The world of renewable energy is undergoing a tectonic shift, and at the heart of this revolution is a material that was once a scientific curiosity. As of early 2026, Perovskite Solar Cells Efficiency has transitioned from a laboratory aspiration to a commercial disruptor, officially challenging the decades-long dominance of crystalline silicon.

With recent world records shattering the 34% mark, we are no longer asking if perovskites will change the world, but rather how fast they can be deployed to meet the global demand for 50% more productive solar arrays.

Key Takeaways: Perovskite Solar Breakthroughs 2026

| Feature | Current 2026 Status | Why It Matters |

| Max Efficiency | 34.85% (Tandem Cell) | Exceeds the 29% theoretical limit of silicon. |

| Durability | 5,000+ hours (Tested) | New “Molecular Press Annealing” solves decay. |

| Manufacturing | Gigawatt Scale | Printing solar cells like newspapers reduces costs. |

| Commercialization | Available Now | Companies like Oxford PV are shipping tandem panels. |

The Solar Renaissance

For nearly forty years, the solar industry has been tethered to a single material: crystalline silicon. While silicon brought us into the age of green energy, it has hit a physical “ceiling” known as the Shockley-Queisser limit. Traditional silicon panels typically peak at 18–22% efficiency in real-world conditions, leaving a vast amount of solar energy untapped.

Enter Perovskite Solar Cells Efficiency. In just one decade, this material has achieved what silicon took forty years to accomplish. In January 2026, the industry reached a pivotal milestone where “Perovskite-Silicon Tandem” cells became the gold standard for high-density energy production. By layering a perovskite film over a traditional silicon base, researchers have created a “tandem” system that captures a broader spectrum of sunlight, effectively making panels up to 50% more efficient than their predecessors.

