Warehouses can feel like endless mazes, with slow moves of pallets and picking errors. You may spend hours hunting for goods. You scan stock with a warehouse management system or RFID tags.

That slows orders. That drives up costs. Studies show warehouse robotics can boost picking speed by fifty percent.

This post will cover seven top logistics robots. We will look at automated storage and retrieval systems, automated guided vehicles, autonomous mobile robots, robotic arms, unmanned aerial vehicles, automated forklifts, and conveyors.

You will learn how these tools cut errors, boost safety, and speed up fulfillment. Read on.

Key Takeaways

- Warehouse robots boost picking speed by 50% and cut order-fulfillment time by about 30%.

- AS/RS towers, vertical carousels, Cube storage bots, and AutoStore systems raise density by up to 400% and reclaim floor space.

- AMRs and AGVs power goods-to-person picking in e-commerce hubs, slash walking time, and cut mispicks.

- Amazon’s Sparrow robotic arm cuts defects by 65%, while conveyors and sortation bots lift picking accuracy by 20%.

- Drones trim stock-scanning time by 60% with 24/7 audits; stacker cranes boost vertical storage by 60% and lower accidents by 40%.

AS/RS (Automated Storage and Retrieval Systems)

Tower lifters and vertical carousels work together to shuttle pallets in seconds, all tracked by spectrum labels for near-perfect picks. Our machine eyes spot misalignments that would trip up a human picker.

Enhancing storage efficiency

Cube storage robots pack bins close together. Shuttles and miniload systems speed material handling in tight aisles. Vertical Lift Modules haul trays up to sky-high racks. AutoStore systems boost density by up to 400 percent.

This design cuts idle floor space and holds more pallets in each rack.

Automated storage and retrieval systems link to inventory management software. Warehouse robots guide picks with computer vision systems and RFID. They lift, sort, and track stock with better picking accuracy.

Teams cut time and errors with these tools. Operations hum along like a well-oiled machine.

Reducing human error in retrieval

Smart racks keep bins neat, now robots guard against pick mistakes. Robotic rack systems, guided carts and smart movers link with vision systems to spot wrong items before someone grabs a box.

Picking robots scan RFID tags and barcodes to fetch the right case every time. Warehouse robotics cut manual handling and improve inventory accuracy. Conveyor belts carry goods to pack stations without human checks, so order fulfillment stays smooth and safe.

Mobile Robots

Autonomous carriers zip through racks with radio tags and laser scanners, grabbing bins at breakneck speed. They slash pick times, and let teams focus on high-value tasks.

Autonomous navigation within warehouses

Automated guided vehicles follow magnetic strips, wires, or light beams on warehouse floors. They zip like busy bees, hauling pallets and totes from one bay to the next. These systems cut labor costs and boost safety by avoiding collisions.

Autonomous mobile robots, or AMRs, rely on detectors, vision units, and machine smarts to map aisles in real time. Each unit scans QR codes and RFID tags to check its exact spot. These machines adapt on the fly, dodging workers and racks with ease.

Goods-to-person picking systems

Goods-to-person systems speed up picking. Shelves arrive to the picker instead of the worker scouting aisles. Robots and automated guided vehicles move racks with help from WMS. Vision systems guide units and radio frequency identification tags track stock.

Warehouse automation cuts walking and slashes errors.

E-commerce hubs use these tools for fast order fulfillment. Autonomous mobile robots link to WMS for hands-free tasks and order consolidation. Systems often use vertical lift modules or horizontal carousels.

Picking robots grab items from trays and send them to pack stations. Sites using these systems see better throughput and fewer mispicks.

Robotic Arms

Robotic arms use smart logic, pick and place parts with razor-sharp focus, and pack boxes in record time. They scan goods with optic modules, flex joints on demand, and zip through tasks like a pro juggler.

High-precision tasks such as picking and placing

A robotic arm picks and places parts with tiny error. Machine learning helps camera modules spot exact locations on each item. Automated guided vehicles bring bins to the arm, so workers walk less.

