In today’s interconnected global economy, geopolitical conflicts are not just distant political events—they are dynamic forces that shape the way U.S. supply chains operate on a daily basis. These conflicts influence everything from sourcing raw materials and transportation routes to regulatory environments and financial stability.

In this article, we delve deeply into the Top 10 Effects of Geopolitical Conflicts on U.S. Supply Chains, offering a comprehensive exploration backed by practical insights, well-researched examples, and current data trends.

We provide interactive tables, case studies, and easy-to-follow bullet points to ensure that every reader, whether a supply chain professional or an interested observer, gains valuable and actionable insights.

Throughout this article, you will notice a recurring emphasis on the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

This concept encapsulates the complex interplay between global political tensions and domestic logistical operations, highlighting how external instability can translate into tangible challenges and strategic opportunities.

With an engaging conversational tone, this guide breaks down complex ideas into simple, digestible sections designed to promote clarity, retention, and practical application.

Understanding the Nexus: Geopolitical Conflicts and U.S. Supply Chains

Before we dive into the Top 10 Effects, it’s essential to establish a clear understanding of what geopolitical conflicts are and how they directly impact U.S. supply chains.

Defining Geopolitical Conflicts

Geopolitical conflicts are disputes or tensions between nations or regions, often driven by territorial claims, resource competition, ideological differences, or historical grievances. These conflicts can manifest in several ways:

- Economic Sanctions and Trade Restrictions: Governments impose sanctions or embargoes that restrict the flow of goods and services.

- Political Instability: Ongoing political turmoil in key regions disrupts business operations and market confidence.

- Military Confrontations: Active conflicts or the threat thereof can lead to sudden changes in trade routes and investment climates.

These types of conflicts are a significant component of the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains, as they directly challenge the stability and efficiency of logistics operations.

Components of U.S. Supply Chains

U.S. supply chains comprise a series of interlinked stages that facilitate the production, distribution, and delivery of goods. These include:

- Manufacturing and Production: Facilities where raw materials are transformed into finished products.

- Logistics and Transportation: The movement of goods across regional and international borders.

- Distribution and Warehousing: Storage and sorting hubs that prepare products for the market.

- Retail and Delivery: The final leg of the supply chain where products reach the consumer.

Each component is sensitive to external shocks. For instance, a conflict in a resource-rich region can disrupt the supply of essential raw materials, while political tensions can lead to delays in transportation. The integrated nature of these components means that even minor disruptions can have cascading effects on the entire system.

Interrelationship Between Conflicts and Supply Chains

The interplay between geopolitical conflicts and supply chain operations is complex and multifaceted. Here are some of the primary ways in which these conflicts exert their influence:

- Disruption of Trade Flows: Conflicts can close off traditional trade routes, forcing companies to find alternative paths that are often longer and more expensive.

- Regulatory Shifts: In response to conflicts, governments may impose new tariffs, sanctions, or export controls that directly affect cross-border trade.

- Economic Volatility: Political instability can lead to fluctuations in currency values, affecting the cost structures of international transactions.

Interactive Overview Table: Key Dynamics of Geopolitical Conflicts and Supply Chains

| Aspect | Description | Impact |

| Economic Sanctions | Government-imposed restrictions on trade and finance | Disrupts raw material supply and increases costs |

| Political Instability | Uncertainty in key regions affecting investor and market confidence | Leads to supply chain unpredictability and delays |

| Military Conflicts | Active combat or military maneuvers in strategic locations | Forces rerouting of shipments and increases security costs |

| Regulatory Shifts | Rapid changes in trade policies and customs regulations | Requires frequent adjustments and increases administrative burdens |

This table clearly outlines how each aspect of geopolitical conflict can ripple through and affect U.S. supply chains, emphasizing the critical nature of the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

Top 10 Effects of Geopolitical Conflicts on U.S. Supply Chains

In this section, we break down the Top 10 Effects of Geopolitical Conflicts on U.S. Supply Chains, offering detailed insights, practical examples, and interactive elements to enhance comprehension and retention. Each effect is explained in depth, supported by current data and real-world case studies.

