You may worry that new construction will drive up costs and leave a big carbon footprint. In fact, most structural steel pieces hold 93 percent recycled steel. This guide shows 12 recycled steel solutions, like electric arc furnace frames and hollow structural sections, to boost strength, save energy, and help the circular economy.

Keep reading.

Key Takeaways

- Steel beams, bars, and cladding hold 93% recycled metal; recycling one ton saves 2,500 lbs of iron ore, 1,400 lbs of coal, and 120 lbs of limestone.

- Electric arc furnaces cut steel CO₂ by 75% vs new steel, lower project carbon by up to 58%, and recycle 60–80 million tons of scrap a year in North America.

- Factories prefabricate recycled steel frames to cut waste by 30%, speed build time by 25%, boost site safety, cut labor, and earn LEED credits.

- Hollow structural sections weigh 30–43% less and use 35–52% less material than I-beams, with a life cycle impact of 1,990 kg CO₂e per ton.

What Are Structural Beams Made from Recycled Steel?

Builders use beams made from recycled steel in bridges, warehouses, and high-rises. Typical I-sections contain about 93% recycled materials, cutting energy use in steel production.

Mills melt scrap in electric arc furnaces or basic oxygen furnaces to craft new plates and shapes. Recycling 1 ton of steel conserves 2,500 lbs of iron ore, 1,400 lbs of coal, and 120 lbs of limestone.

North America recycles 60 to 80 million tons of scrap each year for building materials. Nearly all beams, about 98%, reenter the mill after demolition. This closed loop drives a circular economy, shrinks carbon footprint, and cuts CO2 emissions.

Engineers track life cycle data and use environmental product declarations to meet green building goals.

How Do Recycled Steel Reinforcement Bars Improve Concrete Structures?

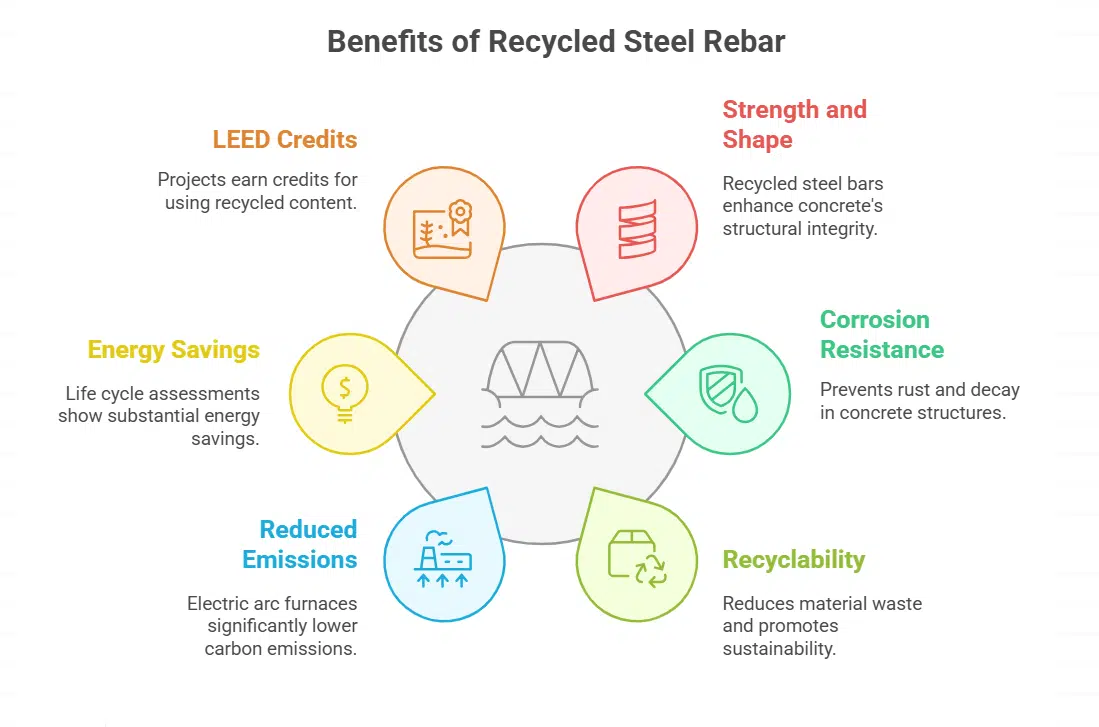

Recycled steel bars boost concrete strength and shape. They act like a metal spine inside slabs. Corrosion resistance hinders rust and decay. Steel resists rot, pest damage, and moisture.

