The world of architecture is rapidly shifting. Sustainability isn’t just a buzzword anymore; it’s a professional mandate. For architects, this means evolving from conventional practices to high-performance standards, with the Passive House standard leading the charge. This rigorous, performance-based approach promises buildings that are energy-efficient, incredibly comfortable, and future-proof. But making the switch from traditional design can feel like learning a new language.

This guide provides a clear roadmap, outlining 10 essential tips to help you seamlessly transition your skills, knowledge, and firm into the rewarding world of Passive House design, ensuring your practice stays relevant and competitive. Let’s begin the transition.

Integrate Passive House Principles Early in the Design Process

Passive House design needs a clear goal from day one. You set a heating load target and run PHPP. The model shows if your walls, roof, and floor meet thermal barrier goals. You map thermal bridges in the walls.

You sketch building orientation for best solar gain too. You plan window size, placement, and passive solar gain early. You name an airtightness goal and call for a blower door test at 0.6 air changes per hour.

Think of it as laying out the sails before you leave the dock, you get ready for smooth sailing.

A pilot project in Vancouver cut energy use by 70% compared to a code home. A house in Germany saved 87.5% on heating and cooling over its life. Thousands of Passive House buildings now stand in cold, hot, and mixed climates.

You keep construction costs near a code home, or only slightly higher. You win lower bills and rising market value each year. Early design slots in heat recovery ventilation and energy recovery ventilators.

It sets you up for a true zero carbon building that runs like a well-oiled machine.

How do you assemble the right team for Passive House projects?

A strong crew makes a Passive House project shine. You need the right mix of skills and early buy-in.

- Involve the building owner and architect at the kickoff to lock in passive house design targets and zero energy building aims. Setting these goals early aligns the team on climate change and greenhouse gas cuts.

- Add a contractor who holds a Passive House certificate or brings solid site experience to guide tight building envelope work and blower door test prep. This pro drives precise installs of thermal insulation and windows.

- Include a mechanical engineer for sizing heat recovery ventilators and underfloor heating systems to boost indoor air quality and cut energy use. Their HVAC plans tackle moisture and maintain thermal comfort year-round.

- Hire an energy modeler versed in PHPP and passive solar architecture tools to refine building orientation and solar gains. Adjustments in this digital lab save energy and spot thermal bridges.

- Invite pros from Weber Thompson, veterans of the Solis multi-family passive solar building, to share lived project tips and streamline team cohesion. Their case study shows clear wins in energy savings.

- Plan workshops that loop in all stakeholders through design and construction to track blower door test targets and spot issues early. Regular syncs curb surprises and make the zero carbon building goal a team win.