Effect 1: Supply Chain Disruptions

Supply chain disruptions are perhaps the most immediate and visible effect of geopolitical conflicts. These disruptions can occur suddenly and without warning, causing significant delays in the movement of goods.

When conflicts erupt, critical transportation routes may be shut down or rerouted. For instance, if a key shipping corridor is compromised, companies must quickly adapt by finding alternative routes—often at higher costs and with longer transit times. These disruptions can lead to inventory shortages, production halts, and a cascade of logistical challenges.

Key Details Table: Supply Chain Disruptions

| Factor | Description | Impact on Supply Chains | Example/Case Study |

| Border Closures | Sudden shutdowns of border crossings | Interrupts continuous flow of goods | 2018 sanctions led to closures at certain ports |

| Rerouting of Shipments | Alternative shipping lanes used to bypass conflict zones | Increases transit times and fuel costs | Rerouting around the South China Sea in 2020 |

| Cyberattacks | Digital attacks disrupting logistics software | Halts operations temporarily and jeopardizes data integrity | 2019 cyberattack on a global logistics firm |

Real-World Example

In 2018, a series of trade sanctions led to immediate supply shortages for U.S. manufacturers reliant on Asian suppliers.

Companies had to scramble to identify new sources for raw materials, which not only increased costs but also forced production delays—clear evidence of how the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains manifests in the real world.

Interactive Timeline of Disruptions

| Year | Event | Description | Resulting Disruption |

| 2018 | Trade Sanctions Imposed | Major sanctions on key Asian suppliers | Immediate material shortages and production halts |

| 2019 | Cyberattack on Logistics Firm | Cyberattack disrupted IT systems in a logistics firm | Temporary shutdown of distribution networks |

| 2020 | Regional Conflict Escalation | Conflicts in strategic regions forced shipping reroutes | Increased transit times and higher costs |

These examples and tables help illustrate the immediate and lasting effects of supply chain disruptions due to geopolitical tensions.

Effect 2: Increased Transportation and Logistics Costs

Geopolitical tensions frequently result in higher transportation and logistics costs. As companies are forced to reroute shipments and adjust their logistics strategies, the cost of moving goods inevitably rises.

When traditional shipping routes are compromised, companies must find alternative paths. These alternatives are often longer and more expensive, as they involve additional fuel costs, increased insurance premiums, and higher security expenses. Moreover, delays caused by rerouting can lead to missed deadlines and additional operational costs.

Key Details Table: Transportation and Logistics Costs

| Cost Factor | Description | Impact | Recent Data/Trend |

| Rerouted Shipping Lanes | Longer, alternative routes to bypass conflict areas | Increases transit times and overall costs | 15-20% increase in fuel costs reported in 2023 |

| Increased Security Measures | Enhanced safety protocols due to higher risk in conflict zones | Additional labor and insurance costs | Security expenses surged by 25% in volatile regions |

| Temporary Port Closures | Closure of key ports due to political instability | Delays and increased demurrage charges | 2022 ports in key regions faced extended closures |

Practical Strategies and Case Studies

A prominent case study is the response of a major U.S. electronics manufacturer during the 2020 conflict escalation in the South China Sea.

Faced with the sudden unavailability of traditional shipping lanes, the company adopted a multi-modal transportation strategy, combining rail and air freight to minimize delays.

Although this approach increased transportation costs by nearly 18%, it allowed the company to maintain production schedules and meet market demand.

Bullet-Point Breakdown: Strategies for Managing Costs

- Diversify Routes: Regularly evaluate and update logistics routes to identify cost-effective alternatives.

- Enhance Security Protocols: Invest in advanced tracking and security technologies to reduce risk premiums.

- Collaborate with Logistics Partners: Work closely with carriers and freight forwarders to negotiate better rates during crises.

