Many global brands struggle with late packages and high shipping fees. They juggle order fulfillment, inventory management, and last-mile delivery. They face tight deadlines and rising costs.

They need a clear plan.

Hybrid fulfillment blends self-fulfillment, third-party logistics (3PL), drop shipping, Fulfillment by Amazon (FBA), local hubs, and in-store picks. It cuts costs and speeds up delivery.

This post shows seven hybrid strategies. It covers smart uses of warehouse management systems and AI tools for real-time inventory tracking. You will read simple tips to boost your supply chain management and customer experience.

Keep reading.

Key Takeaways

- A hybrid plan uses in-house picks until about 1,000 orders per month, taps 3PL hubs for 1–50 K orders to cut transport costs by 20%, and leverages FBA to reach 200 million shoppers.

- Real-time warehouse (WMS) and order (OMS) systems slash mis-picks by 30%, cut stockouts by 50%, and sync Oracle NetSuite with UPS/FedEx for clear delivery timelines.

- Local fulfillment centers halve delivery times and lower last-mile fees, in-store ship-outs power omnichannel sales, and drop shipping trims inventory investment to zero.

- Brands like Shein ship to 100+ countries, cut inventory by 90%, and boost customer experience by mixing central hubs, local nodes, and AI-driven analytics.

Self-Fulfillment: Maintaining Full Control Over Operations

Teams pick, pack, and ship orders in-house each day. You control order fulfillment, supply chain management, and last-mile delivery. A warehouse management system slashes mistakes with bar code scans.

Staff test product packaging, and they spot errors fast.

You skip 3PL fees and outsourcing bills. That saves costs until you hit 1,000 orders per month. Beyond that mark, bottlenecks slow packing, and delays hit customer experience. Some brands hire extra hands once they cross that limit.

Third-Party Logistics (3PL): Scaling Operations with External Partners

Small and mid-size brands often outsource warehousing, inventory management, and shipping tasks to third-party logistics (3PL) firms. These partners run large distribution hubs across the US, Canada, and Europe.

They use warehouse management systems (WMS) and automated storage and retrieval systems (AS/RS) to speed order fulfillment. They tap into discounted shipping rates with carriers like Canadian National Railway and major parcel couriers.

That cuts transport costs by up to 20% for brands handling 1,000 to 50,000 orders each month. 3PL teams also manage last-mile delivery and track shipments in real time. They shape a smooth supply chain management flow from checkout to doorstep.

That lifts customer experience and defines brand identity.

Outsourced logistics can add a layer of complexity to your ecommerce platform. You might lose some control over picking, packing, and shipping deadlines. Service-level agreements set targets for delivery windows, yet fees may climb as volumes surge.

Brands often plug 3PL data into google analytics and inventory management systems to analyze patterns. Artificial intelligence and machine learning tools predict reorder points and boost forecast accuracy.

This helps avoid stockouts or extra items. You can still apply print on demand or ship solar panels if you handle special goods. That keeps your strategy flexible and your operations lean.

Drop Shipping: Reducing Inventory Management Burdens

Suppliers ship orders straight to customers, so sellers skip storing products. Retailers dodge inventory management and ditch warehouse rent bills, boosting operational efficiency.

Brands cut stock investment to zero, and distribution centers stay light. Companies add AI and automations to link suppliers, shipping carriers, and order fulfillment systems. Such steps boost supply chain management.

They use natural language processing to power digital agents that handle customer queries around the clock.

Quality checks fall flat, and delays can spike, since nobody holds items for inspection. Shoppers expect fast last-mile delivery, and any slip hurts customer experience. Firms tap 3PL partners to plug gaps, or employ an order management system to analyze data and flag issues.

That hybrid fix helps brands play safe in a tough marketplace.

Fulfillment by Amazon (FBA): Leveraging Amazon’s Logistics Network

Amazon handles order fulfillment at dozens of storage hubs across the globe. Small brands skip third-party logistics (3PL) firms, and trust FBA to cover each step. It uses automated machines, scanners, and conveyor belts to speed picking and packing.