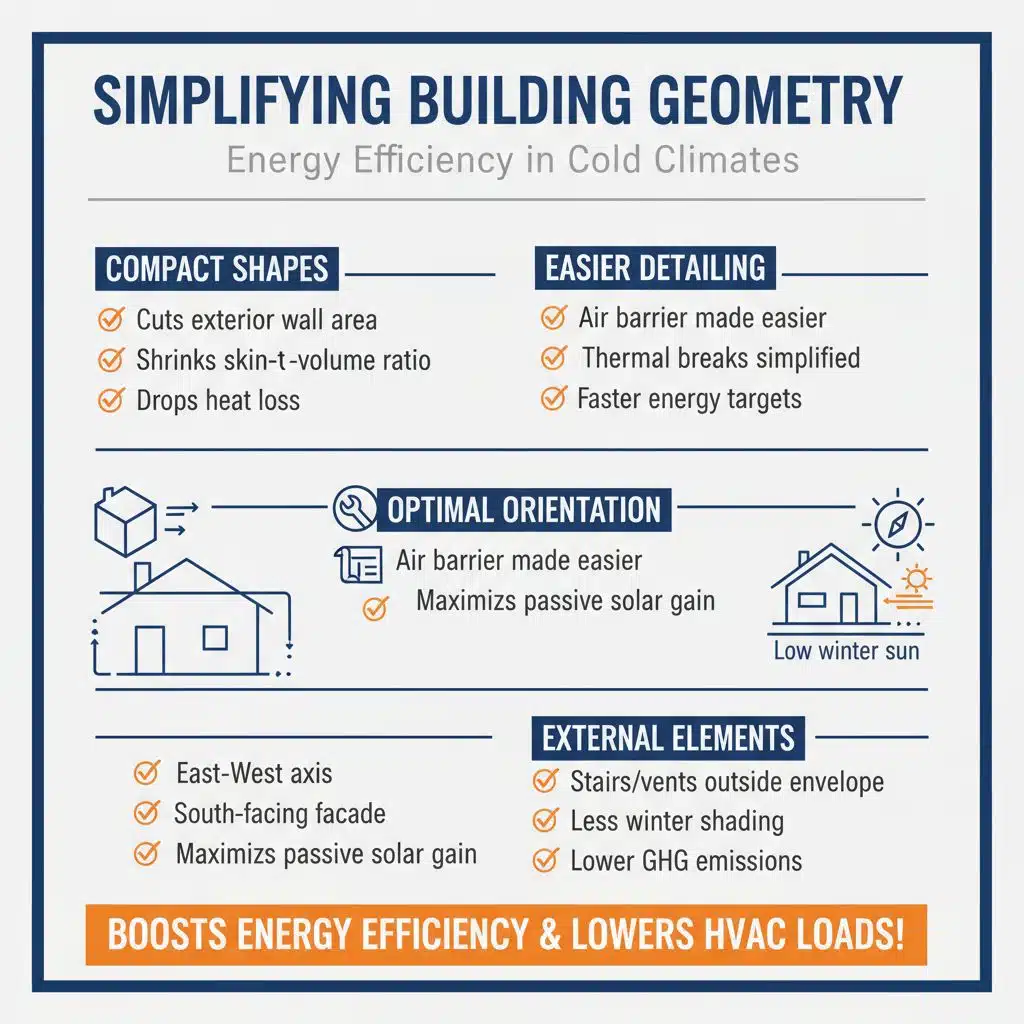

How can simplifying building geometry improve energy efficiency?

Compact shapes cut exterior wall area and shrink the skin-to-volume ratio. This simple form drops heat loss through the building envelope. It makes air barrier and thermal break detailing easier.

Architects feed the shell form into PHPP and run a blower door test faster, nailing energy targets sooner.

Moving stair shafts and vents outside the thermal envelope keeps floors simple and slashes air leakage. Fewer projections limit winter shading, ramp up passive solar gains, and trim greenhouse gas emissions in a zero-energy passive house.

Why is continuous insulation important for Passive House buildings?

Continuous insulation acts like a cozy blanket around the shell of a Passive House. Wolfgang Feist set the passivhaus standard to target a U-value of 0.15 W per square meter Kelvin on walls, floors, and roofs, and this thick, uninterrupted insulations layer cuts heating and cooling loads.

Design teams use PHPP to model air flows and heat loss, and layers of closed-cell foam, wool, or foam board seal corners around window frames and water pipes in the basement.

This unbroken thermal shield stops cold paths under concrete slabs and around ring mains, and it wipes out thermal bridges at key junctions. A blower test shows leaks, but the right insulations detail makes them vanish, boosting airtightness.

Architects meet ultra-low energy targets with continuous insulations, cutting emission of greenhouse gases and supporting zero carbon building aims. That barrier pairs with a ventilation system and heat recovery core to keep fresh air, and it frees up solar energy or heat pump power for hot water.

How do you achieve airtightness with quality detailing?

Install a continuous air barrier across all walls and floors. Lay tape and sealant at every joint and penetration. Fit electrical outlets flush with the barrier. Use gaskets and foams at mechanical ventilation ducts.

Test each phase with a blower door test tool. Target 0.6 air changes per hour at n50.

Architects run interim airtightness tests during the frame stage. They perform a final blower door test before occupancy. These checks aim for 0.6 air changes per hour at n50. That level cuts heating costs to one-eighth of a typical home.

Tight seams and thermal breaks boost the lifespan of a zero carbon building. Designers also use PHPP and heat exchanger data to fine-tune the design.

What makes windows and doors high-performance for Passive House?

High-performance windows and doors cut heat loss and stop drafts. They keep a home snug and quiet. They score a U-value of 0.85 W per square meter Kelvin or lower. Builders pick three layer glass, low emissivity coating, and insulated frames to hit that target.

Warm edge spacers stop cold bridging around the glass too. These features also boost soundproof results, adding to a zero carbon building design.

Certified Passive House products pass strict air leakage and fire rating tests. Experienced fitters wrap edges with special tape and caulk. They model each unit in PHPP and verify with a blower door test.

They block thermal bridge spots and tie into continuous insulation layers. Proper shading cuts excess heat radiation in summer, while low emissivity glass keeps warmth inside during winter.

How do you design to avoid thermal bridges?

Architects detail envelope connections precisely and seal each joint. They align insulating panels and airtightness membranes without gaps at floor joints or wall intersections. Passive House rules demand no thermal bridge at window sills or roof-wall junctions.

Teams limit penetrations, group air vents and water heater pipes in one location. They steer HVAC shafts and roof drains outside the main envelope.

Quality assurance crews check psi-values with Therm and test airtightness using a blower door device. They scan walls with a thermal imaging camera to find hidden cold spots. The PHPP tool models thermal performance and guides heat pump sizing.

Teams spot leaks early to improve solar thermal panels, PV, and renewable energy technologies. Architects align passive house design with zero carbon building standards and resilience.

Why include a heat recovery ventilation (HRV) system in your design?

A heat recovery ventilation system brings fresh air into a tightly sealed, thermally insulated passive house design. It captures heat from outgoing air and uses it to warm incoming air.

Some units recover over 80% of ventilated heat. This flow of fresh air keeps indoor air quality high and limits mold risk in your zero carbon building.

Short, sound-insulating ducts and balanced airflow trim noise and stop pressure swings that fuel the stack effect. You adjust ventilation levels to suit a cellar or main living space.