Warehouse robotics speed up order fulfillment and shrink mistakes. Sparrow, an AI powered picker at Amazon, cuts defects by 65%.

These machines run long shifts handling hundreds of picks each hour. Collaborative robots can team with people on the line to keep pace. Tools like pick and place robots free staff to focus on complex jobs.

Flexible use in packaging and assembly comes next.

Flexible use in packaging and assembly

Following precise picking and placing, robots shift into packaging and assembly roles. Cobots use machine vision and AI algorithms to sort, seal, and label goods.

This gear cuts manual labor on dull tasks, boosts throughput, and adds safety in shared stations. These packaging robots and automation arms join self-driving carriers and sortation systems to speed up order fulfillment in warehouse robotics.

Drones

Sky bots zip through warehouse aisles, scanning RFID tags with thermal cameras, and spot missing stock faster than you can say “oops.” They feed real-time data into your inventory management system.

Inventory management and stock scanning

Small quadcopters zip through aisles on preplanned routes, eyeing each shelf. These aerial units use high-res cameras and AI vision systems for super-fast stock audits. They join warehouse robotics fleets, working alongside picking robots and autonomous mobile robots.

Drones act like vigilant hawks spotting missing items in seconds. Audit flights cut scanning time by up to 60 percent and slash labor costs. Surveillance runs occur at odd hours, boosting 24/7 coverage.

Warehouse managers link drone feeds to inventory management software for real-time insights. RFID scanners on board tag along and log every pallet without human fuss. Operators spot misplaced boxes through a cloud dashboard and fix errors on the spot.

This method saves staff hours each week and tames the chaos in large distribution centers.

Faster inspections of hard-to-reach areas

After full stock scans, unmanned aerial vehicles (UAVs) pivot to inspect high shelves. They zip like bees through narrow aisles, spotting cracks or spill signs. UAVs carry thermal imaging gear and vision systems to boost warehouse automation.

They serve security checks and haul small-item transport loads. They cut the need for manual inspections and raise accuracy. AI steers flight paths, so robots dodge obstacles and scan each rack.

Automated Forklifts

Automated forklifts, a type of AGV, zip through narrow aisles, lift heavy crates with AI vision modules and scan radio chips in one smooth sweep. They drop loads safely, cut injury risks, and free staff to tackle more skilled handling jobs.

Streamlined pallet movement

Forklifts fitted with vision systems pick up pallets and place them on trucks. They run along predefined navigation paths, avoiding stops and slowdowns. Operators handle fewer heavy lifts, cutting manual labor and trimming operational costs.

Autonomous mobile robots read RFID tags on each load, sending live updates to warehouse automation software. They team up with automated guided vehicles in storage and retrieval routines.

This setup speeds truck turnaround times at busy docks.

Reducing workplace accidents

Autonomous mobile robots use camera networks, LiDAR and AI to steer around workers, racks and obstacles. These self-driving carts maintain precise paths, cut collision risks and lower injury rates.

Vision networks scan aisles, spot spills and slow zones, and alert operators. Workers trust safety machines that act with care, cutting accident rates and boosting morale.

Automated guided vehicles shift pallets along marked floors. They stop when sensors detect motion close by. Collaborative arms pause when a person walks into their zone. This precise operation shrinks injury numbers, enhances workplace safety and drives logistics automation forward.

Conveyors and Sorting Robots

Conveyor belts hum beneath shelving, and vision sensors track each crate via RFID tags.

Sorting robots link to sortation systems, shooting parcels to the right dock in seconds.