These centers link with Seller Central, so brands track stock in real time. FBA adds last-mile delivery via fast carriers that reach over 200 million global shoppers. Brands lose some brand flair, but they win high visibility and customer experience reach.

High fees come with the service, so brands must weigh costs in their supply chain management plans. Inventory management stays simple, thanks to AI forecasting tools and the FBA fee calculator in Seller Central.

This setup suits mass-market products, it lets small lines tap big channels. Brands enjoy credibility from Amazon, yet they give up some control over customer experience.

Local Fulfillment Centers: Enhancing Regional Efficiency

Local centers handle order fulfillment near shoppers. They cut delivery time in half. They help brands save on last-mile delivery costs. They tap local roads, low emission trucks, and small hubs.

They run on varied energy sources to cut carbon use. They link with a stock control system and a delivery routing tool. They fit well with artificial intelligence (AI) powered flows.

They team with small carriers to boost the customer experience.

Such hubs aid flexible inventory management and supply chain management. They free up big warehouses. They offer same day or next day shipping. They work cheaper than large third-party logistics (3pl) firms.

They target mid level order volumes. They suit regional businesses best.

In-Store Fulfillment: Utilizing Physical Stores for Omnichannel Success

Physical stores help brands process online orders. This approach boosts order fulfillment and trims delivery time. Store teams watch stock closely and shift inventory on demand. Small brands shine with personal interaction and hands-on control.

Retail checkout systems link to supply chain management. Staff use handheld scanners to update stock levels fast, improving inventory management. Some shops offload less to third-party logistics (3pl) and boost last-mile delivery by shipping from shelves.

Disruptions to sales can hit stores and slow scaling when crews pick orders.

Combining Models for Flexibility: The Hybrid Fulfillment Approach

Think of a hybrid plan like a chef mixing spices. Self-fulfillment keeps control of luxury stock. Fast-moving items ship via Amazon FBA to cut fees. Brands add drop shipping hooks for niche orders.

Cloud-based platforms and an order management system link each step. This mix smooths order fulfillment and powers last-mile delivery.

A sneaker brand once split its packages. It held rare shoes at a warehouse and sent kicks through a third-party center. The team used real-time inventory management and RFID tags. Analysts tweak warehouse layouts with a management platform.

They watch supply chain management on a cloud dashboard. This live feed helps swap shipping paths and cut hold times. It boosts last-mile delivery and trims fees. Brands shape a strong customer experience with this mix.

Real-Time Inventory Tracking: Key to Effective Hybrid Fulfillment

Inventory systems link every shelf and pack station in real time. This live view helps teams track stock for order fulfillment across stores and warehouses. Oracle NetSuite logs and updates counts as soon as a worker scans a barcode.

Automation cuts manual checks, chopping costs like a chef dicing onions. It also feeds data to an order management system that shapes last-mile delivery quotes.

Shipping partners like UPS and FedEx share status updates with the cloud ERP. Postal service moves show up fast, so staff can reroute items before they go astray. Customers see clear delivery timelines on order pages.

That transparency builds trust and cuts calls about missing packages. Solid inventory management steps keep supply chain management smooth.

Optimizing Warehouse Layout for Seamless Hybrid Operations

A layout that places fast-moving items close to packing stations cuts picker travel time. It also speeds order fulfillment. You can set up a U-shaped conveyor belt, a scanner zone, and a dedicated dock for incoming shipments and returns.

A slotting strategy helps staff grab popular products in seconds. Teams can run in-house packing for top sellers, and tap outside carriers in peak season.

A central Oracle NetSuite ERP links shelf data to live order books. That boosts inventory management, reduces errors, and drives the best last-mile delivery. You should review system logs and storage plans each quarter to spot cost cuts and speed gains.

This mix of in-house muscle and outsourced reach builds hybrid strength.

Flexible Shipping Options to Meet Diverse Customer Needs

Brands can offer ground, air, and same-day shipping, plus store pickup to match fast or cheap needs. They tap 3PL hubs, FBA centers, and local depots to spread stock where customers live.

