Right to repair is reshaping the way people buy, own, and maintain technology. For years, many products were designed and sold in a way that made repair difficult, expensive, or effectively impossible outside of a manufacturer’s approved channel. Batteries were glued in. Screws were proprietary. Diagnostic tools were locked behind paywalls. Replacement parts were restricted. Software features were disabled after third-party repairs. The result was predictable: consumers replaced devices sooner, and the waste stream grew.

Now the pressure is shifting. Legislators, regulators, consumer groups, and repair communities are forcing a change in the rules. Instead of treating products like sealed subscriptions that expire, right to repair pushes the market back toward a simple idea: if you bought it, you should be able to fix it. This is not only a consumer-rights issue. It is an economic issue, a sustainability issue, and a competition issue. It also strikes directly at planned obsolescence because it targets the hidden levers that shorten a product’s usable life.

This cluster guide explains what right to repair means in practical terms, how modern repair restrictions work, what laws usually require, how companies respond, and how this movement is turning “replace it” culture into “keep it working” culture.

Why Planned Obsolescence Thrives In Modern Electronics

Planned obsolescence rarely shows up as a product that intentionally dies on a specific day. In modern tech, it is more often engineered through friction. Devices become “obsolete” when it becomes too hard, too costly, or too inconvenient to keep them running.

The industry has many ways to create that friction.

- Sealed designs that require special tools and risky disassembly

- Parts that are unavailable to independent repair shops

- High repair pricing that makes replacement feel “smart”

- Software support that ends while the device still works

- Component pairing that blocks replacement parts from functioning normally

- Service policies that restrict repairs to limited locations

- Warranty language that scares consumers away from third-party repair

Even when individual choices seem minor, the combined effect is powerful. A device can still power on, but if it can’t be serviced affordably, it becomes a replacement candidate.

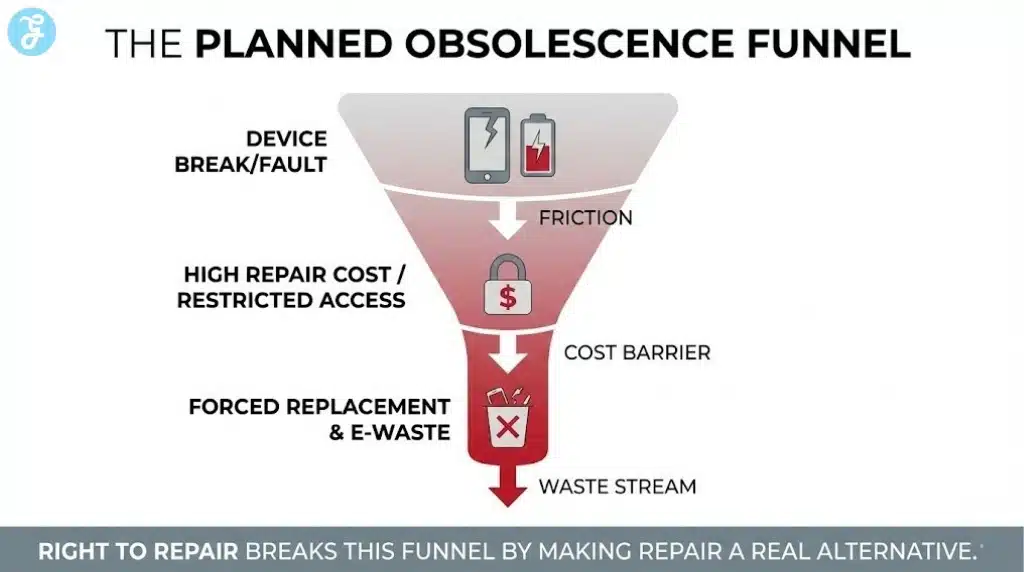

The Replacement Funnel That Obsolescence Creates

A typical consumer journey under repair restriction looks like this:

- A battery weakens, a port becomes loose, or a screen cracks

- Repair is quoted at a high price or is not offered locally

- Parts or tools are unavailable to independent shops

- The brand suggests upgrading or offers a trade-in discount

- The consumer replaces the device, even if the core hardware is fine

Right to repair challenges this funnel by making repair a real alternative again.

What Right To Repair Means In Practice

Right to repair is the principle that owners and independent repair providers should have the information and access needed to repair products. It is not a demand that manufacturers provide free repairs. It is a demand that manufacturers stop using unnecessary restrictions that block repair.

