We touch our phones an average of 2,617 times a day. It is the first thing we reach for in the morning and the last thing we see at night. Yet, for a device that is so intimate to our daily existence, the average user knows shockingly little about where it comes from. We see the sleek glass, the high-resolution display, and the “Designed in California” or “Made in Vietnam” label, but we rarely glimpse the industrial odyssey that brought it there.

As we enter 2026, the complexity of creating these devices has only deepened. The reality of smartphone manufacturing facts is stranger and more complex than fiction. It is a story that involves digging deep into the Earth’s crust for rare elements, purifying water to a level that becomes toxic to humans, and coordinating a logistical ballet that spans more borders than a diplomat.

The “cost” of your phone is far higher than the price tag you paid at the store—it is measured in gallons of water, tons of rock, and a global carbon footprint that might surprise you.

Key Takeaways

-

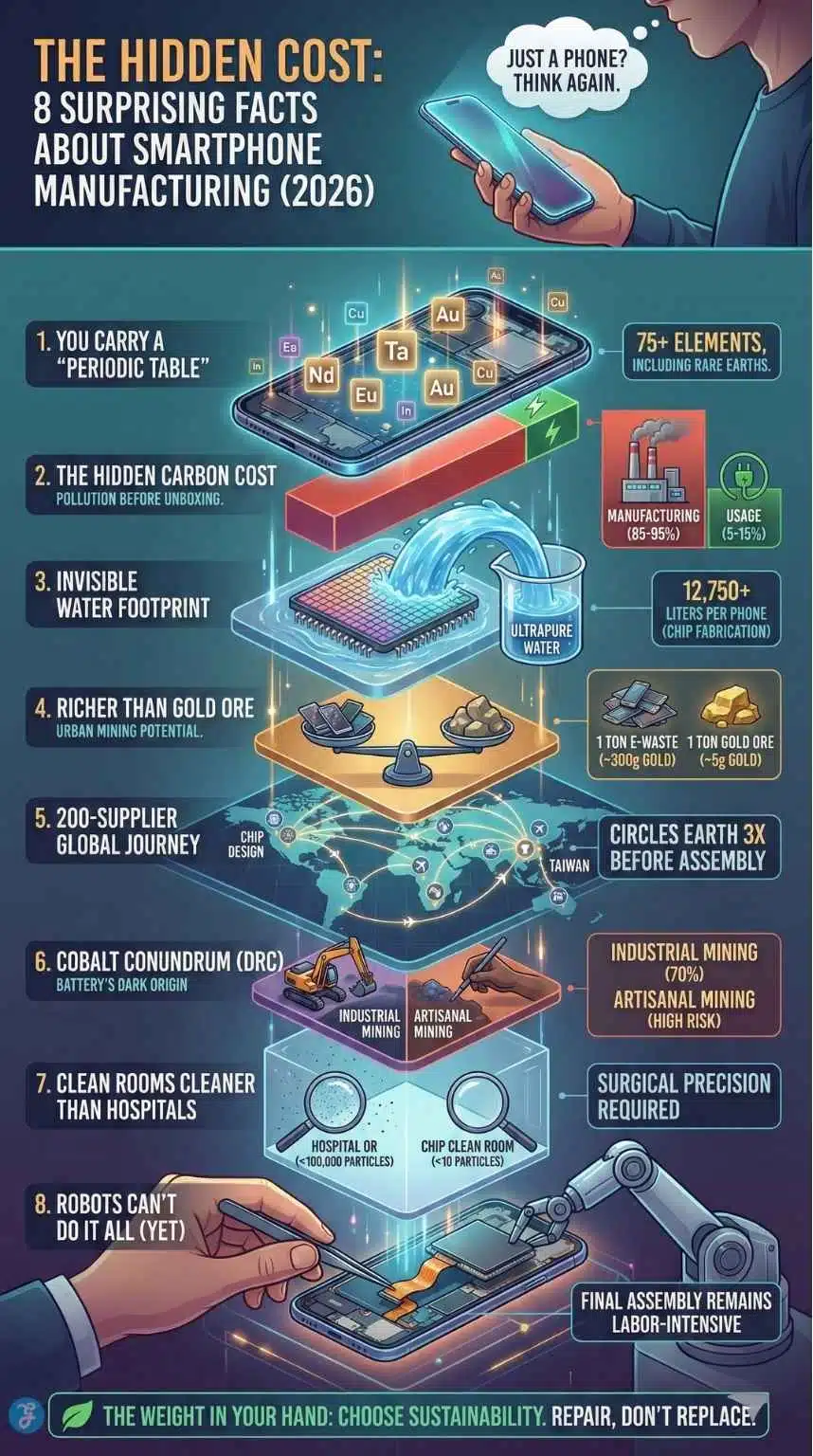

Carbon Load: 90% of your phone’s pollution happens before you buy it.