These measures exemplify how companies can mitigate the impact of rising transportation and logistics costs in the context of Top Geopolitical Conflicts on U.S. Supply Chains.

Effect 3: Inventory Shortages and Stockouts

Inventory shortages and stockouts are critical consequences of disrupted supply chains. When key supplies are delayed or unavailable, businesses face challenges in meeting production demands, which in turn affects their ability to serve end customers.

Inventory management becomes particularly challenging during times of geopolitical instability.

Companies may experience sudden stockouts, forcing them to either halt production or seek last-minute, often more expensive, alternatives.

The unpredictability of supply makes planning difficult and can lead to cascading delays across the production and distribution cycle.

Key Details Table: Inventory Shortages

| Sector | Impact | Mitigation Strategy | Example/Case Study |

| Automotive | Shortages of components lead to halted assembly lines | Multi-sourcing and maintaining safety stock | 2020 semiconductor shortage affecting auto manufacturers |

| Electronics | Critical parts become scarce, delaying production | Strategic partnerships with alternative suppliers | Global chip shortage causing delays in new product launches |

| Pharmaceuticals | Shortage of raw materials disrupts medication production | Buffer inventories and local sourcing | COVID-19-related disruptions in active pharmaceutical ingredients supply |

Real-World Impact and Strategies

For instance, during the semiconductor shortage, major automakers were forced to slow down production significantly. The shortages, directly linked to supply chain disruptions caused by geopolitical tensions, highlighted the vulnerability of relying on single-source suppliers.

In response, these companies diversified their supplier base and increased inventory buffers—a proactive measure that aligns with the insights behind Top Geopolitical Conflicts on U.S. Supply Chains.

Interactive List: Mitigation Strategies for Inventory Management

- Diversify Suppliers: Rely on multiple vendors across different regions.

- Increase Safety Stock: Maintain higher inventory levels for critical components.

- Implement Real-Time Tracking: Use data analytics to monitor stock levels and predict shortages.

- Adopt Agile Production Methods: Be flexible in production planning to quickly adjust to supply changes.

These strategies, when effectively implemented, can help companies overcome the adverse effects of inventory shortages and ensure continuity even during turbulent periods.

Effect 4: Altered Trade Routes and Market Access

Geopolitical conflicts force businesses to reconsider traditional trade routes, leading to significant shifts in market access. This realignment often comes with both challenges and opportunities as companies seek to navigate changing logistics landscapes.

When conflicts disrupt established shipping corridors, companies must seek alternative routes to ensure the continuous flow of goods. These alternatives may involve longer distances, increased costs, and sometimes entirely new market dynamics.

Moreover, changes in trade routes can affect access to key markets, with some regions becoming less reliable while others emerge as new hubs of activity.

Key Details Table: Altered Trade Routes

| Aspect | Description | Impact | Example/Case Study |

| Rerouting Logistics | Shifting from traditional corridors to alternative paths | Increased transit time and additional costs | Companies rerouting shipments due to South China Sea tensions |

| New Market Opportunities | Emerging trade corridors due to shifting geopolitical alliances | Access to untapped or less volatile markets | Increased trade with regional hubs in Southeast Asia during conflicts |

| Regulatory Adjustments | Changes in customs and trade regulations along new routes | Increased administrative burdens and compliance costs | Adjustments required for new trade routes post-Brexit |

Practical Applications

A notable example comes from the global food industry. During periods of conflict, food importers faced challenges in sourcing products from traditional markets in Europe and Asia. In response, several companies began exploring new trade corridors through Latin America and Africa.

These alternative routes not only ensured continued supply but also opened new market opportunities, underscoring how the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains can sometimes catalyze strategic innovation.

Bullet-Point Summary: Adapting to Altered Trade Routes

- Identify Alternative Corridors: Continuously monitor global political developments to spot viable alternative routes.

- Invest in Market Research: Understand the regulatory environment and market potential of new regions.

