Resource shortages in logistics are a growing challenge for businesses worldwide. Delays, rising costs, and supply chain disruptions are becoming more common. Companies struggle to keep up with demand while facing limited resources.

The COVID-19 pandemic worsened these issues, causing labor shortages and shipping bottlenecks. Warehouses face inventory gaps, and transportation routes are strained. These problems affect both businesses and consumers.

This blog explores practical solutions to tackle resource shortages in logistics. From workforce retention to advanced technology, we’ll cover strategies that work. Keep reading to discover how your business can thrive despite these challenges.

Implement Strategies for Workforce Retention in Logistics

Retaining skilled employees is critical for success in the logistics industry. Companies need effective employee retention strategies to thrive in competitive labor markets.

- Offer flexible scheduling to accommodate employee needs and improve work-life balance. This attracts and retains talent in logistics.

- Provide clear career growth opportunities to motivate employees and reduce turnover rates. Workers value paths for advancement.

- Invest in personal development programs to refine skills and boost employee satisfaction. Continuous learning keeps workers engaged.

- Create value-based employee packages that go beyond just higher wages. Benefits like health care and training matter more.

- Foster a positive workplace culture that supports teamwork and recognition. Employees stay longer in supportive environments.

- Use advanced logistics management software to simplify operations and reduce employee stress. Efficient systems make jobs easier.

- Encourage open communication between management and staff to address concerns quickly. Transparent dialogue builds trust.

- Launch retention initiatives customized for logistics personnel, such as safety training and performance bonuses. Specialized programs show commitment.

- Monitor employee feedback regularly to identify areas for improvement. Listening helps companies refine retention strategies effectively.

- Partner with educational institutions for industry-specific training programs that prepare workers for logistics roles. Skilled employees are more likely to stay.

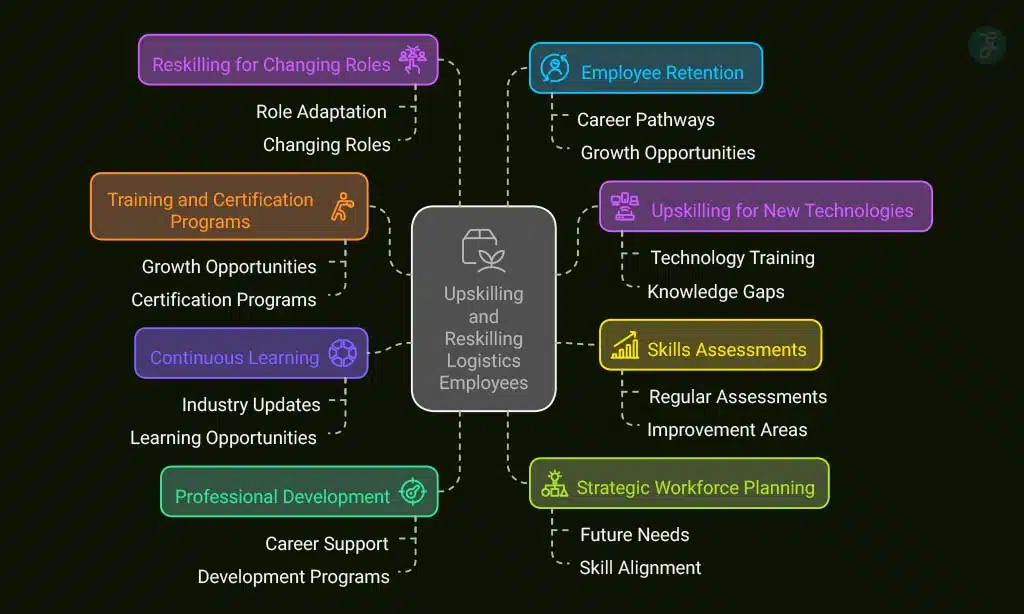

Upskill and Reskill Logistics Employees

Upskilling and reskilling logistics employees is vital for addressing resource shortages. Training programs help bridge knowledge gaps and improve workforce planning.

- Provide training and certification programs to offer growth opportunities for employees.

- Focus on upskilling to address knowledge gaps related to new technologies in logistics.

