Many fleet managers wrestle with missing trucks, wasted fuel, and surprise breakdowns. They lack clear GPS tracking or reliable real-time data. They feel set back by endless compliance rules and driver behavior headaches.

It can feel like herding cats.

Using telematics in fleet management can transform operations, giving managers the tools to monitor vehicles, drivers, and costs effectively.

Telematics gives you GPS tracking, tracks fuel consumption, and sends predictive maintenance alerts. It also guides route optimization and monitors driver behavior. You will learn ten ways to cut costs, boost safety, and simplify compliance.

Keep reading.

Key Takeaways

- A Florida County cut over $150,000 in fuel costs and cut fuel use by 15% with CalAmp GPS tracking and idle-time alerts.

- Sensors show engine heat, oil pressure, and brake wear. Predictive alerts cut downtime by up to 25% with timely maintenance.

- Dash cams like CalAmp Vision spot harsh braking and speeding. Fleets cut insurance costs by 30% and meet hours-of-service rules with ELD logs.

- Smart routing cuts drive time by 20% using past GPS data, traffic maps, and weather layers. Geofences and RFID tags also track assets and stop theft.

- Cloud dashboards link GPS, ELD, and maintenance alerts in one hub. Managers use real-time data to speed up audits, reports, and dispatch.

How Telematics in Fleet Management Enhances Operational Efficiency

Integrating telematics into fleet management offers a transformative approach to optimizing operations. By leveraging GPS tracking, real-time data analytics, and predictive maintenance, fleet managers can streamline processes, reduce costs, and improve overall fleet performance. This section delves into the multifaceted benefits of telematics, highlighting its pivotal role in modern fleet management strategies.

How can I track my fleet vehicles in real time?

GPS tracking feeds live data from each vehicle to a cloud dashboard. A CalAmp LMU-3040 unit mixes sensor readings, satellite signals, and wireless links to track every turn. The fleet manager shifts trucks on the fly to dodge traffic or meet tight delivery windows.

Geofencing draws digital lines around work sites, so alerts pop if a driver crosses a boundary. Breadcrumbing logs past routes to help cut idle time and boost fuel efficiency.

Real-time location monitoring speeds up emergency response and keeps customers in the loop. Vehicle tracking tools show hours of service, engine diagnostics, and even theft detection.

Fleet telematics systems link trucks, trailers, and assets on one screen for full visibility. Managers spot delays before they snowball and cut operational hiccups. This transparency boosts driver accountability, trims fuel costs, and drives a solid return on investment.

How do I monitor driver behavior effectively?

Fleets use driver behavior monitoring to track harsh braking, sharp turns and speeding with telematics hardware. Video safety systems such as CalAmp Vision dash cams capture risks and send audio alerts.

A fleet management system logs each unsafe act to build driver scorecards. Managers use this real time data to coach, reward, or discipline drivers.

Teams tie events to a date, time and GPS mark in the system. Performance analytics spot trends and training needs. Companies boost driver accountability, cut legal risks and improve compliance with hours of service (HOS) rules via ELD records.

Better safety monitoring slashes accidents and trims insurance costs.

What are predictive maintenance alerts and how do they work?

Telematics devices use IoT sensors to monitor engine heat, oil pressure, and brake wear, then send predictive maintenance alerts to fleet managers. The platform pulls real-time data from GPS tracking modules and diagnostic ports.

This equipment monitoring sends warnings before parts fail. CalAmp Tags boost asset tracking by signaling low battery or seal damage. Maintenance teams read these alerts on fleet management software dashboards.

Proactive parts replacement cuts equipment downtime by up to 25 percent. Managers schedule repairs when a warning pops up. Remote health monitoring spots critical issues and prevents breakdowns.

Preventive maintenance extends vehicle lifespans and lowers repair costs. Teams gain operational efficiency and higher ROI through safer fleets.

How can telematics improve fuel management and save costs?

Fuel management tech monitors idling and fuel use across fleets. Managers see waste in real time with gps tracking, fleet telematics dashboards, and cloud apps. Idling in big trucks typically wastes several gallons of diesel every hour.

A Florida County cut over $150,000 in fuel bills after adding CalAmp solutions for fuel consumption optimization. Those tools trim costs by about 15 percent, lifting every fleet’s roi.

Teams tweak routes with route optimization, shrinking miles and raising fuel efficiency.

