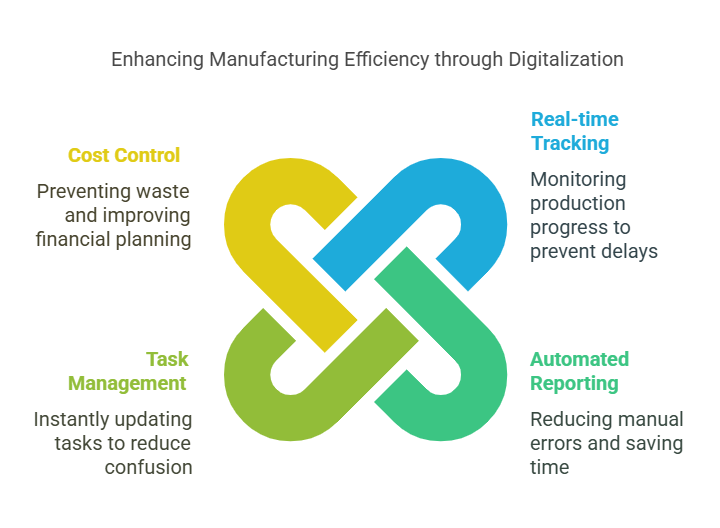

The role of digitalization in boosting efficiency

While digital transformation is often associated with large-scale automation, even small-scale digital improvements can dramatically enhance manufacturing efficiency without significant costs.

One of the biggest benefits of digitalization is real-time tracking of production progress. Imagine being able to monitor ongoing tasks, identify delays, and adjust resources as needed. This proactive approach prevents bottlenecks and ensures a smooth workflow. Another advantage is automated reporting and data analysis. By reducing manual paperwork, your company can save time and eliminate errors that often occur in production records.

Moreover, digital tools enhance task management and prioritization. Your employees can access task updates instantly, reducing confusion and unnecessary disruptions. Digitalization also allows for better cost control, as tracking resource usage in real time prevents waste and improves financial planning.

Even a simple digital management system can make a noticeable difference in your workflow efficiency without requiring huge upfront investments.

Boosting employee engagement for higher productivity

Employees play a crucial role in manufacturing efficiency. However, unmotivated or untrained workers can slow down processes, leading to missed deadlines and increased costs. How often do you talk with your team about their ideas for improvements? One of the best ways to enhance engagement is by providing regular training and upskilling opportunities. Employees who understand their roles and know best practices perform tasks faster and more accurately.

To improve engagement and performance:

- Provide clear goals and expectations – Your employees should know exactly what is expected of them and how their work contributes to overall company success.

- Encourage feedback and innovation – Workers on the production floor often have valuable insights into inefficiencies and potential improvements.

- Recognize and reward high performance – Incentivizing efficiency improvements fosters a more motivated and engaged workforce.

- Offer flexible work arrangements where possible — Adjusting shifts or schedules to better match workloads can increase both productivity and employee satisfaction.

By empowering your employees with the right knowledge and tools, you can significantly improve output without additional capital investment.

Implementing changes without disrupting operations

Many manufacturing companies hesitate to introduce process improvements out of fear that changes will disrupt workflow or cause resistance from employees. Are you feeling this apprehension too? Implementing efficiency-enhancing strategies doesn’t have to be disruptive if done gradually and thoughtfully.

Best practices for introducing changes smoothly include:

- Start with small, incremental improvements – Instead of overhauling the entire system, begin with minor adjustments that are easy to adopt.

- Test new strategies in one department first – Piloting changes on a small scale allows your business to measure their effectiveness before expanding them.

- Involve employees in decision-making – Workers who participate in the improvement process are more likely to accept and embrace changes.

- Monitor and adjust as needed –Tracking the impact of changes and making adjustments based on real-world performance data ensures continuous progress.

This structured approach minimizes disruptions and ensures long-term improvements in efficiency.

Manufacturing efficiency doesn’t depend solely on expensive technology – it often comes down to smarter resource management and process optimization. By addressing organizational inefficiencies, improving communication, leveraging digital tools, and increasing employee engagement, your company can significantly enhance productivity without costly investments.

Is your company ready to maximize production efficiency without major expenses? Start optimizing today and unlock your factory’s full potential!

For businesses looking to implement these strategies effectively, Prodio software offers a comprehensive solution for production optimization. As a specialized software for production planning, Prodio helps you digitize workflows, track production in real-time, and improve communication between departments – all without significant investment. It’s an accessible way to achieve many of the efficiency improvements discussed in this article through one integrated platform.