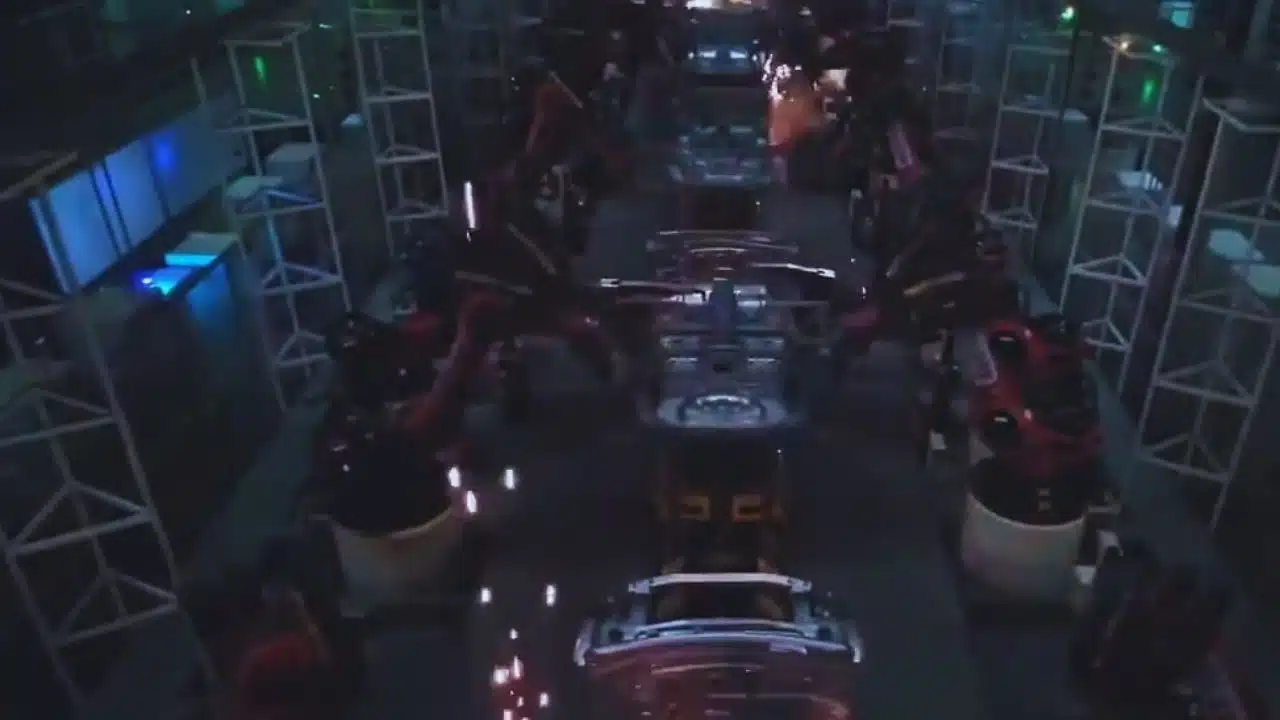

China is at the forefront of a manufacturing revolution with the emergence of “dark factories”—fully automated production facilities that operate without human workers or traditional lighting.

These high-tech plants leverage artificial intelligence (AI), robotics, and advanced sensors to run 24/7, reducing operational costs and increasing efficiency. As part of China’s push toward industrial automation, these dark factories signal a major transformation in global manufacturing.

What Are Dark Factories?

A dark factory is a fully automated production site where machines perform all tasks, from assembly to inspection and logistics. Since human workers are absent, these factories do not require lighting, heating, or regular breaks, significantly lowering energy consumption. While such facilities are still rare worldwide, China’s rapid adoption of automation is making them a reality.

China’s Aggressive Push for Automation

China has been investing heavily in automation under its “Made in China 2025” initiative, launched in 2015 to position the country as a global high-tech manufacturing leader. This strategy prioritizes robotics, AI, and smart factories, with strong government support in the form of subsidies and infrastructure investment.

According to the International Federation of Robotics (IFR), China installed 290,367 industrial robots in 2022, accounting for 52% of the global total—surpassing the combined installations of the U.S. and Japan. By 2023, China’s robot density reached 392 robots per 10,000 manufacturing workers, significantly higher than the global average of 141.

Leading Companies in Dark Factory Development

Several major Chinese companies are pioneering this shift to automation:

- Foxconn: The electronics manufacturing giant replaced 60,000 workers with robots in a Kunshan factory in 2016. By 2025, it aims to automate 30% of its operations, as stated by Chairman Terry Gou.

- BYD: The electric vehicle (EV) manufacturer has implemented robotic systems for EV battery and chassis assembly in plants in Shenzhen and Xi’an, accelerating the move toward workerless production.

Energy and Environmental Benefits of Dark Factories

One of the key advantages of dark factories is their potential to reduce industrial energy consumption. Traditional factories require extensive lighting, heating, and ventilation for human workers. By eliminating these needs, automation can significantly cut energy usage.

The International Energy Agency (IEA) estimates that automation could lower industrial energy consumption by 15-20%. China’s National Bureau of Statistics reported a 1.7% drop in industrial energy use in 2022, partly due to these automation-driven efficiencies. These advancements align with China’s goal of achieving carbon neutrality by 2060.

The Social and Economic Impact

While dark factories enhance efficiency, they also pose serious challenges, particularly in terms of employment. Manufacturing remains a vital sector in China, employing over 100 million people, according to World Bank data. As automation expands, job displacement is becoming a growing concern.

A 2017 study by Oxford Economics projected that 12 million Chinese manufacturing jobs could be lost to robots by 2030. A strike in Guangdong in 2023, reported by China Labour Bulletin, highlighted workers’ fears about robotic replacements, raising concerns about potential social unrest if retraining programs fail to keep up with automation advancements.

China’s Global Competitive Edge

China’s rapid automation push has intensified global competition in the manufacturing sector. The U.S. had a robot density of 274 per 10,000 manufacturing workers in 2022, while Germany’s figure stood at 415. However, China’s government-backed investment in robotics—estimated at $1.4 billion in R&D in 2023, according to Bloomberg—gives it a competitive advantage over Western nations.

The IEA also notes that industrial automation could reduce CO2 emissions in heavy industries by 10%, although the environmental cost of producing robots remains an issue.

The Future of Dark Factories in China

As of March 2025, dark factories in China are likely in pilot phases, primarily in high-tech sectors such as electronics and electric vehicles. These facilities operate in near-darkness using infrared sensors, LIDAR, and AI-driven precision machines, marking a significant shift in manufacturing.

Whether dark factories usher in a new era of industrial efficiency or deepen social and environmental challenges depends on how China balances innovation with workforce adaptation. While automation promises increased productivity and sustainability, ensuring economic stability for displaced workers remains a crucial issue for policymakers and industry leaders alike.

The Information is Collected from Medium and News.com.au