In practical terms, right to repair typically means access to:

- Spare parts at fair and transparent pricing

- Repair manuals, guides, and schematics where applicable

- Diagnostic software, calibration tools, and service modes

- Firmware and software procedures required to complete repairs

- Reasonable access to security features that should not disable lawful repairs

Right to repair does not mean every person must repair their own device. It means consumers can choose who repairs it, and repair providers can operate without artificial barriers.

The Difference Between Repairability And Repair Access

These are related but not identical.

- Repairability is about physical design: can the device be opened, and can parts be replaced?

- Repair access is about rules and systems: are parts, tools, and software available to do the repair?

A device can be physically repairable but still practically impossible to repair if parts pairing or tool restrictions block the work. Strong right to repair outcomes require both.

How Right To Repair Laws Typically Work

Right to repair laws and regulations vary across regions and product categories. Some focus on consumer electronics. Others cover agricultural equipment, appliances, and broader digital devices. While details differ, the intent is usually consistent: reduce artificial repair barriers that shorten product life.

Common legal requirements include:

- Making replacement parts available to owners and independent repair shops

- Providing repair documentation and service information

- Providing diagnostic tools or access to diagnostic systems

- Preventing software locks from disabling lawful repairs

- Requiring continued parts availability for a defined support period

- Increasing transparency about repair options and costs

A Typical Policy Requirement Map

| Policy Element | What It Forces | What It Fixes |

| Parts availability | Parts can be purchased outside authorized channels | Monopoly repair pricing |

| Manuals and guides | Repair knowledge becomes accessible | “No information” barrier |

| Diagnostics access | Shops can identify faults and verify fixes | “Only we can diagnose” barrier |

| Anti-lockout rules | Repairs do not disable features without justification | Software-based obsolescence |

| Support windows | Repair supply lasts longer | Forced upgrades due to missing parts |

These rules attack planned obsolescence by removing the “repair is not realistic” outcome.

The Real Battleground: Software Locks And Parts Pairing

Right to repair has moved beyond screwdrivers. Modern devices are software-governed systems. Even if a repair is physically possible, software can still block it.

Parts pairing is one of the most controversial tactics. The device expects a component to be digitally matched to a specific unit. If it is not, the device may show warnings, disable features, or report incorrect health data.

This can appear in:

- Screen replacements that trigger persistent warnings

- Camera replacements that reduce performance or break stabilization

- Battery replacements that block accurate health reporting

- Sensors that stop functioning after third-party repair

- Components that require “authorization” after installation

Manufacturers often justify this with security and quality arguments. In some cases, calibration and security matter. But pairing is frequently broader than necessary, and it can function like a repair tax.

Why Software Lockouts Are A Form Of Obsolescence

A locked repair does not have to break the device to shorten its life. It only needs to make the repair feel uncertain or incomplete. Consumers then lean toward replacement “to be safe.”

Right to repair pushes regulators to define where security ends and anti-competitive restriction begins. This is one of the reasons the movement is accelerating. It addresses the modern reality of digital control, not just physical design.

