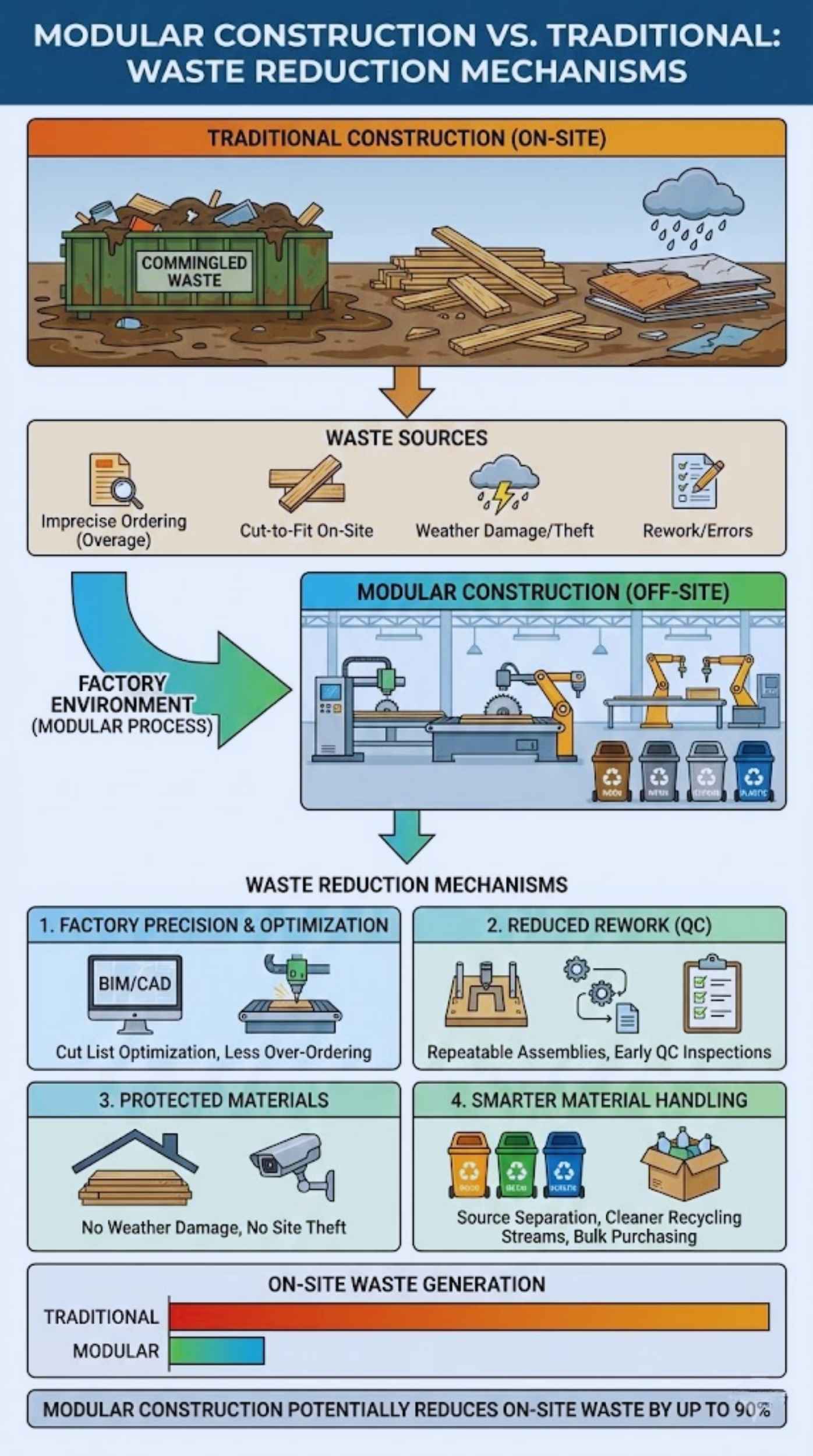

The construction industry faces a silent crisis that often goes unnoticed until the dumpster trucks arrive: waste. For decades, the traditional method of building homes—stick by stick, exposed to the elements—has generated an enormous volume of debris. From rain-warped lumber to piles of drywall offcuts, the inefficiencies of on-site construction are built into the process.