Delivery firms link with fulfillment software to feed data into real-time inventory management. This hybrid approach balances stock across spots, cuts overstock, and avoids stockouts.

Teams tune shipping rules in order fulfillment to send orders from the best location. Storage software and automation keep the flow smooth, like clockwork, even when order volumes hit thousands per day.

Returns Management Strategies for Hybrid Fulfillment Models

A solid reverse logistics plan slashes extra steps. It integrates order fulfillment tools, such as an inventory platform and return approval process. Staff scan each return with scanning devices for quality checks.

Items that pass get restocked. Damaged items head to recycling centers. Seasonal stock management ensures hot items stay near buyers.

Hybrid routes cut inventory holding by up to 90 percent. Teams sort returns at local hubs and at cost effective fulfillment centers in China. This setup tests global expansion with low shipping fees.

Automation in sorting lets brands speed refunds and save time.

Implementing Order Management Systems (OMS) for Accuracy

An Order Management System (OMS) ties orders across all channels. It cuts mistakes in order fulfillment. It supports hybrid models, cutting stock risk by 50 percent. A retail manager used a cloud ERP suite, and stock errors fell 40 percent in 2023.

That tool links ordering, shipping, payment, and warehouse tasks, so teams see real-time inventory counts. Daily consultations on demand forecasts let staff shift stock fast. Faster product launches freed up cash flow for marketing.

Pick strategies in the OMS speed up order picks. Staff follow a zone, batch, or wave plan on mobile screens. This system integrates distribution center software, and it reduces mis-picks by 30 percent.

It guides staff like a conductor leads an orchestra. Customer loyalty climbs when orders ship right, and brand reputation stays safe.

Demand Planning: Aligning Inventory with Customer Demand

Forecasting tools help brands match stock with orders. Teams review 2015 sales spikes, adjust local shelves for fast movers. Seasonal stock management places top sellers in nearby hubs, cutting lead times.

A demand sensing model spots shifts, an inventory tracker logs each sale. Planners use DTC roots from 10 to 15 years ago to fine-tune safety stock.

Drop shipping took off around 2015, letting brands test new markets without buying bulk stock. Planners map peak seasons, move buffer inventory near customers, and tap an order management platform for alerts.

This mix curbs excess stock, keeps shelves full, trims costs.

Data Analytics for Continuous Improvement in Fulfillment Processes

Analytics teams link sales feeds, stock records, and shipping logs in a data mart. They run pattern scans to flag slow movers, surging SKUs, and seasonal spikes. It cuts cash flow risks by ninety percent.

It boosts local stock of fast movers during peak seasons and cuts excess inventory.

Teams share analytics via an enterprise resource planning solution. An order handling system syncs shipments across channels. It pulls demand estimates into planning, halts overstock, and stops empty shelves.

Choosing the Right Technologies for Hybrid Fulfillment

Global brands link stores and warehouses with an ERP platform like NetSuite. A warehouse control system uses wireless sensors and barcode scanners. The link tracks each order from pick to drop.

Automation bots speed tasks and reduce costs.

A cloud OMS calls carrier APIs. Teams set firm delivery dates so customers know when to expect their items. A rule engine shifts orders to lower-fee routes, improving cash flow and lowering risk.

Benefits of Hybrid Fulfillment for Global Brands

Hybrid fulfillment offers major perks for brand leaders.

It cuts costs, trims stock levels, and boosts customer delight.

- Hybrid fulfillment slashes warehousing fees, cutting inventory by up to 50 percent, which keeps budgets lean.

- Local hubs speed product rollouts, since storehouse management software and an instant stock monitor sync stock fast.

- Order processing tool pushes orders from any site, so buyers see items in record time.

- Shein’s system taps central depots and local nodes, shipping goods to over 100 nations.

- Splitting goods across centers softens stock risk, so a single glitch won’t block sales.

- Quick parcels win customer smiles, as locals feel the thrill of fast delivery.

- Balanced budgets and happy buyers blend cost savings with top service.

