Clean water is vital for all businesses. But imagine dirty water flowing backward into your building’s pipes. This can bring germs, chemicals, and other dangerous contaminants into your water supply.

Many industries rely on backflow prevention to keep their water clean and safe. These systems protect drinking water from contamination. In this blog, we’ll explain which types of businesses need backflow services the most—and why it matters so much.

Keep reading to learn how backflow prevention keeps businesses running smoothly!

Importance of Backflow Prevention for Businesses

Backflow prevention keeps water clean and safe. Contaminated water can flow backward into potable water systems without it. This can spread harmful pollutants like pesticides, sewage, or chemicals.

A business cannot risk bad water harming customers or workers.

Safe water is not a luxury; it’s a necessity for every business.

Many industries rely on backflow preventers to protect their plumbing systems and drinking water. For example, hospitals use these devices to avoid chemical contaminants in their labs reaching faucets.

Restaurants need them near kitchen spigots to block back siphonage of wastewater during toilet flushing. Annual testing by certified professionals helps spot leaks early, keeping businesses compliant with safety regulations like those set by the EPA (Environmental Protection Agency).

Critical Industries That Require Backflow Prevention Services

Some businesses can’t risk water contamination, as it could cause serious health issues. Certain industries must use backflow prevention devices to protect water quality and keep their systems safe.

Healthcare Facilities

Hospitals need clean and safe water all the time. Backflow prevention devices help stop contaminated water from mixing with drinkable water. These plumbing systems block harmful bacteria, chemicals, or even sewage from flowing backward into pipes.

Backflow issues can lead to serious health risks like Legionnaires’ disease or intestinal infections. Healthcare facilities must follow strict rules for regulatory compliance to protect patients and staff.

Annual inspection and backflow testing by certified professionals keep systems working well. Clean drinking water is not just needed; it’s a lifesaver in these places.

Food and Beverage Processing Plants

Food plants need clean water. Contaminated water can ruin products and cause health problems. Backflow prevention stops chemical contaminants or sewage from polluting potable water.

Devices like check valves, air gaps, and vacuum breakers protect the supply.

Clean water is key for safe food production.

Annual testing of backflow devices keeps systems safe. Certified professionals inspect and repair plumbing fixtures to follow regulations. Facility managers must keep up with this to avoid fines or shutdowns.

Hospitality and Tourism Establishments

Hotels, resorts, and water parks must protect clean water for guests. A backflow preventer stops contaminated water from mixing with potable water supplies. Pools, spas, or irrigation systems can cause back siphonage without proper devices in place.

Regular backflow testing is required by law in most states. Certified professionals should inspect plumbing systems annually to meet compliance standards. This helps avoid health risks like nausea or gastrointestinal illnesses caused by chemical contaminants or sewage issues.

Manufacturing and Industrial Plants

Factories and plants deal with chemicals, oils, and hazardous substances daily. Backflow prevention stops these from entering the potable water supply. A backflow preventer protects against chemical contaminants harming workers or equipment.

Some plants use processes involving radioactive materials or sewage treatment systems. Contaminated water from faulty plumbing can cause health risks and violate EPA rules. Regular backflow testing ensures compliance while keeping operations safe and smooth.

Agriculture and Irrigation Systems

Agriculture relies on irrigation systems for water. Contaminated water can ruin crops and harm ecosystems. Backflow in these systems risks chemical contaminants mixing with potable water.

Fertilizers, pesticides, and animal waste increase this danger.

Certified professionals install backflow prevention devices to stop contamination. Annual inspection and maintenance keep these systems safe. Double check valve assemblies (DCVAs) or reduced pressure zones protect farms from back siphonage issues during droughts or heavy use.

Proper care ensures clean water for plants and communities nearby.

Commercial Kitchens and Restaurants

Dirty water can ruin food and hurt customers. Backflow preventers stop this by blocking contaminated water from entering clean supplies. Restaurants, catering businesses, and cafes rely on these devices to meet health codes.

A backflow issue could lead to fines or even closure.

Grease traps, hose bibs, and pressure-reducing valves are common in commercial kitchens. These need regular checks for safety. Annual inspections by certified professionals keep plumbing systems safe from chemical contaminants like cleaning agents or sewage backup.

Fire Protection Systems

Fire sprinklers rely on clean water. Backflow prevention devices stop contaminated water from flowing into sprinkler systems. Without these, chemical contaminants or sewage could enter the system during back siphonage.

This can lead to fire suppression systems failing when needed most.

Facility managers should schedule annual inspection and backflow testing for their plumbing system. Certified professionals check inlet valves, air gaps, and double-check valve assemblies (DCVA).

Regular maintenance keeps fire protection systems safe and compliant with EPA standards.