Modular construction offers a compelling alternative. By moving the majority of the building process into a controlled factory environment, builders can drastically reduce material waste, optimize resources, and deliver homes with a significantly lighter environmental footprint. This guide explores exactly how modular construction tackles the waste problem, the realistic reduction benchmarks you can expect, and how to plan a low-waste home project from the ground up.

Why Construction Waste Is A Home-Building Problem

Construction and Demolition (C&D) debris is one of the largest waste streams in the industrialized world. To solve the problem, we first have to understand its scope and its sources. It isn’t just about sloppy work; it is a systemic issue inherent to how we traditionally build.

What Counts as Construction vs. Demolition Debris?

When experts talk about “C&D waste,” they are often grouping two distinct phases together.

- Demolition Waste: This comes from tearing down old structures. It makes up the vast majority (often over 90%) of C&D debris by weight, consisting of concrete, steel, wood, and brick from destroyed buildings.

- Construction Waste: This is the debris generated during the creation of new buildings. This includes cut-offs from lumber and drywall, packaging materials (cardboard, plastic wrap), broken bricks, and unused mortar or paint.

While demolition waste is massive, construction waste is arguably more tragic because it represents new materials that were harvested, manufactured, and transported, only to be thrown away without ever being used. In residential home building, this waste stream is significant.

According to the U.S. Environmental Protection Agency (EPA), C&D debris generation in the United States totaled approximately 600 million tons in 2018. While a large portion of this is roadwork and demolition, the sheer volume highlights a sector ripe for disruption. For a typical 2,000-square-foot home, studies suggest that traditional construction can generate between 2,500 to 8,000 pounds of waste.

Why Waste Happens In Traditional Builds

In a traditional “stick-built” home, waste is often accepted as the cost of doing business. Several factors drive this:

- Imprecise Ordering: Builders often order 10–15% extra material (“overage”) to account for mistakes or bad cuts. It is cheaper to over-order than to stop a crew for a day waiting for ten extra studs.

- The “Cut-to-Fit” Method: Carpenters cut lumber and drywall on-site to fit the framing. Every time a standard 8-foot board is cut to 7 feet, one foot becomes scrap.

- Weather Damage: Materials stored on-site are vulnerable. A rainstorm can ruin stacks of drywall or warp lumber before it’s even installed, sending it straight to the dumpster.

- Rework: Errors in framing or mechanical rough-ins often require tearing out completed work to fix the mistake, doubling the material usage for that specific section.

What “Waste” Really Means In Residential Builds

In the context of building a home, “waste” is not just physical trash. It represents inefficiency in three distinct forms:

- Material Waste: The physical offcuts and damaged goods that end up in a landfill. This is the most visible form of waste.

- Financial Waste: You pay for the materials that end up in the dumpster. You also pay for the dumpster rental and the tipping fees to dispose of them.

- Labor Waste: It takes paid man-hours to move materials, cut them, realize they are wrong, tear them out, and haul them to the trash.

Reducing waste reduces the overall cost of the build and improves the timeline.

Where Waste Typically Comes From On-Site

If you walk a job site, you will quickly identify the primary culprits.

- Framing (Wood/Steel): Short ends of studs, joists, and headers.

- Sheathing & Drywall: Rectangular cutouts from windows, doors, and electrical outlets.

- Packaging: Cardboard boxes for fixtures, plastic wrap for pallets, and protective foam.

- Masonry/Concrete: Broken bricks, hardened leftover concrete, and tile scraps.

