Hey there, have you ever worried about your favorite ice cream melting before it gets to the store? Or maybe you’ve wondered how vaccines stay safe during long trips. These are real problems in cold chain logistics, where keeping things cool is a big deal for perishable goods like food and medicine.

Here’s a cool fact: the cold storage industry is set to grow from $151.68 billion in 2024 to a whopping $190 billion by 2029. That shows just how vital temperature control is in global supply chains.

And guess what? We’ve got the scoop on making it better. In this blog, we’ll walk you through 10 technologies optimizing cold chain logistics, from smart IoT sensors to slick data analytics, helping solve these chilly challenges.

Stick around!

Key Takeaways

- IoT sensors give real-time updates on temperature and location for perishable goods, cutting waste and boosting supply chain visibility.

- AI uses predictive analytics to spot issues like temperature excursions before they happen, improving safety for products like fresh produce.

- Blockchain tracks temperature-sensitive goods with clear records, enhancing trust and transparency in global supply chains.

- Advanced refrigeration, like RSA Global’s ammonia-based systems, saves energy and pairs with solar panels to lower costs.

- Cold storage industry is set to grow from $151.68 billion in 2024 to $190 billion by 2029, showing the importance of these technologies.

Internet of Things (IoT) for Real-Time Monitoring

Moving from our introduction to cold chain logistics, let’s zoom in on a game-changer, the Internet of Things, or IoT, for real-time monitoring. This tech is like having a trusty sidekick keeping tabs on your goods 24/7.

With IoT sensors and RFID tags, you get instant updates on temperature and location for temperature-sensitive products. No more guessing if your frozen food or perishable goods are safe; IoT delivers real-time data to keep everything in check.

Think of IoT as the eagle eye of cold chain management. It spots issues before they spiral, cutting down on waste and boosting supply chain visibility. E-commerce growth for perishables means this kind of tracking is a must-have.

Plus, teaming up with dependable 3PL partners using IoT devices makes operational efficiency soar. It’s like having a safety net for your logistics, keeping those costly temperature excursions at bay.

Artificial Intelligence (AI) for Predictive Analytics

Hey there, folks, let’s chat about how artificial intelligence, or AI, is shaking things up in cold chain logistics with predictive analytics. Imagine having a crystal ball that tells you what might go wrong before it even happens.

That’s pretty much what AI does. It sifts through tons of data, like weather patterns or delivery delays, to spot trouble ahead. This isn’t just guesswork; it’s smart tech making real predictions.

For instance, AI can warn about possible temperature excursions in a truck carrying perishable goods. How cool is that? With this, companies keep temperature-sensitive products safe and sound.

Now, dig into this neat fact: AI boosts supply chain visibility like never before, especially in industries such as fresh produce and pharmaceuticals. Back in 2023, investments poured into logistics for these sectors to ramp up product quality.

Think of AI as your trusty sidekick, helping spot patterns and fix issues proactively. It uses machine learning algorithms to crunch numbers fast, giving insights for better planning.

This means less waste and lower operational costs. Plus, with predictive maintenance, equipment breakdowns don’t catch anyone off guard. Isn’t it amazing how AI helps build supply chain resilience for 2024 and beyond?

Blockchain for Supply Chain Transparency

Guess what, folks, blockchain isn’t just for cryptocurrencies; it’s shaking up cold chain logistics too. This tech acts like a digital ledger, tracking every step of temperature-sensitive goods with crystal clarity.

It cuts through the fog of supply chain management, letting you see exactly where your perishable goods are, no guesswork needed. Plus, with smart contracts in play, last-mile delivery gets a boost by slashing costs and squashing disputes before they even start.

Now, imagine a world where trust in global supply chains is as solid as a rock. Blockchain brings that to life by boosting transparency, and strategic partnerships, like AR Racking and GCCA, are pushing this forward on a huge scale.

Their teamwork aims to improve cold chain logistics services worldwide. So, with real-time visibility and traceability at your fingertips, you’re not just moving products; you’re building reliability.

Temperature Sensors for Precision Tracking

Hey there, folks, let’s talk about something really impressive in cold chain logistics: temperature sensors for precision tracking. These small devices are transformative, monitoring the exact conditions of perishable goods like bananas or vaccines.

