The logistics and supply chain sectors have seen rapid transformation over the past decade, influenced by technological advancements, shifting consumer expectations, and the challenges posed by global events like the COVID-19 pandemic.

As we move into 2025 and beyond, businesses must adapt to these evolving trends to maintain a competitive edge.

In this article, we will explore the 9 Key Themes Dominating U.S. Logistics and Supply Chains, offering valuable insights and practical advice on how businesses can leverage these changes for success in the years to come.

Introduction to the Future of U.S. Logistics and Supply Chains

The logistics and supply chain industries form the backbone of the U.S. economy, facilitating the movement of goods and services from producers to consumers.

However, as global trade becomes more complex and consumer demands shift, these industries are undergoing significant changes.

As businesses grapple with rising consumer expectations for faster delivery times, greater transparency, and sustainability, the 9 Key Themes Dominating U.S. Logistics and Supply Chains will play a central role in shaping the future of this sector. This article will delve into these themes and offer actionable strategies for businesses to stay ahead.

Theme 1: Automation and Artificial Intelligence in Logistics

Automation and AI have already begun transforming U.S. logistics and supply chains, and their influence will only increase in the coming years. From robotic warehouses to AI-powered route optimization, automation promises to reduce costs, improve efficiency, and enhance accuracy.

Role of AI in Streamlining Operations

AI is increasingly being used to automate decision-making processes across the logistics industry. By analyzing historical data, AI algorithms can predict demand, optimize inventory, and streamline the delivery process. For example, AI can adjust routes in real-time based on weather patterns, road closures, or traffic congestion, ensuring faster and more efficient deliveries.

AI in Logistics Operations

| AI Application | Benefits | Example |

| Demand Forecasting | More accurate predictions of demand | Amazon’s AI-based inventory management system |

| Route Optimization | Faster deliveries, cost savings | UPS’s ORION system for route optimization |

| Predictive Maintenance | Reduces downtime, extends equipment life | DHL’s predictive maintenance system for trucks |

How Automation is Redefining Warehouse Management

Automated warehouses use robots and drones to handle tasks such as picking, packing, and sorting goods. This automation not only increases speed and accuracy but also reduces reliance on human labor.

Autonomous mobile robots (AMRs) are increasingly being deployed in warehouses to move goods around more efficiently. These robots are equipped with sensors and AI to navigate, lift, and transport items without human intervention.

Case Study: Amazon Robotics

Amazon has invested heavily in robotics to automate its fulfillment centers. With over 200,000 robots working alongside humans, Amazon has reduced its processing times and increased operational efficiency. The use of robots for picking and packing orders has helped Amazon meet the growing demand for faster delivery times.