What Modular Construction Is (And What It Isn’t)

Before diving into waste reduction, we must clarify what modular construction actually is. The terminology in this industry is frequently confused, leading to misconceptions about quality and permanence.

Modular construction is a process, not a building type. It describes a method where a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities. These “modules” are then transported to the site and assembled.

Volumetric Modular vs. Panelized vs. Component Prefab

Not all “off-site” construction is the same. The level of waste reduction often depends on how much of the home is finished in the factory.

- Volumetric Modular: This is the most complete form. Large, three-dimensional boxes (rooms or sections of rooms) are built in the factory. They arrive on site with walls, floors, ceilings, wiring, plumbing, and often finishes (flooring, cabinets) already installed. This offers the highest potential for waste reduction.

- Panelized Construction: The walls, floor systems, and roof trusses are built in a factory as flat panels. They are stacked on a truck and assembled on site. This reduces framing waste significantly but still leaves mechanicals and finishes (and their associated waste) to be handled on site.

- Component Prefab: This involves smaller factory-made elements, such as roof trusses or pre-hung doors. Most “traditional” builders use component prefab, but it offers only marginal waste benefits compared to full modular.

Modular vs. Manufactured Homes (Code + Permanence Basics)

This is the most critical distinction for homeowners to understand.

- Modular Homes: Built to local building codes (IBC/IRC)—the exact same codes as a stick-built house. They are permanent structures, placed on a permanent foundation, and appraise the same as traditional homes.

- Manufactured Homes (formerly “Mobile Homes”): Built to the federal HUD code. They are constructed on a permanent steel chassis (which stays with the home) and are often movable.

While manufactured homes are also low-waste, “modular construction” in this guide refers to code-compliant, permanent architecture.

How Modular Construction Reduces Waste (The Mechanisms)

This is the core advantage of the modular methodology. The factory environment fundamentally changes the economics of material use. Here is how the mechanism of waste reduction works in practice.

Factory Precision = Fewer Offcuts And Less Over-Ordering

In a factory, technology drives the saw. Modular factories utilize advanced software systems (BIM/CAD) that feed directly into automated cutting machinery.

- Cut List Optimization: If a traditional carpenter needs ten 7-foot boards, they might cut ten 8-foot studs, wasting 10 feet of lumber. A factory computer system analyzes the entire day’s production run. It might cut a 7-foot board, and then use the remaining section for a window header or a truss web component for a completely different house on the line.

- Inventory Management: Factories buy in bulk and store standard lengths. They do not need to “over-order” for a specific house because the extra inventory simply moves to the next project. There is no leftover pile of lumber at the end of the job that isn’t worth hauling away.

The Result: Optimization software can reduce framing waste to nearly zero by ensuring almost every inch of purchased lumber is utilized in the structure.

Less Rework (Quality Control, Repeatable Assemblies)

Rework is a major source of waste in traditional construction. If a wall is framed out of square, or plumbing is placed in the wrong bay, materials must be ripped out and discarded.

Modular factories operate like automotive assembly lines with strict Quality Control (QC) stations.

- Jigs and Tables: Walls are framed on steel tables that ensure perfect squareness every time.

- Standardized Processes: Workers specialize in specific tasks (e.g., one team only does electrical rough-ins). This repetition leads to mastery and drastically fewer errors compared to a general contractor who might be juggling multiple trades.

- Inspections: Third-party inspectors often check the modules in the factory before walls are closed up, catching issues early when they are easy to fix without massive demolition.

Less Weather Damage + Site Theft/Loss

One of the simplest yet most impactful waste reduction factors is the roof over the factory.

- Dry Materials: Lumber, insulation, and drywall never get wet. In traditional builds, a sudden storm can ruin thousands of dollars of material. Wet lumber warps and twists, leading to structural waste; wet insulation must be thrown out to prevent mold.

- Security: Job site theft is rampant. When materials are stolen, they must be replaced, doubling the resource consumption for that item. Secure factories eliminate this variable.