- Develop Contingency Plans: Create flexible logistics strategies that can quickly adapt to route changes.

- Leverage Technology: Utilize digital mapping and tracking tools to optimize new trade pathways.

These actions help companies maintain market access and ensure a steady flow of goods despite disruptions caused by geopolitical events.

Effect 5: Increased Regulatory and Compliance Challenges

Geopolitical conflicts often result in rapid changes in trade policies and regulatory environments. Companies must adapt to these changes, which can impose additional administrative and financial burdens.

As geopolitical tensions rise, governments tend to revise trade regulations, impose new tariffs, and enforce stricter compliance measures. This creates an environment of regulatory uncertainty where businesses must be vigilant and adaptable.

Navigating this maze of compliance issues can be daunting, yet it is a critical part of managing the overall impact of the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

Key Details Table: Regulatory and Compliance Challenges

| Regulatory Aspect | Description | Impact on Businesses | Recent Trend/Data |

| Tariff Adjustments | Changes in tariffs and duties imposed on imports | Increased cost of goods and administrative overhead | U.S. tariffs have increased by up to 10% in recent conflicts |

| Customs Inspections | Enhanced scrutiny at borders | Longer wait times and delays in shipping | Average wait times increased by 15-20% in volatile regions |

| Documentation Requirements | More rigorous reporting and documentation standards | Additional labor costs and compliance expenses | Increased digitalization of compliance reporting tools |

Practical Examples and Strategies

During the trade tensions between the U.S. and several Asian countries, companies were forced to quickly adjust their customs procedures.

Many invested in compliance management software and hired regulatory experts to navigate the evolving landscape. These proactive measures helped mitigate delays and reduce the risk of costly non-compliance penalties.

Bullet-Point Summary: Best Practices for Regulatory Compliance

- Implement Robust Compliance Systems: Invest in technology to streamline documentation and reporting.

- Engage Regulatory Experts: Collaborate with legal and trade specialists to remain updated on policy changes.

- Conduct Regular Audits: Monitor and review compliance processes to ensure adherence to new regulations.

- Train Staff Continuously: Keep your team informed about the latest regulatory requirements and best practices.

These practical steps allow companies to navigate the intricate world of trade regulations and reduce the operational risks associated with the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

Effect 6: Heightened Security Risks and Cyber Threats

Geopolitical conflicts not only disrupt physical operations but also expose supply chains to a range of security risks, including cyber threats. With increased tensions, both physical and digital vulnerabilities become more pronounced.

Security risks in supply chains can arise from a variety of sources. Cyberattacks targeting logistics software, data breaches compromising sensitive information, and physical threats like piracy and vandalism are all more likely during times of geopolitical instability. Companies must therefore bolster both their digital defenses and physical security measures to safeguard operations.

Key Details Table: Security Risks and Mitigation

| Security Risk | Description | Impact on Supply Chains | Mitigation Strategy |

| Cyberattacks | Hacking attempts targeting supply chain management systems | Disruption of IT systems and potential data loss | Multi-factor authentication, regular audits |

| Physical Security Threats | Risks such as theft, piracy, or vandalism | Loss of assets and increased insurance costs | Enhanced surveillance, secure transport protocols |

| Insider Threats | Risk from internal breaches or human error | Compromise of sensitive information | Comprehensive training and strict access controls |

Case Study: Cybersecurity in Logistics

A major U.S. logistics company experienced a sophisticated cyberattack during a period of heightened geopolitical tension in 2019.

The attack targeted their supply chain management system, leading to temporary shutdowns and data integrity concerns. In response, the company overhauled its cybersecurity protocols, implemented continuous monitoring tools, and established a dedicated crisis response team.

These measures not only mitigated the immediate impact but also strengthened the company’s resilience against future threats.

Bullet-Point Summary: Strengthening Supply Chain Security

- Invest in Advanced Cybersecurity: Utilize modern technologies such as AI-driven threat detection.

