Every day, hospitals rely on medical gases to sustain life, manage pain, and support critical treatments. While they all fall under the same category, oxygen, nitrous oxide, and medical air serve very different functions in patient care. Whether it’s delivering oxygen to a patient in respiratory distress, using nitrous oxide for anesthesia, or supplying medical air to power surgical tools, these gases must be handled, stored, and distributed with precision to ensure safety.

To maintain reliability, medical gas installation must follow strict standards. Certified medical gas installers play a vital role in ensuring proper pipeline design, preventing contamination, and maintaining NFPA 99 compliance. A clear understanding of how these gases function helps healthcare providers use them safely and effectively.

Understanding the Three Essential Medical Gases

Oxygen (O₂): The Lifeline of Medical Gases

Oxygen is the most widely used medical gas, essential for treating patients with respiratory distress, trauma, and chronic conditions. In hospitals, it is delivered through ventilators, nasal cannulas, and oxygen masks to maintain or restore oxygen saturation levels in the bloodstream.

In emergency care, oxygen is indispensable. Studies show that nearly 34% of hospitalized patients require some form of oxygen therapy. It is a key component in managing COPD, pneumonia, and acute respiratory distress syndrome (ARDS). In surgical settings, it supports anesthesia administration and post-operative recovery.

However, oxygen must be handled with extreme caution. High concentrations can increase the risk of fire, and long-term exposure to excessive oxygen levels may lead to oxygen toxicity, particularly in neonatal patients. Proper storage and pipeline delivery are critical, requiring dedicated oxygen tanks and pipeline systems installed by certified professionals.

Nitrous Oxide (N₂O): The Pain and Sedation Gas

Nitrous oxide, commonly known as “laughing gas,” is widely used for its anesthetic and analgesic properties. It is most frequently found in dentistry, obstetrics, and surgical anesthesia, where it provides mild sedation and pain relief without rendering a patient unconscious.

In labor and delivery rooms, nitrous oxide offers a non-invasive pain management option, with studies showing that approximately 25% of birthing mothers in the U.S. opt for nitrous oxide over epidural anesthesia. It is also a preferred sedative in pediatric dental procedures, allowing for anxiety-free treatments.

While nitrous oxide is effective, it requires proper ventilation and scavenging systems to prevent occupational exposure. Prolonged exposure has been linked to neurological and reproductive risks for healthcare workers. Medical gas installation must include exhaust and filtration mechanisms to safely remove excess gas from clinical environments.

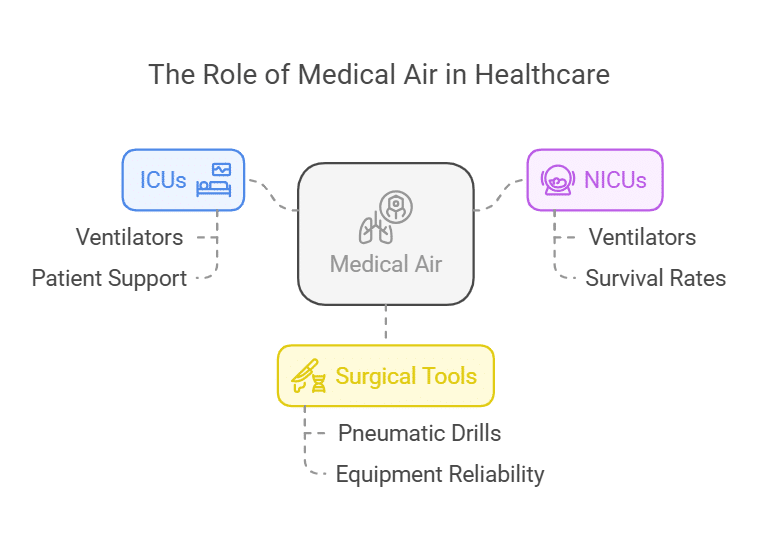

Medical Air: The Unsung Hero of Healthcare Facilities

Medical air is often overlooked but plays a crucial role in healthcare environments. Unlike oxygen, medical air is a blend of clean, compressed atmospheric air that is free from contaminants, moisture, and oil residues. It is used in ICUs, neonatal care, and surgical tools that require a dry, stable air supply.

Neonatal intensive care units (NICUs) rely heavily on medical air for ventilators to support premature infants with underdeveloped lungs. Studies indicate that preterm infants on medical air-blended oxygen therapy have improved survival rates compared to those exposed to 100% oxygen, reducing the risk of retinopathy of prematurity (ROP).

In surgical settings, medical air powers precision tools such as pneumatic drills and ventilators. It is essential that medical gas installers ensure proper filtration and pressure regulation in these systems, as moisture buildup or contamination can cause equipment malfunctions and infections.

The Role of Medical Gas Installation in Delivering Safe and Reliable Medical Gases

How Medical Gas Installers Ensure Safe Delivery

The installation of medical gas systems requires meticulous planning and execution to prevent leaks, cross-contamination, and supply failures. Certified medical gas installers follow NFPA 99 guidelines, ensuring that each gas is transported through dedicated, color-coded pipelines to avoid dangerous mix-ups.

Key safety measures include:

- Separation of gas lines to prevent cross-contamination between oxygen, nitrous oxide, and medical air.

- Regular pressure testing to maintain consistent gas flow and prevent supply interruptions.

- Leak detection systems to identify and repair potential hazards before they become serious safety risks.

Hospitals and clinics must also implement routine maintenance schedules to keep medical gas systems operational. Even minor installation flaws can lead to severe consequences, such as oxygen supply failures in critical care units.

Medical Gas System Design Considerations for Hospitals

Properly designed medical gas systems ensure efficiency, safety, and compliance in healthcare facilities. Whether a hospital is undergoing a new medical gas installation or upgrading an existing system, several factors must be considered:

- Centralized vs. decentralized supply – Larger hospitals typically use a centralized medical gas system with bulk storage, while smaller clinics may rely on portable or localized sources.

- Emergency shutoff valves – Placed strategically throughout the facility to allow immediate isolation of gas flow in case of a leak or emergency.

- Monitoring and alarm systems – Integrated digital sensors that alert staff to pressure drops, leaks, or contamination.

By working with experienced medical gas installers, healthcare facilities can ensure their gas delivery systems meet the highest safety and performance standards.

Conclusion

Oxygen, nitrous oxide, and medical air each serve a distinct function in healthcare, from sustaining life to providing pain relief and powering essential equipment. While their applications differ, all three gases require precise handling, proper storage, and a reliable delivery system.

As medical technology advances, the need for well-designed and properly maintained medical gas systems will only grow. By investing in high-quality medical gas installation and routine system maintenance, healthcare facilities can continue to provide safe and effective care to their patients.