Have you noticed how packages arrive faster these days? Behind this magic are smart warehouses changing how goods move around the world. Old warehouses were slow and made many mistakes.

Workers had to find items by hand and track them on paper. This caused delays and wrong orders. But now, tech is fixing these problems in big ways.

The smart warehouse market hit $14.21 billion in 2021. It’s growing fast at 14.5% each year. This growth shows how much companies need better ways to store and ship products. Smart warehouses use robots, computers, and special tools to speed up work and cut down errors.

In this blog, we’ll show you the cool tech making warehouses smarter. You’ll learn how these changes help get your orders faster and more correctly. We’ll also look at how these new systems save energy and what’s coming next for supply chains.

The future of shipping is here.

Key Takeaways

- Smart warehouses grew to a $14.21 billion market in 2021 and are expanding at 14.5% yearly.

- IoT sensors, AI systems, and robots work together to track items in real-time, cutting errors by up to 95%.

- Automated systems can fulfill orders 65% faster than traditional methods, with robots working 24 hours without breaks.

- Blockchain technology creates transparent supply chains where all partners can see item locations and handling history.

- Green practices like solar power and hydrogen-powered drones make smart warehouses more eco-friendly while cutting costs.

The Role of Smart Warehousing in Modern Supply Chains

Smart warehouses now sit at the heart of modern supply chains. They act as smart hubs that link makers to buyers through tech-driven systems. With the market worth $14.21 billion in 2021, these high-tech storage spaces use IoT devices, AI, and robots to track goods in real time.

Gone are the days of paper lists and manual counts. Today’s warehouses use digital twins and cloud systems to know where each item is at all times.

These smart spaces do more than just store stuff. They cut costs, speed up shipping, and make fewer mistakes. Automated guided vehicles move boxes without human help while machine learning spots trends to plan for busy times.

Supply chain managers can see their whole network on digital dashboards and fix problems before they start. As the smart warehouse field grows at 14.5% each year, more firms add these tools to stay ahead in the fast-paced world of global trade.

Key Technologies Driving Smart Warehouses

Smart warehouses run on cutting-edge tech that changes how goods move from factories to homes. These tools work together like a well-oiled machine, making supply chains faster and smarter than ever before.

Internet of Things (IoT)

IoT forms the backbone of smart warehouses today. These tiny sensors and devices talk to each other throughout the warehouse, keeping tabs on every item. They track where products are, how many you have, and when you need more.

No more guessing about stock levels! IoT devices watch your inventory in real-time, so you never run out or order too much. This cuts costs and keeps customers happy.

These smart gadgets do more than count boxes. They can check temperature for cold items, spot damage, and flag safety issues. Workers get alerts on their phones when something needs fixing.

The best part? All this happens without human help. The system collects data all day and night, helping bosses make better choices about what to order and when. This makes the whole supply chain run smoother from factory to front door.

Artificial Intelligence and Machine Learning

AI and machine learning form the brain of smart warehouses. These smart systems can look at past sales data and tell you what products will sell next month. This helps keep just the right amount of items on shelves.

No more empty spots or too much stuff taking up space! AI tools also watch how machines work in the warehouse. They can spot when a forklift might break down before it happens. This stops work from stopping due to broken gear.

Smart warehouses use these tools to make fast choices without humans. For example, they can route robots to pick items in the best path or sort packages by zip code. The best part? These systems get smarter over time as they learn from each task they do.

Many top shops now use AI to cut costs and speed up how fast you get your online orders.

Robotics and Automation

Robots are changing how warehouses work today. Smart machines like AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) now zip around warehouse floors. They pick items and move boxes faster than people can.

These robots don’t get tired or make mistakes. They work 24 hours a day without breaks!

Warehouse owners love automated systems too. Things like AS/RS (Automated Storage and Retrieval Systems) and sorting machines cut labor costs big time. A robot can do the job of many workers.

This means orders get filled quicker and with fewer errors. Plus, these smart machines talk to each other through computer networks. They know exactly where every item is stored. This makes the whole supply chain run smoother from start to finish.