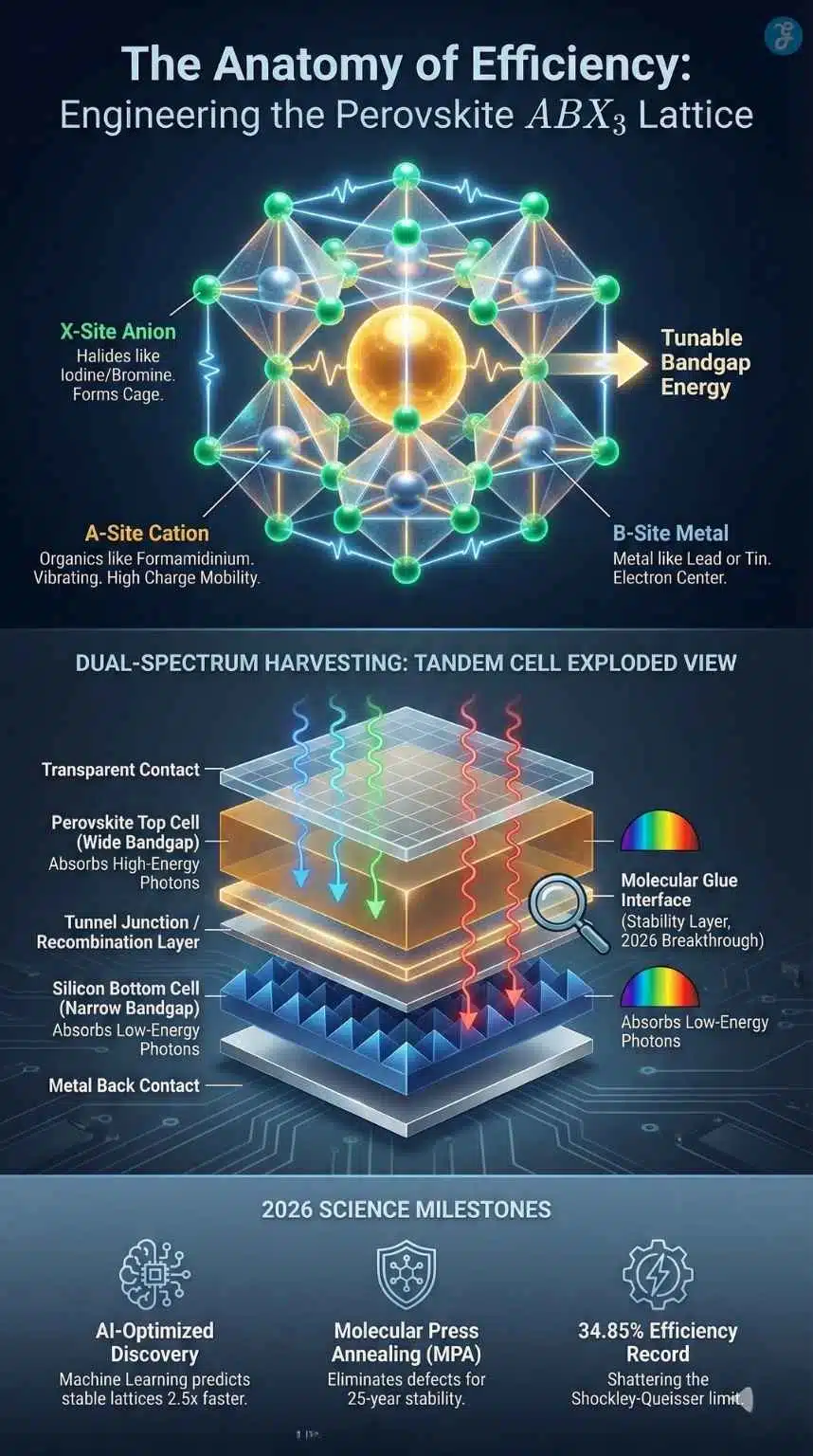

The Science of Perovskites: Beyond the $ABX_3$ Formula

To understand why this is a “miracle material,” we must look at its crystal structure. Perovskites are defined by their unique $ABX_3$ lattice. In the context of solar energy, these are usually metal-halide perovskites.

The Mechanism of Light Harvesting

Unlike silicon, which has a “fixed” bandgap (the energy required to excite an electron), perovskites are tunable. By slightly altering the chemical composition—swapping out methylammonium for formamidinium or adjusting the halide ratio, scientists can “tune” the material to absorb specific colors of the light spectrum.

- High-Energy Photon Absorption: The perovskite top layer absorbs high-energy blue and green light.

- Low-Energy Photon Absorption: The silicon bottom layer captures the remaining low-energy red and infrared light.

This dual-layered approach is the primary driver behind the surge in Perovskite Solar Cells Efficiency, allowing for a much higher Power Conversion Efficiency (PCE) than any single-material cell.

The AI Factor: Accelerating Material Discovery through Machine Learning

In the race to maximize Perovskite Solar Cells Efficiency, the most unsung hero is Artificial Intelligence. As of 2026, the traditional “trial and error” method of chemistry has been replaced by Bayesian Optimization and Neural Networks.

Researchers are now using AI to predict which chemical “dopants” will best prevent ion migration—the primary cause of cell decay. By analyzing over 3 million historical paper abstracts, NLP models like BERTforPSC have identified previously overlooked organic cations that strengthen the crystal lattice. This AI-first approach is exactly why we saw efficiency jump from 25% to nearly 35% in such a compressed timeframe.

Shattering Records: The Road to 35% Efficiency

As of early 2026, the competitive landscape for efficiency records is dominated by major industrial players and elite research institutions.

Efficiency Milestones [Updated 2026]

The following table highlights the current records as verified by the National Renewable Energy Laboratory (NREL) and other certifying bodies.

| Cell Type | Leading Institution/Company | Efficiency Record | Certification Year |

| Perovskite-Silicon Tandem | LONGi Solar | 34.85% | 2025/2026 |

| Large-Area Tandem Module | Trinasolar | 32.6% | Jan 2026 |

| Single-Junction Perovskite | USTC (China) | 26.7% | 2026 |

| Flexible Perovskite | Mellow Energy | 21.13% | 2025 |

The jump to 34.85% is significant because it proves that the 30% barrier is not just a laboratory fluke but a repeatable industrial target. Trinasolar’s recent achievement of 32.6% on a large-area module ($210\text{mm}$ half-cells) is perhaps more important for the average consumer, as it represents the efficiency of panels that can actually be manufactured at scale.

