In today’s rapidly evolving world, automation is taking center stage in industries across the globe, and warehousing is no exception. With advancements in robotics, AI, and machine learning, automation is revolutionizing how goods are stored, sorted, and shipped.

This comprehensive guide dives into the top 12 ways automation is transforming U.S. warehousing, enhancing efficiency, reducing operational costs, and improving safety.

We’ll explore the technological innovations reshaping the industry, provide real-life examples, and examine the future outlook of automated warehouses.

The impact of automation on U.S. warehousing is undeniable, with companies increasingly adopting automated solutions to stay competitive.

From inventory management to order fulfillment, automation is optimizing every aspect of warehouse operations. The integration of advanced robotics, AI, and data analytics is pushing the boundaries of traditional warehousing practices, allowing businesses to scale faster and more efficiently.

1. Streamlining Inventory Management

One of the most significant ways automation is transforming U.S. warehousing is in inventory management. Accurate and efficient tracking of stock is a critical factor in warehouse success. With automation, companies can reduce human error and increase operational efficiency.

Benefits of Automated Inventory Tracking

- Increased Accuracy: Automation minimizes the chance of human error, which is common in manual inventory tracking. By using barcode scanning and RFID (Radio Frequency Identification) technology, warehouses can track inventory in real time, ensuring that stock levels are always accurate.

- Real-Time Tracking and Visibility: With automated systems, managers can have access to live data, providing an up-to-the-minute view of inventory. This leads to better decision-making, faster replenishment, and more accurate demand forecasting.

Use of Robots in Inventory Control

- Autonomous Mobile Robots (AMRs): AMRs can roam the warehouse, scanning shelves for inventory and automatically updating the database. These robots also communicate with other warehouse systems to ensure that stock levels are properly managed.

- Integration with Warehouse Management Systems (WMS): The synergy between automated inventory tools and a WMS ensures smooth data flow between systems, reducing stockouts and preventing overstocking.

2. Enhancing Order Fulfillment Speed

As e-commerce continues to grow, consumers expect faster deliveries. Automation plays a pivotal role in meeting these demands by significantly enhancing order fulfillment speed.

Robotic Picking Systems

- How Robots Speed Up Order Picking: Traditional order picking methods often involve workers manually retrieving items from shelves. Automated systems, however, use robots that can pick products faster and with higher precision, reducing the time needed to fulfill orders.

- Case Studies: Amazon is one of the leaders in using robotic picking systems, utilizing robotic arms and autonomous robots to speed up order fulfillment and improve accuracy. This enables the company to process millions of orders a day, all while maintaining high customer satisfaction.

Automated Sorting Systems

- Faster Sorting of Products: Automated sorters, such as conveyor belts with scanning systems, help sort products based on their destination in the warehouse. This dramatically cuts down on time spent manually sorting items.

- Integration with Conveyors and Automated Sorters: The automated sorters work in tandem with conveyor systems to speed up product movement. Once items are sorted, they are automatically routed to the correct shipping area, ensuring smooth flow and faster deliveries.

3. Reducing Labor Costs

Labor costs are one of the largest operational expenses for warehouses. Automation is significantly reducing these costs while also shifting the workforce toward more skilled and value-added roles.

How Automation Cuts Labor Expenses

- Cost Savings from Robotic Systems: By implementing robots for routine tasks such as picking, sorting, and shelving, warehouses can significantly reduce their reliance on manual labor. This not only reduces labor costs but also minimizes human error.

- Reducing Human Errors and Inefficiencies: Human workers can get fatigued, leading to mistakes in order fulfillment or inventory tracking. Automated systems, on the other hand, work consistently, maintaining high performance levels throughout the day.

Transitioning to Skilled Workforce Roles

- Shifting Labor Roles: While automation can replace certain manual tasks, it also creates new job opportunities. Workers can transition into roles that require more skill, such as overseeing robots, maintaining automated systems, or managing data.