- Enhance Physical Protections: Upgrade security systems at critical logistics hubs.

- Develop a Response Plan: Create detailed protocols for rapid incident response.

- Regular Staff Training: Ensure all employees understand security best practices.

By adopting these measures, companies can significantly reduce the risks associated with both cyber and physical threats, ensuring that the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains does not lead to operational vulnerabilities.

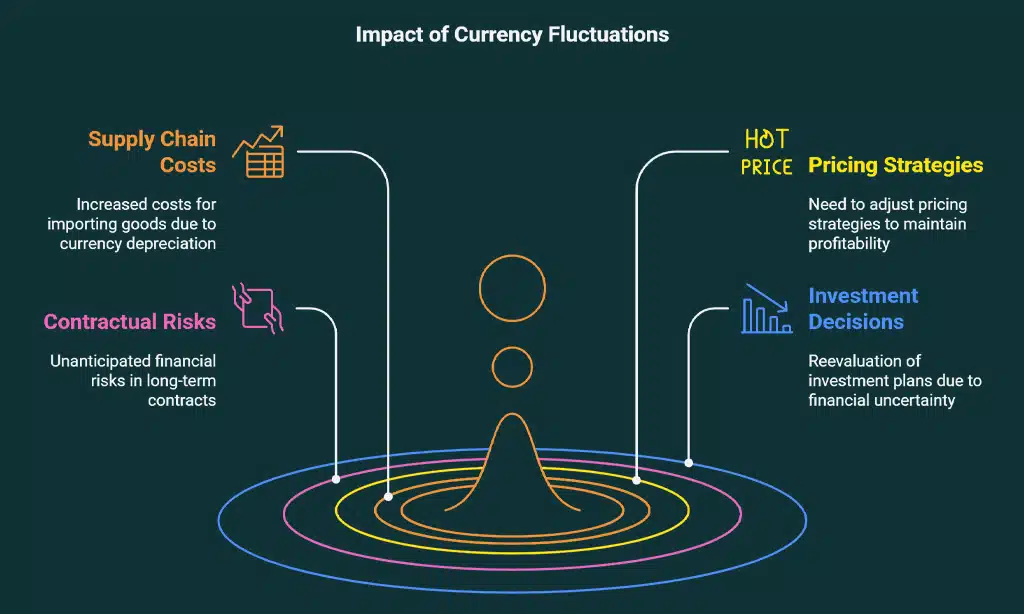

Effect 7: Currency Fluctuations and Financial Risks

Economic volatility is a common fallout from geopolitical conflicts. Currency fluctuations and financial uncertainties can dramatically alter the cost structure of supply chains, affecting pricing, contracts, and investment decisions.

Currency exchange rates can swing wildly during periods of political instability. When a country’s currency depreciates, the cost of importing goods can rise sharply.

Additionally, companies engaged in long-term contracts may find that sudden shifts in currency values lead to unanticipated financial risks.

This financial uncertainty is a critical aspect of the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

Key Details Table: Financial Risks

| Financial Factor | Description | Impact on Supply Chains | Recent Data/Trend |

| Exchange Rate Volatility | Rapid fluctuations in currency values | Increases cost uncertainty for imported goods | Notable fluctuations up to 12% in emerging markets during conflicts |

| Inflationary Pressures | General rise in prices due to economic instability | Raises overall production and logistics costs | Inflation rates spiked in several key regions in 2022 |

| Long-Term Contract Risks | Fixed contracts become less viable as currencies shift | Can lead to renegotiation or financial losses | Several multinational companies have revised contracts post-conflict |

Practical Strategies and Case Studies

For example, a U.S.-based manufacturing firm experienced significant cost pressures during a period of geopolitical uncertainty in Eastern Europe. By implementing currency hedging strategies and negotiating flexible contract terms, the firm was able to stabilize its cost structure despite volatile exchange rates.

Bullet-Point Summary: Financial Risk Mitigation

- Implement Hedging Strategies: Use financial instruments to offset currency risk.