Smarter Material Handling + Cleaner Recycling Streams

On a muddy job site, waste separation is difficult. Wood, plastic, and metal often get thrown into a single “commingled” dumpster because there isn’t space or time to sort it.

Factories have the space and the systems for source separation.

- Dedicated Bins: A factory will have specific bins for drywall gypsum, untreated wood, copper wire, and cardboard.

- Volume = Viability: Because the factory generates waste from many homes in one location, they generate enough volume to make recycling economically viable. A recycler might not pick up a small pile of drywall from a single home site, but they will happily pick up a full roll-off container from a factory.

- Reintegration: Some waste, like clean drywall scraps, can sometimes be ground up and used as soil amendments or returned to the manufacturer, a process rarely feasible on a dispersed construction site.

Packaging + Logistics (When It Improves, When It Doesn’t)

Packaging waste is a mixed bag, but modular generally wins on bulk.

- Bulk Purchasing: Factories buy fasteners in giant barrels, not small plastic clam-shells. They buy caulk in bulk drums, not individual tubes. This drastically cuts down on single-use plastic and cardboard packaging.

- Protective Wrap: However, the finished modules do require significant plastic wrapping (shrink wrap) to protect them during transport to the site. While this is a new waste stream, it is generally less than the aggregate packaging waste of thousands of individual deliveries to a traditional site.