How can I optimize routes to increase fleet efficiency?

It takes smart routing to boost fleet efficiency. You can trim 20% of drive time with solid route optimization.

- Collect historical breadcrumb data from gps tracking logs to spot top routes.

- Map traffic patterns and job site spots in fleet management systems for smarter paths.

- Add weather layers and road alerts into gps tracking feeds for real-time data.

- Smart plans cut travel time by 20 percent, slash fuel use and wear.

- Set geofences around work zones and docks to flag wrong turns or off-route trips.

- Swap path options in a mobile app to dodge jams, transit hold ups and road work.

- Link electronic logging devices with telematics sensors to track hours of service and safety.

- Let predictive analytics sort stops and loads to boost asset tracking and driver accountability.

How does telematics assist with accident reconstruction and reporting?

Fleet telematics captures crash moments with dashboard cameras and GPS tracking. Video safety systems record visual and audio clips at the impact site. Real-time data traces each vehicle’s location and movement within seconds.

Accelerometers note harsh braking or swerves to fill out event logs.

Operators use historical route and driver behavior monitoring records to piece together the sequence leading up to a collision. Electronic Logging Devices confirm hours of service at the moment of impact.

Managers get data for fleet compliance, regulatory audits, and claims probes. Dispatchers get alerts instantly to call in medical crews or tow trucks. Integration with fleet management software gives managers one hub for detailed reporting and follow-up.

How can telematics help ensure compliance with fleet regulations?

Telematics plugs into an ELD to automate HOS and RODS tracking. It handles Driver Verification and Inspection Reports (DVIR) and keeps IFTA tax logs tidy. GPS tracking and telematics-generated reports feed compliance reporting tools that cut fines.

Cloud dashboards show inspection status and driver hours in real time. Systems also track fuel consumption and idle reduction, helping meet green goals.

Managers slash paperwork with automated alerts in fleet management software. Reports pop up before audits and spot missing inspection forms. Data flows into a central hub and updates records for every vehicle and driver.

This setup adapts to new regulations and keeps teams safe.

How can I track asset utilization and boost productivity?

GPS trackers and RFID labels keep tabs on each machine. Fleet telematics software feeds real-time data through cloud servers. Geofencing alerts fire whenever devices stray from a set zone.

Usage analytics flag underused equipment for reallocation. Real-time data cuts downtime by up to 25 percent. Job site visibility solutions guide crews toward idle units.

CalAmp Tags bundle GPS modules and sensors to prevent theft and track availability. Managers watch these signals on a fleet management software dashboard. Alerts buzz when a device nears a service window or drifts out of bounds.

Remote monitoring speeds project timelines and raises productivity. Equipment monitoring fosters on-time completion with smarter planning.

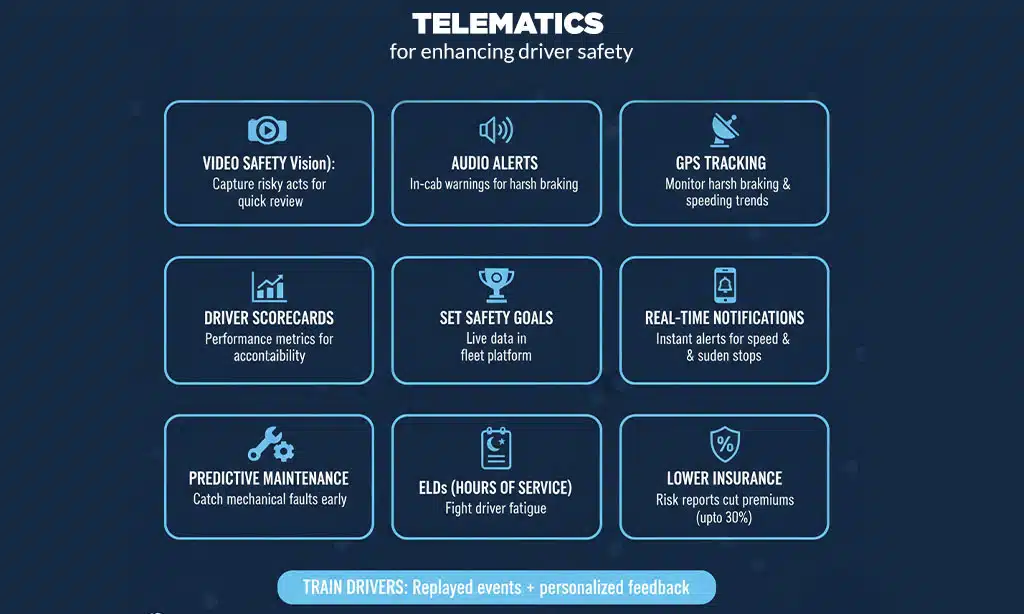

What are the best telematics practices to enhance driver safety?