- Negotiate Flexible Contracts: Build in clauses that allow for adjustments based on currency fluctuations.

- Monitor Market Trends: Leverage real-time financial data to anticipate economic shifts.

- Diversify Currency Exposure: Source from multiple regions to balance risks.

These strategies not only help manage financial risks but also ensure that the broader implications of Top Geopolitical Conflicts on U.S. Supply Chains are met with a robust, informed approach.

Effect 8: Supplier and Vendor Reliability Issues

One of the more subtle yet critical impacts of geopolitical conflicts is the challenge of maintaining reliable supplier relationships. When conflicts disrupt operations in supplier regions, businesses face delays, quality issues, and increased uncertainty.

Reliability issues in the supplier network can manifest as delayed shipments, fluctuating quality, or even complete cessation of operations from certain vendors.

This uncertainty forces companies to constantly evaluate their supplier relationships and build contingency plans. The focus keyword Top Geopolitical Conflicts on U.S. Supply Chains is inherently linked to the stability and reliability of the global supplier network.

Key Details Table: Supplier Reliability Issues

| Issue | Description | Impact on Operations | Case Example |

| Supplier Interruptions | Vendors in conflict zones may face shutdowns | Sudden stoppage of essential supplies | 2019 disruptions in parts supply from conflict regions in the Middle East |

| Quality Control Variations | Shifts in production quality due to rapid changes | Compromised product integrity and customer satisfaction | Electronics manufacturers facing inconsistent component quality |

| Lead Time Increases | Extended delays due to difficulty in sourcing | Production delays and increased inventory costs | Increased lead times in the automotive sector during trade conflicts |

Practical Strategies

To manage these risks, companies are increasingly:

- Diversifying Supplier Base: Engaging multiple vendors from different regions to avoid reliance on a single source.

- Implementing Rigorous Quality Checks: Establishing robust quality control processes to monitor supplier output.

- Developing Contingency Plans: Having backup suppliers in place to quickly replace unreliable vendors.

Bullet-Point Summary: Managing Supplier Reliability

- Conduct Regular Risk Assessments: Evaluate supplier stability and geopolitical risks.

- Establish Strong Communication Channels: Ensure timely updates and transparency with all suppliers.

- Leverage Local Sourcing: Where feasible, source locally to reduce exposure to international conflicts.

- Build Long-Term Partnerships: Develop relationships that can withstand short-term disruptions.

These measures empower companies to better manage the risks associated with supplier and vendor reliability, ensuring continuity even during periods of geopolitical instability.

Effect 9: Impact on Production and Manufacturing Timelines

Delays in production and manufacturing can be one of the most visible outcomes of disrupted supply chains. When components are delayed or unavailable, production lines slow down or even halt entirely.

The impact on production timelines is multifaceted:

- Component Shortages: A lack of essential parts can force assembly lines to shut down.

- Logistical Delays: Increased transit times and rerouted shipments disrupt scheduled production runs.

- Cost Increases: Production delays often result in higher labor and operational costs, reducing overall profitability.

Key Details Table: Production Impacts

| Production Factor | Description | Operational Impact | Real-World Example |

| Component Availability | Delays in receiving critical parts | Production stoppages and scheduling issues | Automotive sector experiencing delays in semiconductor supplies |

| Manufacturing Scheduling | Disruptions in assembly line scheduling | Increased overtime and potential product defects | Electronics manufacturers facing extended production cycles |

| Operational Costs | Rising costs due to extended production times | Reduced margins and increased end-product prices | Increased production costs reported during the COVID-19 pandemic |

Practical Insights and Examples

Consider a leading automotive manufacturer that experienced significant delays in 2020 due to shortages of microchips—a direct consequence of geopolitical tensions in key manufacturing regions.

By adopting agile production methodologies and investing in real-time inventory monitoring, the company minimized downtime and gradually restored production efficiency.

