Agriculture is the backbone of New Zealand’s economy, contributing significantly to the country’s GDP. Kiwi farmers are known for their resilience, adaptability, and innovative spirit. With growing challenges such as rising costs, equipment shortages, and the need for sustainability, farmers are continuously seeking modern solutions to enhance productivity. One of the most groundbreaking technological advancements in this sector is 3D printing.

How 3D Printing is Innovating Equipment Production for Kiwi Farmers is not just a futuristic concept—it is a practical, real-world innovation already transforming the way farming equipment is designed, manufactured, and maintained. By allowing farmers to produce tools and spare parts on demand, 3D printing eliminates supply chain delays, reduces waste, and significantly cuts costs.

This article explores how 3D Printing is Innovating Equipment Production for Kiwi Farmers, delving into its benefits, real-world applications, challenges, and future prospects. We will also highlight real-life examples of Kiwi farmers leveraging this technology to enhance efficiency and sustainability.

What is 3D Printing and How Does it Work?

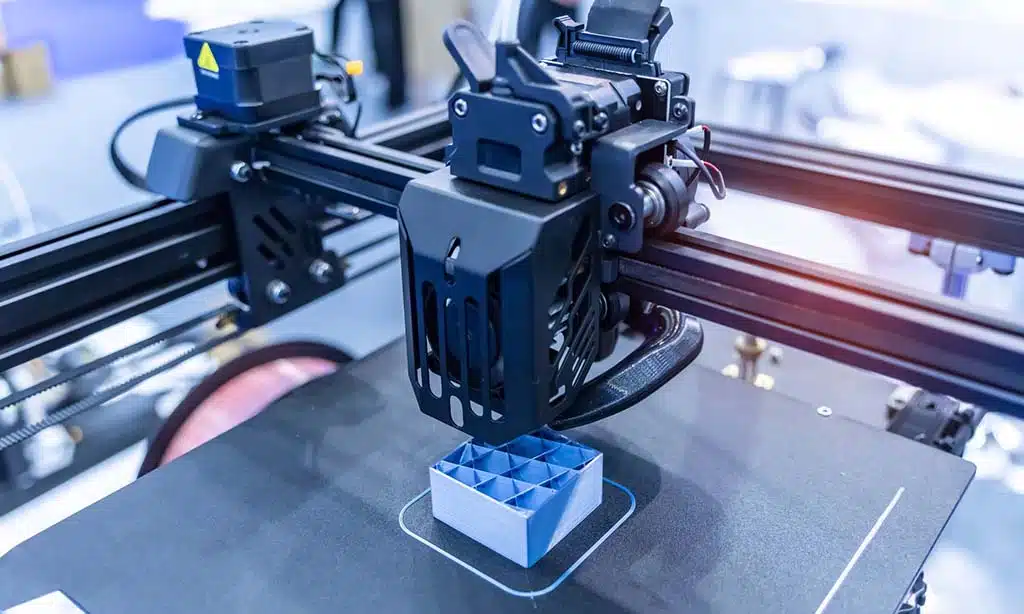

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects layer by layer using digital design models.

Unlike traditional manufacturing, which often involves cutting away material from a solid block, 3D printing builds objects from the ground up, reducing waste and increasing efficiency.

Key components of 3D printing technology include:

| Component | Function |

| 3D Printers | Machines that translate digital models into physical objects |

| Printing Materials | Includes plastics, metals, resins, and biodegradable substances |

| Digital Design Software | Used to create and modify designs before printing |

With the rapid evolution of 3D printing, new materials and printing techniques are being developed to enhance durability, flexibility, and environmental sustainability.

Today, some advanced agricultural 3D printers can even use recycled farm waste as printing material, further driving eco-friendly practices.

Why 3D Printing is a Game-Changer for Farming Equipment?

How 3D Printing is Innovating Equipment Production for Kiwi Farmers lies in its ability to solve critical agricultural challenges.