-

Geology: Your phone contains 75 elements, making it a geological map of the world.

-

Gold Mine: Discarded phones are 300x richer in gold than actual gold ore.

-

Water Crisis: Making one phone call uses over 12,000 liters of water.

-

Human Element: Final assembly remains surprisingly manual, relying on huge workforces.

The Invisible Industrial Iceberg

While the interface in your hand feels seamless, the infrastructure behind it is anything but. As we settle into 2026, the smartphone remains the crown jewel of modern engineering, yet it is also the tip of a massive industrial iceberg. Most of the device’s story, and its environmental weight, remains submerged, hidden within a “black box” of global logistics that few consumers ever see.

We tend to measure a phone’s worth by its screen refresh rate or AI capabilities, often ignoring the gritty smartphone manufacturing facts that define its true cost. This disconnect is significant. Today’s mobile supply chain is a sprawling ecosystem that intersects with nearly every major global industry, from deep-sea mining and chemical refining to semiconductor fabrication and international shipping.

Despite the industry’s recent push for “carbon-neutral” branding, the core reality of production remains heavily resource-intensive. As you read the following facts, remember that each component represents a triumph of logistics and a withdrawal from the planet’s resources. To truly understand the future of technology, we must first understand the messy, fascinating, and often surprising reality of how it is built.

8 Surprising Smartphone Manufacturing Facts You Didn’t Know

To truly understand the device in your pocket, we have to look beyond the sleek exterior and marketing hype. The following insights peel back the layers of global logistics, rare earth geology, and industrial complexity that go into every modern device. These realities reveal a supply chain that is far more intricate, resource-intensive, and surprisingly fragile than the average consumer might expect.

1. You Carry a “Periodic Table” in Your Pocket

If you were to pulverize your smartphone and analyze its dust, you wouldn’t just find plastic and glass. You would find a geological marvel. A single modern smartphone contains roughly 75 of the 81 stable elements found in the periodic table.

In 2026, as chips become more powerful (pushing toward 2nm and 1.8nm architectures), the reliance on exotic materials has intensified.

-

The Rare Earths: Your phone’s ability to vibrate, play music, and display vivid colors relies on roughly 16 of the 17 rare earth metals. Neodymium is used in the magnets for the speakers and vibration motor. Europium and Yttrium are responsible for the vibrant reds and greens on your OLED screen.

-

The Conductors: Beyond the obvious copper and gold, your phone uses Tantalum (mainly from Africa) for capacitors that regulate electricity, and Indium (often from China), which allows your screen to be touch-sensitive.

This reliance on such a broad spectrum of elements means that a disruption in a mine in one corner of the world—say, a strike in a Bolivian lithium mine or a trade embargo on Chinese gallium—can halt production lines globally.

2. The Hidden Carbon Cost: It’s Not the Charging

When we think of “green” tech, we often worry about how much electricity our chargers pull from the wall. However, this is a negligible part of the problem. One of the most startling smartphone manufacturing facts is that 85% to 95% of a smartphone’s total lifetime carbon footprint is generated before you even open the box.

Unlike a gas-powered car, which generates most of its pollution while it is being driven, a smartphone generates its pollution while it is being born.

-

Extraction intensity: Mining the raw materials requires massive diesel-powered machinery.

-

Refining heat: Smelting aluminum and refining silicon requires furnaces running at thousands of degrees, often powered by coal or natural gas in industrial hubs.

-

The 2026 Shift: While companies like Apple and Samsung are pushing for “Carbon Neutral” supply chains by 2030, the reality in 2026 is that the manufacturing phase remains the most polluting sector of the tech industry. Keeping your phone for four years instead of two is the single most effective way to reduce your carbon impact—far more effective than unplugging your charger.

3. The “Invisible” Water Footprint of Chips

The semiconductor industry is one of the thirstiest on the planet. As of 2026, the fabrication of the advanced microchips inside your phone requires water treated to a level of purity that doesn’t exist in nature.