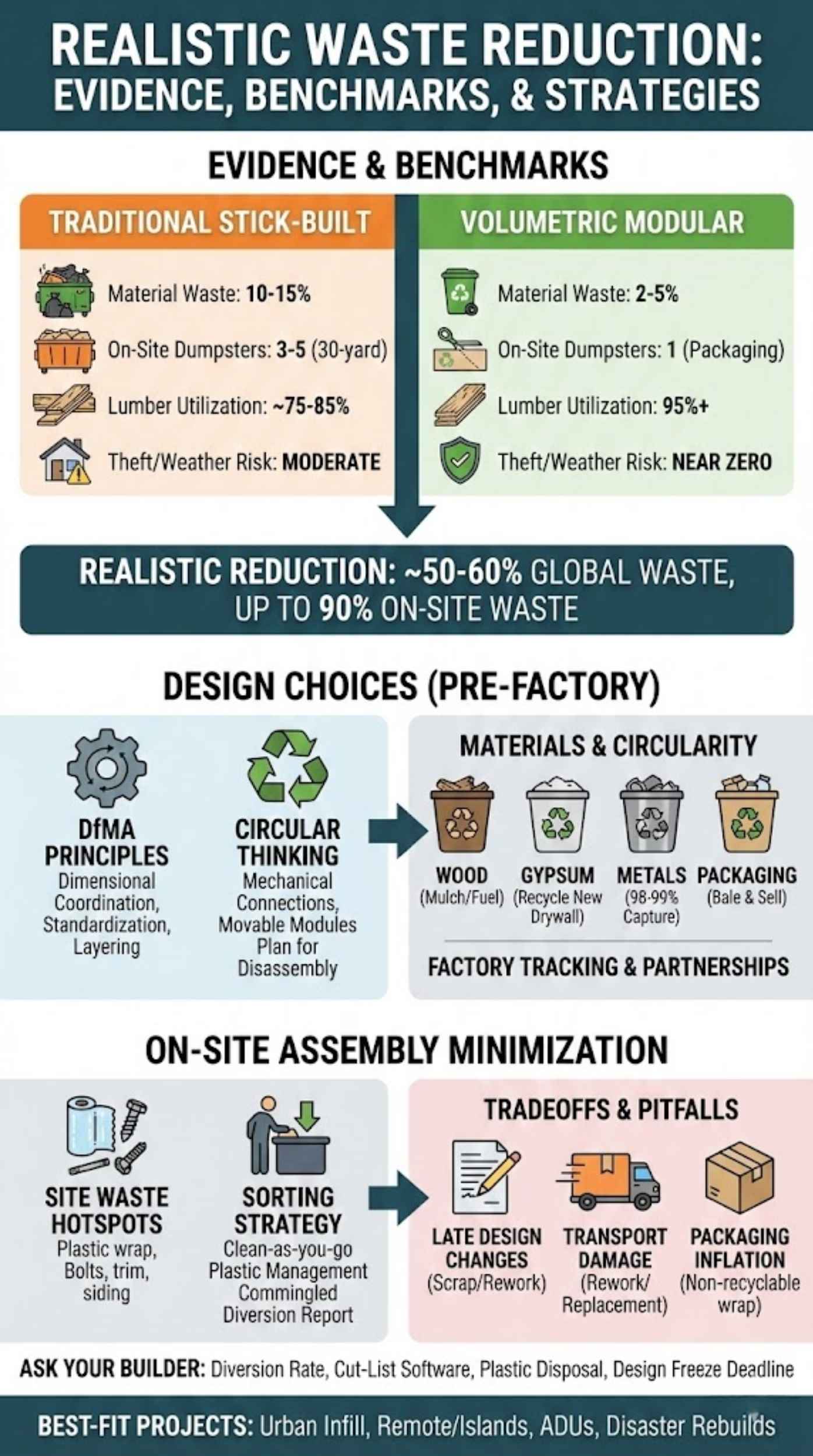

How Much Waste Reduction Is Realistic? (Evidence + Benchmarks)

It is easy to claim “sustainability,” but what do the numbers say? The extent of waste reduction varies depending on the type of project and how “waste” is measured.

What Studies Measure (On-Site Waste vs. Total Lifecycle Waste)

When reading stats, check the boundary.

- On-Site Reduction: This measures only what ends up in the dumpster at the final building location. Modular construction reduces this by 70–90% because the cutting happens elsewhere.

- Total Lifecycle Reduction: This includes the waste generated at the factory plus the waste at the site. Even including factory waste, modular is more efficient due to the optimization software mentioned earlier.

According to a report by WRAP (Waste & Resources Action Programme), off-site construction can generate up to 90% less waste than traditional on-site methods. Peer-reviewed studies in the Journal of Cleaner Production consistently show that prefabrication significantly reduces material consumption—specifically timber and concrete—by minimizing the “safety factor” over-ordering required in manual construction.

A Practical Benchmark Range For Home Projects

For a standard single-family home, here is a realistic comparison:

| Metric | Traditional Stick-Built | Volumetric Modular |

| Material Waste Factor | 10% – 15% | 2% – 5% |

| On-Site Dumpsters | 3 – 5 (30-yard containers) | 1 (mostly for packaging/connections) |

| Lumber Utilization | ~75% – 85% | 95%+ |

| Loss to Theft/Weather | Moderate Risk | Near Zero |

The Takeaway: You can realistically expect to reduce total material waste by about 50% to 60% globally (factory + site) and reduce on-site landfill waste by up to 90%.

Design Choices That Cut Waste Before The Factory Starts

Waste reduction doesn’t start with a saw; it starts with a pencil (or a mouse). The design phase is where the biggest opportunities lie.

DfMA Principles For Residential Modular

DfMA stands for Design for Manufacture and Assembly. It is an engineering methodology that focuses on ease of manufacturing and efficiency of assembly.

- Dimensional Coordination: In DfMA, a home is designed around standard material dimensions. If drywall comes in 4×8 or 4×12 sheets, the room dimensions are adjusted slightly to ensure full sheets are used, eliminating narrow strips of offcut waste.

- Standardization: Using a limited “library” of standard wall types, window sizes, and cabinetry allows the factory to optimize cuts across multiple projects.

- Layering: Designing wall assemblies so that plumbing and electrical runs do not conflict with structural studs reduces the need for drilling and notching, which weakens lumber and creates sawdust/chip waste.