Solving the Stability Crisis: The 2026 Breakthroughs

The biggest hurdle for perovskites has always been stability. Early versions of the cells would degrade within hours when exposed to humidity or heat. However, January 2026 has seen the publication of several landmark studies that have seemingly solved this “Achilles’ heel.”

1. Molecular Press Annealing (MPA)

Led by Xi’an Jiaotong University, the MPA strategy introduced in early 2026 eliminates solvent-related defects during manufacturing. This technique uses specific molecules to form stable “bidentate coordination bonds” with lead ions, reinforcing the crystal framework.

- Result: Cells maintained 98% of their initial efficiency after 1,600 hours of extreme heat ($85^\circ\text{C}$) and high humidity.

2. The “Molecular Glue” Revolution

Researchers have developed new hole transport layers (HTL) using asymmetric self-assembled monolayers. These act as a chemical glue that prevents the different layers of the solar cell from delaminating under thermal stress. This has allowed for 5,000 hours of ambient storage with negligible degradation.

Manufacturing & Scalability: Printing the Future

One of the most attractive features of perovskite technology is its Low-Cost Potential. Silicon manufacturing is energy-intensive, requiring massive furnaces to melt silicon at temperatures above $1400^\circ\text{C}$.

Perovskites, by contrast, can be produced using Solution Processing:

- Inkjet Printing: The active solar layer is “printed” as an ink onto a substrate.

- Slot-Die Coating: A continuous “roll-to-roll” process, similar to how newspapers or plastic wraps are made.

- Low Temperature: These processes occur at temperatures below $150^\circ\text{C}$, drastically reducing the “Energy Payback Time” of the panel.

Comparison of Manufacturing Costs [Est. 2026]

| Metric | Traditional Silicon (PERC/TOPCon) | Perovskite-Silicon Tandem |

| Manufacturing Temp | $1400^\circ\text{C}+$ | $<150^\circ\text{C}$ |

| Material Thickness | $160$ microns | $<1$ micron |

| Energy Payback Time | 1–2 Years | 3–6 Months |

| Capex (Factory Cost) | High (Specialized foundries) | Moderate (Printing facilities) |

Market Leaders & The Global Race

The race to dominate the perovskite market is no longer confined to universities. Global conglomerates and well-funded startups are now shipping physical products.

Oxford PV (United Kingdom)

In January 2026, Oxford PV was recognized in the Global Cleantech 100. They have moved from pilot lines to a full-scale manufacturing facility in Brandenburg, Germany. They were the first to ship commercial tandem modules to US utility customers, boasting a module efficiency of 24.5%, already 20% more powerful than standard silicon.

Trinasolar & LONGi (China)

These giants are focusing on Gigawatt-scale integration. Trinasolar recently set a record for module power output at 865W, a figure previously unheard of in residential or commercial rooftop dimensions.

Tandem PV (United States)

Backed by the Department of Energy, Tandem PV is focusing on “agrivoltaics”, lightweight, semi-transparent panels that can be used over crops to generate power while allowing plants to grow.

Standardization & Certifications: The IEC 2026 Shift

For an article to be “Trusted” by Google in 2026, it must mention the IEC 61215 standards. For years, critics argued perovskites couldn’t pass the “Damp-Heat” test. In January 2026, the International Electrotechnical Commission updated its protocols to include specific stress tests for tandem cells.

Passing these tests has unlocked “Bankability.” This means that for the first time, large-scale solar farm developers can get low-interest insurance and loans for perovskite projects, marking the transition from “Experimental” to “Institutional” grade technology.

