Managing logistics can harm the environment and increase costs. Around 70% of corporate emissions come from supply chains. This blog shares the top strategies for sustainable logistics practices to cut emissions and boost efficiency.

Continue reading to make your logistics greener and smarter.

Optimized Route Planning

Optimized route planning cuts fuel consumption and lowers carbon emissions significantly. Advanced algorithms, GPS, and real-time data help find the best paths, reducing traffic congestion and travel time.

Tools like Route Matrix compare travel distances and times, highlighting the most efficient options. Geofencing and monitoring systems allow quick adjustments to routes, improving operational efficiency.

Following traffic laws and regulations ensures smoother, safer journeys. These strategies save resources while making logistics greener and more cost-effective.

Green Warehousing

Green warehousing focuses on reducing energy consumption and waste in storage facilities. Solar panels and LED lighting cut down electricity use, making operations more eco-friendly.

Recyclable materials are often used for packaging, lowering the environmental impact. These steps help shrink carbon footprints significantly.

Warehouses with advanced insulation systems maintain temperature control without excessive energy use. Efficient waste management practices ensure less landfill contribution, promoting a circular economy.

Green initiatives improve brand image while protecting the environment, which appeals to environmentally conscious consumers.

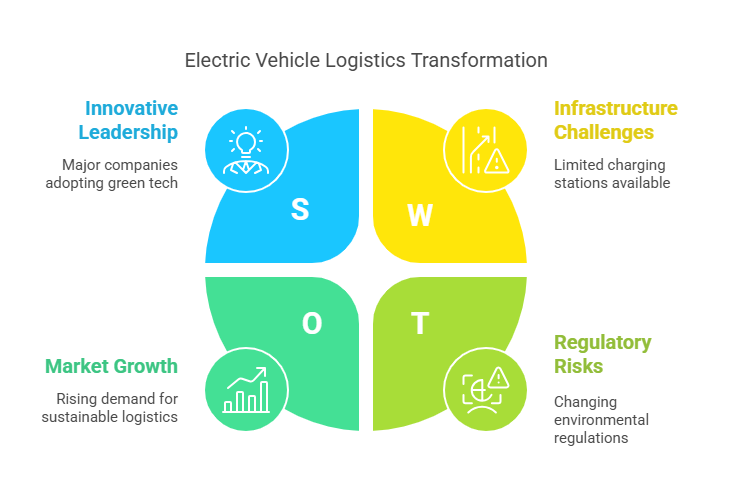

Electric and Alternative Fuel Vehicles

Electric vehicles and alternative fuel options are transforming logistics. Companies like Amazon, DHL, and FedEx are leading the charge. Amazon plans to use zero-emission fuels for 10% of international shipments by 2030, scaling up to 100% by 2040.

DHL aims to electrify 60% of its last-mile delivery vehicles by the same decade. Through its Priority Earth initiative, FedEx is making significant investments in vehicle electrification.

DPD targets low-emission deliveries in 350 European cities by 2025. Hydrogen fuel cells and biofuels also play a role in reducing carbon emissions. These technologies help cut down on fossil fuel use and air pollution.

Electric trucks powered by renewable energy sources are gaining traction too, offering greener solutions for freight transport across supply chains globally.

Sustainable Packaging

Sustainable packaging focuses on reducing waste and minimizing environmental impact. Companies like Diageo have made progress by replacing plastic ring packaging for Guinness with biodegradable cardboard.

Procter & Gamble is taking additional steps, aiming for 100% recyclable or reusable packaging by 2030. They’re even testing paper bottles for Lenor fabric softener, showcasing innovation in action.

Using recyclable materials and eco-friendly designs helps reduce resource depletion and greenhouse gas emissions (GHG). This approach supports supply chain transparency while appealing to environmentally conscious consumers.

Sustainable packaging aligns with green initiatives, benefiting both brands and the planet.

Carbon Offsetting Programs

Carbon offsetting programs help reduce greenhouse gas emissions by supporting environmental projects. Companies can invest in reforestation, renewable energy initiatives, or methane capture to balance their carbon footprint.

These efforts contribute to sustainability goals and align with environmental, social, and governance (ESG) standards. Offsetting emissions isn’t a complete solution, but it plays a key role in reducing environmental impact.

Programs like these encourage cleaner practices across the logistics sector. They also appeal to environmentally conscious consumers by promoting supply chain transparency. With climate change accelerating, carbon offsetting remains a practical step for greener logistics.