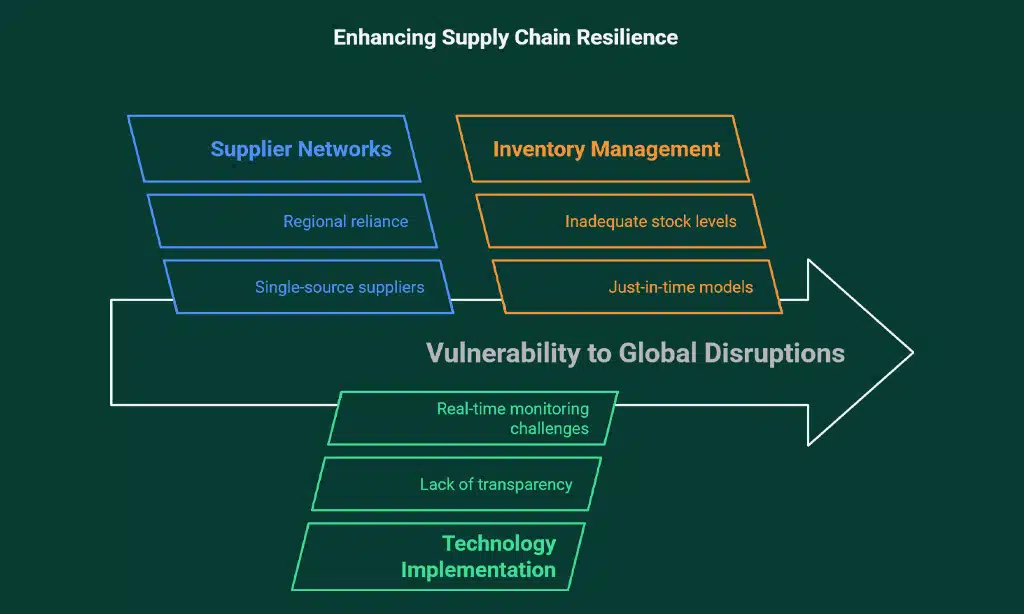

Theme 2: Supply Chain Resilience and Risk Management

Global supply chains are more vulnerable than ever to disruptions, from natural disasters to geopolitical tensions. The COVID-19 pandemic exposed the fragility of just-in-time inventory models and underscored the need for more resilient supply chains.

Building Robust Systems to Withstand Global Disruptions

Businesses are increasingly looking for ways to diversify their supply chains and reduce reliance on single suppliers or regions. This involves building stronger relationships with multiple suppliers and increasing stock levels for critical components.

Additionally, companies are leveraging technologies like blockchain and IoT to enhance transparency and monitor their supply chains in real time.

Key Strategies for Building Resilient Supply Chains

| Strategy | Benefits | Example |

| Diversified Supplier Networks | Reduces risk of supply chain disruptions | Nike’s shift from single-source suppliers to a more diversified network |

| Real-Time Tracking | Provides visibility into supply chain performance | Walmart’s use of blockchain for tracking food products |

| Inventory Buffering | Ensures stock availability during disruptions | Apple’s use of strategic stockpiling during semiconductor shortages |

Strategic Risk Mitigation for 2025

Companies will need to implement more agile and flexible strategies to adapt to unforeseen risks. Predictive analytics can help companies identify and mitigate risks before they escalate. By using advanced algorithms to assess potential disruptions, companies can adjust production schedules or re-route shipments to avoid delays.

Tips for Enhancing Supply Chain Resilience:

- Adopt a multi-supplier strategy to reduce dependence on one vendor.

- Use predictive analytics to foresee potential risks.

- Invest in flexible warehousing and distribution models to adjust quickly to demand shifts.

Theme 3: Sustainability and Green Logistics

As environmental concerns become more pressing, sustainability is no longer optional for businesses in logistics. Companies are increasingly under pressure from consumers, investors, and regulators to adopt green practices that reduce the carbon footprint of their operations.

The Growing Demand for Eco-Friendly Logistics Solutions

Consumers are more eco-conscious than ever, and they prefer companies that align with their values. Green logistics not only meets these consumer expectations but also often results in long-term cost savings. Sustainable practices in logistics can range from reducing energy consumption in warehouses to transitioning to electric vehicles for deliveries.

Innovations in Sustainable Packaging and Transportation

The logistics industry is also focusing on sustainable packaging materials to reduce waste. Companies like Unilever and Coca-Cola are experimenting with biodegradable and recyclable packaging. On the transportation side, electric trucks and drones are becoming increasingly popular as alternative solutions to reduce greenhouse gas emissions.

Innovations in Sustainable Logistics

| Innovation | Benefits | Example |

| Electric Delivery Vehicles | Reduces emissions, lowers operational costs | UPS’s electric delivery trucks |

| Biodegradable Packaging | Reduces plastic waste, eco-friendly | Unilever’s transition to biodegradable packaging |

| Drones for Last-Mile Delivery | Reduces traffic, improves efficiency | Amazon Prime Air using drones for deliveries |

How Sustainability is Shaping Consumer Expectations

Sustainability has become a key factor in consumer purchasing decisions. A 2023 survey found that nearly 80% of consumers are more likely to buy from companies that prioritize environmental sustainability. As a result, businesses that invest in green logistics are gaining a competitive advantage and building stronger relationships with their customers.

Theme 4: Blockchain Technology for Transparency

Blockchain technology offers a game-changing solution for improving transparency, security, and accountability in supply chains. By providing a decentralized, tamper-proof ledger of transactions, blockchain ensures that all parties involved in the supply chain can access real-time information and track goods more accurately.