Traditional equipment manufacturing often requires expensive imports, lengthy delivery times, and limited customization. 3D printing, however, provides a cost-effective, quick, and tailor-made alternative.

| Benefit | Traditional Manufacturing | 3D Printing |

| Cost Efficiency | High production and shipping costs | Lower costs due to localized manufacturing |

| Customization | Limited to mass-produced designs | Fully customizable for specific farming needs |

| Production Time | Weeks to months | Hours to days |

| Sustainability | High material waste | Minimal waste with precise material usage |

How 3D Printing is Transforming Equipment Production for Kiwi Farmers?

With traditional farming methods facing increasing pressure due to rising costs, supply chain disruptions, and the need for sustainability, Kiwi farmers are turning to cutting-edge technology to stay competitive.

One of the most promising innovations in modern agriculture is 3D printing, which is reshaping the way farming equipment is produced and maintained.

By enabling farmers to manufacture custom tools, replace broken machinery components, and create cost-effective solutions, 3D printing is opening new possibilities for efficiency and self-sufficiency on farms across New Zealand.

This section explores the various ways in which 3D printing is driving change in Kiwi agriculture and how farmers are using this technology to address real-world challenges.

Custom Farming Tools and Replacement Parts

One of the most practical ways that 3D Printing is Innovating Equipment Production for Kiwi Farmers is through the creation of customized tools and replacement parts. Traditional equipment often requires expensive and time-consuming imports, but 3D printing allows farmers to:

- Design and produce unique tools tailored to their specific needs.

- Print spare parts for tractors, irrigation systems, and machinery.

- Reduce downtime by printing components on-site.

Real-World Example:

A dairy farmer in Canterbury needed a specialized nozzle for a milking system. Instead of waiting weeks for an international shipment, he 3D printed the part in under 24 hours, saving time and money. This improved efficiency and prevented production losses.

| Tool/Part | Traditional Cost | 3D Printed Cost | Time Saved |

| Irrigation Nozzle | $100+ | $10-$20 | 3 weeks |

| Tractor Gear | $500+ | $50-$100 | 2 months |

| Animal Prosthetic | $3000+ | $150-$500 | 4 weeks |

Sustainable and Cost-Effective Solutions

Sustainability is a major concern for modern agriculture. How 3D Printing is Innovating Equipment Production for Kiwi Farmers extends to eco-friendly innovations such as:

- Biodegradable Printing Materials: Farmers can now print equipment using sustainable materials like bioplastics.

- Recyclable Components: Waste from previous prints can be reused to minimize environmental impact.

- On-Demand Production: Reduces overproduction, preventing excess inventory and waste.

Case Study:

A Kiwi vineyard started using 3D-printed vine protectors made from biodegradable materials. These protectors decompose naturally after a growing season, reducing plastic waste significantly.

| Sustainable Solution | Impact |

| Biodegradable Vine Protectors | Eliminated 10,000+ plastic sleeves per year |

| 3D-Printed Irrigation Pipes | Reduced leakage and water waste by 30% |

| Solar-Powered 3D Printers | Cut energy costs by 40% |

Enhancing Farm Efficiency with 3D-Printed Equipment

Precision farming relies on high-efficiency tools, and 3D printing is helping farmers optimize operations through:

- Lightweight and Durable Equipment: 3D-printed components are strong yet lightweight, improving handling and performance.

- Smart Irrigation Systems: Farmers can print customized irrigation components tailored to their farm layouts.

- Livestock Care Enhancements: Printing prosthetic limbs or medical devices for injured animals.

Table: 3D Printing Applications for Farm Efficiency

| Application | Benefit |

| 3D-Printed Drone Parts | Enhances precision agriculture with cost-effective maintenance |

| Customized Irrigation Nozzles | Increases water efficiency and crop yield |

| Durable Seed Planters | Reduces labor costs and improves planting precision |

Challenges and Future Prospects of 3D Printing in Kiwi Agriculture

As 3D printing continues to gain traction in the agricultural sector, it brings both opportunities and obstacles. Kiwi farmers are beginning to recognize the immense potential of this technology, from reducing costs to increasing efficiency.