PHPP models let you check heat recovery rates and energy use. Strict energy ratings and fire codes drive each electrical installation. A blower door test finds leaks before you add the heat recovery core.

How do you optimize building orientation for solar gain?

Site layout taps local solar and wind data to guide building orientation. South facing walls catch low winter sun. Winter sun streams deep into living rooms. Compact shapes cut shading from roof overhangs.

PHPP helps model sun paths, study solar gain and cooling demand.

Urban lots pose fixed grids that limit solar gain. Solis uses sensors to raise and drop shades at key times. High performance glazing links light with heat control. Roof overhangs block high summer sun without blocking winter rays.

This passive house design aids zero carbon building goals.

What are effective shading strategies for Passive House homes?

Architects position automated exterior roller shades on south facades, hitting the sweet spot between style and function. These devices tame solar gain in summer and welcome low winter sun.

Designers link balconies and movable louvers to shade glass walls while adding extra outdoor space. Movable elements shift with solar angles, cutting glare and easing loads on air conditioners and heat pumps.

Teams plug shading specs into PHPP for solar simulation early in their passive house design, so they catch hot spots before construction. Urban projects often miss ideal building orientation, so shading tools guide window placement and roller shade sizing.

Shading systems fit within airtightness plans and work with blower door test goals to keep thermal bridges under control. This approach aligns with zero carbon building targets and supports heat recovery ventilation efficiency.

How can moisture be managed in airtight buildings?

Airtight, breathable walls seal leaks but let moisture escape. A blower door test spots gaps around windows, doors, and electrical installations. Slip in vapor‐permeable membranes behind drywall to vent trapped humidity.

Short, insulated plumbing runs cut condensation risks.

An MHVR unit, also called a heat recovery ventilation system, pushes stale air out, pulls fresh air in, and reclaims heat. Pair it with a water‐source heat pump for tight humidity control.

Occupants tweak simple controls to match each season. Quality checks on roof, wall, and floor assemblies block moisture at its source, boosting durability in passive house design and zero carbon building projects.

What are the benefits of using PHPP and other Passive House tools?

PHPP lets design teams model heating and cooling loads at 15 kWh/m² per year. It predicts total primary energy use at 120 kWh/m² per year. Modeling supports zero carbon building targets.

Teams can test air tightness goals of 0.6 air changes per hour at n50. It links to blower door test results for auditing. It shines light on thermal bridge risks. Data drives early design choices.

It spots weak zones in the envelope. It guides window and door specs for high performance. You can tweak building orientation to harness solar gain or avoid overheating.

Cost estimates flow from PHPP models. Teams compare these figures with conventional plans. Auditors need the Passive House Planning Package for compliance. Designers size heat recovery ventilation units with this tool.

They also size water-source heat pump systems. Builders tighten wall layers to boost sound insulation and cut drafts. Clear reports keep budgets on track. Contractors hit targets without guesswork.

Clients adjust glass and shading for better solar control. Energy modeling forms the backbone of passive house design.

Why is ongoing training and certification important for Passive House architects?

Architects join workshops to master passive house design and zero carbon building techniques. Certified professionals bring real skills to projects. Education keeps architects up to date on new standards and tools.

They learn energy modeling, airtight detailing, heat recovery, and ways to stop thermal bridge leaks. Many use the Passive House Planning Package and airtightness test in their work.

Clients look for architects who hold Passive House certification. This credential shows they can hit the Passivhaus standard. Trainers cover moisture control, blower door test results, building orientation tips, fuels, and fresh air flows.

The 2023 Passive House Northwest Conference let pros share tips and swap project notes. Ongoing study helps builders cut emissions, save cash, and build homes that last.

Takeaways

The shift to Passive House design is a journey, not a single step. While it demands a meticulous approach to detail and a commitment to new knowledge—from understanding WUFI modeling to mastering blower door testing—the long-term rewards are undeniable. You will be delivering superior, healthier, and truly sustainable buildings that actively mitigate climate change.

Use these 10 tips as your professional checklist and your guide to continuous improvement. Start small, prioritize training, and build your confidence project by project. The future of architecture is high-performance, and by embracing the Passive House standard, you secure your role as a leader in that future. Now, go design a healthier planet.

FAQs on Tips for Architects Transitioning to Passive House Design

1. What is passive house design?

Passive house design makes homes very tight and well insulated. It cuts most heat loss and can lower energy use by 90 percent.

2. How does building orientation help a passive house?

Building orientation points main windows south, like giving your house a warm hug in winter and a cool breeze in summer. It draws in winter heat and blocks summer rays. This simple move cuts heating and cooling needs.

3. How can I stop thermal bridge in my passive house?

A thermal bridge is a weak spot where heat slips out. You fix it with continuous insulation, sealed joints, and material breaks. This keeps your home cozy and cuts drafts.

4. Why pick passive house for zero carbon building goals?

Passive house cuts energy use to a bare minimum. If you add solar panels, you can reach zero carbon building status. You save money, and you make a green project.