- Data analytics show demand shifts, guiding teams to tweak stock and prevent waste.

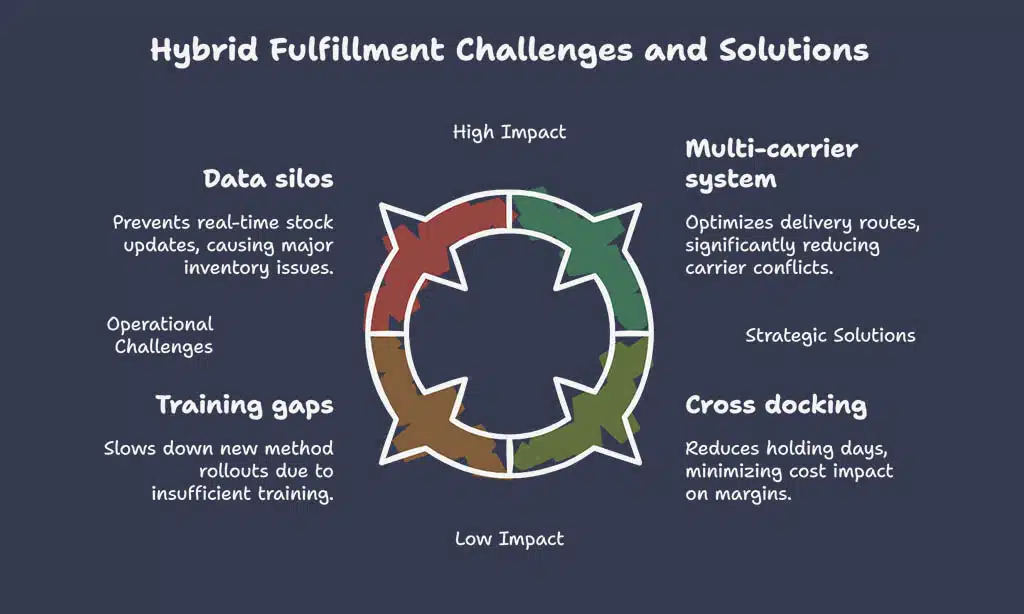

Challenges of Hybrid Fulfillment and How to Overcome Them

Global brands face tight margins. They juggle interest costs and customer needs.

- Data silos hinder stock views and lead to stockouts or overstock. Brands link an order hub interface and the distribution center tool, using API hooks for real-time updates.

- Inventory imbalances drive up costs and frustrate buyers. Teams use an inventory dashboard with demand planning to log sales across all channels and stores.

- Rising costs bite margins as rates hit 5 percent in 2024. Sellers add cross docking and just-in-time picks to cut holding days and curb interest fees.

- Process sprawl adds errors when teams juggle 3PL, FBA, store picks and drop ship. Brands set a control tower to steer orders and assign each channel plainly.

- Carrier conflicts stall deliveries across regions. Many firms tap a multi-carrier system that picks best routes per zone.

- Return chaos hurts CX when buyers drop items at stores, hubs or via mail. Brands merge returns into a single portal and scan labels with handheld label readers to speed refunds.

- Training gaps slow rollouts when staff face six new methods. Companies run hands-on labs and quick video demos for each model to boost skills fast.

Aligning Fulfillment Strategies with Business Goals

Leaders link order tasks to each goal. They tune stock levels to cash flow needs, service quality, and brand growth. Teams test new markets with small stock runs before they buy in bulk.

That step cuts risk and frees up funds. It also sharpens skills for big launches.

Managers build simple scorecards in a dashboard. Key figures include order times, costs, fill rates, and profit. Data guides every swap, shift, and pick. Teams pick a hybrid model to scale fast, stay lean, and stay agile.

Partnering with Reliable Logistics Providers

Eimskip Vietnam holds over 100 years of shipping experience. It has served Vietnam since 2007 from 96 Cao Thang Street, Ward 4, District 3, Ho Chi Minh City. This team moves goods like clockwork across land and sea.