However, the widespread adoption of 3D printing in farming still faces hurdles that need to be addressed. Understanding these challenges is crucial for ensuring a smooth transition toward integrating this innovative technology into daily agricultural practices.

Key Challenges to Adoption

While How 3D Printing is Innovating Equipment Production for Kiwi Farmers presents many advantages, some challenges must be addressed:

- Initial Setup Costs: 3D printers and materials require an upfront investment.

- Technical Knowledge: Farmers must learn how to design and operate 3D printers.

- Material Limitations: Not all farming tools can be effectively printed with current materials.

The Future of 3D Printing in Agriculture

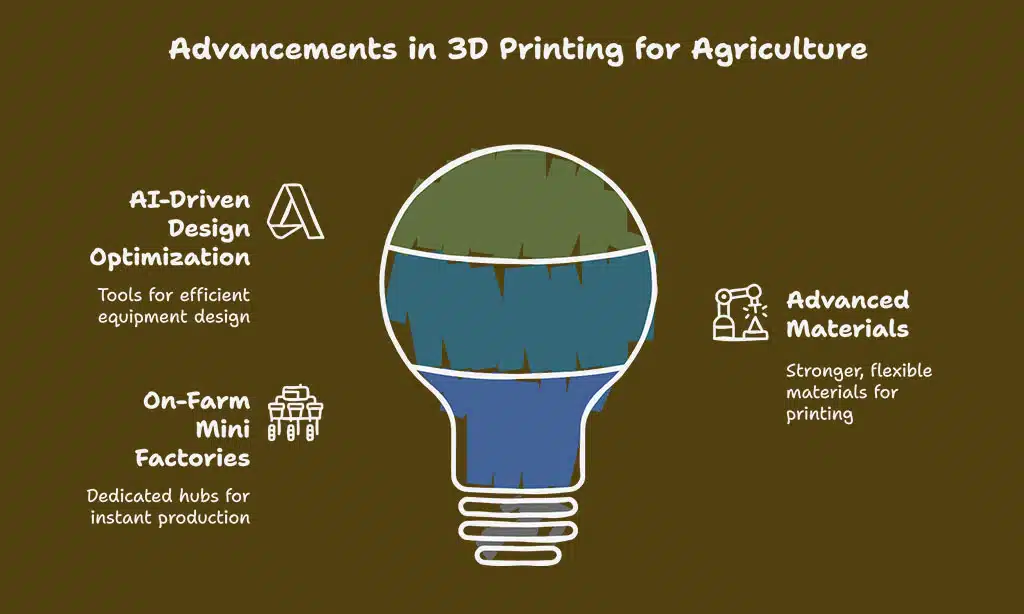

The future looks promising for 3D printing in New Zealand’s agricultural sector. Advancements in material science and automation are expected to further enhance its applications. Emerging trends include:

- AI-Driven Design Optimization: AI-powered tools will help farmers create more efficient equipment designs.

- Advanced Materials: Stronger and more flexible printing materials will expand the range of printable equipment.

- On-Farm Mini Factories: Future farms may feature dedicated 3D printing hubs for instant equipment production.

Final Thoughts

How 3D Printing is Innovating Equipment Production for Kiwi Farmers is more than a technological trend—it is a revolutionary shift that is making farming more efficient, cost-effective, and sustainable. By enabling farmers to create customized tools, reduce waste, and speed up equipment production, 3D printing is redefining agricultural practices in New Zealand.

As technology continues to evolve, Kiwi farmers who embrace 3D printing will gain a competitive edge, reducing operational costs while enhancing productivity. Now is the time for the agricultural sector to invest in this game-changing innovation and pave the way for a more sustainable and efficient farming future.