How Blockchain Enhances Security and Traceability

Blockchain helps track the movement of goods at every stage of the supply chain, reducing the risk of fraud and ensuring compliance with regulations. For example, the food industry uses blockchain to trace the journey of products from farm to table, ensuring food safety and quality.

Blockchain Applications in Supply Chains

| Blockchain Application | Benefits | Example |

| Traceability of Goods | Enhances transparency and reduces fraud | Walmart’s blockchain traceability for food safety |

| Streamlining Payments | Reduces transaction costs and delays | IBM and Maersk’s blockchain for shipping payments |

| Automated Contracts | Reduces paperwork, increases efficiency | Food safety certifications using blockchain |

Theme 5: Data-Driven Decision Making and Predictive Analytics

Big data and predictive analytics are becoming essential tools in modern supply chains, helping businesses make more informed decisions and improve operational efficiency.

Leveraging Big Data to Improve Forecasting and Planning

Big data allows logistics companies to analyze large volumes of information from various sources, such as consumer behavior, weather forecasts, and shipping data. By combining this data with predictive analytics, businesses can forecast demand more accurately, optimize inventory levels, and plan more efficient delivery routes.

The Role of Predictive Analytics in Enhancing Operational Efficiency

Predictive analytics helps logistics managers anticipate potential issues before they arise. For example, predictive models can forecast when a piece of equipment is likely to break down or predict the likelihood of delays due to weather or traffic conditions, allowing companies to make adjustments in real time.

Data-Driven Tools for Logistics

| Tool | Benefits | Example |

| Predictive Maintenance Systems | Reduces downtime, increases equipment lifespan | FedEx’s use of predictive analytics for truck maintenance |

| Inventory Optimization Software | Reduces stockouts, minimizes waste | Target’s use of data analytics for inventory management |

| Route Optimization Platforms | Reduces delivery times and fuel costs | DHL’s use of real-time data for route adjustments |

Theme 6: E-commerce and Last-Mile Delivery Innovations

The rise of e-commerce has put immense pressure on logistics companies to improve last-mile delivery. Consumers expect faster, more reliable delivery options, and businesses are responding by exploring new delivery models and technologies.

The Rise of Same-Day and Next-Day Delivery Expectations

Consumers now expect faster delivery, often opting for same-day or next-day shipping. Companies like Amazon, Walmart, and Target have set the standard, and now other retailers must follow suit. The demand for faster deliveries has led to increased competition and innovation in the logistics sector.

Innovations in Last-Mile Logistics to Meet E-commerce Demands

To meet these expectations, logistics companies are increasingly experimenting with new technologies such as drones, autonomous delivery vehicles, and even delivery robots. These innovations help reduce delivery times and improve operational efficiency, all while maintaining cost-effectiveness.

Last-Mile Delivery Innovations

| Innovation | Benefits | Example |

| Autonomous Delivery Vehicles | Faster deliveries, reduced human labor | Nuro’s autonomous vehicle for local deliveries |

| Delivery Drones | Avoids traffic, reduces delivery times | UPS’s testing of drone deliveries in rural areas |

| Smart Lockers and Pickup Points | Reduces delivery costs, increases convenience | Amazon’s Locker system for parcel pickups |

Theme 7: The Role of Supply Chain Visibility and Real-Time Tracking

Real-time tracking and visibility have become essential for businesses that want to improve customer satisfaction and operational efficiency. By having access to up-to-the-minute data, companies can optimize their supply chains and make better-informed decisions.

The Need for End-to-End Visibility in Logistics

End-to-end visibility allows companies to track products from manufacturing to delivery. This visibility helps identify bottlenecks, improve forecasting, and increase transparency for customers. It also allows companies to proactively address potential issues before they escalate.

Technologies Enhancing Supply Chain Visibility

| Technology | Benefits | Example |

| GPS Tracking Systems | Provides real-time location data | FedEx’s use of GPS for package tracking |

| IoT Sensors | Tracks product condition and location | Maersk’s IoT-enabled containers for real-time monitoring |

| Cloud-Based Platforms | Centralizes data, enables collaboration | IBM’s Watson Supply Chain for visibility and AI-driven insights |

Theme 8: Labor Force Evolution and Skill Development

The logistics industry is facing a workforce evolution driven by automation, AI, and changing market demands. As technology continues to play a larger role, companies must invest in training their employees for the jobs of the future.