- Worker Retraining Programs: Many warehouses are investing in retraining programs to help their workforce adapt to these new roles, ensuring they remain competitive in an increasingly automated environment.

4. Improving Warehouse Safety

Safety is a top priority in any warehouse, and automation is playing a critical role in reducing workplace accidents.

Robots Enhancing Workplace Safety

- Reducing Workplace Accidents: Robots take on the physically demanding tasks, such as lifting heavy objects or navigating hazardous areas, reducing the risk of injury to human workers. By taking over these tasks, robots help create a safer work environment.

- Safety Features in Automated Systems: Automated systems are equipped with sensors that can detect obstacles, prevent collisions, and ensure safe operation. These safety features not only protect workers but also enhance the efficiency of operations.

Predictive Maintenance for Safety

- AI and IoT-Driven Maintenance: Predictive maintenance tools use data collected from automated systems to predict when equipment is likely to fail. By addressing potential issues before they become critical, warehouses can avoid downtime and improve overall safety.

- Avoiding Equipment Breakdowns: Timely maintenance is key to preventing accidents and operational disruptions. Predictive maintenance ensures that systems remain functional and safe to use, even during peak periods.

5. Optimizing Space Utilization

Warehouses are constantly looking for ways to maximize their storage space, especially as e-commerce demand continues to rise. Automation provides solutions that optimize both vertical and horizontal storage.

Automated Storage and Retrieval Systems (ASRS)

- Maximizing Vertical and Horizontal Storage: ASRS systems make use of high-density shelving and robotic retrieval systems that can operate in tight spaces. These systems improve the efficiency of storage, allowing warehouses to store more products in less space.

- Improving Product Accessibility: Automated systems ensure that products are stored in locations that make them easily accessible. By streamlining the process of locating and retrieving products, warehouses can reduce the time it takes to fulfill orders.

Dynamic Slotting and Storage Optimization

- Real-Time Analysis for Optimal Product Placement: Automated systems can continuously analyze product demand and adjust storage accordingly. For instance, frequently ordered items can be placed closer to picking areas, reducing retrieval times.

6. Scaling Operations for Growth

As businesses grow, they need scalable solutions that can handle increased demand. Automation offers the flexibility needed to scale operations effectively.

Flexibility in Scaling Automated Systems

- Easily Scalable Robotic Systems: Robotic systems can be added or upgraded as needed to accommodate increased order volumes. This flexibility is essential for businesses that experience fluctuating demands, such as seasonal spikes in orders.

- Adapting Automation to Fluctuating Demand: Automation allows warehouses to easily adjust their operations to meet changing demand without the need to hire additional labor or invest in new infrastructure.

Benefits for E-commerce and Retail Growth

- Meeting the Demands of Growing E-Commerce Orders: As e-commerce continues to expand, the need for faster order fulfillment becomes more urgent. Automation enables warehouses to handle larger volumes of orders with ease, ensuring businesses can meet customer expectations.

- Automation’s Role in Peak Season Management: During peak shopping seasons, such as Black Friday or the holiday rush, automated systems help warehouses manage the influx of orders, ensuring timely and accurate deliveries.

7. Enhancing Supply Chain Visibility

One of the biggest challenges in modern warehousing is maintaining visibility across the entire supply chain. Automation solves this issue by providing real-time tracking and data analysis.

Real-Time Data Analytics

- Insights into Inventory Levels, Movement, and Performance: Automated systems collect valuable data on inventory levels, product movement, and system performance. This data can be analyzed to optimize inventory management, improve order fulfillment, and enhance overall operational efficiency.

- Benefits of Cloud-Based Warehouse Management Systems: By using cloud-based systems, warehouses can access data from anywhere, enabling managers to make data-driven decisions and react quickly to changing conditions.

Integration with Broader Supply Chain Systems

- Linking Warehousing Automation with Transportation Management: Automation in the warehouse is only part of the puzzle. Integration with transportation management systems ensures that products are efficiently shipped to customers, reducing lead times and optimizing delivery routes.