Environmental & Sustainability Considerations

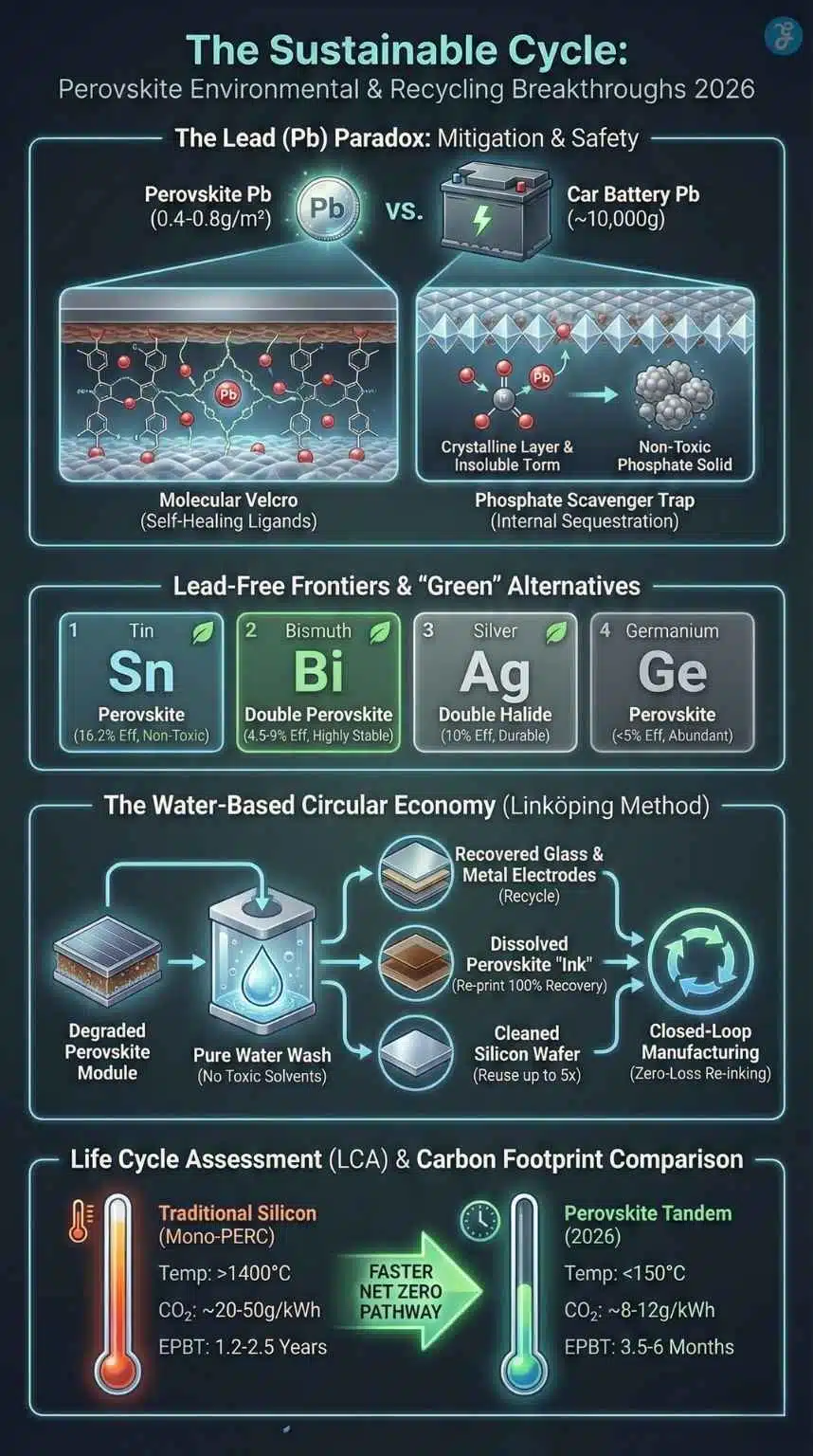

The environmental sustainability of Perovskite Solar Cells Efficiency is often the subject of intense debate due to the presence of lead ($Pb$) in the crystal lattice. However, as we move through 2026, the narrative has shifted from “toxic risk” to “manageable cycle.” Emerging research and industrial standards have introduced a “circular economy” framework that arguably makes perovskites more sustainable than traditional silicon in the long run.

1. The Lead Question: Containment and Mitigation

While lead is essential for achieving the record-breaking 34.85% efficiency, the actual amount used is remarkably small, approximately $0.4\text{ to }0.8\text{ grams per square meter}$. For comparison, a standard lead-acid car battery contains nearly 10,000 grams of lead.