They handle freight, warehousing, customs clearance, and order fulfillment. Brands link transportation management software and a warehouse management system to track every shipment.

Customs brokerage experts clear imports in hours, not days. Clients use order management tools to speed returns and restocks. Call 091-922 6984, 028 6264 6380, or 19003979 for quotes.

Email long@eimskip.vn or visit en.eimskip.vn for details.

Best Practices for Implementing Hybrid Fulfillment

Global brands need a smart mix to grow fast. China hubs test demand, they cut big risks.

- Craft clear goals for delivery speed, cost and reach, so teams hit global sales targets.

- Launch initial stock in a China hub to probe demand before local buys.

- Sync local and overseas stock via a real-time inventory API, to cut out-of-stock losses.

- Deploy a cross dock process in your warehouse workflow to speed final delivery.

- Pick a cloud ERP module with multi-site support for smooth data flow.

- Employ a warehouse software tool for slotting and scanning to slash pick errors.

- Add a demand plan module to predict spikes in fresh markets.

- Link an order system, like an eCommerce dashboard, for all sales channels.

- Build a simple returns path using a reverse logistics platform to win back buyers.

- Offer various ship methods, ground, air or same day local drops to boost choice.

- Host monthly drills to train staff on mixed pick and pack routines.

- Pull live data into a dashboard to track KPIs in real time.

- Audit stock turn rates each week to fine-tune reorder runs.

- Team up with a freight agent in China and a local courier network for coverage.

- Test small batches in fresh markets to learn fast and limit waste.

Monitoring and Evaluating Fulfillment Performance

Teams hold daily calls with clients and shipping partners, checking current stock counts and delivery hubs. They log updates in a data dashboard, then sync figures with an enterprise resource planning system.

Data analytics flags low stock, delayed shipments, or wrong routes. Leaders adjust routes or restock points to speed up orders.

Managers meet weekly to review key performance indicators like order cycle time and shipping accuracy. They tweak hybrid models, shifting items between local centers and in-store picks.

This process keeps brands quick, and drives happy shoppers in the cutthroat fashion game.

Case Studies: Success Stories of Global Brands Using Hybrid Fulfillment

Shein ships to more than 100 countries, mixing China-based hubs and local sites. This hybrid approach cuts inventory holding by up to 90%. It uses Google Analytics with an order management system to spot top sellers.

Local hubs store fast-moving items through seasonal stock management and support final-mile delivery. Their leaders test global growth with low-cost cargo transport out of China.

Key Takeaways for Global Brands Adopting Hybrid Fulfillment

Global brands cut costs, speed up delivery with a hybrid model. Some use an outsourced warehouse partner, others tap store pickup spots. Real-time stock software links every hub, and an order management tool tracks each parcel.

Data analytics spots hot trends fast, and a transport management system keeps deadlines tight. These key takeaways light the path for savvy e-tailers. Teams get control and clear growth markers.

You ditch shipping headaches.

Takeaways

These tips pack seven ways to ship fast and save costs. You can run your own order management system, or tap a 3PL when volume spikes. Local hubs and in-store ship-outs cut time for nearby shoppers.

Eimskip Vietnam links you to sea and air freight, customs clearance, and warehousing with ease. Mix data analytics, real-time inventory tracking, and the right tools, then watch orders flow, profits rise, and smiles spread.

FAQs on Hybrid Fulfillment Strategies for Global Brands

1. What are hybrid fulfillment strategies for global brands?

Hybrid fulfillment mixes main centers, local storage sites, and direct shipping. This mix gives brands more speed, lower cost, and greater flexibility.

2. How do hybrid strategies improve inventory tracking?

Mixing local and central stock helps you spot low levels fast. You cut waste, boost sales, and keep shoppers happy.

3. Can hybrid methods speed up last-mile delivery?

Yes, you pack orders near buyers, so trucks drive less. That means faster drops and happier customers. It’s like beating the line at a busy show.

4. How do brands find the right mix for global reach?

They test setups, note what works, then tune the plan. They watch order patterns and shipping lanes, they tweak until each region runs smooth.