Envision a tiny guardian that’s always on duty, ensuring bananas stay above 13 degrees Celsius to prevent chilling injury. That’s crucial for preserving quality!

Now, imagine a situation involving life-saving vaccines. These sensors protect them closely, maintaining temps between 2 and 8 degrees Celsius, as recommended by the WHO. With real-time temperature monitoring, they notify us immediately if anything goes wrong, reducing the chances of spoilage.

In the field of temperature-sensitive products, this kind of technology enhances supply chain transparency and minimizes waste. Isn’t it amazing how such compact tools deliver a powerful impact for cold chain management?

Advanced Refrigeration Technologies

Let’s chat about some cool stuff in cold chain logistics, specifically advanced refrigeration technologies. These systems are game-changers for keeping perishable goods fresh. Imagine a world where your ice cream never melts on the way home.

Companies like RSA Global are leading the pack with ammonia-based refrigeration systems. They cut down on energy consumption big time. Plus, they pair this with solar energy panels to slash operational costs even more.

It’s like hitting two birds with one stone, saving money and the planet.

Now, think about how vital it is to keep things chilly at just the right level. Research from Nomad Foods shows frozen foods kept at negative 15 degrees Celsius, or 5 degrees Fahrenheit, stay top-notch in quality.

This trick also trims energy use and shrinks the carbon footprint. On top of that, preventive maintenance of refrigeration equipment plays a huge role in sustainability. It keeps everything running smooth, avoiding breakdowns and waste.

So, with smart temperature control and green technologies, the cold chain management game is stronger than ever.

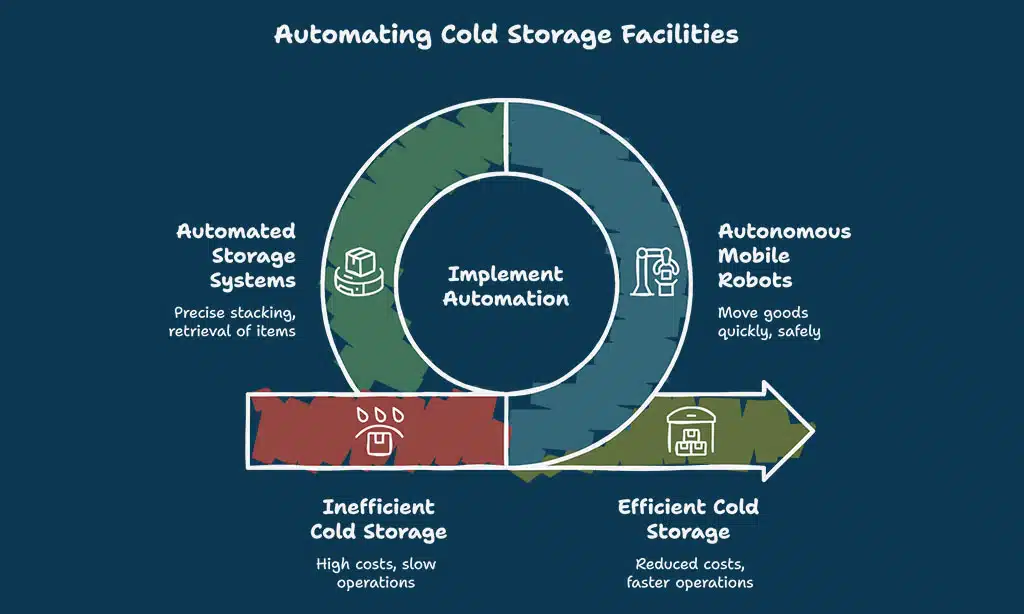

Automation in Cold Storage Facilities

Hey there, folks, let’s chat about how automation is changing the game in cold storage facilities. Picture a warehouse buzzing with machines that work on their own, no coffee breaks needed! Autonomous mobile robots are rolling in, and stats predict that by the next decade, half of all warehouses will have these helpers zooming around.

They move perishable goods fast, keeping temperature-sensitive products safe from spoilage. It’s like having a trusty sidekick who never gets tired, making sure your ice cream stays frosty.

Now, think about this, another cool shift is coming with automated storage and retrieval systems. Experts say 10 to 20 percent of warehouses will adopt these setups in the next 10 to 15 years.