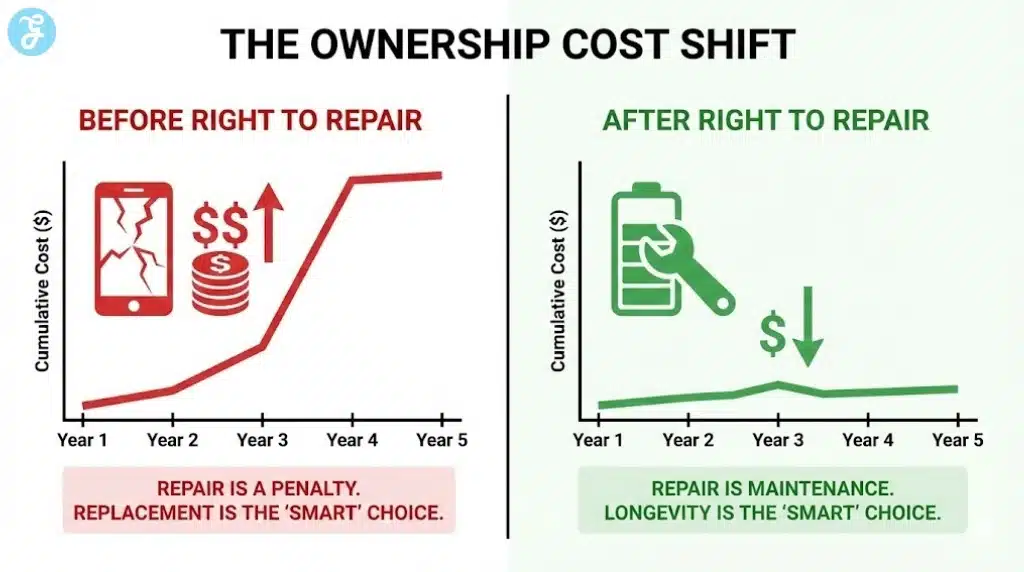

How Right To Repair Changes The Economics Of Ownership

When repair becomes accessible, it changes the total cost of owning a product. A replaceable battery can add years of life to a phone or laptop. A screen replacement can prevent a functional device from becoming waste. A simple port repair can stop a “dead device” from being discarded.

Right to repair also creates price competition. When independent shops can access parts and diagnostics, repair prices tend to move toward market reality rather than monopoly pricing.

The Ownership Cost Shift

- Without repair access: repair feels like a penalty, replacement feels like the “smart” choice

- With repair access: repair becomes a normal maintenance decision, like replacing tires on a car

This is how right to repair undermines planned obsolescence at scale. It changes consumer math.

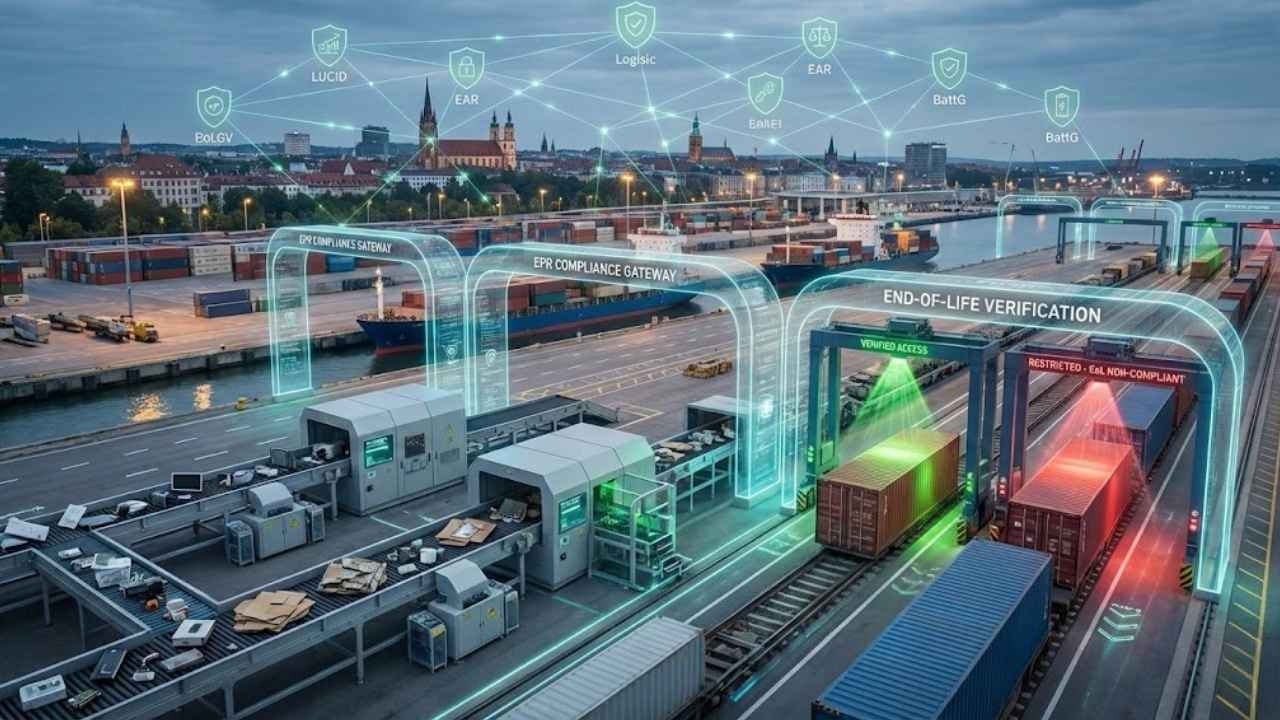

Why Right To Repair Is A Circular Economy Accelerator

Circular tech depends on keeping products in use. That means repair, refurbishment, parts harvesting, and reliable resale. Right to repair strengthens each of these.

- Refurbishers can restore devices more efficiently

- Second-hand markets gain trust because repair is possible

- Parts harvesting becomes more standardized and useful

- Trade-in programs can lead to real reuse instead of token recycling

If you care about e-waste reduction, repair access is one of the highest leverage points. Recycling is important, but reuse is usually better because it keeps the full product functioning, not just its raw materials.