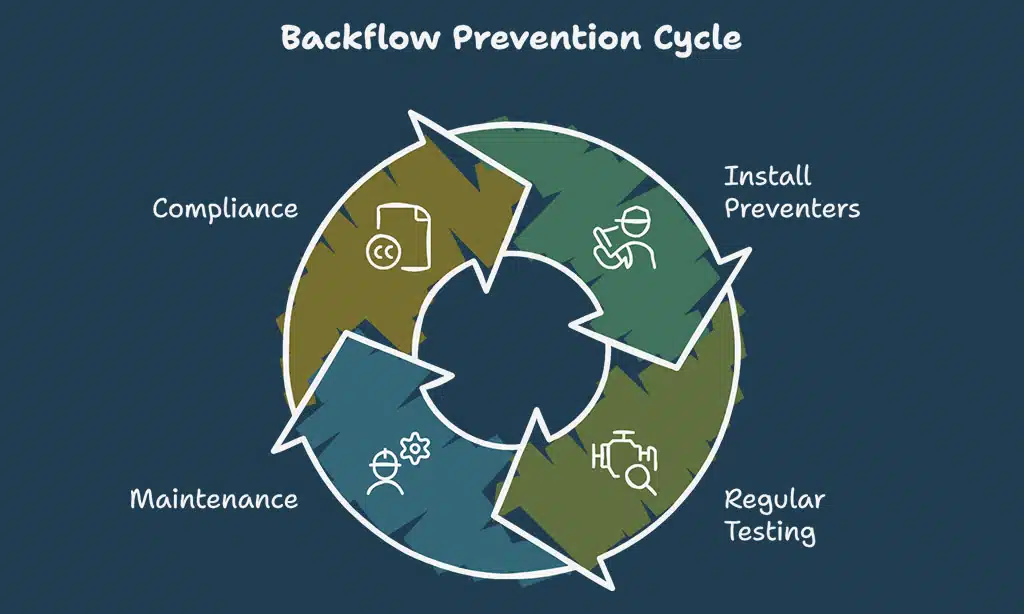

Key Backflow Prevention Methods

Stopping backflow keeps water safe and clean. Proper tools and care make all the difference.

Installation of Backflow Preventers

Plumbers install backflow preventers to stop contaminated water from entering clean water lines. These devices protect potable water and keep plumbing systems safe. A popular option is the double check valve assembly (DCVA).

It has two valves that block back siphonage and chemical contaminants.

Certified professionals must handle installation to meet EPA rules. Facility managers need proper placement based on the building’s layout. Fire suppression systems, commercial kitchens, or irrigation systems often need these setups during construction or remodeling projects.

Regular Testing and Maintenance

Backflow prevention devices need regular testing to work right. Annual inspection by certified professionals is key. Facility managers must focus on this to avoid water contamination or chemical hazards.

EPA regulations require commercial properties to maintain these systems properly.

Testing checks for issues like back siphonage or valve failure. Maintenance prevents costly repairs and protects potable water supply. Professional plumbing services can handle backflow testing for sprinkler systems, fire hydrants, and irrigation systems.

This keeps operations safe and in line with health and safety rules.

Takeaways

Clean water keeps businesses running strong. Hospitals, factories, farms, and restaurants all need it safe. Stopping backflow stops dirty water from mixing with clean supplies. Using tools like air gaps or valves makes this job easier.

Testing yearly ensures your system works right every time. Hire certified pros to handle the work for expert care. Protecting water is smart, simple, and crucial—take action today!

FAQs

1. What is backflow prevention, and why do businesses need it?

Backflow prevention stops contaminated water from flowing backward into potable water supplies. Businesses need it to protect water quality, avoid chemical contaminants, and meet regulatory compliance requirements.

2. Which industries require backflow prevention services?

Critical industries like sewage treatment plants, laboratories, irrigation systems, fire suppression systems, and commercial properties with sprinkler systems rely on backflow preventers to prevent water contamination.

3. How often should businesses schedule backflow testing?

Businesses should arrange annual inspections and regular testing by certified professionals to maintain their plumbing system and ensure the proper function of backflow prevention devices.

4. What are common types of backflow issues in commercial plumbing?

Back siphonage caused by pressure changes or faulty air gaps can lead to contaminated water entering clean supplies. This poses risks for viruses or even water-borne diseases.

5. Who is responsible for maintaining a business’s backflow prevention assembly?

Facility managers or property owners must handle maintenance tasks like testing and repairs using professional plumbing services to stay compliant with EPA standards.

6. Can improper maintenance affect insurance coverage for businesses?

Yes! Many insurance companies may deny claims if a business neglects its plumbing system or fails routine checks on its double check valve assembly (DCVA) or other critical devices used for remediation purposes.