Your work truck is more than just a vehicle—it’s the backbone of your business operations, a mobile office, and often your most significant business investment. Whether you’re hauling construction materials, landscaping equipment, or making deliveries across town, your truck faces daily challenges that can quickly lead to costly wear and tear. Understanding how to properly protect your work vehicle not only extends its lifespan but also maintains its resale value and keeps your business running smoothly.

The harsh reality of commercial truck ownership is that these vehicles endure conditions far beyond what typical passenger cars experience. From heavy payloads and frequent loading and unloading to exposure to harsh weather conditions and rough terrain, work trucks face a perfect storm of factors that accelerate deterioration. However, with the right preventive measures and protective strategies, you can significantly reduce the impact of these challenging conditions.

Understanding Common Sources of Damage

Work trucks are particularly vulnerable to specific types of damage that differ from regular vehicle wear. The truck bed, being the primary workspace, often suffers the most abuse. Heavy tools, equipment, and materials can scratch, dent, and even puncture the metal surface. Repeated sliding of materials across the bed creates deep grooves, while chemical spills from paint, concrete, or other substances can cause permanent staining and corrosion.

The exterior of your truck also faces unique challenges. Construction sites expose vehicles to flying debris, while landscaping work means constant exposure to moisture, fertilizers, and organic materials that can promote rust. Road salt in winter climates creates additional corrosion concerns, particularly affecting the undercarriage and wheel wells.

Interior components suffer from the demanding nature of work truck usage as well. Muddy boots, dirty clothing, and frequent entry and exit with tools and equipment can quickly deteriorate upholstery and floor surfaces. Dashboard and control surfaces face exposure to dust, dirt, and temperature extremes that can cause cracking and fading.

Establishing a Comprehensive Protection Strategy

The key to protecting your work truck lies in taking a proactive approach rather than waiting for problems to develop. This means implementing protective measures from the moment you acquire your vehicle, whether it’s brand new or used. A comprehensive protection strategy addresses both the mechanical and cosmetic aspects of your truck.

Regular maintenance forms the foundation of any protection plan. This goes beyond basic oil changes to include frequent inspections of suspension components, brake systems, and drivetrain elements that work harder in commercial applications. Keeping up with manufacturer-recommended service intervals becomes even more critical when your truck operates under severe duty conditions.

Protective coatings and barriers represent another crucial element of truck protection. Modern technology offers various solutions designed specifically for commercial vehicles. A spray on bedliner for trucks has become increasingly popular among contractors and business owners who need maximum protection for their truck beds. These professionally applied coatings create a durable, textured surface that resists scratches, dents, and chemical damage while providing better grip for cargo.

Protecting the Truck Bed and Cargo Area

The truck bed requires special attention since it bears the brunt of daily abuse. Traditional rubber mats and plastic liners offer basic protection but have limitations in demanding work environments. They can shift during loading, trap moisture underneath that leads to rust, and may not provide adequate protection against sharp or heavy objects.

Professional-grade protective solutions offer superior performance. Spray-applied coatings bond directly to the metal surface, creating a seamless protective barrier that won’t shift or move. These coatings typically offer excellent chemical resistance, making them ideal for contractors who work with concrete, paint, or other potentially damaging substances. The textured surface also helps prevent cargo from sliding, improving both safety and efficiency during transport.

When selecting bed protection, consider the specific demands of your work. Heavy equipment operators might prioritize impact resistance, while contractors working with chemicals need superior chemical resistance. Landscapers might focus on easy cleaning and moisture resistance. Understanding your specific needs helps ensure you choose the most appropriate protection system.