Its recyclability makes rebar a green choice that cuts material waste.

Electric arc furnaces slash carbon emissions by seventy five percent compared to virgin steel. Life cycle assessments show big drops in embodied energy, boost energy savings and cut the carbon footprint.

Projects earn LEED credits for high recycled content in reinforcement bars. This practice supports a circular economy, drives resource conservation, and lifts material efficiency.

What Are Pre-Fabricated Steel Frames Using Recycled Materials?

Pre fabricated frames use recycled steel beams made offsite. Factories melt scrap in electric arc furnaces, drive beams into shape with CNC machines. They cut waste by 30%, shrink timelines by 25%.

Offsite prefabrication ensures precise fits and raises safety on site. These components slot together like Lego.

Such frames rely on EAF steel to lower the carbon footprint by up to 58%. They fit into modular building components, speed build by weeks. Low waste taps circular economy goals. Owners see faster ROI and lower material cost.

What Are High-Strength Hollow Structural Sections (HSS) from Recycled Steel?

Recyclers feed scrap into electric arc furnaces to make high-grade tubing. Steel makers also use basic oxygen furnaces to recycle scrap into tube stock. Hollow structural sections pack more compressive strength than wide flange columns.

Designers note they weigh 30–43% less and have 35–52% smaller perimeter than I-beams. Life cycle analysis shows a global warming potential of 1990 kgCO2e per metric ton, cutting embodied carbon in projects.

Tight spaces? These slim tubes fit the bill and speed assembly. This choice boosts material efficiency and backs a true circular economy in structural applications.

How Are Modular Building Components Made with Recycled Steel?

Steel mills feed scrap into arc furnaces. Arc furnaces cut carbon emissions by 75 percent with low-emission steelmaking. This process generates less slag and lowers acidification potential.

CNC machines slice steel plates and trusses into modules.

Welders and robots join wall, floor, and roof panels in factories. They seal joints to cut air leaks, lower CO2 equivalent, and boost energy conservation. This step serves the circular economy by raising material efficiency and recyclability of steel.

Builders assemble modules on site like big toy blocks.

What Are the Benefits of Recycled Steel Roofing and Cladding?

Cladding built with recycled steel resists rot, pests and decay, cutting maintenance and long term costs. It stands the test of storms, hail, and fire without sagging or warping. These roofs last decades with little fuss.

Most structural panels contain 93% recycled steel. This slash in virgin material use shrinks carbon footprint and fuels resource conservation in the construction industry. Electric arc furnace mills melt scrap into fresh sheets.

LCA data show clear carbon emissions reduction in sustainable construction. Such metal roofs fit circular economy goals and earn LEED points.

How Are Steel Bridges Built with Recycled Materials?

Crews gather scrap steel from old cars and demo waste. Workers sort scrap by grade before melting. They feed steel into an electric arc furnace at 1,600°C. The furnace slashes carbon footprint by over 50% versus ore smelting.

Techs shape beams in hot rolling mills. Welders connect girders and tie plates on site.

Recycled steel offers a top strength-to-weight ratio. It supports heavy trucks and braces against strong winds. Builders save ore and water, feeding a circular economy. Steel can cycle through electric arc or basic oxygen furnaces again and again.

Bridge decks can last 75 years with routine care. Inspectors scan welds with ultrasonic tools and digital cameras.

What Makes Recycled Steel Ideal for Industrial Warehouses and Plants?

Recycled steel resists rot, pests, and decay. This strength cuts maintenance bills. An electric arc furnace reuses scrap, not iron ore. That step drops CO2 emissions by up to 58 percent.

Circular economy goals gain momentum. Builders praise lower carbon footprint and resource conservation. Yield strength rivals new steel. Basic oxygen furnace also turns slag into beams.

Offsite prefabrication speeds up builds. It cuts labor needs, and it slashes waste. This process boosts safety rates on site. Modular frames made from reclaimed metal fit together like Lego bricks.