- Improving Coordination and Reducing Delays: Automated systems help coordinate with suppliers, transportation networks, and customers, reducing delays and improving overall supply chain efficiency.

8. Boosting Energy Efficiency in Warehouses

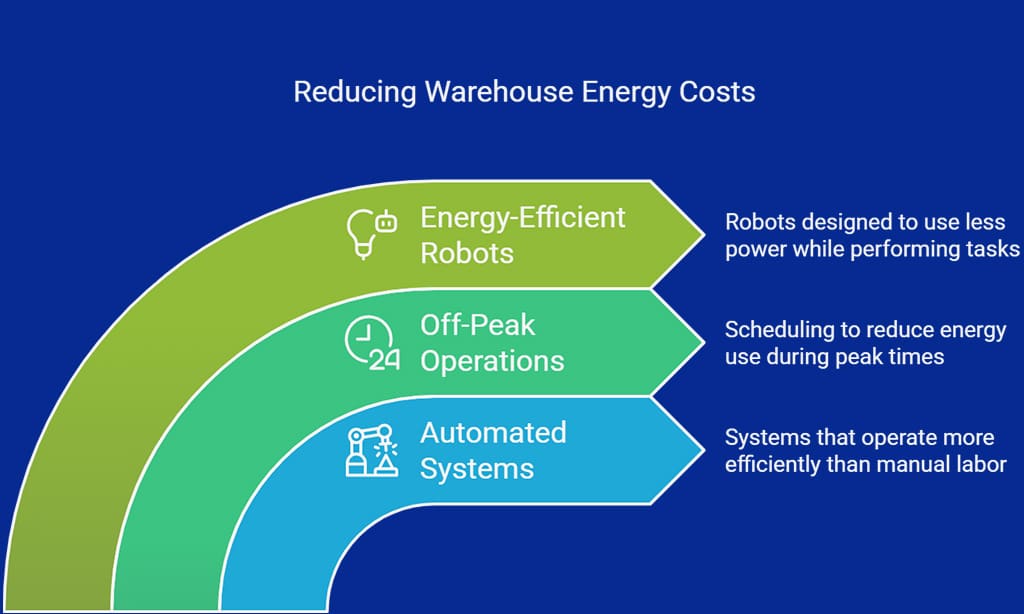

Energy costs are a significant concern for many warehouses, and automation is helping businesses reduce their energy consumption while maintaining operational efficiency.

Energy-Efficient Automation Technologies

- How Automation Can Reduce Energy Consumption: Automated systems are typically more energy-efficient than their manual counterparts. For example, robots can operate more efficiently than human workers, and automated systems can be programmed to work during off-peak hours, reducing energy usage during peak periods.

- Energy-Efficient Robots and Systems: Many robots and automated systems are designed to use less power, ensuring that warehouses can operate more sustainably without sacrificing performance.

Sustainable Practices and Green Warehousing

- Integration of Renewable Energy Sources: Some automated warehouses are incorporating renewable energy sources, such as solar power, to power their operations. This reduces their carbon footprint and makes the warehouse more environmentally friendly.

- Benefits of Energy-Efficient Systems for Sustainability: The combination of energy-efficient technology and renewable energy helps warehouses reduce their environmental impact while keeping operational costs down.

9. Enhancing Customer Experience

At the end of the day, automation is all about improving the customer experience. Faster order fulfillment, accurate inventory, and timely deliveries lead to greater customer satisfaction.

Faster Delivery Times and Accuracy

- How Automation Impacts Delivery Speed: By automating the order fulfillment process, warehouses can significantly reduce the time it takes to pick, pack, and ship orders. This results in faster delivery times, which is crucial for customer satisfaction.

- Ensuring Order Accuracy with Robotics: Robots equipped with precision tools ensure that orders are picked and packed accurately, reducing the chances of shipping errors.