Blockchain for Enhanced Transparency

Blockchain makes supply chains clear as glass. This tech acts like a digital ledger that can’t be changed, showing where items are at all times. Retailers now use blockchain to group packages from different sellers into one box for faster delivery.

This smart move helps them ship products to customers without delays. They can also add more products to their online stores by working with other sellers.

Supply chain partners trust each other more thanks to blockchain. They can see who handled what and when in real time. This cuts down on mistakes and helps fix problems fast. If something goes wrong, everyone knows who’s responsible.

Blockchain also helps track items from the factory to your door, making sure nothing gets lost along the way. This kind of tracking makes supply chains work better for everyone.

Benefits of Smart Warehouses in Supply Chains

Smart warehouses boost supply chains with faster, more exact order handling. They cut costs while making customers happier through real-time tracking and fewer mistakes.

Real-Time Inventory Management

Smart warehouses now track every item in real time. IoT sensors watch products as they move through the building. These tiny devices send data to the main system right away. No more waiting for daily counts or weekly reports! The system knows exactly what’s in stock at any moment.

This cuts down on mistakes that happen with old paper methods or manual counting.

AI helps make this even better by spotting patterns. The system can order more products before they run out. Warehouse staff get alerts on their tablets about what needs attention.

This means stores never miss sales because items are out of stock. Companies save money too since they don’t buy too much of things that don’t sell fast. Real-time tracking makes the whole supply chain work faster and smoother for everyone.

Improved Accuracy and Reduced Errors

Smart warehouses cut down mistakes in big ways. Automated picking systems grab the right items almost every time, unlike humans who might grab wrong products when tired. These robots work non-stop without getting sleepy or bored.

The result? Orders have fewer mix-ups and customers get what they asked for.

Warehouse management systems track each item with pinpoint detail. They know exactly where products sit on shelves and how many remain in stock. Machine learning spots patterns that humans miss, flagging potential problems before they happen.

With vision systems checking packages, wrong shipments drop by up to 95%. This means less money wasted on returns and happier buyers who trust your business more.

Faster Order Fulfillment and Last-Mile Delivery

Smart warehouses cut order times by up to 65% with robots that zoom through aisles picking items faster than humans ever could. These systems spot and fix errors right away, so you get what you ordered the first time.

No more waiting weeks for your package! Drones now play a big role too. They fly over traffic jams to bring items to your door in hours instead of days. A small box that used to take two days to reach you might now arrive the same day thanks to these flying helpers.

The whole supply chain moves quicker with smart tech. Warehouse bots talk to trucks and drones to plan the best routes. This team effort means your order goes from shelf to doorstep without delays.

Companies use AI to guess what you’ll buy next and stock those items close to you before you even click “buy.” The result? You get your stuff faster, and stores spend less money on shipping.

It’s a win for both sides of the shopping world.