Bullet-Point Summary: Optimizing Production Timelines

- Adopt Agile Production: Implement flexible manufacturing processes that can adapt quickly to supply changes.

- Enhance Inventory Monitoring: Use real-time data to predict shortages and adjust production schedules.

- Invest in Automation: Automation can help reduce dependency on manual adjustments during delays.

- Develop Contingency Plans: Prepare alternative production strategies in case of prolonged disruptions.

These strategies underscore the importance of proactive planning and agile responses in mitigating the production impacts stemming from Top Geopolitical Conflicts on U.S. Supply Chains.

Effect 10: Shifts in Global Sourcing and Strategic Planning

The final effect we explore is the strategic shift in sourcing practices and overall supply chain planning. As companies grapple with the challenges posed by geopolitical instability, many are reevaluating their sourcing strategies and moving toward more localized or diversified supply networks.

In an era of global uncertainty, reliance on a single, global supplier can be a significant liability. Many companies are now pivoting toward nearshoring and regional sourcing to minimize the risks associated with distant supply chains.

This shift not only reduces exposure to international conflicts but also promotes agility and faster response times.

Key Details Table: Shifts in Sourcing

| Sourcing Strategy | Description | Benefits | Case Study/Trend |

| Nearshoring | Moving production closer to home markets | Reduced transportation costs and lead times | U.S. companies increasingly sourcing from Mexico or Canada |

| Diversification | Engaging multiple suppliers from various regions | Mitigates risk of dependency on a single source | Trend toward multi-sourcing observed in the electronics industry |

| Localized Sourcing | Sourcing components from domestic suppliers | Enhances control over quality and supply stability | Growth in domestic manufacturing due to supply chain disruptions |

Practical Applications and Strategies

A notable case study involves a major consumer goods company that shifted its production base from Asia to domestic facilities in response to repeated disruptions.

By localizing part of its supply chain, the company not only reduced costs associated with long-haul logistics but also improved its responsiveness to market changes—an adaptive measure in line with the dynamics of Top Geopolitical Conflicts on U.S. Supply Chains.

Bullet-Point Summary: Strategic Sourcing Shifts

- Conduct a Sourcing Audit: Identify vulnerabilities in your current global sourcing strategy.

- Invest in Local Partnerships: Develop relationships with regional and domestic suppliers.

- Utilize Predictive Analytics: Forecast risks and plan alternative sourcing strategies.

- Embrace Flexibility: Design contracts and operations to adapt quickly to geopolitical changes.

These strategic adjustments are essential for building resilient supply chains capable of withstanding the long-term impacts of global political uncertainty.

Strategic Recommendations to Mitigate Supply Chain Risks

Given the multifaceted challenges posed by geopolitical conflicts, companies must adopt proactive, strategic measures to protect their supply chains. The following recommendations, supported by real-world examples and data, offer a roadmap for businesses navigating the complexities of the focus keyword Top Geopolitical Conflicts on U.S. Supply Chains.

1. Building Resilient Supply Networks

Integrating advanced technology into supply chain management is no longer optional—it is imperative. Predictive analytics and real-time monitoring systems enable companies to forecast potential disruptions and adjust operations before issues escalate.

Key Recommendations Table: Technology Integration

| Technology | Function | Benefits | Example/Trend |

| Predictive Analytics | Forecast potential supply chain disruptions based on real-time data | Allows proactive adjustments, reducing downtime | Adoption increased by 40% among Fortune 500 companies |

| Integrated Supply Chain Platforms | Centralizes communication and data sharing among partners | Enhances coordination and decision-making | Cloud-based platforms now dominate the market |

| Automation Tools | Streamline operations and adjust production schedules automatically | Reduces manual errors and increases efficiency | Robotics in warehousing growing by 25% annually |

Practical Strategies

- Invest in Data Analytics: Implement systems that integrate data from various points of the supply chain.

- Develop Integrated Platforms: Enhance communication between suppliers, logistics partners, and internal teams.