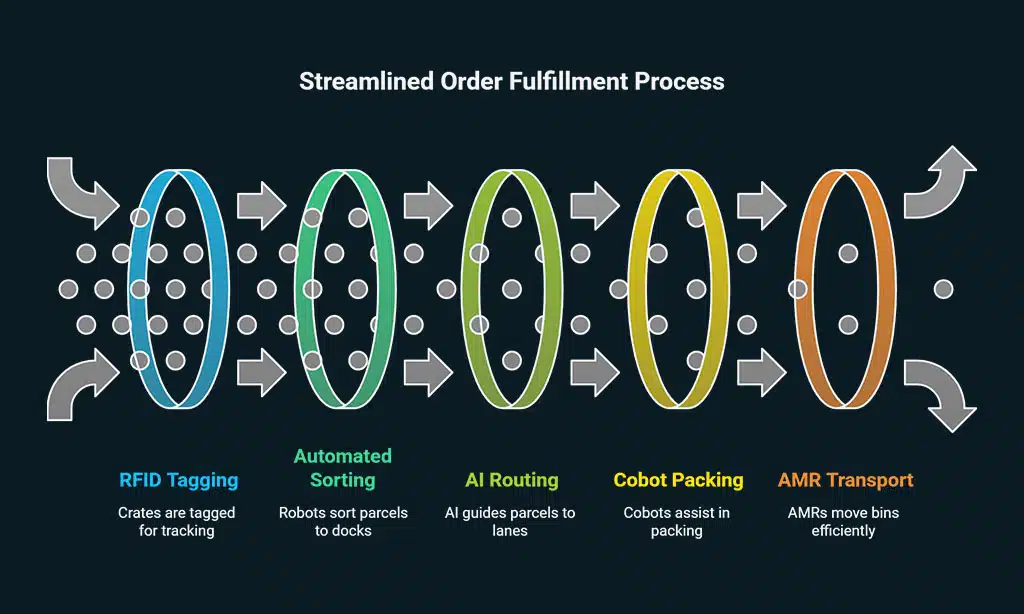

Automated sorting for order fulfillment

Sorting robots act like traffic cops on a busy warehouse floor. They read each barcode with RFID scanners and vision cells. Bins move along guided by AMRs and AGVs. This setup optimizes material flow and speeds tasks.

It cuts manual errors and lifts picking accuracy by 20%.

AI routes every package down the best lane, like a pro chess player. Cobots team with humans at packing stations, with no coffee breaks needed. The system boosts order fulfillment rates during peak seasons.

It also chops labor hours by half.

Speeding up product movement

Conveyor belts haul pallets and cartons across warehouse floors, 24/7. Smart sortation robots pick out items by size and shape, shuttling them onto correct chutes. This mix of conveyor systems, sortation systems, and logistics automation cuts manual lifting and transport time.

Warehouse teams scan RFID tags, then machine learning and vision systems guide parcels along correct routes. This blend of automated systems boosts throughput and trims delays.

Autonomous mobile robots rendezvous with conveyor lanes to hand off bins. Integration with warehouse management software syncs every move, cutting handoff delays. On busy days, this setup sustains a steady flow of orders, even during peak seasons.

Managers track progress via dashboards powered by artificial intelligence, spotting hiccups before they grow. Such cohesion slashes cycle times and ramps up operational efficiency.

Automated Cranes

Automated cranes haul heavy pallets in tight racks with ease. They use AI-driven motors and radio frequency tags to grab and stack loads at dizzying heights.

Lifting and stacking heavy loads

Stacker cranes hoist pallets above 30 feet in narrow aisles. They drive high-density storage by stacking loads in tight racks. They cut manual labor reliance and lower accident risk.

They use AI and vision systems to spot load position.

They feed into AS/RS and free up floor space for more racks. Operators see a big jump in space utilization and order fulfillment speed. Their work sets the stage for the key benefits of using logistics robots.

Ideal for high-density storage

Automated cranes scale racks like giants dancing in narrow halls. They tuck pallets between tight pallet racks, nailing each slot with millimeter precision. AI vision systems scan barcodes midair as the crane glides.

RFID tags let it spot the right pallets in a blink. This setup squeezes aisles down to 3 feet with no hit to safety. Teams can fill 60 percent more vertical space, turning high-density storage into a power move.

These cranes work well with automated guided vehicles and robotic arms. You can sync them using warehouse automation platforms or AI-powered control software. They cut human lifts, lowering accident rates by up to 40 percent.