- Conduct regular skills assessments to identify areas for improvement.

- Encourage continuous learning to keep employees updated with industry advancements.

- Invest in professional development programs to support career advancement.

- Use strategic workforce planning to align skills with future logistics needs.

- Offer reskilling opportunities for employees to adapt to changing roles.

- Promote employee retention by creating clear paths for career growth.

- Leverage technology advancements to enhance training effectiveness.

- Ensure training programs are accessible and relevant to all logistics staff.

Enhance Efficiency with Automation and Robotics in Logistics

Automation and robotics are transforming the logistics industry, boosting productivity and lowering costs. The global logistics automation market hit $73 billion in 2023 and is expected to grow to $217.26 billion by 2033.

Companies using robotics see a 48% increase in productivity and a 42% drop in operating expenses. Collaborative robots, or cobots, now make up 32% of operations, enhancing collaboration between humans and machines.

Warehouse robotics optimize repetitive tasks like picking, packing, and sorting—allowing workers to focus on more advanced roles. Automated material handling systems improve accuracy while minimizing delays caused by human error.

Robotic process automation accelerates order processing and inventory management, ensuring faster deliveries. By incorporating these technologies into supply chain automation strategies businesses can achieve significant improvements—enhancing efficiency across their networks without sacrificing quality or reliability.

Utilize Advanced Software for Logistics Management

Advanced software is transforming the logistics industry. Cloud-based logistics management tools automate supply chain processes globally, boosting efficiency. Real-time analytics powered by AI helps companies make quick, data-driven decisions.

Route optimization software minimizes delays and reduces costs. Warehouse Management Systems (WMS) streamline operations, addressing labor shortages effectively. These tools enhance supply chain agility, ensuring businesses adapt to changing demands.

Automation technologies also improve accuracy in inventory tracking. By adopting these solutions, logistics companies stay competitive in a fast-paced market.

Optimize Processes in the Supply Chain

Optimizing processes in the supply chain is essential for reducing costs and improving efficiency. Companies without real-time visibility can face up to $95 billion annually in logistics expenses.

High costs often result from isolated operations, manual processes, and limited transparency. Implementing automated systems improves operational efficiency and reduces errors.

Visibility solutions like real-time tracking tools offer better control over inventory management. These tools help identify bottlenecks and streamline workflows. Data analytics is crucial for process improvement by providing actionable insights into supply chain performance.

Automated processes also minimize delays, ensuring smoother operations.

Focusing on customer satisfaction requires clear communication and timely deliveries. Supply chain optimization ensures products move faster while reducing unnecessary expenses. Investing in technology enhances visibility across the entire network—this leads to better decision-making and cost-saving strategies that benefit both businesses and customers.

Strengthen Logistics Recruitment with Competitive Packages

Attracting and retaining talent in the logistics industry requires competitive compensation packages. Offering sign-on bonuses and retention incentives helps address workforce shortages effectively.

Flexible working hours and remote options appeal to younger candidates, making roles more attractive. Benefits like these draw skilled professionals and keep them engaged long-term.

A strong package combines salary, perks, and work-life balance to strengthen logistics recruitment efforts. This approach ensures companies stay ahead in a competitive hiring market while building a loyal workforce.

Promote Flexible Work Arrangements in the Logistics Sector

Flexible work arrangements can help address labor shortages in the logistics sector. Introducing flexible scheduling allows companies to adapt to seasonal demand fluctuations without overburdening employees.

This approach ensures smoother operations during peak times while maintaining staff morale. Flexible staffing solutions also provide a way to manage workforce needs efficiently, reducing turnover and improving retention.

Innovative recruitment strategies often focus on upskilling existing employees for adaptable roles. By offering training programs, logistics firms can prepare their teams for diverse responsibilities, increasing workplace adaptability.

These measures improve employee management and build a stronger workforce capable of handling industry challenges effectively.

Collaborate for Industry Training with Educational Institutions

University-industry collaboration plays a vital role in driving digital transformation within the logistics industry. Partnerships between educational institutions and logistics companies create opportunities for innovation through knowledge exchange.

This synergy helps bridge the gap between academic theory and real-world practice, ensuring employees gain relevant skills.