At this point, it is worth stating directly: right to repair does not merely help individuals fix gadgets. It helps entire markets keep products in circulation longer.

The Safety And Security Debate: What’s Legitimate And What’s A Smokescreen

Safety and cybersecurity are real concerns. Lithium batteries can be dangerous if mishandled. Medical devices and vehicles require careful controls. Firmware changes can introduce vulnerabilities.

But the policy question is not whether safety matters. The policy question is whether safety is being used to justify restrictions that go far beyond what safety requires.

A mature approach balances both.

Better Solutions Than Repair Lockdowns

- Clear safety procedures for high-risk components

- Training and certification options for complex repairs

- Secure diagnostic access that does not require monopoly control

- Component calibration protocols that can be used by qualified shops

- Standards for aftermarket parts quality and traceability

This approach protects consumers without turning repair into a privilege.

How Companies Adapt When Repair Restrictions Lose Power

Some companies resist right to repair. Others adapt and redesign their service strategy. As repair policy expands, companies tend to move in a few directions.

- Offering official parts sales through self-service channels

- Publishing manuals and expanding service documentation

- Building partnerships with independent repair networks

- Designing products with easier battery and screen replacement

- Improving take-back and refurbishment programs to control quality

This does not eliminate profitability. It shifts profit toward parts, services, and long-term customer trust rather than forced replacement cycles.

A Manufacturer Response Table

| Response Type | What It Looks Like | Impact On Consumers |

| Resistance | Limited parts, strict pairing, expensive repairs | Replacement stays common |

| Partial compliance | Some parts/tools available, still restrictive pricing | Mixed outcomes |

| Full adaptation | Parts, manuals, diagnostics, fair service options | Longer product life |

In 2026 and beyond, the brands that win trust will likely be the ones that make repair feel normal instead of “forbidden.”

Right To Repair’s Economic Impact: Local Skills And Local Jobs

Repair is local. It can’t be fully offshored the way manufacturing can. When repair becomes viable, it supports small businesses, technicians, and community services.

Potential impacts include:

- More independent repair shops and technicians

- More training programs and entry-level technical work

- Lower household costs because products last longer

- More resilient communities that are less dependent on constant replacement

- Stronger refurbished and second-hand markets

This is why right to repair is also a competition and small-business issue, not only an environmental issue.

What Buyers Should Look For In Repair-Friendly Products

Consumers can turn right to repair from policy into practical power by buying products that support repairability and long-term use. You do not need perfect information to make better choices. You need a few consistent checks.

A Buyer Checklist That Works

- Are spare parts available in your region?

- Is battery replacement reasonably priced and practical?

- Does the device have long software and security support?

- Do independent shops repair this model successfully?

- Are manuals or guides available from official or reputable sources?

- Does the brand have a real take-back or refurbished program?

A Quick Repairability Table

| Feature | Strong Signal | Weak Signal |

| Battery service | Affordable replacement path | Sealed and expensive |

| Parts access | Sold to owners and shops | Restricted to authorized repair |

| Manuals | Clear documentation exists | No official repair info |

| Software support | Long and predictable | Short and uncertain |

| Post-repair behavior | No feature lockouts | Warnings and disabled features |

At around this point in the article, the keyword should appear again naturally: right to repair becomes meaningful when buyers reward repair-friendly design and long support, not just marketing claims.

How Right To Repair Changes Product Design Over Time

The biggest long-term impact of right to repair is not the repair manual. It is design incentives.

When manufacturers know parts must be available, and independent repair will exist, products tend to shift toward:

- More modular components

- Less adhesive-based assembly

- Standardized fasteners and easier access points

- Better documentation and calibration workflows

- Longer support windows aligned with repair supply

This change takes time. But it is a structural force. Repair access reduces the business advantage of sealed design and forced replacement.

How Right To Repair Affects Pricing And Competition

Right to repair changes more than repair access. It changes market pricing power. When only one repair channel exists, pricing can drift upward because consumers have no alternatives. When independent repair becomes viable, competition increases and repair prices tend to move closer to real labor and parts costs. That pricing shift matters because high repair costs are one of the strongest drivers of early replacement.

Practical competitive effects include:

- More repair providers competing on price and turnaround time

- More transparent parts pricing as aftermarket supply grows

- Lower “repair anxiety” because consumers have options

- Stronger second-hand markets because repairs are predictable

This is one of the quiet ways right to repair weakens planned obsolescence. It removes the pricing trap that makes replacement feel like the rational choice.