Staff can focus on picking robots or inventory management tasks instead. Up next, explore the key benefits of using logistics robots.

Key Benefits of Using Logistics Robots

Automated guided vehicles and vision systems slash pick errors and shorten pack time like clockwork. RFID tags and conveyor belts speed stock down aisles, cut costs, and protect staff from harm.

Boosting overall productivity

Warehouse robots boost efficiency by scanning and sorting items in seconds, not minutes. They cut picking errors and slash labor costs. AGVs and autonomous mobile robots zip through aisles, dodging bottlenecks with RFID and vision systems.

Robotic arms swing like pros, handling heavy loads with high picking accuracy.

Cobots team up with staff, lifting pallets and packing boxes at 4 mph. AS/RS lifts crates straight to conveyors, speeding order fulfillment by 30 percent. This system runs like a well-oiled machine, freeing staff to tackle more complex tasks.

Clients at Amazon Robotics, Vecna Robotics, and Zebra Technologies applaud faster deliveries and smoother material handling.

Minimizing operational costs

Cutting costs flows from boosted throughput to lean operations. Automating picking with AMRs and AGVs slashes labor bills and tames manual handling. AI-powered palletizing robots speed up order fulfillment and trim errors.

RFID tags and vision systems link stock fast, and warehouse robotics cut inventory time and cost. Collaborative robots pack shelves around the clock, and logistics automation pays off in savings.

Enhancing workplace safety

Locus Robotics AMRs patrol warehouse aisles with Cognex vision systems. They detect obstacles and slow down just before a collision. Warehouse robotics and logistics automation cut injuries and human error.

Universal Robots cobots and Vecna Robotics AGVs partner with drivers to lift heavy crates safely.

Zebra RFID scanners and AI algorithms track pallets for inventory management, alerting teams to hazards. Toyota automated forklifts take bulky loads off worker plates, cutting strain.

Conveyor belts with Honeywell sortation systems drop items into bins without manual lifting. These steps set the stage for our conclusion.

Takeaways

Smart machines now steer pallets, scan shelves, and sort goods with ease. Each grab bot, stacker setup, and camera sensor works hand in hand with floor staff. Stock trackers and tag scanners keep counts tight, so bosses can sleep easy.

These helpers slash errors, slash wait times, and shine in the fast lane of order processing. Team leads will toast lower costs and fewer bumps, as smart carriers take on heavy loads.

Warehouses will hum along like a well-oiled clock, with robotics and humans synced in step.

FAQs on Logistics Robots That Boost Warehouse Efficiency

1. What are the 7 logistics robots that boost warehouse productivity?

It lines up retail giant’s bots, Fetch mobile bots, RFID pioneer trucks, a top AMR firm, plus collaborative robots, robotic arms, and palletizing robots.

2. How do autonomous mobile robots help speed order fulfillment?

They zip through aisles with AI, pick and carry loads. They tap vision systems and RFID tags to find items, skip mistakes, and cut wait times. It feels like magic.

3. What part do automated guided vehicles play in material handling?

They ride on magnetic tape or follow radio frequency identification cues. These AGVs haul pallets, link with conveyor systems, support high-density storage, and keep stock moving without a hitch.

4. How do collaborative robots improve picking accuracy and inventory management?

They team up with workers on picking lines. A cobot will steady a box, use machine learning, then a robotic arm will sort and label. This combo lifts speed, cuts errors, so you never lose a shipment in the shuffle.

5. Can unmanned aerial vehicles help with inventory management?

Yes, these drones scan barcodes on high racks. They feed data to inventory management systems so counts stay sharp. They reach spots humans cannot, like birds in the sky.

6. How do vertical lift modules and automated storage and retrieval systems boost space and speed?

They stack stock tall, then a robot grabs the exact box in seconds not minutes. ASRS, packaging robots, and case erectors wrap and seal goods in one go. Warehouses save floor space, scale with demand, and get an all-star cast of packing pros.