Collaborative teaching programs allow students to learn directly from industry experts, preparing them for future roles. Research activities shared between universities and logistics firms lead to new solutions for resource shortages.

Facilities like labs or training centers can be jointly used, reducing costs while enhancing learning experiences.

Coordination with educational institutions also strengthens recruitment pipelines. Companies benefit from access to well-trained graduates ready to tackle industry challenges. Mutual benefits arise as students gain practical experience, and businesses secure skilled talent—this integration fosters long-term growth and adaptability in the logistics sector.

Plan for Contingency in Logistics Resource Allocation

Resource shortages can disrupt logistics operations, making contingency planning essential. Companies must develop backup plans to ensure operational continuity during supply chain disruptions.

Using logistics intelligence, they can create resilient strategies through data-driven insights and predictive analytics. Simulation models help assess vulnerabilities and improve preparedness for potential risks.

Effective contingency measures focus on risk management and resilience planning, ensuring businesses remain adaptable. Investing in detailed preparedness strategies minimizes the impact of unexpected challenges, maintaining smooth operations across the supply chain.

Invest in Analytics Tools for Real-Time Data in Logistics

Investing in analytics tools for real-time data transforms logistics operations. These tools gather and interpret large amounts of information, improving supply chain optimization.

Real-time tracking minimizes delivery times and reduces transportation costs significantly. Enhanced data interpretation leads to better inventory management and demand forecasting.

Operational improvements become evident with predictive analytics guiding fleet management and route optimization. Customer service improves as businesses respond faster to changing needs.

Analytics tools also support decision-making by providing actionable insights into daily operations. This approach ensures smoother workflows and higher efficiency across the entire logistics network.

Enhance Collaboration among Supply Chain Partners

Effective collaboration among supply chain partners boosts operational visibility and cuts delivery delays. Strengthening cooperation ensures smoother workflows and better outcomes for all involved.

Digital tools, like cloud-based solutions, enable real-time information sharing—keeping everyone on the same page.

Improving communication in supply chain collaboration helps identify bottlenecks early. Enhanced transparency allows partners to address issues before they escalate. Monitoring efficiency with KPIs ensures quality remains high while minimizing disruptions.

Building strong relationships with supply chain partners fosters trust and reliability. Using digital technologies simplifies processes, making operations more efficient. This approach improves performance and builds a reliable network capable of managing challenges effectively.

Focus on Sustainability to Reduce Dependencies in Logistics

The logistics industry is a significant contributor to global greenhouse gas emissions, making sustainability a necessity. Rising consumer demand for carbon-neutral delivery encourages businesses to embrace eco-friendly methods.

Companies can lessen their environmental impact by adopting green logistics practices, such as utilizing renewable energy in transportation and low-carbon freight solutions. Sustainable supply chains also thrive with carbon-neutral transportation and climate-friendly delivery options.

Committing to green shipping practices and sustainable packaging further reduces reliance on non-renewable resources. These actions address resource shortages while also combating climate change, aligning with both environmental objectives and consumer expectations.

Explore Supply Chain Solutions on a Regional Basis

Focusing on regional logistics solutions can streamline supply chains effectively. Local supply chain management reduces delays by cutting down transportation time and costs. Regional distribution networks ensure products move faster to meet local demand.

Area-specific supply chain strategies adapt to unique market needs, improving efficiency. Regional transportation systems offer flexibility and resilience during disruptions.

Local sourcing options minimize dependency on distant suppliers, enhancing reliability. Regional inventory management helps businesses stock items closer to customers, reducing lead times.

Area-focused procurement processes target nearby resources for quicker access. Regional warehousing solutions provide storage closer to consumer hubs, speeding up delivery. Local demand forecasting strategies allow precise planning based on regional trends, boosting accuracy in operations.