They hold heavy loads in warehouse floors and plant roofs. Energy efficient cladding trims heating bills. Owners praise lower long-term costs. That makes recycled steel a star pick for industrial hubs.

How Do Lightweight Steel Panels Enhance Energy-Efficient Construction?

Lightweight panels often use recycled steel from an EAF mill. Those panels cut the carbon footprint, boost material efficiency, and help sustainable construction. Panels snap together like building blocks, trimming assembly time.

The tight envelope holds indoor heat, lowering energy bills.

R-value tests show thermal performance up to R-40. Contractors load panel data into BIM for accurate modeling. Steel strength lets architects craft bold designs. Modular sections adapt for reuse, supporting a circular economy.

What Are Steel Flooring Systems Using Recycled Content?

Steel flooring systems use beams and sheets made from about 93 percent recycled steel. Mill operators in electric arc furnace mills melt scrap steel with slags and alloying elements.

Some mills use basic oxygen furnace for cleaner melts. Producers shape panels in cold-rolled lines, then cut them into interlocking decks. Circular economy drives this trend in construction industry.

These decks earn leed certification points, as they cut co2 emissions and lower the carbon footprint.

Builders lock decking tight and fill ribs with concrete. Installers cheer its quick pace. Owners watch demolition waste vanish like magic, as recycling technologies reclaim old metal.

Designers praise its resource conservation and reliability. Engineers use an lca tool to track acidification potential and prove green claims.

How Is Recycled Steel Used in Transportation Infrastructure Projects?

Recycled steel beams brace highway bridges and guardrails. Rail tracks use recycled steel ties that resist rot and decay. Airport runways get steel plates made in an electric arc furnace (EAF).

It shrinks carbon impact by over 50 percent. Basic oxygen furnaces (BOF) cut acidification potential and CO2 emissions. Engineers run LCA to find material efficiency gains. They run FEA to check load strength in beams.

Fishplate joints in rail lines last decades with this steel. Road sign posts from stainless mixes stand up to salt and rain, lowering maintenance. The method reuses construction and demolition waste and scraps.

This drives a circular economy in the steel industry and cuts waste disposal. It boosts resource conservation and builds resilient cities with greener building materials.

Steel Recycling Processes to Enhance Durability and Sustainability

A life cycle study shows how recycled steel from a steel furnace cuts CO2, trims acidification potential, feeds a circular economy, so read on.

What Are the Main Steps in Recycling Steel for Construction Use?

Steel scrap shapes stronger buildings. It costs less energy than new steel.

- Collect scrap metal at yards and sites, adding 60-80 million tons in North America to the circular economy.

- Sort steel scrap with electromagnets, pulling ferrous bits from mixed waste to boost recyclability of steel.

- Shred pieces into bits under 50 mm, raising surface area for faster melting and better material efficiency.

- Melt scrap in electric arc furnaces, using 60-70% recycled material to drive carbon emissions reduction.

- Purify molten steel with oxygen lances and fluxes, trimming sulfur and phosphorus to meet strength specs.

- Cast liquid steel into billets or slabs, setting shape for beams, bars, and hollow structural sections.

- Roll and shape billets in hot mills, crafting reinforcement bars, panels, or cladding for sustainable construction.

- Test final steel for tensile strength, chemistry, and form, meeting ASTM rules and aiding resource conservation.

How Does Recycling Steel Improve Structural Durability?

Recycled steel goes through EAF mills and BOF steel-making steps. That process keeps strength at 100 percent and delivers consistent quality.

It stops rot, pest damage, and decay, so beams last decades with low upkeep. It adds to a circular economy, cuts CO2 emissions in construction, and trims long-term costs.

What Sustainable Practices Are Involved in Steel Recycling?

Modern mills sort scrap and feed recycled steel to basic oxygen furnaces. Electric arc furnaces run on scrap metal and cut carbon emissions by 75%. They use less energy than primary steel making.

Magnetic separation and eddy current machines keep mixed scrap clean. Plants reclaim wash water to cut water use. Life cycle assessments guide material efficiency and carbon footprint cuts.

These steps drive resource conservation across iron industries.

Recyclers track stainless steel and ferritic grades across the supply chain. They mix melted scrap with virgin iron to boost strength. This circular economy method boosts recyclable materials use in structural applications.