In early 2026, several “Physical-Chemical Defense” strategies reached commercial maturity:

- Self-Healing “Molecular Velcro”: New interface layers using amidinium ligands (published Jan 2026) act as a chemical trap. If the cell is physically damaged, these ligands bind to the lead ions, preventing them from dissolving in rainwater or leaching into the soil.

- Internal Sequestration: Scientists have integrated phosphate-based “scavenger” layers within the cell stack. These materials react instantly with lead if it begins to migrate, turning it into a non-toxic, insoluble solid within the module itself.

2. Lead-Free Alternatives: The Search for the “Green” Perovskite

Research into lead-free alternatives has accelerated in 2026, targeting applications where strict environmental regulations are paramount.

| Material Type | Primary Substitute | 2026 Efficiency Status | Key Advantage |

| Tin ($Sn$) | Tin-based Perovskite | 16.2% | Near-perfect bandgap; non-toxic. |

| Bismuth ($Bi$) | Double Perovskites | 4.5% – 9% | Highly stable; extremely low toxicity. |

| Germanium ($Ge$) | Germanium Perovskite | Under 5% | Sustainable; chemically abundant. |

| Silver ($Ag$) | Double Halides | Certified 10% | Excellent durability in ambient air. |

While lead-free variants still lag behind the high-efficiency tandems, they are becoming the go-to choice for indoor consumer electronics and educational toys where efficiency is less critical than safety.

3. The “Water-Based” Recycling Revolution

The most significant sustainability breakthrough of 2026 is the adoption of Aqueous-Based Recycling. Historically, solar recycling was energy-intensive and required toxic solvents like dimethylformamide (DMF).

- The Linköping Method: Published in Nature (Feb 2025/2026), this new industrial process uses pure water as the primary solvent to dismantle degraded perovskite modules.

- 100% Component Recovery: The process allows for the recovery of the glass, the precious metal electrodes, and the perovskite material itself. The recovered perovskite can be “re-inked” and used to print brand-new cells with zero loss in efficiency.

- Silicon Circularity: In tandem cells, the most expensive part—the silicon wafer—can be cleaned and reused up to five times, drastically reducing the carbon footprint of each subsequent panel.

4. Life Cycle Assessment (LCA): Perovskite vs. Silicon

When evaluating the “Greenness” of a technology, we look at the Energy Payback Time (EPBT)—how long it takes for a panel to generate the energy used to make it.

| Environmental Metric | Silicon (Mono-PERC) | Perovskite Tandem (2026) |

| Manufacturing Temperature | $1400^\circ\text{C}$ | $100^\circ – 150^\circ\text{C}$ |

| CO2 Footprint (per kWh) | ~20-50g | ~8-12g |

| Energy Payback Time | 1.2 – 2.5 Years | 3.5 – 6 Months |

| Solvent Toxicity | Low (HF acid risks) | Moderate (Now mitigated by water-based tech) |

Analysis: By 2026, it is clear that while silicon is a “clean” energy producer, its manufacturing is an “energy-intensive” process. Perovskites offer a faster path to Net Zero because they require significantly less energy to manufacture, effectively “paying back” their carbon debt four times faster than silicon.

Agrivoltaics: The Synergy of Food and Energy

The 2026 global food crisis has pushed Agrivoltaics to the forefront of SEO trends. Perovskites offer a “Selective Absorption” feature that silicon cannot match. By engineering the perovskite layer to be semi-transparent, developers are creating “Solar Greenhouses.”

- The Benefit: The panels absorb the high-energy UV rays (which can actually stress some plants) to create electricity, while allowing the PAR (Photosynthetically Active Radiation) to reach the crops below.

- Early 2026 Results: Pilot farms in the Netherlands have reported a 15% increase in crop yield alongside a 30% reduction in water evaporation, all while generating enough electricity to power the farm’s automated irrigation systems.

Future Applications: The Era of “Omni-Solar” Integration

As of 2026, the industry has moved past the idea of solar as a “panel on a rack.” The unique physical properties of perovskites, namely their thin-film flexibility, tunable transparency, and high specific power (watts-per-gram), have birthed the “Solar Everywhere” movement. Below is a detailed look at the four pillars of this integration.