The Stat: Manufacturing the components for a single smartphone requires roughly 12,750 liters (approx. 3,360 gallons) of water.

This water is primarily used to rinse silicon wafers. But this isn’t just tap water; it is Ultrapure Water (UPW).

-

What is UPW? It is water that has been filtered 1,000 times more thoroughly than drinking water. It is so pure that it acts as a solvent; if you were to drink it, it would leech minerals from your body cells.

-

The Crisis: This massive water consumption is why tech hubs like Taiwan and Arizona face critical challenges during droughts. A single “Fab” (fabrication plant) can consume as much water daily as a small city.

4. Phones are “Richer” than Gold Ore

This is perhaps the most economically baffling fact on this list. We are digging deep mines to find gold, while simultaneously burying tons of gold in landfills.

-

The Comparison: A high-grade gold mine might yield 5 to 6 grams of gold per metric ton of earth excavated. In contrast, one metric ton of discarded smartphones (roughly 6,000 units) contains roughly 300 to 350 grams of gold.

-

Urban Mining: This makes electronic waste (“e-waste”) literally 50 to 100 times richer than the best gold ores on Earth.

-

The Waste: Despite this, as of 2026, global e-waste recycling rates hover around 20-25%. We are throwing away billions of dollars in gold, silver, palladium, and platinum every year. This “Urban Mining” potential is why startups in 2026 are aggressively developing robots to disassemble phones automatically, trying to recover these materials before they are lost to landfills.

5. The 200-Supplier Global Journey

The “Made in China” label is a simplification that borders on a lie. A flagship smartphone is the ultimate citizen of the world.

-

The Web: A single device relies on components from over 200 different suppliers across 40+ countries.

-

The Journey:

-

Design: California, South Korea, or Finland.

-

Chips: Designed in the UK/US, fabricated in Taiwan (TSMC) or South Korea.

-

Sensors: Japan (Sony) and Germany (Bosch).

-

Glass: USA (Corning) or Japan.

-

Assembly: China, India, Vietnam, or Brazil.

-

-

The Logistics: Before a phone lands in your pocket, its components have collectively traveled a distance equivalent to circling the Earth three times. In 2026, we are seeing a massive shift as manufacturing moves away from a China-centric model to a “China Plus One” strategy, with India rising as a major export hub (accounting for over 25% of iPhone exports as of late 2025).

6. The Cobalt Conundrum & Battery Origins

The lithium-ion battery is the heart of the modern mobile experience, but it has a dark origin story that the industry is still struggling to rewrite in 2026.

-

The Ingredient: Cobalt is the critical stabilizer in batteries that prevents them from overheating and allows them to hold a charge.

-

The Source: Approximately 70% of the world’s cobalt comes from one country: The Democratic Republic of the Congo (DRC).

-

The Reality: While industrial mines produce the bulk of this, a significant percentage comes from “artisanal” miners—independent workers, often children, digging by hand in dangerous conditions. Because this artisanal cobalt is often sold to the same refiners as industrial cobalt, it becomes “blended” in the supply chain, making it nearly impossible to guarantee a phone is 100% ethically sourced.

-

The Innovation: This ethical and supply risk is driving massive research in 2026 into LFP (Lithium Iron Phosphate) batteries and solid-state batteries that reduce or eliminate cobalt usage, though these are yet to become the standard for flagship smartphones.

7. Clean Rooms Cleaner Than Hospitals

We often worry about our phones getting dirty, but they are born in the cleanest places on Earth. The processor inside your phone is built in a class-1 clean room.

-

The Standard: A surgical operating room is considered “clean” if it has fewer than 100,000 particles (0.5 microns or larger) per cubic foot of air.

-

The Fab: A semiconductor clean room must have fewer than 10 particles per cubic foot.

-

Why? A single speck of dust falling on a silicon wafer during lithography is like a boulder falling on a city—it ruins the circuitry instantly. Workers must wear full-body “bunny suits,” undergo air showers, and work in yellow light (to prevent UV damage to photo-resists) for 12-hour shifts.

8. Robots Can’t Do It All (Yet)

Despite the images of high-tech automation, smartphone manufacturing facts reveal that the final assembly is still incredibly human-reliant.

-

The Human Touch: While robots handle the chips and the soldering of the motherboard, the final putting together of the phone—connecting delicate ribbon cables, pressing in the battery, screwing in microscopic pentalobe screws—is often done by hand.