The Changing Landscape of the Logistics Workforce

The automation of warehouses and transportation systems will reduce the need for certain manual tasks, but it will also create new jobs in areas like robotics maintenance, data analysis, and software development. Businesses must adapt by offering continuous training to keep their workforce skills up-to-date.

Theme 9: The Evolution of Global Trade and Geopolitical Influences

Global trade is an essential component of U.S. logistics and supply chains. However, geopolitical tensions, trade policies, and shifting global alliances are playing an increasingly significant role in shaping logistics strategies. In particular, the ongoing shifts in trade dynamics and international relationships can impact trade routes, tariffs, and the availability of raw materials and goods.

Navigating the Impact of Geopolitical Shifts on U.S. Supply Chains

Trade wars, sanctions, and changing international alliances have the potential to create disruption across the global supply chain. These shifts require businesses to stay vigilant and flexible, adapting their supply chains to minimize risks and costs associated with geopolitical uncertainty.

For instance, the trade tensions between the U.S. and China have prompted many companies to reevaluate their dependency on overseas manufacturing, leading to reshoring efforts and diversification of suppliers.

The U.S. government’s imposition of tariffs on Chinese goods has made products more expensive, forcing companies to rethink their sourcing and manufacturing strategies.

Key Geopolitical Risks Affecting Logistics

| Geopolitical Risk | Potential Impact | Example |

| Trade Wars | Increased tariffs, higher production costs | U.S.-China trade war and its impact on tech companies |

| Sanctions and Trade Restrictions | Disruption of trade routes and product availability | U.S. sanctions on Iran affecting oil supply chains |

| Changing Trade Agreements | New tariffs, shifts in trade routes | USMCA replacing NAFTA and its effect on cross-border logistics |

Strategies for Managing Geopolitical Risks

To manage the evolving risks posed by global trade and political changes, companies can adopt several proactive strategies:

- Diversification of Suppliers and Manufacturing: Businesses should avoid over-reliance on any single supplier or region. By diversifying their supply chains and production facilities, companies can mitigate risks associated with trade wars, tariffs, and other geopolitical disruptions.

- Close Monitoring of International Policy Changes: Staying up-to-date on international relations, trade deals, and policy shifts is critical. Companies must work with trade experts and legal advisors to ensure they understand the ramifications of new policies and prepare for changes in trade rules or tariffs.

- Agile and Flexible Supply Chains: A flexible and adaptable supply chain allows companies to respond quickly to geopolitical disruptions. Leveraging tools like predictive analytics, real-time tracking, and multi-source logistics can help businesses quickly reroute shipments or switch suppliers when necessary.

Case Study: Apple’s Supply Chain Diversification

Apple has long been reliant on Chinese manufacturers for assembling its products, but in recent years, the company has diversified its supply chain in response to escalating U.S.-China trade tensions. Apple has moved some of its manufacturing to countries like India and Vietnam to mitigate the risk of tariffs and to continue meeting its global demand without significant disruptions.

Wrap Up: Preparing for the Future of U.S. Logistics and Supply Chains

As we look toward 2025 and beyond, the 9 Key Themes Dominating U.S. Logistics and Supply Chains are not just passing trends—they represent significant shifts that will reshape the way businesses operate.

From automation and artificial intelligence to geopolitical shifts and sustainability, these trends will influence every aspect of logistics, from the way products are sourced to how they are delivered to consumers.

For businesses to thrive in this new landscape, it’s crucial to stay ahead of these changes, invest in technology, and foster flexibility in their supply chain strategies. Automation, AI, and predictive analytics will continue to drive efficiency, while sustainability and resilience will become key differentiators in the marketplace.

Meanwhile, companies must also remain vigilant about global trade dynamics, ensuring their supply chains are robust enough to withstand geopolitical risks.

The companies that successfully navigate these 9 key themes will not only optimize their logistics operations but will also position themselves as leaders in a rapidly evolving and highly competitive global marketplace.

With the right strategies in place, U.S. logistics and supply chains will be better equipped to face the challenges of the future while seizing the opportunities that lie ahead.