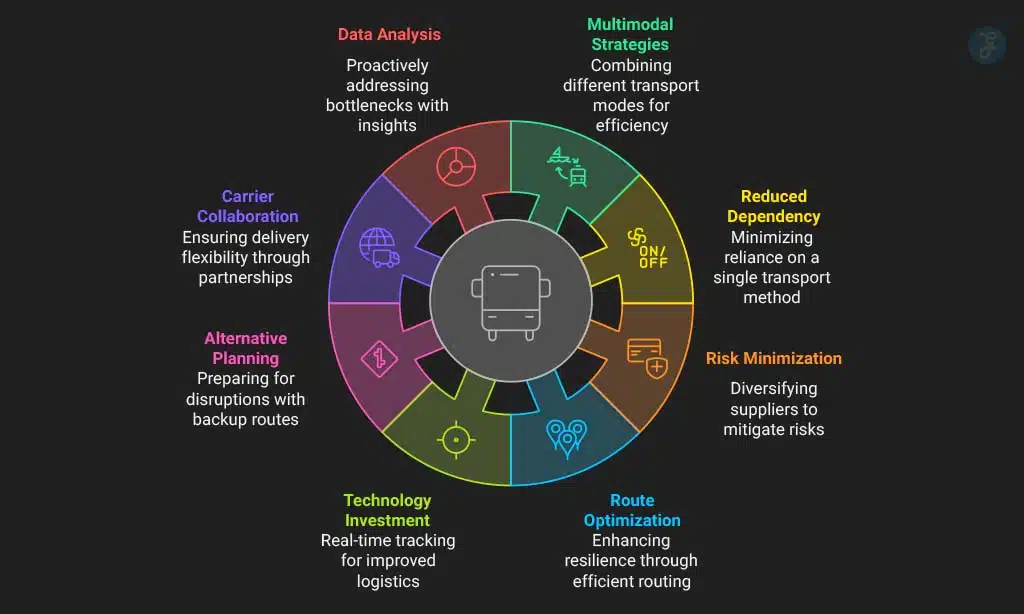

Diversify Transportation Methods to Avoid Bottlenecks

Diversifying transportation methods is key to avoiding bottlenecks in logistics. It ensures smoother operations and faster recovery during disruptions.

- Use multimodal transportation strategies to improve capacity and cost efficiency.

- Combine rail, road, air, and sea transport to reduce dependency on one method.

- Implement a multisupplier strategy to minimize risks from supplier reliance.

- Optimize transportation routes to enhance supply chain resilience.

- Invest in technology for real-time tracking of shipments across different modes.

- Plan for alternative routes in case of unexpected disruptions.

- Collaborate with multiple carriers to ensure flexibility in delivery options.

- Analyze data to identify potential bottlenecks and address them proactively.

- Train teams to manage diverse transportation methods effectively.

- Monitor industry trends to adapt strategies for avoiding future bottlenecks.

Monitor and Adjust Logistics Strategies Based on Trends

The logistics industry faces 11 major trends shaping management in 2024. Real-time data and visibility are essential for improving customer communication and operational efficiency.

Global labor shortages push companies to adopt automation more widely. Staying updated with these trends helps firms adjust strategies effectively. Monitoring trends ensures logistics operations remain competitive and adaptable.

Using real-time analytics tools allows companies to make informed decisions quickly. Adaptation to trends reduces risks and improves supply chain management. Regularly reviewing and updating strategies keeps logistics firms ahead of challenges.

Automation in logistics continues to grow, driven by labor shortages and the need for efficiency. Focusing on trends ensures better resource allocation and smoother operations.

Prioritize Employee Well-Being in the Logistics Industry

Fatigue is responsible for 40% of accidents among commercial vehicle drivers. Sleep management initiatives can help prevent these incidents. Poor health results in higher burnout and turnover rates.

It also raises insurance claims. Health and wellness programs improve employee satisfaction and retention. Safety efforts reduce accidents and improve occupational health. Flexible schedules contribute to maintaining a better work-life balance.

Emphasizing driver fatigue prevention increases safety levels. Tackling recruitment challenges begins with focusing on employee well-being. Healthy employees perform better and remain longer.

Adequate rest and wellness programs foster a safer, more efficient workplace.

Takeaways

Tackling resource shortages in logistics requires smart strategies and quick action. Retain workers, use automation, and improve supply chain efficiency for better results. These practical steps can cut costs, boost delivery speed, and strengthen customer trust.

Explore regional solutions and sustainable practices for long-term success. Start applying these tips today to transform challenges into growth opportunities.