Sustainability in Smart Warehousing

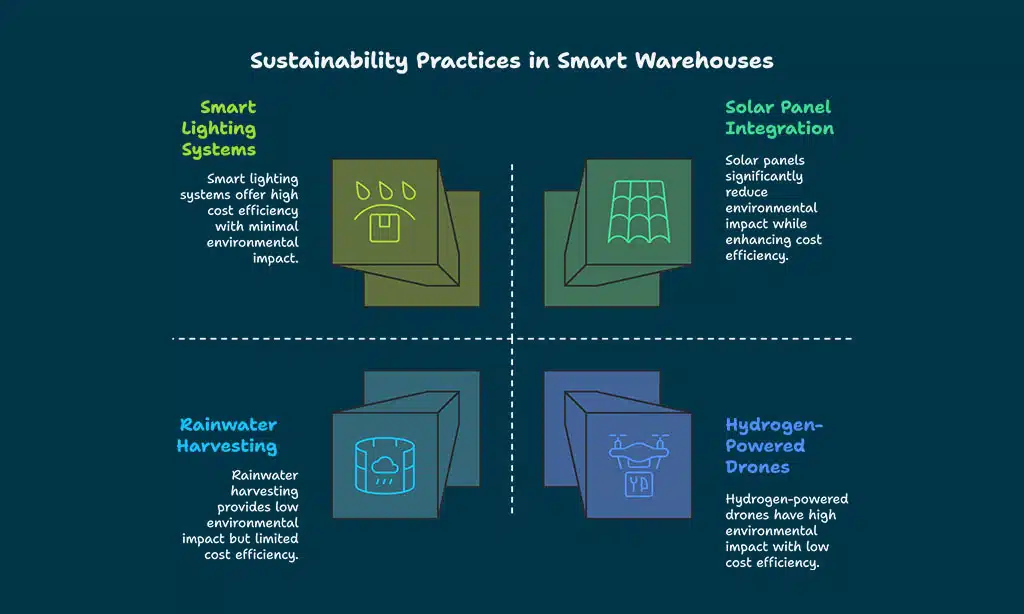

Smart warehouses now lead the way in green business practices. They cut power use with smart lights and solar panels while robots and AI trim waste by moving only what’s needed, when it’s needed.

Energy Efficiency and Green Practices

Smart warehouses are going green in big ways. Companies like CaPow have created clean energy systems for warehouse robots that cut downtime and help the planet. These systems don’t pollute and keep robots running longer without stops for charging.

Many warehouses now use solar panels on their huge roofs to power lights, conveyor belts, and computer systems. LED lights and smart sensors turn off power when no one is in an area, saving lots of money and energy.

Gadfin’s hydrogen-powered drones show how green tech helps supply chains. These flying robots deliver items without making carbon pollution like trucks do. Some warehouses also collect rainwater to use in bathrooms and for watering plants outside.

Smart building materials keep heat in during winter and out during summer. This cuts heating and cooling costs. These green steps help both the earth and a company’s bottom line through lower power bills and less waste.

The Future of Supply Chains with Smart Warehouses

Supply chains will look very different by 2025. The old step-by-step models are going away. New systems using AI and robots will take their place. These smart warehouses will use self-driving trucks and drones to move goods faster than ever.

Your packages might soon arrive by flying robots instead of delivery trucks!

The next wave of change is already starting. Warehouse robots now pick and pack orders without human help. Data systems spot problems before they happen. Smart returns systems make sending items back simple and fast.

Companies that use these tools gain an edge. They save money, work faster, and make fewer mistakes. This shift means better service and lower costs for everyone in the supply chain.

Takeaways

Smart warehouses are changing how goods move around the world. With robots, AI, and IoT tools working together, companies can track items in real time and ship orders faster than ever.

These tech-driven spaces cut costs while making fewer mistakes. They also help the planet by using less energy and creating less waste. As more firms adopt these smart systems, we’ll see even faster, cheaper, and greener supply chains that can adapt to what customers want right away.

The future of getting stuff from point A to point B looks bright, thanks to these smart storage hubs.

FAQs on Rise of Smart Warehouses

1. What are smart warehouses and how do they work?

Smart warehouses use digital twins, IoT technologies, and artificial intelligence to run better than old warehouses. They track items in real-time with vision systems and use robots to move stuff around. These spaces work with warehouse management systems to make fewer mistakes.

2. How do automated guided vehicles help in smart warehouses?

Automated guided vehicles (AGVs) move boxes without human help. They work with autonomous mobile robots to speed up order fulfillment. This cuts down on mistakes and makes workers safer.

3. What role does machine learning play in smart warehousing?

Machine learning helps predict what customers will buy. It spots patterns in data that humans might miss. The computer brain learns over time, getting better at predicting maintenance needs and fixing bottlenecks before they cause problems.

4. Can smart warehouses improve inventory management?

Yes! Smart warehouses track every item using real-time inventory tracking systems. They know when stock is low and can order more stuff automatically. This means fewer empty shelves and happier customers.

5. How do drones fit into smart warehouse operations?

Drones count inventory in tall shelves where it’s hard for people to reach. Some big companies are testing drone delivery from warehouses to homes. These unmanned aerial vehicles also check for problems in large warehouse spaces.