It stops tons of CO2 emissions. Recycling one ton of stainless steel prevents 4.3 tons of CO2 emissions. Producers in steel manufacturing meet acidification potential goals and lower environmental harm.

Advantages of Recycled Steel in Reducing Environmental Impact

Recycled steel slashes CO2 emissions, as it melts old scrap in an EAF and cuts power use and water waste. A quick LCA shows big wins for the circular economy, and that green beam even laughs at rust.

How Does Recycled Steel Lower Carbon Footprint in Construction?

Builders cut carbon emissions by picking recycled steel for beams and braces. A steel smelting furnace holds scrap metal and runs on electric arcs. That method emits 75 percent less CO2 than a converter method.

It fuels circular economy goals and helps the construction industry meet sustainable construction standards.

Some hollow steel posts weigh 30 to 43 percent less. They need fewer truck trips, and they shrink global warming potential. Reusing scrap boosts material efficiency, and it trims acidification potential.

Your project gains resource conservation and lower life cycle impact.

What Are the Cost Benefits of Using Recycled Steel?

Recycled steel melts in an electric arc furnace, so mills spend less on raw input. Scrap feed beats ore for cost in a basic oxygen furnace. Lower feed bills shrink budgets. Faster build times lower costs and improve return on investment.

Offsite prefabrication uses scrap steel frames. Manufacturers cut labor and waste before vehicles arrive. Teams fit modules fast, trim work hours, and slash overhead. Recycled steel also cuts carbon footprint and boosts resource conservation in a circular economy.

How Does Recycled Steel Contribute to Resource Conservation?

Builders scrap steel feeds electric arc furnaces or basic oxygen furnaces for fresh beams. This method cuts demand for virgin iron ore by 2,500 pounds per ton processed. It spares 1,400 pounds of coal and 120 pounds of limestone.

Companies boost material efficiency and strengthen the circular economy in construction.

Savings extend to greenhouse gases too. One ton of stainless scrap stops 4.3 tons of CO2 emissions. Projects use less power and water, curbing acidification potential and shrinking the carbon footprint.

Civil engineers value full life cycle gains for greener roads, bridges and buildings.

Takeaways

You have twelve recycled steel ideas that strengthen US builds and shrink carbon footprints. The list covers structural beams, tubular sections, and modular frames with high recycled content.

Arc furnace, LCA, and green rating link up to cut CO2 and snag eco points. Steel flooring panels and energy saving cladding seal out leaks and save energy. Your next project can tap these gifts from steel recycling to stand long and firm.

This plan keeps scrap moving in a circular economy with 93 percent recycled in each beam.

FAQs on Recycled Steel Solutions for Durable US Structures

1. What makes recycled steel a smart choice for durable US structures?

Recycled steel slashes the carbon footprint, thanks to material efficiency. It ranks high on the recyclability of steel. It drives carbon emissions reduction. It fits a circular economy, and aids water conservation.

2. How do electric arc furnace (eaf) and basic oxygen furnace (bof) methods affect sustainability?

The electric arc furnace (eaf) reuses scrap steel, it runs on less energy and trims carbon emissions. The basic oxygen furnace (bof) can use new iron, it often burns more gas. Eaf often wins on resource conservation, but both play a role in the value chain.

3. Can recycled steel help reduce acidification potential and CO2 emissions?

Yes, recycled steel lowers acidification potential, which hurts water and soil. It cuts co2 emissions in life cycle assessments (lcas). It brings big wins on climate goals, in the construction industry.

4. How does recycled steel fit into sustainable construction and structural applications?

Recycled steel plays well with mass timber, recycled plastics, and recycled glass. It works in beams, columns, and panels. You see it in adaptive reuse projects and in new sustainable construction.

5. What should suppliers and builders consider in the value chain for recycled steel?

They should check lcas, track material selection and supplier ties. They can work with local suppliers to cut transport, they can back a sustainable business model. This locks value at every step in the value chain.

6. How can the construction industry boost a circular economy with recycled steel?

It can loop scrap back into new structures, like a boomerang. It can cut packaging waste, and ramp up water conservation. It can team up with mass timber or asphalt suppliers to close the loop on resource conservation.