-

The Scale: This is why factories like Foxconn’s Zhengzhou facility (iPhone City) are essentially cities, housing up to 350,000 workers during peak season. Humans are still more adaptable and have better tactile feedback for delicate tasks than the most advanced robots of 2026.

The $1,000 Myth: The True Cost of Components

One of the most controversial smartphone manufacturing facts is the gap between what a phone costs to build and what you pay for it.

-

The Bill of Materials (BOM): As of late 2025 data, the estimated cost of components for a flagship phone (like the iPhone 16 Pro Max or Galaxy S25 Ultra) is roughly $485 to $570.

-

The Markup Mystery: If the parts cost $500, why is the price tag $1,200? The difference isn’t just profit. It pays for the “Invisible Manufacturing”:

-

R&D: Billions spent developing the 3nm chips years before production starts.

-

Software: Maintaining the OS for 5-7 years.

-

Global Logistics: Shipping secure components across 40 borders.

-

-

The 2026 Trend: As memory (RAM) and storage prices spike due to AI demand, the “BOM” cost is rising faster than retail prices, squeezing manufacturers and forcing them to cut costs in less visible areas (like box accessories or frame materials).

The 2026 “Right to Repair” Revolution

For the last decade, manufacturing was designed to keep you out of your phone. In 2026, the law is forcing manufacturers to let you in.

-

The EU Directive: The European Union’s “Right to Repair” directive fully kicks in by July 2026. This forces global manufacturers (who won’t make separate phones just for Europe) to change how they build phones worldwide.

-

The Changes:

-

Spare Parts: Manufacturers must make parts (screens, batteries, cameras) available for 10 years after the phone is released.

-

Battery Access: By 2027, designs must shift to allow user-replaceable batteries, meaning 2026 is the final year of the “glued-shut” battery era.

-

-

The Impact: This is shifting manufacturing away from “planned obsolescence” toward modularity. We are seeing a return to screws instead of glue, making the 2026 generation of phones potentially the longest-lasting devices ever built.

Comparative Look: Manufacturing vs. Usage

To understand the true weight of these facts, it helps to compare the cost of making the phone versus using it.

| Impact Category | Manufacturing (The Hidden Cost) | Usage (3 Years of Charging) |

| Energy Impact | High (Smelting, Refining, Logistics) | Low (Efficient 5V Charging) |

| Water Footprint | ~12,750 Liters (Industrial & Mining) | Negligible |

| Material Displacement | ~30kg of Rock Mined | None |

| CO2 Emissions | ~85-95% of Lifetime Total | ~5-15% of Lifetime Total |

| Human Labor | High (Miners, Factory Workers) | None |

Frequently Asked Questions (FAQs)

1. Is it better to repair my old phone or buy a new eco-friendly one?

Repair is almost always better. Because 85-95% of the carbon footprint is in manufacturing, extending the life of your current phone from 2 years to 4 years essentially cuts its annual environmental impact in half. No “green” new phone can compete with the phone you already own.

2. Why don’t we recycle 100% of smartphones?

It is an economic and design problem. Modern phones are glued shut to be waterproof and slim, making them incredibly difficult and expensive to disassemble. Often, it costs more to separate the materials than the materials are worth. However, 2026 regulations in the EU are pushing for easier battery removability, which may improve this.

3. Will we run out of materials to make smartphones?

Not exactly, but they will get expensive. Elements like Indium (for touch screens) and Cobalt are finite. As demand from EVs and phones grows, we may face “supply crunches” that drive up prices or force manufacturers to use inferior alternative materials.

4. How much gold is actually in my phone?

A tiny amount, but it adds up. An average smartphone contains about 0.034 grams of gold. While that’s worth only a few dollars, when you consider 1.5 billion phones are sold a year, that is tons of gold entering the market annually.

5. Are “Fair Trade” smartphones real?

Yes, but they are niche. Companies like Fairphone produce modular, ethically sourced devices. However, for major giants like Apple and Samsung, “Fair Trade” is a goal, not a reality. They are making progress, but the supply chain is too vast to be 100% perfect yet.

Final Thought: The Weight in Your Hand

As we navigate 2026, the smartphone remains the most successful consumer product in history. But the next time you pick yours up, remember the smartphone manufacturing facts that built it. You aren’t just holding glass and metal; you are holding a device that moved mountains, drained rivers, and connected the furthest corners of the globe.

The most sustainable phone isn’t the one coming out next year—it’s the one currently in your pocket. Treat it with care.