It is no longer necessary to have a big workshop to develop parts. When you use the desktop CNC systems with Makera, you transform your den into a power hub. These small machines not only make the process easy, but they reinvent it. The fact is that nowadays, regardless of whether you are engaged in the design of the product or in teaching or testing of the material, you can perform professional cycles directly at the workplace.

Carvera and Carvera Air are high precision and fast with a small footprint. Ones that are completely enclosed, quiet, and clean (suitable for office or labs). What it means is that you prototype in the workplace, not in the waiting place. Such machines limit the dependence on outsourcing and provide you with physical control throughout the process.

Compact Format, Industrial Power

Makera machines are small, yet they do not compromise. You continue to make straight cuts on aluminum, wood, plastic, or circuit board with high accuracy. Due to stiff frames and high-speed spindles, every job maintains its tolerance throughout. This implies that you come up with viable parts, not merely prototypes.

The machines are steady for long cycles and sensitive to fine detail. You make brackets, gears, enclosures, and PCBs without having to rely on outside suppliers. It alters the speed at which you can implement new ideas. You are able to convert your prototype into a usable product with Makera in a very minimal turnaround.

Prototyping Moves Faster with Full Automation

Makera systems minimize delays as they are smartly built-in. You do not stop the job in order to change tools manually. Rather, the machine changes tools according to the design path. This maintains a smooth running of your operation without interruption, even with the complicated jobs.

Calibration is taken care of by auto auto-probing feature before each cut. It gauges the height of the surfaces of materials and determines the depth of the tools accurately. That does away with misalignment and rework because of human error. Under this automation, each part will begin and end with professional formality.

From Educational Labs to Scientific Applications

Makera machines offer a real CNC experience in academic labs. The students would study manufacturing using real tools and not simulations. It is also ideal in teaching settings, courtesy of the safety enclosure and automated workflow. You are able to teach advanced machining, and you do not require an industrial facility.

Makera is used by scientists and engineers in investigating the behavior of materials and the functioning of parts. This machine can do mechanical stress testing to electrical prototyping. You in-house fabricate parts of the experiment and make modifications fast. That enhances testing cycles and reduces your research schedule.

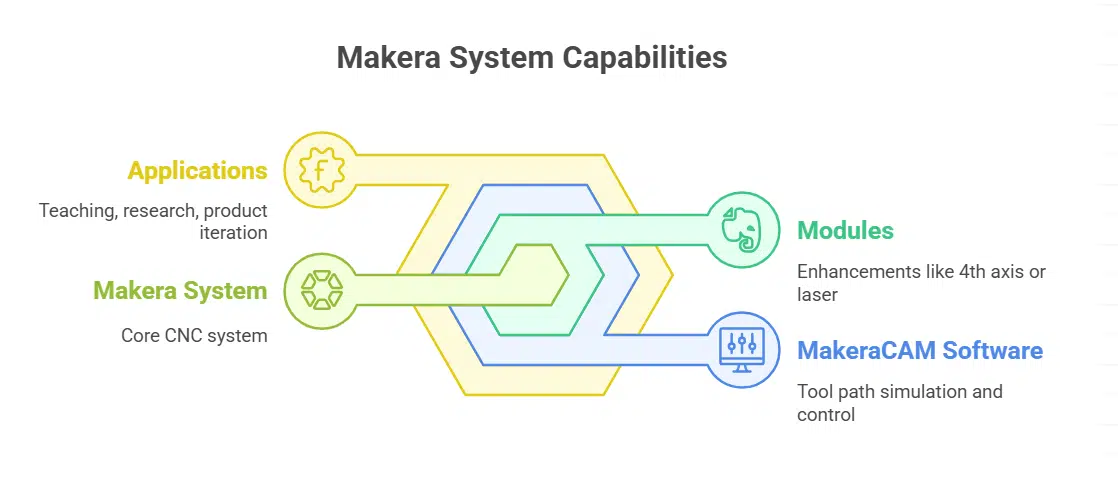

Flexible System That Grows With Your Work

The modular system by Makera brings a serious value to any project. A 4th axis can be attached to rotate parts, or a laser module can be used to mark the parts directly. The modules enhance your CNC capacity without a new machine. That elasticity implies that you can grow in size without downtime or retraining.

All things are synchronized with MakeraCAM software. You do all the tool paths graphically, simulate the tool paths before cutting, and feed directly to the machine. This eliminates the complexity and leaves everything to your control. Still, it hardly matters whether you are teaching, researching, or iterating products; Makera is for you.

CNC Tools That Fit Modern Innovation Cycles

Makera allows you to prototype and test parts in real time. You avoid lengthy queues at the supplier side and put production schedules in your hands. You might need to change a part, correct the CAD, and recut the same day. This dynamism evens up the competition in any industry.

Makera helps startup companies to skip the outsourcing expenditures at the early stage of development. It is used by research teams to make fast changes in experiments. Teachers rely on it to provide practice in the real world on contemporary tools. Makera simplifies, automates, and scales the complex CNC in each one of them.

You Prototype Better When You Control the Process

Makera gives you full ownership of the design-to-build process. No more delays waiting for shops or freelancers. You control speed, material, and tool changes directly from your workspace. Every feature is designed to help you move faster and build smarter.

If you need reliable results in a compact system, Makera delivers. Its automation, precision, and flexibility make it a smart fit for modern prototyping needs. You stay productive, consistent, and ahead of the curve; no outsourcing required.