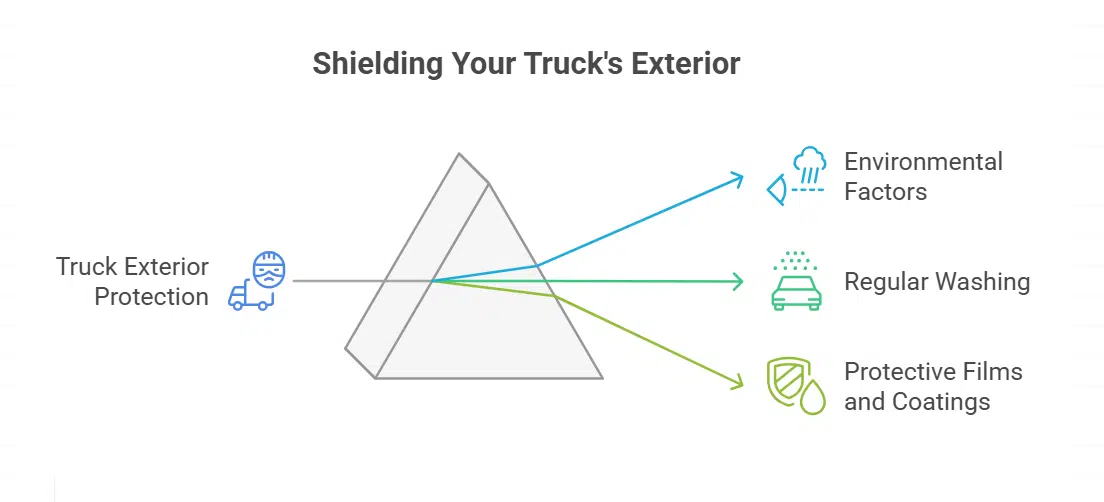

Exterior and Paint Protection

Your truck’s exterior finish faces constant assault from environmental factors and work-related hazards. UV radiation gradually breaks down paint and plastic components, while airborne contaminants can cause permanent staining. Road debris creates chips and scratches that expose bare metal to corrosion.

Regular washing becomes more than just aesthetics when you’re protecting a work truck. Removing dirt, salt, and chemical residues prevents these contaminants from causing long-term damage. However, frequent washing in itself can cause wear if not done properly. Using proper techniques and quality cleaning products helps maintain the protective qualities of your truck’s finish.

Protective films and ceramic coatings offer additional defense against environmental damage. These transparent barriers can protect high-impact areas like the front bumper, hood, and side panels from stone chips and scratches. While the initial investment might seem significant, the cost of repainting damaged panels often exceeds the price of preventive protection.

Interior Preservation Techniques

The interior of your work truck deserves attention equal to the exterior and mechanical components. Heavy-duty floor mats designed for commercial use can protect carpeting from mud, water, and debris. These mats should be removable for easy cleaning and designed to contain spills rather than allowing them to seep through to the underlying carpet.

Seat protection becomes particularly important in work trucks. Custom-fitted seat covers designed for commercial use can protect original upholstery from tears, stains, and excessive wear. Look for covers made from durable materials that can withstand frequent cleaning while maintaining their protective qualities.

Dashboard and interior plastic surfaces benefit from UV protection products that prevent cracking and fading. These treatments help maintain the professional appearance of your vehicle while preserving the functionality of controls and displays.

Long-term Value and Business Benefits

Investing in comprehensive truck protection pays dividends beyond simple maintenance cost savings. Well-maintained work trucks command higher resale values, providing better return on your initial investment. This becomes particularly important for businesses that regularly update their fleet or need to liquidate assets.

Professional appearance also impacts your business image. A well-maintained truck reflects positively on your company’s attention to detail and professionalism. This can influence customer perceptions and potentially impact your ability to secure new business contracts.

Insurance considerations also come into play. Some insurers offer reduced rates for commercial vehicles with comprehensive protection plans, recognizing the reduced risk of claims. Additionally, proper maintenance and protection can help avoid costly downtime that impacts business operations.

Protecting your work truck from wear and tear requires a multifaceted approach that addresses mechanical maintenance, exterior protection, and interior preservation. By implementing these strategies consistently, you ensure your vehicle continues to serve your business effectively while maintaining its value over time. The investment in proper protection inevitably costs less than dealing with premature replacement or major repairs down the road.