Plan For Disassembly And Future Reuse (Circular Thinking)

The ultimate form of waste reduction is circularity—ensuring the home doesn’t become waste 50 years from now.

- Mechanical Connections: Modular homes often use screws and bolts for structural connections (to withstand transport) rather than just nails and glue. This makes them easier to deconstruct later.

- Movable Modules: In some high-concept designs, the modules themselves remain structurally independent. Theoretically, a modular ADU (Accessory Dwelling Unit) could be unbolted from its foundation and moved to a new location rather than being demolished.

Materials And Circularity: Reuse, Recycling, And “Next Use” Pathways

Because factories generate waste in a central location, they can participate in the circular economy much more effectively than scattered job sites.

High-Impact Materials In Residential Waste

Certain materials contribute disproportionately to the volume and toxicity of construction waste.

- Wood: The largest volume. Factories can send untreated wood scraps to be chipped for mulch, animal bedding, or biomass fuel.

- Drywall (Gypsum): Gypsum in landfills can produce toxic hydrogen sulfide gas. Factories can separate clean gypsum scraps for recycling back into new drywall—a process that requires zero contamination (no nails, no paint), which is hard to achieve on a muddy site but easy in a factory.

- Metals: Steel, copper, and aluminum are high-value recyclables. Factories capture 98-99% of metal scrap because it is profitable.

- Packaging (Cardboard/Plastic): Factories can bale cardboard and plastic wrap, selling them to recyclers rather than paying to landfill them.

How To Build A Waste Diversion Plan That’s Actually Trackable

If you are commissioning a modular home, ask the manufacturer for their Waste Diversion Plan.

- Tracking: A good factory tracks “waste per module” as a Key Performance Indicator (KPI).

- Partnerships: They should have contracts with specific recyclers for their wood, gypsum, and plastic streams.

- The “Next Use”: The EPA encourages “Next Use” thinking. Is the waste being burned? Landfilled? Or turned into a new product? The factory should be able to tell you where their scrap wood goes.

On-Site Assembly Still Creates Waste—Here’s How To Minimize It

The modules arrive 90% complete, but the remaining 10%—the “stitch work”—happens on your land. This phase can still generate trash if not managed.

Site Waste Hotspots In Modular Installs

- Transport Wrap: The heavy-duty plastic wrapping that protects the modules on the highway is a significant volume of waste. It is usually removed immediately upon crane arrival.

- Structural Connections: Lag bolts, straps, and plywood strips used to join modules together generate small amounts of packaging and wood waste.

- Marriage Walls: The area where two modules meet often requires on-site drywall finishing, flooring transitions, and trim work, generating typical construction debris.

- Siding and Roofing: Often, the final layer of siding or shingles over the “mate line” is done on-site to ensure a seamless look.

Sorting Strategy And Documentation Basics

Do not let the local contractor treat the site like a traditional build.

- The “Clean” Site: Because there is so little waste, it is easy to become complacent. Mandate a “clean as you go” policy.

- Plastic Management: Have a dedicated plan for the transport wrap. It is often LDPE (Low-Density Polyethylene) and can be recycled if kept clean and baled. If it gets stomped into the mud, it becomes trash.

- Commingled vs. Sorted: For the small amount of waste generated on a modular set, a single commingled dumpster is often the only practical choice, provided it goes to a facility that sorts C&D waste. Ask your waste hauler for a “diversion report” to prove they sort recyclables.

Tradeoffs And Common Pitfalls (What Can Increase Waste)

Modular is not magic; if managed poorly, it can create different kinds of waste.

Design Changes Late In Process → Scrap/Rework

In traditional building, you can move a window while the framing is happening with moderate cost. In modular, once the drawings are “frozen” and production starts, a change is catastrophic.

If you decide to move a wall after the module is built, the factory has to demolish the existing work. This generates more waste than traditional changes because the construction is so integrated and robust.

The Fix: commit to your design early. Do not start production until you are 100% certain of the layout.

