Managing inventory across many levels can feel like juggling too many balls. Too much stock? Costs go up. Too little? Customers leave unhappy. Balancing inventory at every step in your supply chain is a tough puzzle to solve.

Multi-echelon inventory optimization (MEIO) makes this easier. It saves money, improves stock availability, and boosts customer satisfaction. This guide offers simple steps to help you master MEIO with better practices for your supply chain.

Stay tuned for smart tips!

Explore Your Supply Chain Network

Understand the flow of goods from raw materials to finished products. Identify weak links and improve connections between suppliers, warehouses, and retailers.

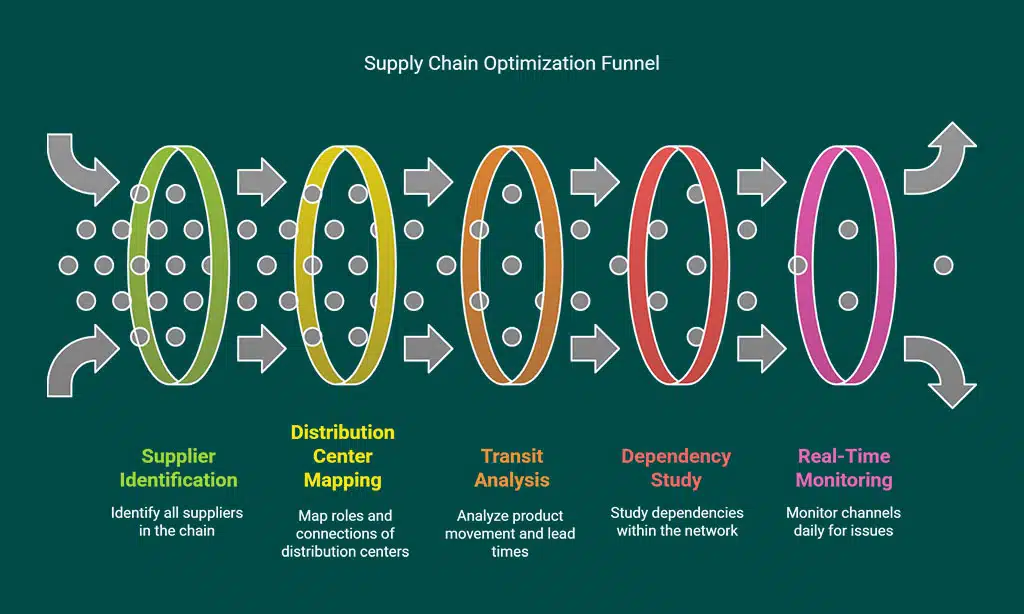

Map supplier and distribution channels

A clear map of your supply chain network is critical. It helps track stock flow and prevents delays or shortages.

- Identify all suppliers in your chain. Include both those for raw materials and finished goods.

- List every distribution center involved. Cover their roles and connections to other points.

- Check how products move between locations. Note lead times and transit methods.

- Highlight key suppliers or centers that impact service levels most deeply.

- Study dependencies within your network. For example, if one supplier stops, who else gets affected?

- Use real-time data to monitor these channels daily for reliability issues.

- Document the entire process with software tools for easy updates later on.

Effective mapping paves the way for smooth inventory management across echelons!

Highlight key echelons and their dependencies

Suppliers, manufacturers, distribution centers, and retail stores form key layers in a supply chain. Each layer depends on the other to work smoothly. Suppliers provide raw materials.

Manufacturers turn these into goods. Distribution centers store and ship finished products to retail stores or end users.

Every link in the chain impacts inventory flow.

A weak link at any level causes delays and raises costs. For example, if suppliers fail to deliver on time due to lead times or demand variability, it disrupts production cycles downstream.

High safety stock levels may help buffer this but increase holding costs instead of optimizing service levels. Keeping all echelons coordinated is critical for efficiency and customer satisfaction!

Enhance Demand Forecasting Accuracy

Forecasting demand is like reading the tea leaves of your business. Use solid data, spot trends, and predict needs with sharp precision.

Utilize data analytics for demand predictions

Use historical data to spot demand patterns. Predictive analytics tools can help estimate future needs based on past trends and market shifts. For example, a retailer might use point-of-sales data to prep for holiday rushes by analyzing last year’s numbers.

Factor in seasonality and sudden market changes. Machine learning models process real-time data, allowing businesses to adjust quickly. This reduces the bullwhip effect across supply chains, balancing inventory levels and boosting stock availability at every step.

Factor in seasonality and market trends

Seasonal shifts change demand. For example, winter coats sell more in cold months. Study past sales trends to spot such patterns. Use statistical data to predict changes for better inventory planning.

Market trends also guide stocking decisions. A rising trend in direct-to-consumer (D2C) sales may lower retail store needs but increase warehouse demand. Adjust your supply chain strategy to match these market signals.

Failing to plan for seasons and trends is like skating on thin ice—risky and avoidable.

Optimize Inventory Across All Echelons

Keep your stock balanced across all locations, like raw materials and finished goods. This control avoids shortages and extra costs.

Determine safety stock with demand variability in mind

Demand can change fast. Use historical data to spot trends and patterns. Factor in market shifts, holidays, or promotions that impact demand variability.

Set safety stock levels based on lead times and service level goals. For example, higher variability might need more buffer stock to avoid shortages at distribution centers or retail stores.