Competition Impact Table

| Market Condition | Repair Pricing Behavior | Likely Consumer Choice |

| Authorized monopoly | Higher and less flexible | Replace sooner |

| Mixed repair ecosystem | Competitive and varied | Repair more often |

| Strong independent network | Lower average cost, faster access | Extend device life |

Right To Repair And Software Support: The Missing Half Of Longevity

Even if a device can be physically repaired, it can still become obsolete when software support ends. Security updates, OS upgrades, and app compatibility are now essential to device usefulness. This is why right to repair is increasingly connected to the idea of “right to updates” or minimum support windows.

If legislation only addresses parts and manuals, but ignores software timelines, consumers still get pushed into upgrades.

Key software-related signals to watch:

- Minimum security update periods that match real hardware lifespan

- Clear disclosure of support timelines at the point of sale

- Repair supply aligned with the software support period

- Policies that prevent artificial slowing through unsupported software

Longevity Alignment Table

| Feature | Strong Longevity Outcome | Weak Longevity Outcome |

| Repair access | Parts and tools for years | Parts disappear early |

| Software support | Long and predictable updates | Updates stop quickly |

| Combined effect | Device stays usable longer | Device becomes “obsolete” anyway |

What Repair-Friendly Compliance Looks Like In Real Life

Some companies will “comply” with right to repair in ways that technically meet requirements but still discourage repair. This is the difference between legal compliance and functional access.

Watch for these warning signs:

- Parts are available, but priced so high that repair is irrational

- Manuals exist, but are incomplete or difficult to use

- Diagnostics are provided, but locked behind confusing systems

- Parts take weeks to ship, making repair impractical

- Warranty messaging continues to scare consumers away from repair

A Practical Compliance Checklist

- Parts prices are reasonable compared to device value

- Manuals include step-by-step guidance, not just diagrams

- Diagnostics are usable by independent shops without special approval

- Calibration steps are documented and accessible

- Parts shipping and availability are consistent

How Consumers And Repair Shops Can Take Advantage Of The Shift

Right to repair delivers value only when people use it. Consumers and repair shops can both turn legal change into practical outcomes.

Consumer Actions That Strengthen Repair Culture

- Choose devices known for repair access and long support

- Replace batteries instead of replacing phones or laptops

- Ask repair shops about parts sourcing and warranty coverage

- Sell or donate old devices instead of letting them sit unused

Repair Shop Actions That Scale Circular Impact

- Build standardized testing and quality assurance procedures

- Document repair outcomes to improve trust

- Use traceable parts sources and clear grading

- Offer warranties that reduce consumer risk

Repair Culture Benefits Table

| Stakeholder | Immediate Benefit | Long-Term Benefit |

| Consumers | Lower cost and more options | Longer device life, higher resale value |

| Repair shops | More business demand | Stronger skills ecosystem and trust |

| Society | Less e-waste | Lower manufacturing demand and emissions |

These shifts keep the article’s core point intact: right to repair weakens planned obsolescence by making repair normal, affordable, and competitive.

The Next Wave: Repairability Scores, Transparency, And Enforcement

As right to repair expands, the conversation shifts from “do we allow repair” to “how do we ensure repair works in real life.” Laws only matter if they are enforceable and practical.

What to watch next:

- Whether parts pricing becomes fair or remains inflated

- Whether diagnostics access is usable, not token access

- Whether pairing and lockouts decline meaningfully

- Whether software support aligns with expected device lifespans

- Whether repairability labeling becomes clearer and standardized

- Whether enforcement targets “compliance in name only” strategies

Right to repair will be judged by outcomes: repair availability, repair cost, device lifespan, and reduced waste.

To Recap

Right to repair is one of the most direct tools society has to weaken planned obsolescence. When owners and independent repair providers have access to parts, tools, manuals, and diagnostics, devices stay useful longer. Repairs become normal maintenance decisions rather than expensive dead ends. Refurbished markets grow, e-waste shrinks, and product design shifts toward maintainability.

Safety and security concerns are real, but they can be addressed through standards and secure access rather than repair monopolies. As legislation evolves, the key measure will be whether repair becomes truly practical: fair parts pricing, real diagnostic access, fewer software lockouts, and longer support windows.

If the movement continues to strengthen, tech ownership will change. Products will be treated less like disposable trends and more like long-life assets. That is how right to repair kills planned obsolescence: not with slogans, but with access, competition, and durability.