Transportation Damage Risk

If a module is not braced correctly or if the driver takes a turn too fast, drywall can crack, and tiles can pop. This results in on-site rework, requiring new materials to replace the damaged ones.

The Fix: Ensure your manufacturer uses air-ride trailers and has a rigorous “ship-loose” policy for fragile items (shipping them in boxes rather than installed).

Packaging Inflation

As noted, the shrink wrap is significant. If the manufacturer uses non-recyclable wrap or excessive foam that cannot be processed locally, you are left with a mountain of plastic.

Questions To Ask Your Builder/Factory

- “What is your factory’s average waste diversion rate?”

- “Do you use cut-list optimization software?”

- “How do you handle the disposal of the transportation plastic wrap?”

- “What is the deadline for ‘design freeze’ to avoid rework?”

Real-World Use Cases (Residential Scenarios Where Modular Cuts Waste Most)

While modular reduces waste generally, it is a “slam dunk” in specific scenarios.

Best-Fit Projects

- Urban Infill / Tight Lots: In dense city centers, there is no room for dumpsters or material staging. Traditional builders often have to trash cut-offs immediately because they have nowhere to stack them. Modular arrives by crane, eliminating the need for on-site material storage and the associated waste/damage.

- Remote Locations / Islands: Hauling waste off an island or a remote mountain site is incredibly expensive and carbon-intensive. By importing a finished home, you avoid the need to truck tons of construction debris back down the mountain.

- ADUs (Accessory Dwelling Units): Backyard cottages are small. Traditional crews often buy full bundles of material and waste a high percentage because the project is too small to use up the “bulk.” Factories can build an ADU using the scraps from a larger mansion project, maximizing efficiency.

- Disaster Rebuilds: After wildfires or hurricanes, local landfills are often overflowing. Rebuilding with modular reduces the burden on local waste infrastructure during a critical recovery period.

When Traditional May Be Lower-Waste

If you are building a highly irregular, organic-shaped home (e.g., curved earth-ship walls or non-orthogonal geometry), forcing it into rectangular modules can result in excessive structural redundancy (double walls, heavy steel frames). In these hyper-custom “sculptural” homes, a skilled artisan builder using local materials might actually be lower-waste than a factory trying to force a square peg into a round hole.

Step-By-Step: A Low-Waste Modular Home Plan (Checklist)

Use this checklist to ensure your modular project lives up to its green potential.

Pre-Design

- Set a Waste Goal: Define a target (e.g., “90% diversion of on-site waste”) and put it in the contract.

- Select the Right Partner: Choose a manufacturer that uses BIM and automated saws. Ask for their sustainability report.

Design + Procurement

- Design for Standard Dimensions: work with your architect to align room spans with the factory’s material widths (usually 12, 14, or 16 feet).

- Minimize Site Work: Scope the project so the factory does as much as possible (e.g., factory-installed siding, painted drywall). The more done in the plant, the less waste on the site.

- Order “Ship Loose” Carefully: Ensure items shipped loose (flooring for mate lines) are calculated precisely, not just “extra boxes.”

Factory + Site

- Review the Shop Drawings: Catch errors here, on paper, to avoid physical rework.

- Plan the Crane Set: Ensure the crane area is clear to prevent damage to trees or existing structures (landscape waste).

- Wrap Recycling: designate a specific spot on site for the plastic transport wrap and arrange for a hauler who accepts soft plastics.

Final Thoughts

Modular construction is not just a faster way to build; it is a smarter way to manage the planet’s resources. By moving construction from the chaos of the job site to the precision of the factory, we can transform home building from a wasteful industry into a model of efficiency.

The key to unlocking this benefit lies in early planning. Embrace the discipline of the “design freeze,” choose a manufacturer with advanced technology, and manage the on-site assembly with a focus on sorting and recycling. The result will be a home that is high-quality, cost-effective, and built with a conscience.