NASA has funded an early-stage study exploring whether astronauts could one day live inside large, glasslike spheres made from Moon dust. The concept—LUNGS (Lunar Glass Structure)—is a 2025 NASA Innovative Advanced Concepts (NIAC) Phase I selection led by Skyeports (PI: Martin Bermudez). NIAC Phase I funds feasibility: modeling and benchtop tests, not construction. The pitch is to melt the Moon’s glass-rich regolith with microwaves and “blow” it into a monolithic spherical shell that later gets outfitted as a pressurized habitat.

Why this approach matters

Launching bulky habitat parts from Earth is mass- and cost-prohibitive. LUNGS aims to use local materials (ISRU), eliminating complex assembly of prefabricated modules or the logistics of large inflatable systems. By forming one continuous shell on site, the team argues you could reduce interfaces, seams, and assembly risk while gaining very large interior volume for living, labs, and greenhouses. This is a departure from standard lunar construction concepts, which is precisely what NIAC is designed to probe.

The construction concept — from regolith to shell

Feedstock & prep. Lunar regolith contains silicates and natural glass, making it suitable for glassmaking once processed. Collected soil would be screened and blended to target glass-forming behavior.

Melting. A “smart” microwave furnace would heat the material to glass-forming temperatures. Microwaves are attractive on the Moon because they couple with certain minerals and don’t require oxygen or combustion, which are scarce in vacuum.

Blowing the shell. In low external pressure, an inert gas can expand the molten charge into a near-perfect sphere with comparatively little force. The vacuum and low gravity help the sphere form with uniform thickness. Temporary gas lines used to inflate the shell could be reused as an entrance/airlock conduit once the shell solidifies.

Annealing & integration. Controlled cooling would relieve internal stresses; then engineers would integrate floors, life-support, radiation mitigations, and power systems. Much of the interior structure could be 3D-printed on site from regolith-derived materials to save launch mass.