Tracking and Transparency for Customers

- Improved Visibility into Order Status: Customers appreciate being able to track their orders in real-time. Automated systems provide better tracking capabilities, giving customers more transparency into their order status and shipping progress.

- Providing Real-Time Updates to Customers: Automated warehouses can integrate with customer-facing platforms, sending automated notifications to customers about the status of their orders, including shipping updates and expected delivery times.

10. Reducing Operational Errors

Operational errors can lead to costly mistakes, and automation plays a key role in minimizing these issues.

How Automation Minimizes Human Error

- Automation in Order Picking and Packing: Automated picking and packing systems are highly accurate, ensuring that the right products are selected and packed for shipment. This minimizes the chances of errors that could lead to returns or dissatisfied customers.

- Reducing Mistakes in Inventory Management: Automated systems track inventory in real-time, reducing the chance of stockouts or overstocking. This helps prevent errors related to inventory management, such as misplaced goods or incorrect stock counts.

Self-Optimizing Systems

- The Role of AI in Identifying and Correcting Errors: AI-driven systems can continuously analyze performance data and make adjustments to optimize processes, reducing errors in the warehouse.

- Continual Improvement Through Machine Learning: Machine learning allows automated systems to learn from past mistakes and improve over time, further reducing the chances of operational errors.

11. Enhancing Flexibility and Adaptability

Flexibility is essential in today’s dynamic marketplace. Automation provides warehouses with the agility needed to respond to changing customer demands, product types, and market conditions.

Agile Warehousing Systems

- Automation’s Role in Adapting to Changing Product Lines: As businesses introduce new products or change product categories, automated systems can easily adapt to the new requirements. For example, automated storage systems can accommodate different sizes and types of products without requiring major modifications.

- Flexibility in Managing Various Types of Products: Automated warehouses can handle a wide range of product types, from perishable goods to bulky items. This flexibility allows warehouses to diversify their offerings without needing to change their fundamental infrastructure.

Customizable Automation Solutions

- Tailoring Automation to Specific Warehousing Needs: Automation solutions can be customized to meet the unique needs of each warehouse. Whether it’s increasing storage capacity, speeding up order fulfillment, or enhancing safety, automation can be adapted to provide optimal results.

- Case Examples of Customized Automation Systems: Leading companies like Walmart and Target have developed highly customized automation systems to meet their specific warehousing needs, ensuring efficient and effective operations.

12. Future Trends in Warehouse Automation

As automation continues to evolve, new trends are emerging that will further transform U.S. warehousing. These trends are reshaping the way warehouses operate and setting the stage for future developments.

The Rise of AI and Machine Learning

- Potential Applications of AI in Warehousing: AI is revolutionizing warehouse operations by optimizing processes, enhancing decision-making, and reducing operational costs. From predictive analytics to demand forecasting, AI is enabling warehouses to operate more efficiently.

- Machine Learning for Smarter Decision-Making: Machine learning algorithms can learn from data patterns and make smarter decisions, improving inventory management, route optimization, and customer service.

Autonomous Vehicles and Drones

- Future Use of Drones in Inventory Management: Drones are expected to play an increasingly important role in warehouse automation, from flying around to conduct inventory checks to delivering items in hard-to-reach places.

- Autonomous Vehicles in the Supply Chain: Self-driving vehicles will likely become more common in warehouses, improving the speed of inventory movement and reducing reliance on human drivers.

Wrap Up

The ways automation is transforming U.S. warehousing are vast and varied, from streamlining inventory management to improving safety and customer experience. As automation continues to evolve, warehouses will become more efficient, cost-effective, and adaptable to changing market demands.

The future of warehousing is bright, with endless possibilities for further innovations in robotics, AI, and machine learning. Businesses that embrace these technologies today will be poised for success in an increasingly automated world.

Are you ready to take your warehouse operations to the next level? The future of automation is here, and it’s time to start reaping the benefits!