- Embrace Automation: Use automation to quickly adjust operations when disruptions occur.

2. Diversification of Suppliers and Routes

To mitigate risks, companies must diversify their supplier base and develop alternative logistics routes. This approach not only reduces dependency on a single source but also builds flexibility into the supply chain.

Key Recommendations Table: Supplier Diversification

| Strategy | Description | Benefits | Implementation Example |

| Multi-Sourcing | Engage with several suppliers across different regions | Minimizes risk if one supplier fails | Electronics firms partnering with multiple chip manufacturers |

| Alternate Routing | Regularly update logistics routes to bypass conflict-prone areas | Reduces transit time and unexpected delays | Diversification of shipping lanes around the South China Sea |

| Local Sourcing | Develop local or regional supplier networks | Enhances control and reduces international exposure | U.S. manufacturers investing in domestic production facilities |

Practical Strategies

- Conduct Regular Supplier Audits: Evaluate supplier stability and geopolitical risks.

- Develop Backup Plans: Establish secondary suppliers and alternative shipping routes.

- Collaborate with Logistics Experts: Engage professionals to identify and secure cost-effective alternatives.

3. Aligning with International Trade Regulations

Adapting to rapidly changing trade regulations is critical. Companies should implement robust compliance management systems to navigate new tariffs, customs requirements, and sanctions.

Key Recommendations Table: Regulatory Compliance

| Compliance Area | Description | Benefits | Trend/Example |

| Tariff Management | Monitor and adapt to changing tariff policies | Prevents unexpected cost increases | Companies using automated tariff tracking software |

| Customs Efficiency | Streamline documentation and inspection processes | Reduces delays and administrative burdens | Digitalization reducing wait times at major ports |

| Trade Policy Monitoring | Stay updated on global trade agreements and sanctions | Enhances readiness for regulatory shifts | Increased reliance on real-time regulatory dashboards |

Practical Strategies

- Implement Compliance Management Software: Use technology to manage and update regulatory information.

- Engage Trade Experts: Collaborate with legal advisors specialized in international trade.

- Train Staff: Regularly update team members on new compliance procedures and requirements.

4. Collaborative Strategies with Global Partners

Collaboration is key when facing complex geopolitical challenges. Building strong relationships with global partners can provide shared insights, resources, and a unified response to disruptions.

Key Recommendations Table: Collaborative Strategies

| Collaboration Type | Description | Benefits | Example/Case Study |

| Joint Risk Assessments | Regular evaluations conducted with partners to identify vulnerabilities | Shared insights reduce individual risk exposure | Industry consortiums performing collective risk assessments |

| Resource Sharing | Agreements to share critical resources during disruptions | Enhances overall supply chain resilience | Shared warehousing and logistics networks among regional suppliers |

| Crisis Management Planning | Collaborative creation of contingency plans | Streamlines response and minimizes downtime | Multi-company crisis response teams in the automotive sector |

Practical Strategies

- Establish Regular Communication Channels: Schedule periodic meetings and updates with key partners.

- Develop Joint Contingency Plans: Collaborate on risk mitigation and emergency response strategies.

- Share Best Practices: Create forums for sharing lessons learned and effective strategies.

Takeaways

Navigating the complexities of global politics requires a proactive, informed approach to managing supply chains. The insights provided in this article underscore the need for continuous monitoring, agile response mechanisms, and strategic collaborations.

By embracing the strategies and best practices outlined above, businesses can build more resilient operations capable of withstanding the shocks associated with Top Geopolitical Conflicts on U.S. Supply Chains.

We invite you to share your thoughts and experiences in the comments below. Engage with other industry professionals and experts to further refine your strategies and stay ahead in this ever-evolving landscape.

In the end, while geopolitical conflicts present undeniable challenges, they also pave the way for innovation and strategic reinvention.

By leveraging technology, diversifying your supply chain, and fostering global partnerships, your organization can not only weather the storm but emerge stronger, more agile, and better prepared for the future.