Efficient Load Management

Efficient load management cuts down on unnecessary trips and lowers carbon emissions. Advanced systems help companies maximize vehicle space, ensuring trucks operate at full capacity.

This reduces fuel consumption and greenhouse gas emissions, making logistics greener. Collaborative networks also play a key role, allowing businesses to share cargo space and optimize resources.

By improving operational efficiency, companies save costs and reduce their environmental impact. Smart load management is a win-win for both the planet and the bottom line.

Reverse Logistics

Reverse logistics turns returns into opportunities, supporting a circular economy. By streamlining processes with prepaid labels and user-friendly online portals, businesses enhance customer satisfaction and reduce waste.

Technology like inventory management systems and barcode scanners improves efficiency, cutting down on unnecessary returns. Quality control measures in the supply chain further minimize returns, saving resources and costs.

Embracing reverse logistics promotes recycling and responsible disposal, aligning with sustainability goals while boosting operational efficiency.

Digital Transformation in Logistics

Digital transformation is reshaping logistics, making it smarter and greener. Technologies like IoT, AI, and blockchain boost transparency and traceability across the supply chain.

They help track shipments in real time, reduce delays, and cut unnecessary costs. These tools also improve decision-making, allowing companies to respond faster to disruptions. This approach isn’t just about saving money; it’s about improving efficiency and sustainability in logistics.

A whopping 75% of logistics leaders say ignoring digital capabilities could harm business survival. About 67% of shipping and logistics firms already have a formal digital strategy.

These strategies focus on automation, reducing human errors, and optimizing operations. For example, IoT devices monitor fuel use in trucks, reducing emissions. AI predicts demand, helping companies manage inventory better.

By collecting user feedback, businesses refine their digital tools for smoother, eco-friendlier logistics. This shift isn’t just a trend—it’s a necessity for a sustainable future.

Smart Inventory Management

Smart inventory management keeps stock levels in check, reduces waste, and boosts efficiency. Just-in-time (JIT) systems align inventory with production needs, cutting down on excess materials.

Advanced forecasting techniques help predict demand accurately, preventing overstocking or shortages. This approach saves money and supports environmental sustainability by minimizing resource depletion.

Using energy-efficient storage methods in warehouses further lowers carbon emissions. Both businesses and the planet benefit from this, as it streamlines operations and safeguards natural resources.

Collaborative Transport Networks

Collaborative transport networks bring companies together to share resources like vehicles and routes, reducing total emissions. By working together, businesses cut down on traffic congestion and resource depletion, making logistics greener.

Partnerships in this space encourage innovative solutions to logistical challenges, boosting operational efficiency. Sharing resources helps lower greenhouse gas emissions and supports companies in achieving sustainability goals.

These networks enhance supply chain transparency and eco-friendliness. Joint efforts contribute to reduced carbon footprints, creating a significant impact on climate change. Green logistics prospers when companies join forces to address common challenges.

Role of Technology in Driving Sustainable Logistics

Technology plays a giant role in making logistics greener and smarter. Advanced algorithms and real-time data help companies map the most efficient routes. The result cuts down on fuel use and reduces harmful emissions.

Take electric trucks, for example. They’re becoming more common and they rely on renewable energy sources to lower greenhouse gas emissions. Smart systems in warehouses manage energy use, like turning off lights when not needed.

Solar panels on warehouse roofs can also generate clean power. These tech solutions make logistics operations more eco-friendly and cost-effective.

Digital tools like IoT and AI improve how goods move through the supply chain. Sensors track shipments in real-time, preventing delays and reducing waste. Blockchain technology provides supply chain transparency, making it easier to verify sustainable practices.

AI enhances load management, ensuring trucks carry full loads to cut unnecessary trips. Electric and hybrid vehicles, powered by natural gas or electricity, replace traditional gasoline-fueled ones.

These innovations reduce carbon footprints while improving operational efficiency. By using tech, the logistics sector moves closer to meeting sustainability goals while protecting the environment.

Takeaways

Switching to sustainable logistics isn’t just a trend—it’s a must. By embracing electric vehicles, smarter routes, and green warehousing, businesses can cut costs and help the planet.

Collaborative networks and tech like AI make it easier to reduce waste and emissions. Together, these steps create a supply chain that works for both companies and consumers. The future of logistics is green, and it starts now!