Hex nuts are crucial components that have a significant impact across different sectors, such as construction and manufacturing fields. They come in the shape of pieces with holes for screws and are known for their flexibility and widespread usage. This article seeks to delve into the adaptability and significance of hex nuts in building venture equipment assembly. Various manufacturing uses.

1. Basic Function and Design of Hex Nuts:

A hex nut is created to fasten bolts or screws in place for stability firmly and to prevent them from coming loose and compromising the integrity of objects. They are used in securing mechanisms with their design comprising six flat sides and internal threads that align with those of the bolts or screws they are paired with.

2. Wide Range of Sizes:

Different sizes of hex nuts are available to match bolt diameters or thread sizes. Whether for electronic circuitry or heavy-duty construction projects, there’s a size that fits every need.

3. Selection Based on Material Properties:

Sectors of the economy’s industries necessitate unique material qualities for their hexagonal nuts, depending on the surrounding environment and planned uses thereof. Among the used materials is steel, known for its ability to resist corrosion. Brass is favored for its good electrical conductivity, and carbon steel is valued for its robustness and durability.

4. Standard Hex Nuts vs Specialty Hex Nuts:

In industries like locking applications and temperatures/high-pressure environments, specialized hex nuts with unique features are essential beyond the standard nuts that meet general requirements.

5. Locking Mechanisms:

To avoid loosening caused by vibrations or external forces and ensure safety, nylon insert locknuts are commonly used, for instance, those containing an elastic ring inside the nuts’ threads to provide a tighter grip around bolts.

6. Flange Nuts for Enhanced Pressure Distribution:

Flange nuts are great at spreading pressure because they have a surface area against the item they secure. This broader grip can prevent harm from force or turning power, making flange nuts a top pick for automotive and machinery uses.

7. Hex Nuts in Construction:

Hex nuts play a key role in the construction sector as they are essential for securing beams and frames together in structures worldwide using different types of steel hex nuts known for their durability and ability to withstand heavy loads and harsh environments.

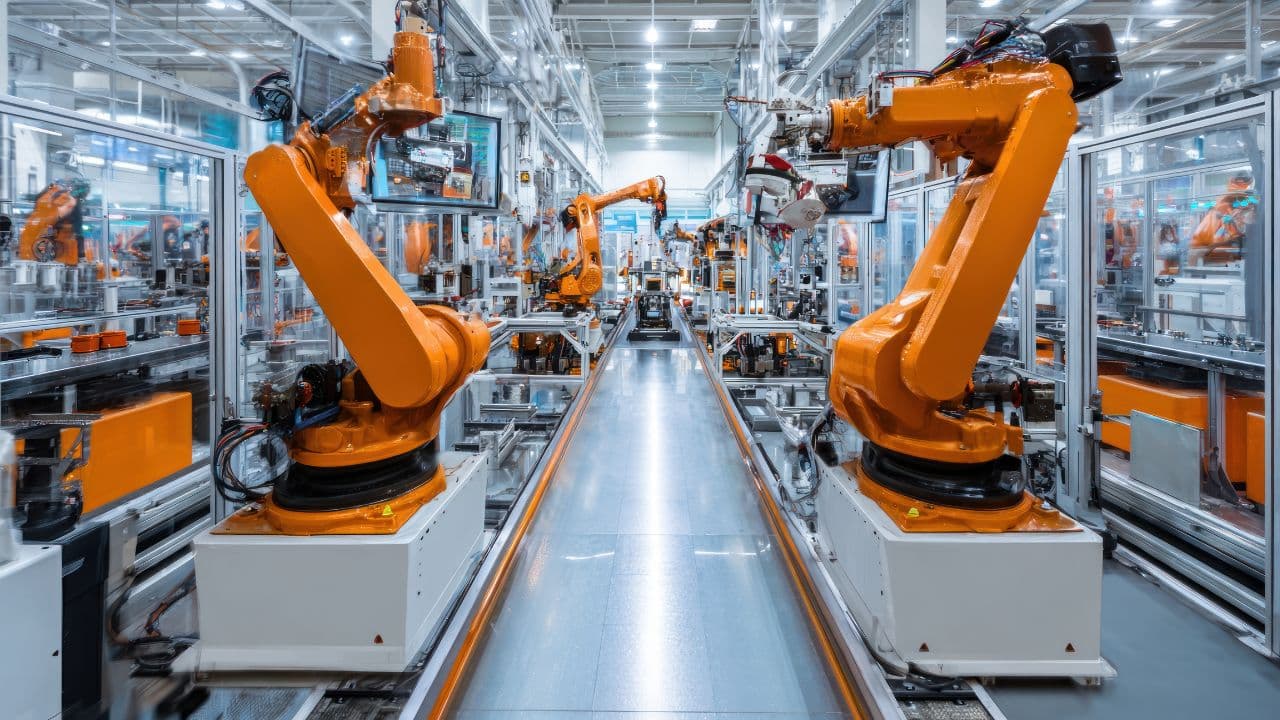

8. Hex Nuts in Machinery Assembly:

Hex nuts are widely used in machinery assembly to fasten parts, like bearings and gears, and keep them in place—an essential step in maintaining smooth operation and reducing downtime due to loose components.

9. Convenience in Repair and Maintenance:

In addition to their function in construction and production endeavors, hexagon nuts provide benefits when it comes to fixing and upkeeping activities. Their uniform threading enables substitution without requiring any equipment or intricate methods.

10. Applying Torque:

Properly adjusting hex nuts on bolts or screws requires applying the amount of torque for accuracy and safety reasons. Not tightening enough could cause parts to loosen gradually, while over-tightening may damage threads or result in bolt breakage.

11 Ways Hex Nuts are Used in the Automotive Industry:

Hex nuts play a significant role in the sector by facilitating the assembly of different vehicle parts, such as engine components and wheel hubs, as well as ensuring stability and safety in systems, like the suspension system, to help cars endure the rigors of driving effectively.

12. Use in Electrical Connections:

Hex nuts are also used in connections to secure wires and connectors together for reliable electrical conductivity and to prevent any loose connections that may cause malfunctions or safety risks. They can be made of materials like brass or stainless steel to resist corrosion effectively.

13. The Sector of Aerospace and Defense;

The aerospace and defense industries heavily depend on hex nuts because of their reliability and durability in challenging conditions like vibrations and high speeds. They need to follow safety standards while ensuring the perfect assembly of parts that can handle rigorous operational demands such as gravitational forces.

In summary

Hex nuts may appear insignificant in the context of construction and manufacturing endeavors. Their significance should not be underestimated. They provide versatility, with options in size and material properties, along with locking mechanisms and specialized functions that are greatly valued across a range of industries. From ensuring stability to enabling repairs and maintenance work, hex nuts play a vital role in securely connecting objects together, an essential element of every prosperous construction or manufacturing venture.