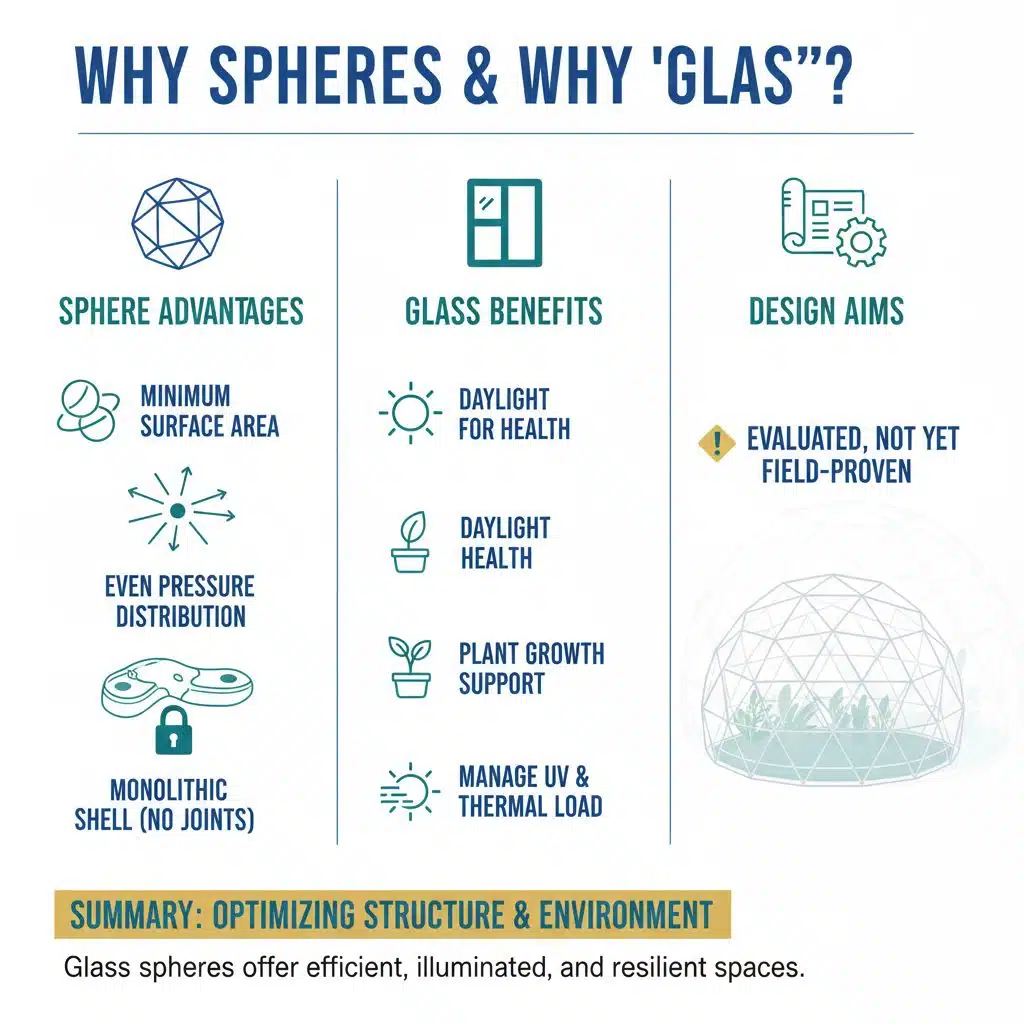

Why spheres and why “glass”?

A sphere minimizes surface area for a given volume and distributes internal pressure evenly, a classic advantage for pressure vessels. A monolithic shell (no joints) can simplify sealing and leak paths. Translucency allows daylight for circadian health and plant growth, with coatings/films to manage UV and thermal load. These are design aims being evaluated, not yet field-proven.

Durability — the big engineering questions

Material tuning. The study examines composition tweaks and metal-doping (e.g., aluminum/titanium compounds) to boost toughness and reduce brittleness. Layered shells with inert-gas gaps—akin to giant double-glazed windows—are being explored to dissipate micrometeoroid energy and manage thermal gradients.

Self-healing prospects. Public discussion around the concept has referenced self-healing polymer–glass hybrids that can slow micro-crack propagation or seal pinholes. Self-healing materials are a real research area in aerospace, but not yet baselined for LUNGS. Any such capability remains forward-looking pending test data.

Cracking, impacts, and pressurization safety. Key risks include residual stresses from uneven cooling, micrometeoroid spall, and safe procedures to pressurize large shells. These are exactly the failure modes Phase I will model and try to bound before any flight demo is considered.

How big could these habitats get?

Some media reports describe very large diameters or city-scale clusters linked by glass bridges. The official NIAC pages confirm “large-scale monolithic shells” but do not commit to specific diameters; scaling is constrained by furnace power, melt handling, fracture mechanics, and operational risk. Treat extreme size claims as aspirational until peer-reviewed models and data appear.

Power, lighting, and human factors

Design studies anticipate solar power integration, daylight admission through the shell (with filters), and internal decks for living, working, and greenhouses. Concepts even include thermal zoning (warmer vs. cooler layers) to drive condensation cycles that support plant growth and water recovery—again, promising ideas to be substantiated in lab and micro-g tests.

What NASA actually funded next

Phase I covers analyses and bench tests, including thermal-vacuum experiments of microwave melting and controlled blowing in relevant pressure/temperature conditions. If successful and competitively selected, later phases could pursue microgravity trials to validate forming dynamics. Any ISS or lunar demonstration would require separate selection, safety reviews, and funding—there is no commitment to deploy hardware on the Moon under this award.

How this fits alongside other Moon-building methods

LUNGS sits within a wider push to build with in-situ resources (ISRU). Complementary lines include:

-

Laser or concentrated-light melting of regolith to make pavers for roads, landing pads, and dust control—shown in multiple lab programs and covered by Physics Today and others.

-

Regolith 3D printing for berms and shells (e.g., ICON’s work under NASA), which could be combined with glass spheres depending on site and mission phase. The point: future bases will likely mix methods to balance shielding, mass, and habitability.

Artemis timing — context, not dependency

The Artemis II crewed lunar flyby is scheduled no earlier than April 2026, per NASA updates, with Artemis III (first Artemis landing) targeted for 2027. These missions don’t require glass habitats; LUNGS is a long-horizon technology exploration for sustained surface presence later on.

What’s solid vs. speculative (reader checklist)

-

Confirmed: NASA selected Skyeports’ LUNGS for NIAC 2025 Phase I to analyze microwave-melted, blown-glass habitat shells made from lunar regolith. Status: feasibility study, not a construction or flight program.

-

Plausible and under study: multi-layer shells, metal-doped glass, gas gaps, interior 3D-printed fit-outs, integrated solar, greenhouses, thermal zoning. These are engineering directions being modeled and prototyped at lab scale.

-

Speculative until published: kilometer-class diameters, self-healing structural glass, near-term ISS or lunar demos. Consider these aspirational unless they appear in NASA updates or peer-reviewed results.