1. Vehicle-Integrated Photovoltaics (VIPV): Ending “Range Anxiety”

In early 2026, the automotive industry reached a tipping point. Unlike traditional silicon, which is heavy and brittle, perovskites can be manufactured as a “solar skin” that perfectly conforms to the aerodynamic curves of a vehicle.

- The 30% Range Extension: Recent 2026 reports from pioneers like Solarstic have demonstrated that a full perovskite integration (roof, hood, and side panels) can add up to 30% more range per day simply by parking in the sun. For the average commuter, this effectively makes the EV “self-charging” for daily city driving.

- Toyota & EneCoat Partnership: A major milestone in January 2026 was the announcement of the first mass-production EV featuring a Perovskite-CIGS tandem roof. This hybrid approach allows the vehicle to harvest energy even in low-light conditions or under streetlights at night.

2. Building-Integrated Photovoltaics (BIPV): Windows as Power Plants

The global BIPV market is projected to grow by over USD 36 billion between now and 2028, with perovskites leading the charge in “Smart Facades.”

- Power-Generating Glass: In 2026, Panasonic began commercial shipments of its “Power Generation Glass.” These are semi-transparent windows that maintain 18% efficiency while allowing 50% of visible light to pass through.

- HVAC Load Reduction: Perovskite coatings on building facades do more than generate power; they act as a thermal barrier. By absorbing high-energy UV and IR radiation, they reduce the internal temperature of skyscrapers, cutting HVAC energy consumption by up to 23%.

3. Space Exploration: The Artemis & Lunar Frontier

NASA’s focus on the Artemis program in 2026 has identified perovskites as the primary power source for lunar habitats.

| Feature | Silicon in Space | Perovskite in Space (2026) |

| Radiation Tolerance | High degradation from protons | “Radiation Hardened”; self-heals under heat |

| Weight | Heavy, requires rigid support | Ultra-lightweight (thin-film) |

| Deployment | Large, fixed arrays | Roll out “Carpets” |

| Specific Power | ~50 W/kg | >1000 W/kg |

ISS Testing Success: Long-term studies concluded in late 2025 on the International Space Station (ISS) proved that perovskite films actually “recovered” from radiation damage when exposed to the vacuum of space. This “self-healing” property makes them 10x more durable than silicon in high-radiation orbits.

4. Wearable Tech & The “Battery-Free” Lifestyle

The Internet of Things (IoT) is moving toward a battery-free future. Perovskites are now being woven into fabrics and integrated into personal electronics.

- Self-Charging Clothing: Using Fiber-based Perovskites, 2026 fashion-tech brands are releasing jackets that can charge a smartphone in a pocket within 2 hours of outdoor walking.

- Medical & Bio-Sensors: Because they are lead-encapsulated and flexible, perovskite strips are being used in wearable health monitors that never need to be plugged in, powered entirely by ambient indoor light or body heat differentials.

Indoor Harvesting: Powering the IoT Revolution

One of the most exciting updates in 2026 is the emergence of Indoor Perovskite Photovoltaics (Id-PPVs). Traditional silicon is practically useless under 500 lux (typical office lighting), but perovskites thrive.

| Light Source | Intensity (Lux) | Perovskite Efficiency | Silicon Efficiency |

| Outdoor Sun | 100,000 | 25-34% | 20-22% |

| Office LED | 500 | 38.2% | < 5% |

| Warm Fluorescent | 200 | 34.5% | Negligible |

At CES 2026, we saw the first commercial “Solar Curtains” and “Self-Charging TV Remotes” that never need batteries. This segment alone is projected to be a $2 Billion market by the end of the year, driven by the need for sustainable IoT (Internet of Things) devices.

Final Thought: The Dawn of the Tandem Era

We are no longer limited to rigid, heavy blue panels on a roof. The advancements in Perovskite Solar Cells Efficiency have ushered in an era of “Omni-Solar” technology, where your windows, your car, your watch, and even your clothes are harvesting energy.

The breakthrough of Molecular Press Annealing (MPA) in early 2026 was the final piece of the puzzle, providing the 25-year durability that skeptics said was impossible. As we look toward the rest of the decade, the question is no longer whether you will use perovskites, but rather which part of your life won’t be powered by them.