Balance carrying costs with service levels

Carrying costs and service levels must work together. A good balance keeps inventory costs low while meeting customer needs.

- Calculate safety stock based on demand variability. This helps manage unexpected spikes without overstocking.

- Monitor carrying costs like storage, insurance, and taxes. High levels of stock increase these expenses fast.

- Set service level targets using historical data and demand patterns. Meeting customer expectations builds loyalty.

- Use inventory management software to track key performance indicators (KPIs). Real-time data can prevent shortages or surplus.

- Adjust safety stock levels during peak seasons or holidays. Market trends often need swift action to avoid delays.

- Include lead time in planning for raw materials and finished goods. Delays at this stage raise both costs and frustration.

- Focus on economic order quantities (EOQ) to reduce excessive storage needs while meeting demand forecasts effectively.

- Review supplier reliability and consistency often. Unpredictable suppliers may disrupt supply chain coordination efforts.

- Automate reorder points with ERP systems for routine efficiency gains, making restocking faster and smoother across locations.

- Balance all decisions by regularly checking updated metrics like cost-per-unit or service rate percentages to stay agile in planning tasks.

Improve Ordering Efficiency

Streamline your ordering to save time and cut errors. Smart systems can sync orders with real-time stock needs, boosting accuracy.

Automate order management systems

Automation speeds up order management. It reduces human mistakes and saves time. Using software, orders process faster across the supply chain. Retail stores, distribution centers, and suppliers benefit from this efficiency.

Automation aligns inventory levels with demand forecasts.

Programs using real-time data help track order statuses. For example, point-of-sale systems can feed back stock updates instantly. This helps avoid out-of-stock problems or over-ordering raw materials and finished goods.

Automated workflows also lower costs by cutting manual tasks while boosting customer satisfaction through quicker delivery times.

Align replenishment with supply chain goals

Set clear supply chain goals first. For example, focus on reducing inventory costs or improving stock availability. Next, adjust replenishment strategies to match these goals. Use data like demand forecasts and lead times to decide how much to reorder and when.

Automate order systems for faster decisions. This helps align work-in-progress (WIP) inventories with demand patterns in retail stores or distribution centers. Keep safety stocks balanced to avoid overstocking while maintaining service levels across all echelons of the supply chain network.

Implement Advanced Technology Solutions

Tech can simplify inventory control and boost accuracy. Use smart tools to track stock in real time and plan better.

Adopt inventory optimization software

Inventory optimization software helps manage stock more effectively. It calculates safety stock based on demand variability and lead times. This technology balances inventory costs with service levels, ensuring proper stock at each level of your supply chain.

It uses real-time data to track inventory performance across distribution centers and retail stores. By analyzing demand forecasts and market trends, it prevents overstocking or shortages.

This streamlines operations, improves customer satisfaction, and reduces carrying costs.

Track real-time inventory performance metrics

Real-time tracking helps you see stock levels instantly. It boosts supply chain efficiency and reduces risks.

- Use inventory optimization software to monitor stock as it moves through your supply chain network. This provides quick updates on raw materials, finished goods, and distribution centers.

- Track lead times to identify delays early. Knowing exact timings keeps customer service levels strong.

- Analyze historical data alongside real-time data for improved demand forecasting accuracy. This helps adjust safety stock and address demand variability effectively.

- Set alerts for low inventory levels at retail stores or pharmacies. Alerts prevent out-of-stock issues and enhance customer satisfaction.

- Measure supply chain coordination with performance metrics like order fulfillment rate or carrying costs. Effective metrics demonstrate inventory and operational efficiency.

- Implement point-of-sale systems to collect live sales information from stores directly. These tools offer valuable insights into demand patterns swiftly.

- Examine normal distributions in demand probabilities to better plan reorder points in uncertain situations without overstocking products.

- Leverage statistical techniques or simulations to predict growth trends based on current performance metrics within each level of the network.

Tracking real-time metrics provides actionable insights promptly, improving decisions across all levels of management!

Takeaways

Mastering multi-echelon inventory planning boosts supply chain success. Map your network, predict demand smartly, and balance stock levels. Fine-tune ordering processes to save money and time.

Use technology to track and improve inventory flow. With these strategies, you’ll cut costs and keep customers happy!

FAQs

1. What is multi-echelon inventory planning?

Multi-echelon inventory planning manages stock across the entire supply chain network, including raw materials, distribution centers, and retail stores, to improve efficiency and reduce costs.

2. How does demand forecasting help in multi-echelon inventory optimization?

Demand forecasting uses historical data and real-time data to predict demand patterns. This helps adjust safety stock levels and improve service levels while reducing excess inventory.

3. Why are lead times important in supply chain management?

Lead times affect how quickly raw materials or finished goods move through the supply chain. Shorter lead times can boost stock availability and customer satisfaction by improving response speed.

4. What role do stochastic models play in inventory management?

Stochastic models account for uncertainty like demand variability or unexpected delays. They use probabilities to optimize safety stock levels, ensuring better coordination across the supply chain.

5. Can machine learning improve multi-echelon inventory planning?

Yes, machine learning analyzes complex demand patterns, identifies inefficiencies like the bullwhip effect, and enhances agility within a supply chain network for smarter decision-making.

6. How can businesses lower their inventory costs without hurting customer service levels?

By using hybrid models that combine deterministic approaches with real-time data analysis, companies can balance safety stock with demand forecasts while maintaining high customer satisfaction rates.