These systems stack and grab items with pinpoint accuracy, slashing operational costs in cold chain logistics. Imagine a giant robotic arm playing a high-stakes game of Tetris with frozen goods, boosting warehouse management to new heights.

Automation like this ramps up efficiency and keeps inventory management tight as a drum.

Data Analytics for Demand Forecasting

Let’s chat about how data analytics is changing the game in cold chain logistics, especially for guessing what’s needed next. Imagine you’re running a warehouse full of perishable goods, like ice cream or vaccines.

Data analytics uses past sales numbers and trends to predict future demand. This means you stock just the right amount, cutting down on waste and saving cash on operational costs. It’s like having a crystal ball, but it’s all based on hard facts and figures.

Now, think about the big picture with the cold storage industry set to jump from $151.68 billion in 2024 to $190 billion by 2029. That’s a steady climb of 4.61% each year. Plus, the cold chain logistics market sits at $249 billion globally today, aiming for over $340 billion by 2031.

Even pharmaceutical logistics shot up from $98.94 billion in 2022 to $109.34 billion in 2023. With data crunching tools, companies can keep up with this growth, match inventory to real needs, and dodge costly overstocking of temperature-sensitive products.

Isn’t it neat how numbers can steer such a massive ship?

Sustainable Solutions for Energy Efficiency

Hey there, folks, let’s talk about making cold chain logistics more environmentally friendly. Sustainable solutions are emerging everywhere, and they’re reducing energy use significantly.

Imagine solar panels capturing sunlight to power warehouses. RSA Global, for example, uses these panels to cut their energy costs. It’s like transforming sunlight into savings, and who wouldn’t appreciate that?

Now, envision electric trucks rolling down the road, taking the place of gas-powered vehicles. On top of that, sustainable packaging for temperature-sensitive goods is something 55% of global consumers favor.

In countries like Brazil, 74% of people support it, while Mexico stands at 66%, and India reaches 67%. Increasing costs for transportation, tariffs, and labor encourage companies to embrace these energy-efficient ideas.

Cold chain management benefits from such advancements, supporting waste reduction and operational efficiency. Pretty neat, right?

Takeaways

Well, folks, we’ve zipped through the cool world of cold chain logistics. It’s amazing how tech like IoT sensors and AI analytics keeps perishable goods fresh as a daisy. These tools don’t just track stuff; they save time, cut waste, and boost efficiency.

So, next time you grab a chilled snack, give a nod to these awesome innovations. Got thoughts on this frosty journey? Drop a comment and let’s chat!

FAQs on Technologies Optimizing Cold Chain Logistics

1. What’s the big deal with cold chain logistics these days?

Hey, cold chain logistics is all about keeping perishable goods safe with tight temperature control. It’s a lifeline for temperature-sensitive products, like food or meds, in global supply chains.

2. How does real-time tracking help in cold chain management?

Well, real-time tracking with IoT sensors gives you supply chain visibility like never before. It’s like having eyes on your shipment 24/7, catching temperature excursions before they spoil temperature-sensitive goods. Plus, real-time data boosts operational efficiency, saving you from costly mishaps.

3. Can artificial intelligence really make a difference in logistics optimization?

You bet, artificial intelligence (AI) paired with predictive analytics is a game-changer for cold chain management. It’s like having a crystal ball, forecasting issues in supply chain resilience before they hit.

4. What role does smart packaging play in protecting perishable items?

Smart packaging, along with active packaging and sustainable packaging, acts like a shield for perishable goods. It uses innovations like phase change materials (PCMs) to maintain shelf life. Think of it as a tiny fortress against waste reduction challenges in international trade.

5. How are warehouse management systems changing the game for cold chain?

Warehouse management systems (WMS) are like the brains behind a distribution center, streamlining inventory management. They cut operational costs by automating tasks with automation technologies. It’s a slick way to dodge errors in handling temperature-sensitive products.

6. Are self-driving vehicles the future of fleet management in cold chain logistics?

Yo, self-driving vehicles and driverless tech, like AGVs, are shaking up fleet management systems. They’re slicing through logistics management headaches, especially for third-party logistics dealing with inflation and the U.S. economy. Picture a world where repairs and delays are just old tales, thanks to these automated systems.