Driver safety needs clear guidance. Telematics gives solid alerts.

- Use video safety with CalAmp Vision to capture risky acts for quick review.

- Enable audio alerts in the cab to warn drivers of harsh braking.

- Track harsh braking and speeding via satellite tracking to spot trends.

- Offer scorecards with safety performance metrics from data analytics to boost driver accountability.

- Set company-wide safety goals with live data in your fleet management platform.

- Send real-time notifications the instant a driver crosses speed limits or stops short.

- Perform predictive maintenance to catch mechanical faults before they cause breakdowns.

- Use electronic logging devices for hours of service tracking to fight driver fatigue.

- Train drivers with replayed events and personalized feedback to reinforce safe habits.

- Negotiate lower insurance bills using risk reports that cut premiums by up to 30%.

How can telematics reduce insurance costs through risk mitigation?

Telematics tools like GPS tracking and fleet management software flag risky moves in real time, cutting claim counts. Safety scores track harsh braking, speeding, or erratic turns.

Accident reconstruction data logs crash details, so insurers can see clear proof and drop liability fees. Companies that use this data report a 30% drop in insurance costs. Proactive incident management stops small issues from growing into big claims.

Electronic logging devices and predictive maintenance alerts guard against violations and breakdowns, so fleets face fewer fines and hiccups. Usage-based insurance models let managers trade safe miles for lower premiums.

Instant compliance reports show regulators and brokers the team meets every standard. Real-time views build trust, they show companies practice due diligence every day.

How does telematics streamline fleet management workflows?

Centralized fleet management platform links gps tracking, asset tracking and driver behavior monitoring in one dashboard. Logbook data from electronic logging devices and vehicle inspections flow as real-time data.

Automated maintenance alerts trim paperwork and compliance chores. Dispatchers catch delays fast and perform route optimization on the fly. The platform logs driver hours, maintenance records and inspection reports for audits and regulatory compliance.

Remote health monitoring spots engine trouble before a tow truck arrives. Data analytics tools slice through fuel consumption numbers and traffic patterns to boost fuel efficiency.

System alerts flag harsh braking and low tire pressure, cutting downtime. Drivers chat on the mobile app for instant notes, so teams stay in sync, customers stay happy, and fleets lock in higher roi.

Takeaways

Telematics can change how you run a fleet. It links GPS tracking with real-time data, so you see every truck on a map. Predictive maintenance alerts flag engine trouble before it hits.

Smart route optimization slashes fuel bills while you stay on schedule. Driver scoring and an electronic logging device keep your team safe and legal. Fleet management software ties it all together, acting like a digital sidekick, minus the cape.

FAQs

1. What is route optimization in fleet management?

Route optimization uses gps tracking and real-time data in fleet management software to pick the fastest roads, avoid traffic, cut fuel costs, and boost fleet efficiency.

2. How does asset tracking help with equipment monitoring?

Asset tracking keeps tabs on vehicles and cargo. It uses cloud technology to show real-time data, and flags worn parts early as part of inventory management, so you avoid surprise breakdowns.

3. What does driver behavior monitoring do for my fleet?

It watches harsh braking, speeding, driver hours, and driving habits. Driver scoring gives each driver a safety grade, like a coach giving a report card, so you can coach them, cut risk management issues, and keep your fleet safe.

4. How can predictive maintenance alerts save money?

Fleet telematics sends alerts before parts fail by tracking engine health and vehicle telematics. This fuels your preventive maintenance plan, slashes maintenance costs, and keeps vehicles moving.

5. How does telematics enforce fleet compliance?

An electronic logging device logs hours of service, vehicle inspections, and driver hours. You meet local rules and fleet compliance, dodge fines, and keep paperwork neat.

6. Can telematics boost fuel consumption optimization?

Yes, telematics measures fuel consumption in real-time, highlights waste like long idles, gives tips to improve fuel efficiency, and delivers a fast return on investment.